INSTALLATION AND OPERATING INSTRUCTIONS: Motor spindle, HF150-003 series

Zimmer GmbH •Im Salmenkopf 5 •77866 Rheinau, Germany •+49 7844 9138 0 • +49 7844 9138 80 •www.zimmer-group.com

4

EN / 2020-10-22DDOC00746 / -

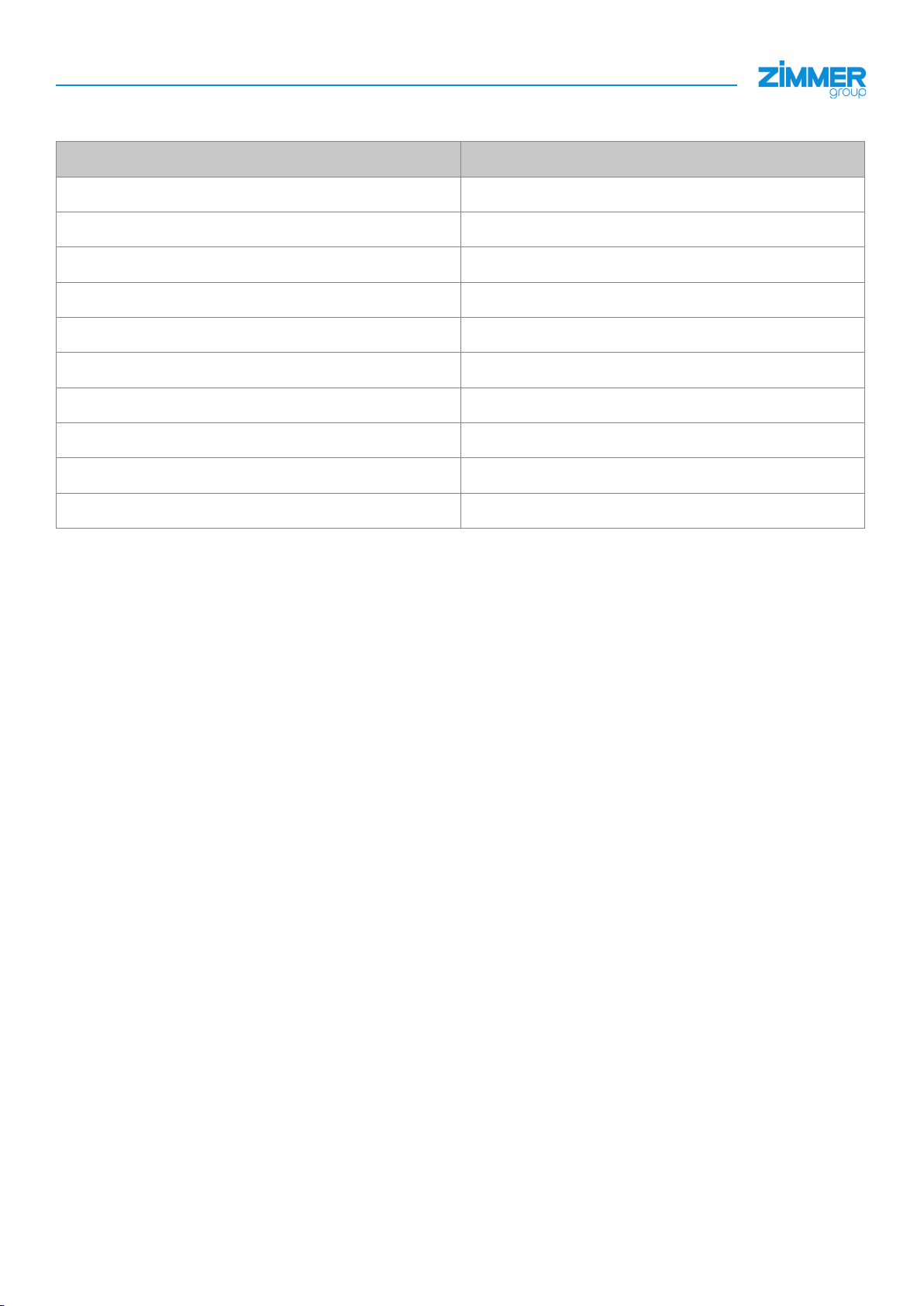

Content

1 Supporting documents ......................................................................................................................................................... 6

2 Notices and graphics in the installation and operating instructions ................................................................................. 6

2.1 Hazard levels of warning notices ...............................................................................................................................................................................6

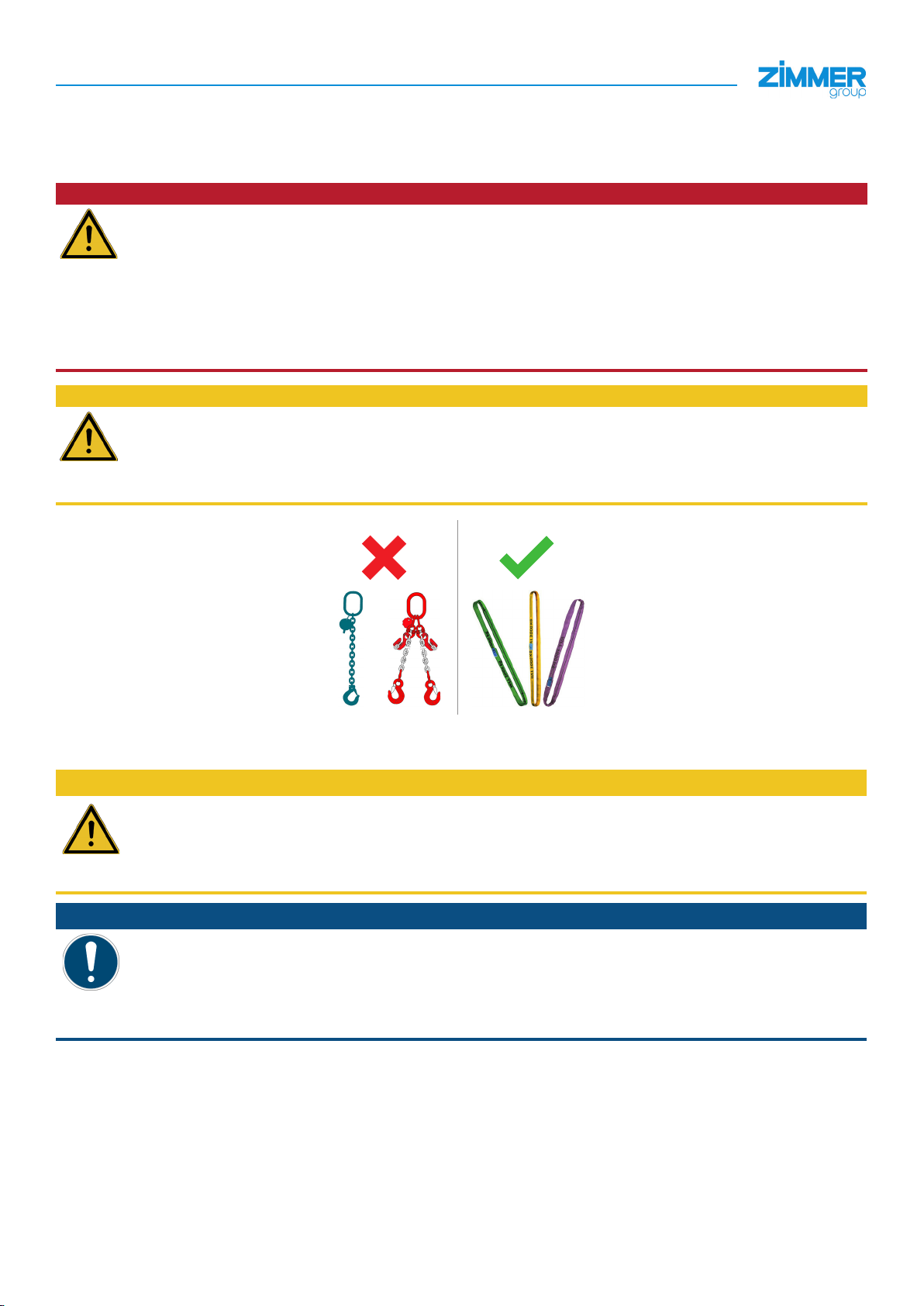

3 Handling/Transport/Scope of delivery................................................................................................................................ 7

3.1 Handling .......................................................................................................................................................................................................................7

3.2 Transportation data .....................................................................................................................................................................................................7

3.3 Scope of delivery .........................................................................................................................................................................................................7

4 Safety notes ........................................................................................................................................................................... 8

5 Proper use ............................................................................................................................................................................. 9

6 Personnel qualication ......................................................................................................................................................... 9

7 Product description ............................................................................................................................................................10

7.1 Type plate ...................................................................................................................................................................................................................10

7.2 Functional description ..............................................................................................................................................................................................10

7.3 Design of the motor spindle .....................................................................................................................................................................................11

8 Technical data .....................................................................................................................................................................12

8.1 Motor ..........................................................................................................................................................................................................................12

8.2 Clamping state ...........................................................................................................................................................................................................12

8.3 Standstill monitoring .................................................................................................................................................................................................12

8.4 Use of thermistors .....................................................................................................................................................................................................12

8.5 Rotary encoder ..........................................................................................................................................................................................................13

9 Installation ............................................................................................................................................................................14

9.1 Safety notes ...............................................................................................................................................................................................................14

9.2 General installation information ...............................................................................................................................................................................15

9.3 Installing the motor spindle ......................................................................................................................................................................................15

9.4 Installing the attachment part ...................................................................................................................................................................................16

9.5 Installing the power supply .......................................................................................................................................................................................17

9.6 Installing the electrical connections ........................................................................................................................................................................18

9.7 Installing the uid connections ................................................................................................................................................................................19

9.8 Installing the cooling system ....................................................................................................................................................................................19

9.8.1 Cooling duct connections ..........................................................................................................................................................................21

9.8.2 Requirements for the screw-on surface ....................................................................................................................................................21

9.8.3 Cooling unit .................................................................................................................................................................................................21

9.8.4 Requirements for the cooling circuit .........................................................................................................................................................21

9.9 Tool holder .................................................................................................................................................................................................................22

10 Commissioning ...................................................................................................................................................................23

10.1 Safety notes ...............................................................................................................................................................................................................23

10.2 Checking operational readiness ..............................................................................................................................................................................24

10.3 Tool interface (setting dimensions/clamping force) ...............................................................................................................................................25

10.3.1 Checking the clamping force ....................................................................................................................................................................26

10.4 Checking the tool interface (analog sensor and switching states) ........................................................................................................................26

10.5 Commissioning the cooling circuit ..........................................................................................................................................................................27

10.6 Thermistors ................................................................................................................................................................................................................27

10.6.1 PTC130 thermistor ......................................................................................................................................................................................27

10.6.2 PT1000 thermistor.......................................................................................................................................................................................27

10.7 Grease distribution ....................................................................................................................................................................................................28

11 Operation .............................................................................................................................................................................28

11.1 Safety notes ...............................................................................................................................................................................................................28

11.2 Warm-up cycle at the start of work ..........................................................................................................................................................................29