easier to grease every slide the same way.

As long as you oil and grease it regularly, you

will not need to do anything else and your

trumpet will be happy.

Amado Waterkey Maintenance

These days many trumpets have Amado warterkeys instead of the

traditional "spitvalves" (I always thought that was a crude name).

Amado waterkeys are actually small valves that open and close if

pressed on. The tolerances are quite tight inside these gismos and

there is a tiny spring inside of them. So, needless to say, don't take

them apart because you will never find the small parts and even if

you do, you will never be able to put them all back. Mineral deposits

from saliva, just like on any other internal part of your trumpet will

jam or freeze the Amado waterkeys. This is why Amado waterkeys

should never be allowed to dry out. They should always be oiled.

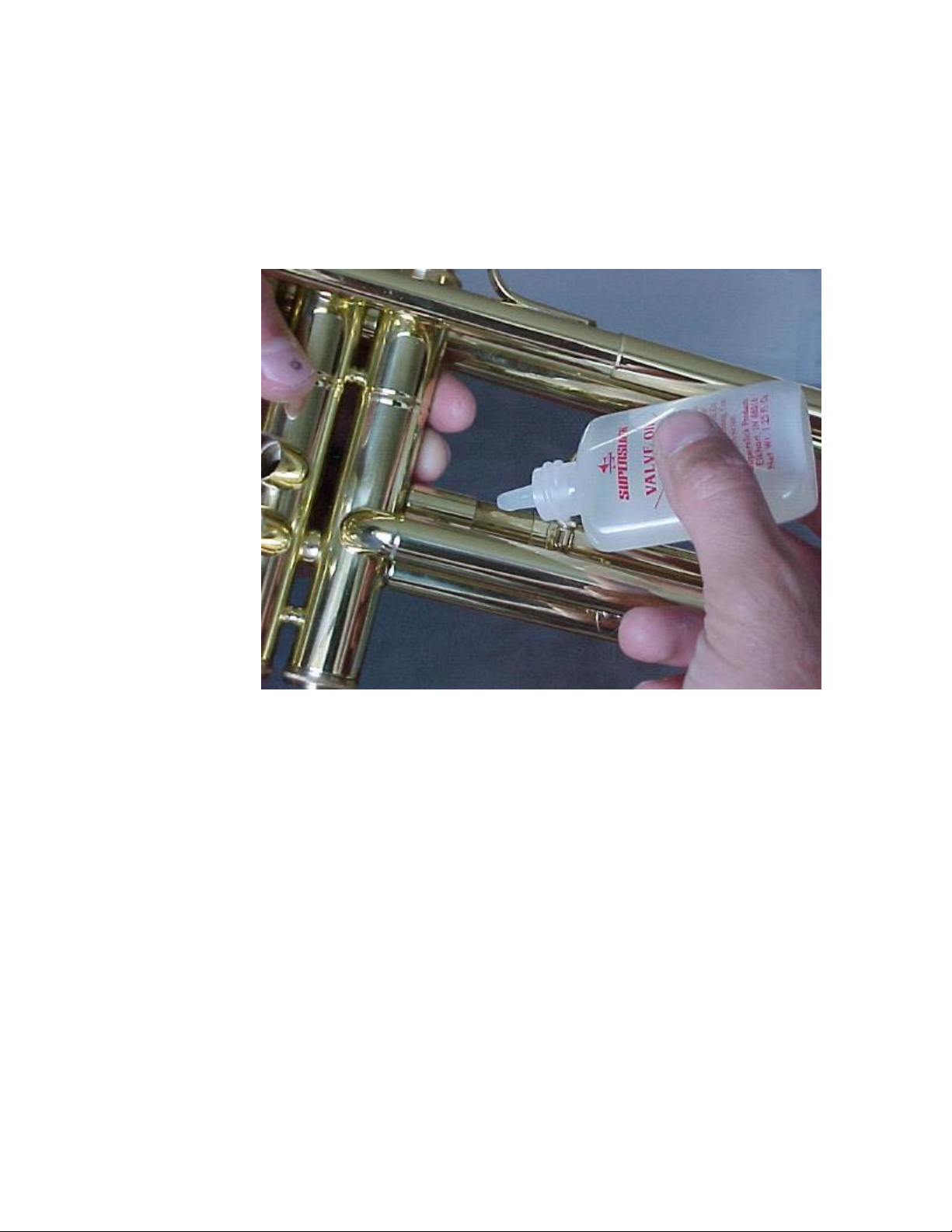

Just put a drop of oil in the actual waterkey hole and around the small

waterkey button. Put another drop on the other side of the Amado

waterkey as well. A total of 3 drops of oil once a month will do the

trick and you will never curse Mr. Amado for his invention. After

oiling each Amado waterkey in these three places, work in the oil by

pressing the button a number of times.

You are probably wondering what type of oil to use. NOT VALVE

OIL. It must by thicker oil. Motor oil is perfect. You can also use

woodwind key oil.

Cleaning your trumpet

CLEANING CLOTH

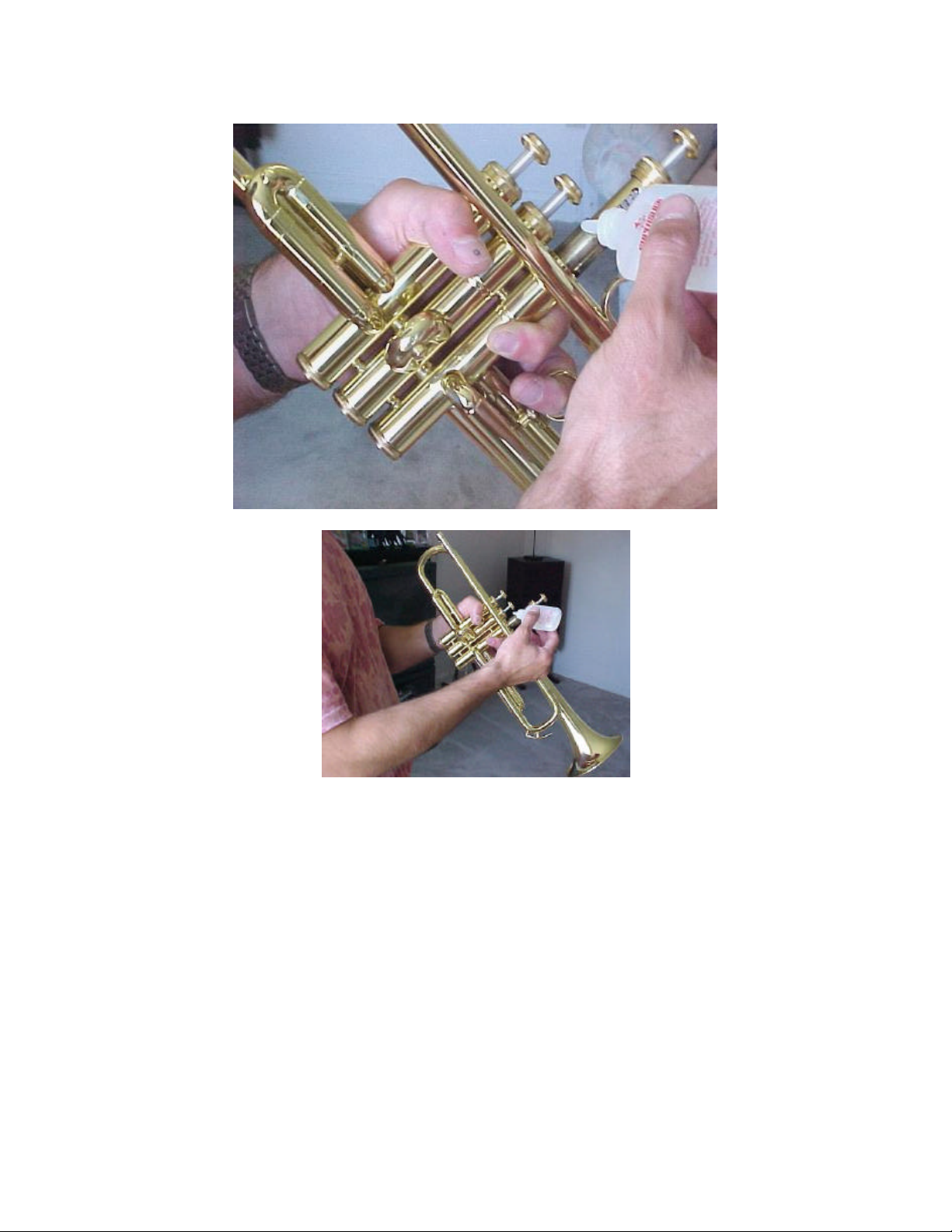

Wipe the outside of your trumpet after use with a cloth. If you have a silver trumpet use a silver polishing cloth. This

process is very important especially with silver instruments. The acids in your hands can deteriorate finishes. Wiping

the instrument after playing doesn't take much time and will always keep your trumpet looking new.

MOUTHPIECE BRUSH

Using a mouthpiece brush to clean you mouthpiece is a good idea. Food particals from your mouth can collect, enter

the trumpet and eventually work their way to the valves slowing piston action.

TRUMEPT SNAKE

A Trumept snake is made out wire with a brush on the end. Picture what the "Roto Ruter" man uses to unclog pipes -

only much smaller. Every three month you should take off the slides and us the snake. It will help remove mineral

deposits inside walls of the tubing. Not cleaning the tubes could lead the deposits being permanently fused to the inside

of the tubes. If this happens you must have it acid cleaned by a professional. Fused deposits inside your trumpet are like

the hard mineral deposits on your bathroom walls, water alone will not remove mineral deposits, only acid will.

Most of the time if your valves and slides don't function its not due to lack of cleaning but due to mechanical problems