Section 4 – 2

Azalea Aviation Copyright 2014

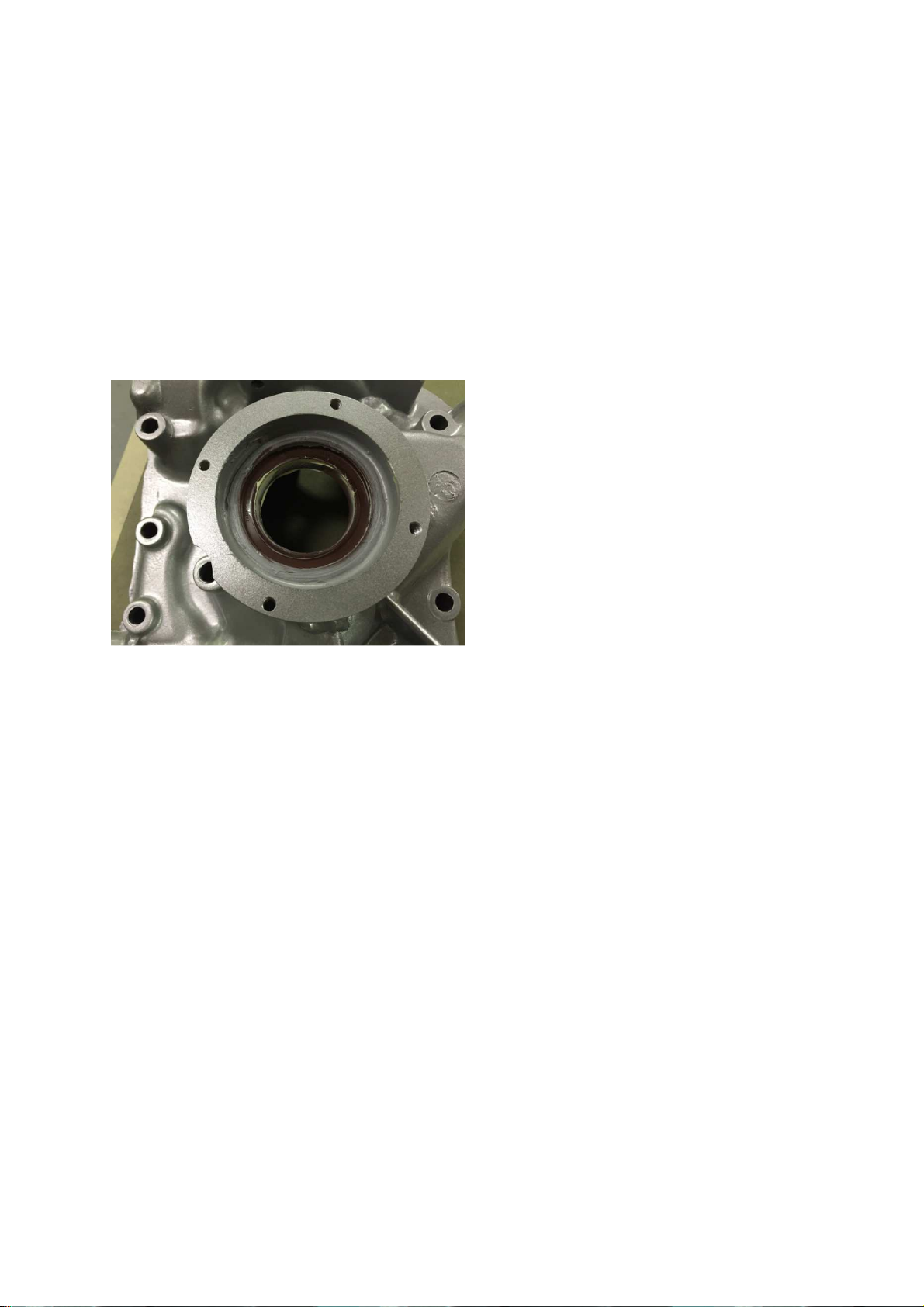

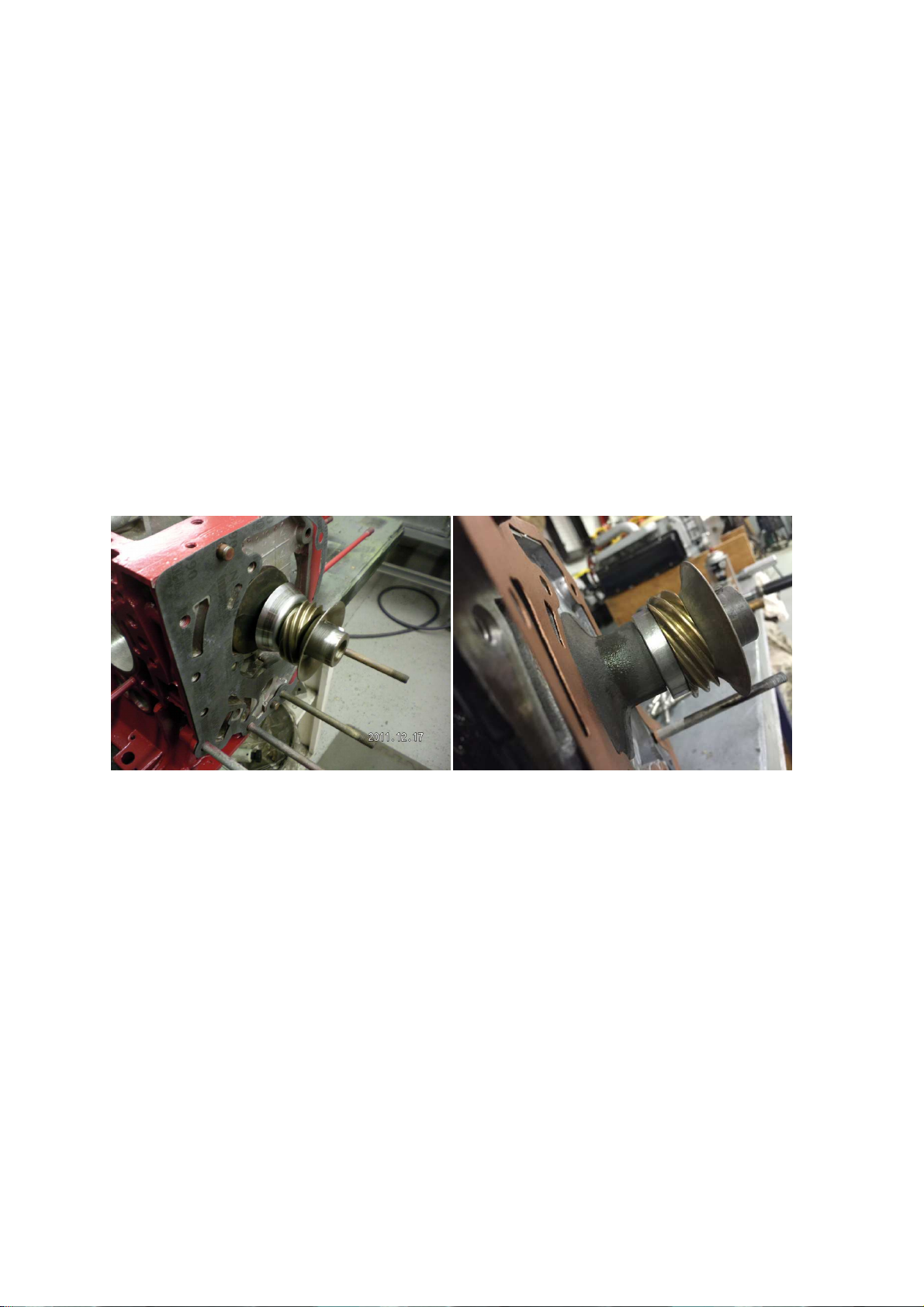

Drive Gear Installation:

The distributor drive gear and slinger need to be installed before the accessory

housing. This assembly is made up of four pieces and need to be in the right order

and orientation. The photos below show the order and the assembled unit. (Fig 1)

Use a large socket or pipe to lightly drive these pieces over the crankshaft end.

The order is…eccentric, spacer, gear, and slinger (facing out). Some engines may

be equipped with the wider spacer that eliminates the concentric and small spacer.

(Fig 1b) Be sure the woodruff keys are installed properly onto the crankshaft prior

to installation.

Fig 1. Rear gear parts installed on the crankshaft Fig 1b.

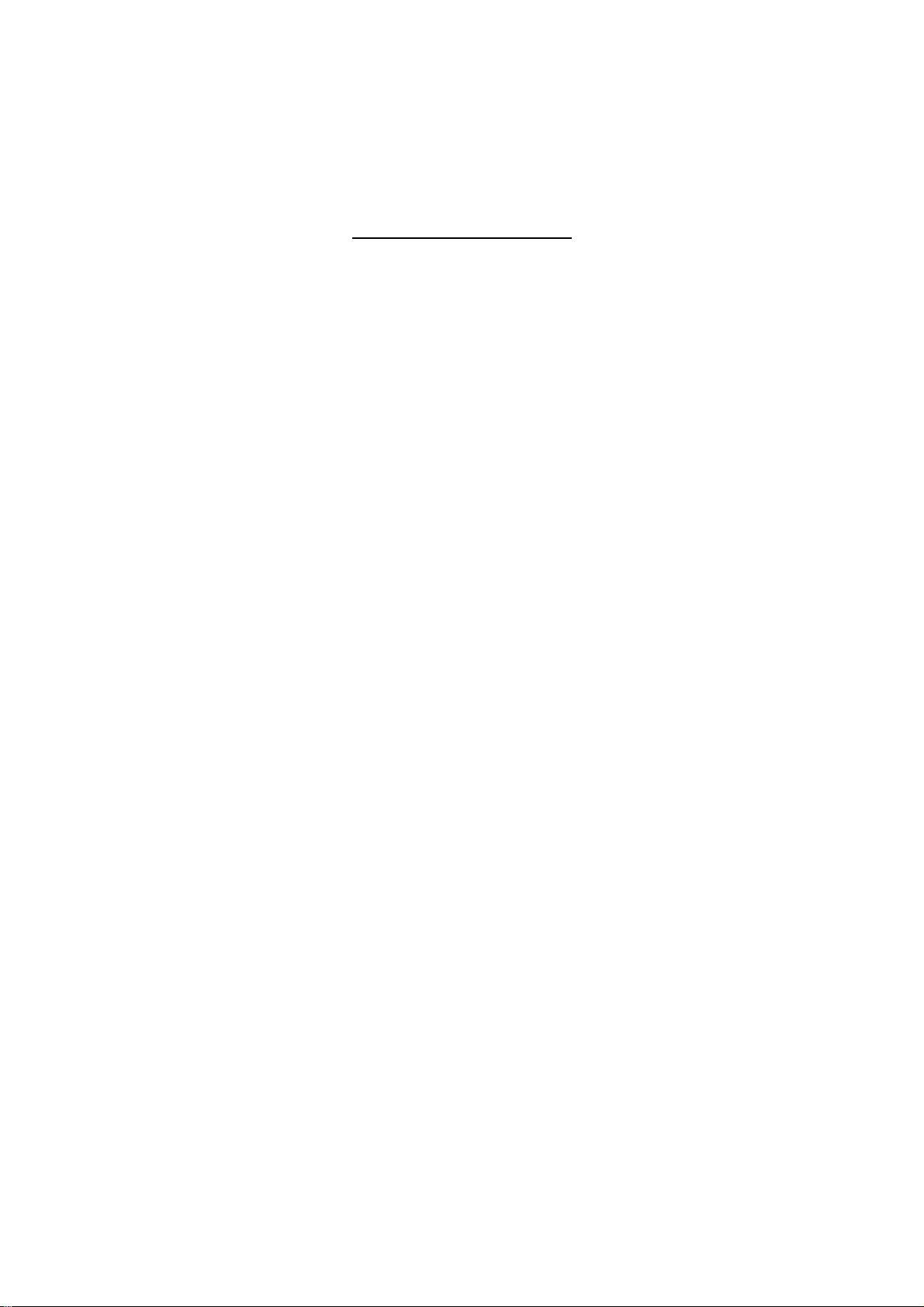

Housing Installation

Apply an even coat of copper spray on both sides of the rear gasket. Once it is

tacky install onto the case. Slide the Accessory housing on and tap into place with

the rubber hammer. Check to see that it has seated all the way around before

installing the hardware. Apply a dab of Loctite onto the threads of the 4 long and 2

short bolts prior to installing them. (Do not install the bolt at the 4 o’clock position

yet. Install three of the four washers and 3/8 nuts onto the studs. Leave the left

one open. (Fig 2) Torque the hardware to the proper specifications. (13 ft/lbs)