IMPORTANT

Remove any obstacle before beginning

work.

4. Inspect the entire unit for loose fasten-

ers and fuel leakage. Make sure that

the cutting attachment is properly

installed and securely fastened.

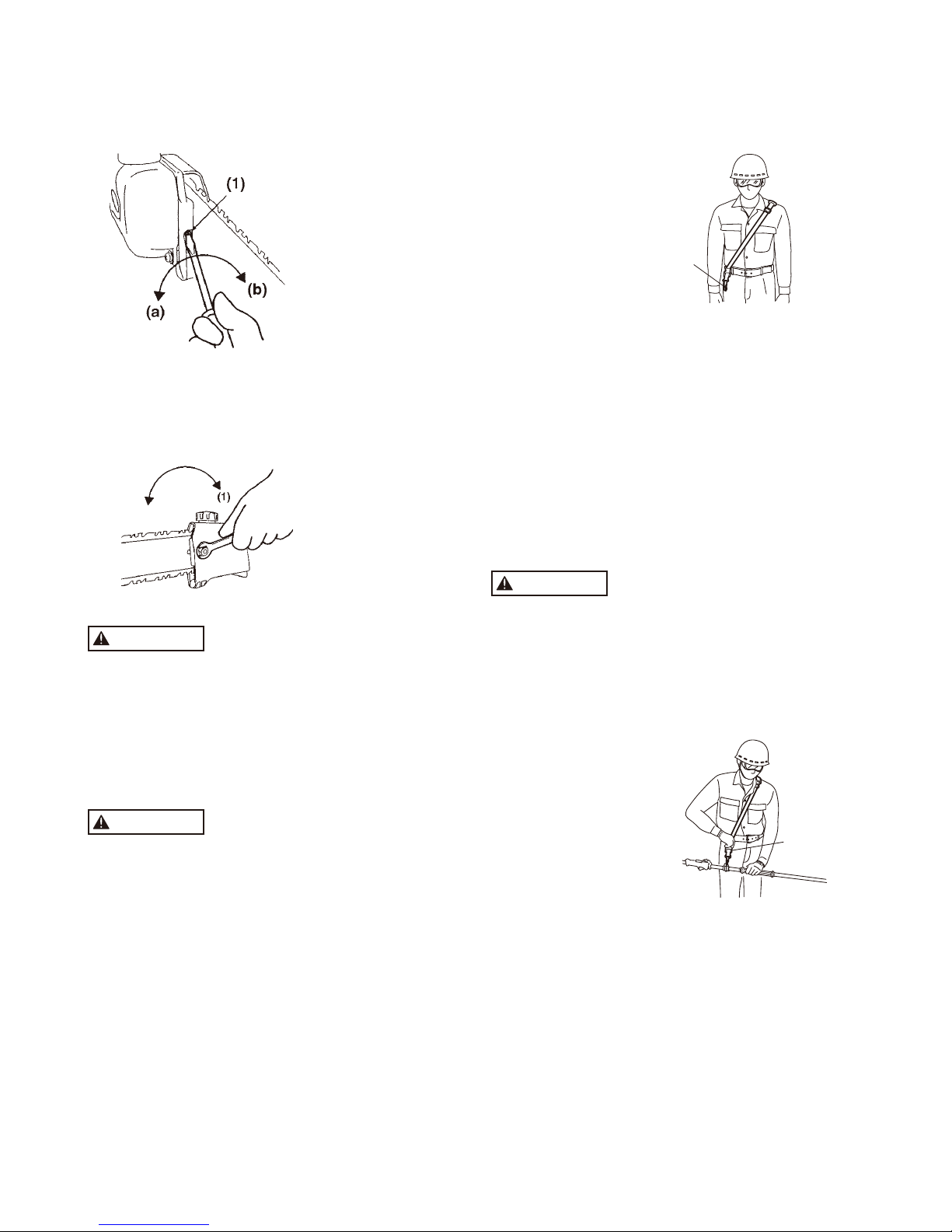

5. Always use the harness. Adjust the

harness for comfort before starting the

engine. The harness should be ad-

justed so the left hand can comfort-

ably hold the handlebar grip ap-

proximately waist high.

STARTING THE ENGINE

1. Keep bystanders and animals at least

15 m away from the operating point.

If you are approached, immediately

stop the engine.

2. The product is equipped with a cen-

trifugal clutch mechanism, so the

cutting attachment begins to rotate as

soon as the engine is started by put-

ting the throttle trigger into the start

position. When starting the engine,

place the product onto the ground in

a flat clear area and hold it firmly in

place so as to ensure that neither the

cutting part nor the throttle come into

contact with any obstacle when the

engine starts.

WARNING

Never place the throttle trigger into the

high-speed position when starting the

engine.

3. After starting the engine, check to

make sure that the cutting attachment

stops rotating when the throttle is

moved fully back to its original posi-

tion. If it continues to rotate even after

the throttle trigger has been moved

fully back, turn off the engine and take

the unit to your authorized ZENOAH

servicing dealer for repair.

USING THE PRODUCT

IMPORTANT

Cut only materials recommended by the

manufacturer. And use only for tasks

explained in the manual.

1. Grip the handles firmly with both

hands using your whole hand. Place

your feet slightly apart (slightly further

apart than the width of your shoulders)

so that your weight is distributed

evenly across both legs, and always

be sure to maintain a steady, even

posture while working.

2. Maintain the speed of the engine at

the level required to perform cutting

work, and never raise the speed of the

engine above the level necessary.

3. Never operate the pruner at an angle

greater than 60° in order to reduce the

risk of being struck by falling objects

during operation.

4. If the unit starts to shake or vibrate,

turn off the engine and check the

whole unit. Do not use it until the

trouble has been properly corrected.

5. Keep all parts of your body away from

rotating cutting attachment and hot

surfaces.

6. Never touch the muffler, spark plug,

or other metallic parts of the engine

while the engine is in operation or

immediately after shutting down the

engine. Doing so could result in seri-

ous burns or electrical shock.

WARNING

Approaching or contacting electric

power lines with the pruner may cause

serious injury death from electrocu-

tion. Electricity can jump from one

point to another by means arcing or

may be conducted through damp

branches. Maintain a clearance of at

least 15m between the pruner and any

electrical line carrying live current.

• IF SOMEONE COMES

1. Guard against hazardous situations

at all times. Warn adults to keep pets

and children away from the area. Be

careful if you are approached. Injury

may result from flying debris.

2. If someone calls out or otherwise inter-

rupts you while working, always be

sure to turn off the engine before turn-

ing around.

MAINTENANCE

1. In order to maintain your product in

proper working order, perform the

maintenance and checking opera-

tions described in the manual at

regular intervals.

2. Always be sure to turn off the engine

and disconnect the spark plug wire

before performing any maintenance

or checking procedures.

WARNING

The metallic parts reach high tem-

peratures immediately after stopping

the engine.

3. When replacing the cutting attach-

ment or any other part, or when re-

placing the oil or any lubricant, always

be sure to use only ZENOAH prod-

ucts or products which have been

certified by ZENOAH for use with

the ZENOAH product.

4. In the event that any part must be

replaced or any maintenance or repair

work not described in this manual

must be performed, please contact a

representative from the store nearest

ZENOAH authorized servicing dealer

for assistance.

5. Do not use any accessory or attach-

ment other than those bearing the

ZENOAH mark and recommended for

the unit.

6. Under no circumstances should you

ever take apart the product or alter it

in any way. Doing so might result in

the product becoming damaged dur-

ing operation or the product becom-

ing unable to operate properly.

5. For safe operation