9

Quick change system for SPRINT Series

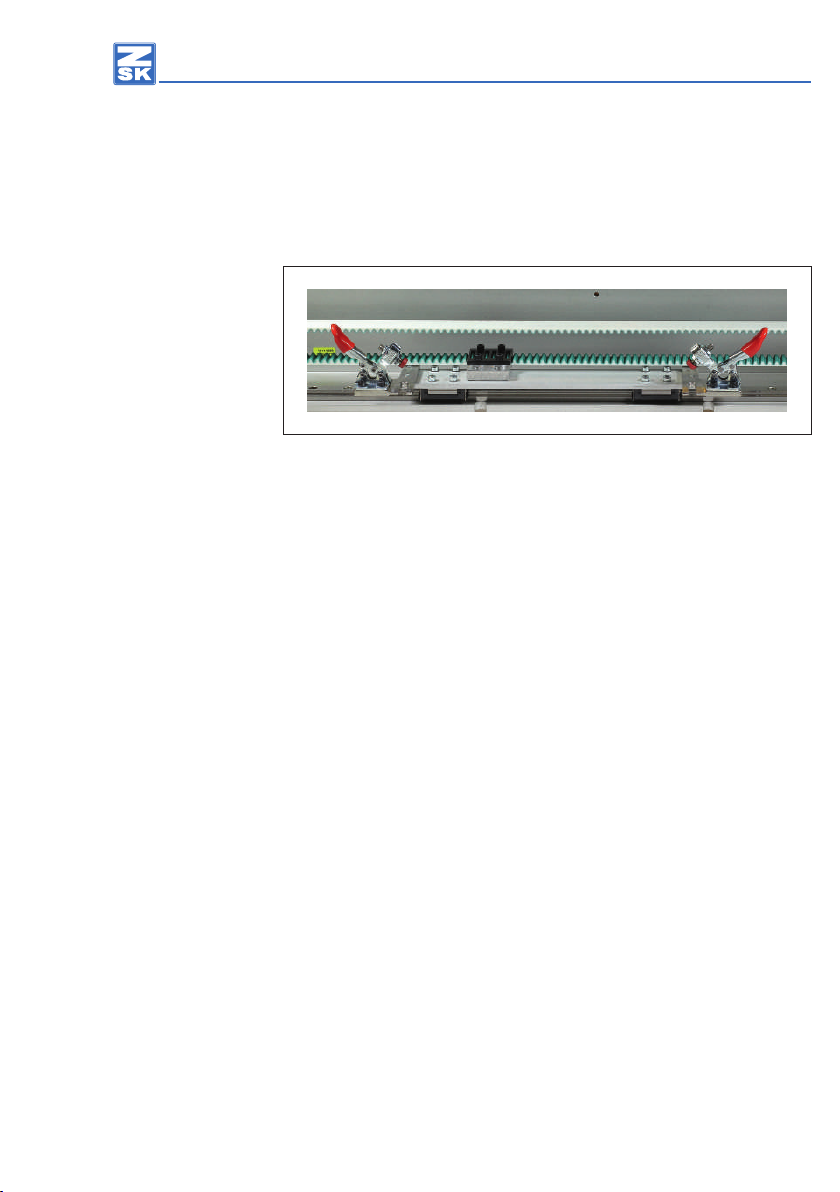

Fig. 11: Horizontal clamping xture assembled, carriage (view from above)

Mount the two pre-assembled clevises with the horizontal clamping xture on the

carriage. Observe the mounting direction of the horizontal clamping screw.

Rotate the mounting screws ca. 1 turn in the thread.

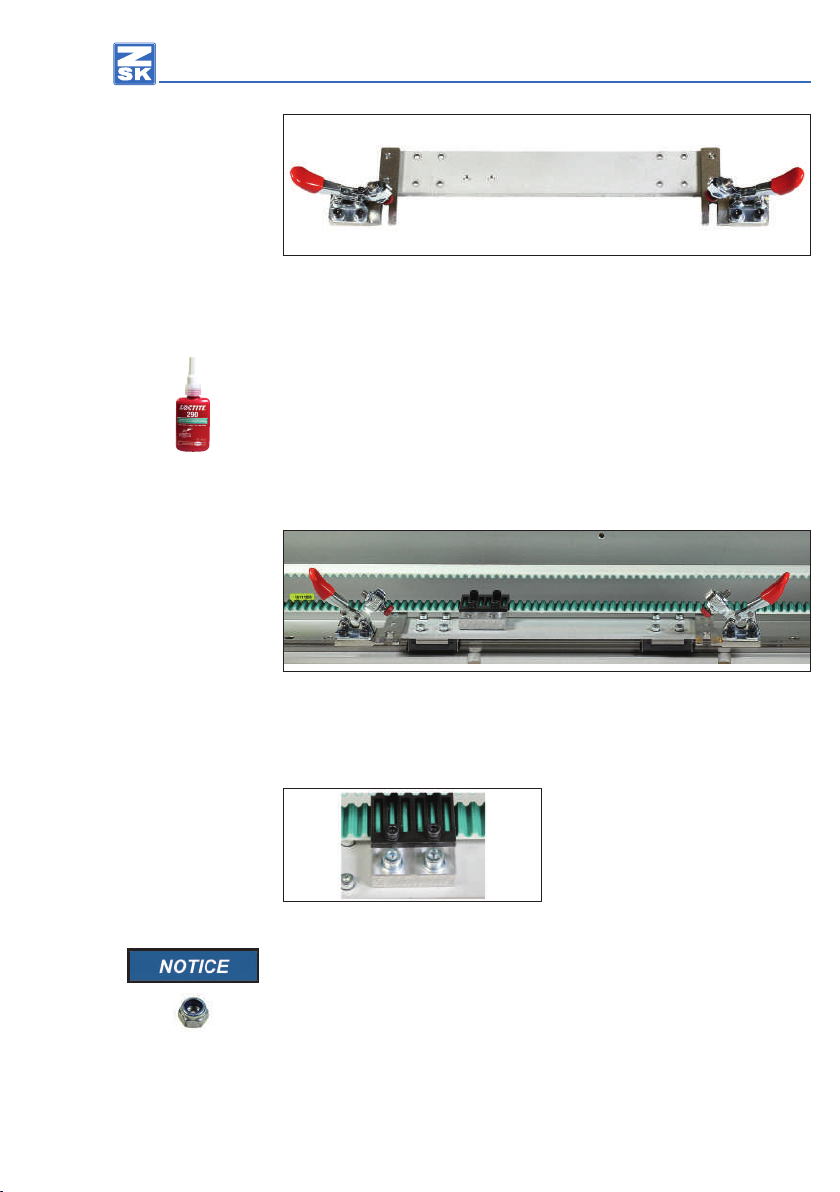

Place a drop of Loctite 290 (or equivalent adhesive from another manufacturer)

on the threads of the 4 mounting screws.

Only tighten the two screws securing the individual clevises rmly after both

countersunk head of the screws are sitting in the intended cuts.

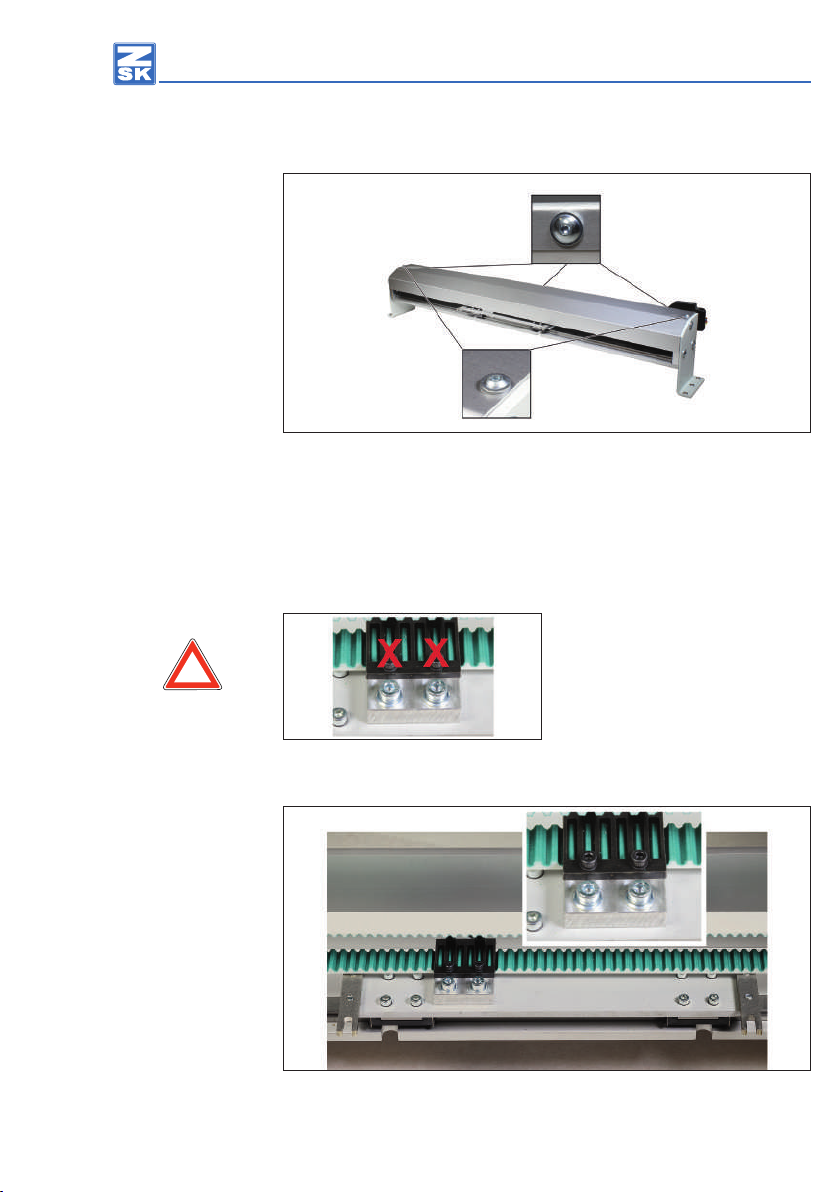

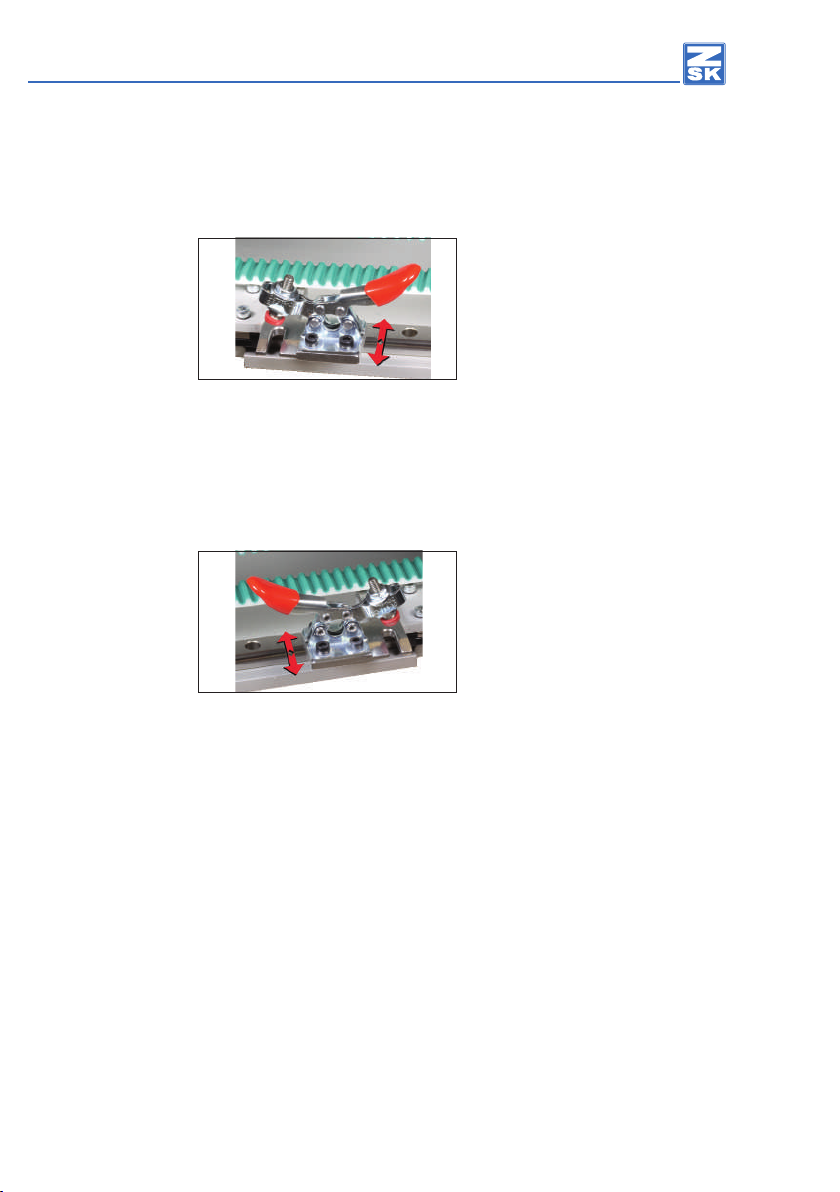

Fig. 12: Carriage, assembly

Assemble the carriage with the 8 mounting screws (incl. locking washer) on the

two movable pilot cariages of the pantograph drive for lateral movement.

Secure the connection with the two

screws incl. the washer on the carriage.

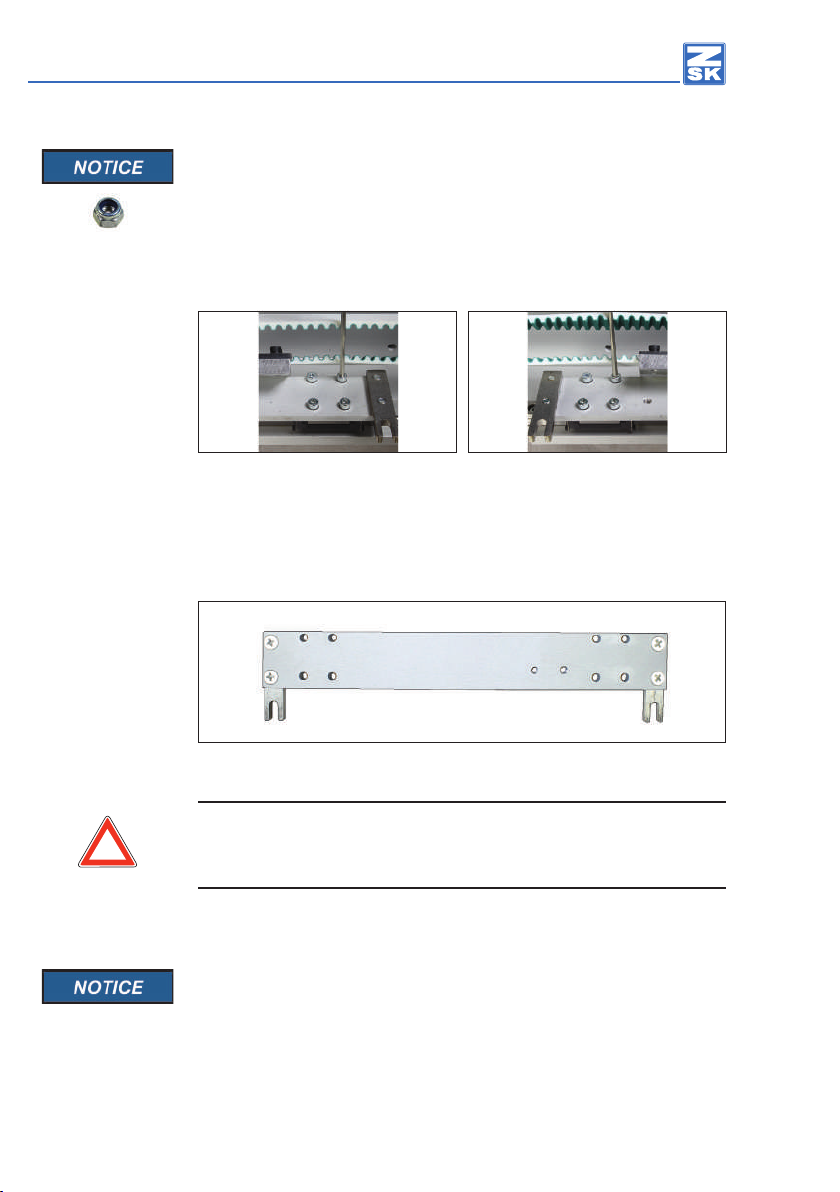

Fig. 13: Connection, assembly

On the bottom of the carriage the screw connection is countered by

2 lock nuts.

For securing the connection, screw the two lock nuts from below rmly on the

screws.

ÖSo the transmission of motion of the pantograph drive for lateral

movement is established again.