1-CUBE SU 6.2. User manual

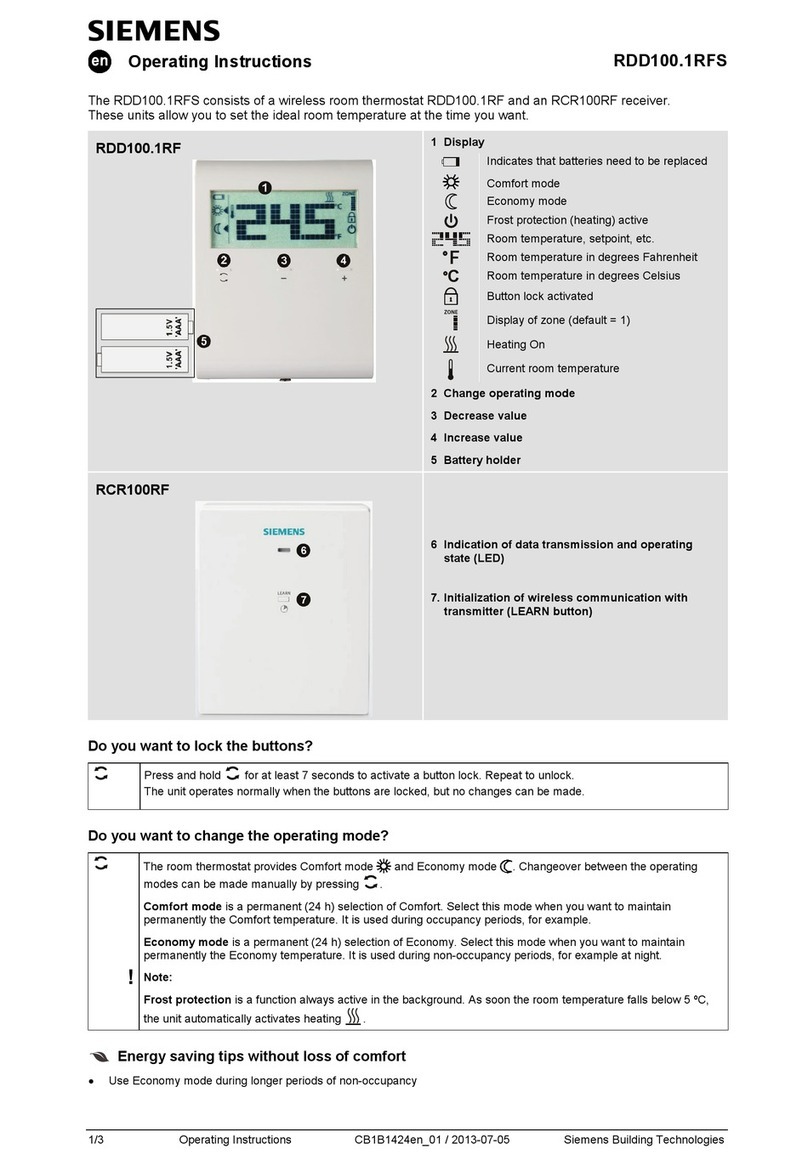

1

1-CUBE

s. r. o.

Hamry 3567, 580 01 Havl. Brod, Czech Rep.

tel + 420 569 433620, fax + 420 569 422144

e-mail: 1-cube@1-cube.com, web site: www.1-cube.com

WATER THERMOSTAT - TYPE SU 6.2.

USER’S GUIDE

Manufacturer and service:

1

-CUBE

s.r.o.

Hamry 3567, 580 01 Havl.Bro

tel. 569 433 620

fax 569 422 144

C

ONTENT

1. Range of the supply ........................................................................................................................................................ 2

2. Installation instructions .................................................................................................................................................. 2

3. Safety recommen ations ................................................................................................................................................ 3

4. Technical ata ................................................................................................................................................................. 4

5. User’s gui e ................................................................................................................................................................... 5

6. Monitoring RS232 ......................................................................................................................................................... 13

7. Maintenance ................................................................................................................................................................. 13

8. Important warnings ...................................................................................................................................................... 13

2

1.

R

ANGE OF THE SUPPLY

Water thermostat type SU6.2- hot bath .......................... 1 pc

Water thermostat type SU6.2- col bath ........................ 1 pc

Bottle hol er for 6 bottles ............................................... 2 pcs

2.

I

NSTALLATION INSTRUCTIONS

The Water Bath is etermine only for work in laboratories which is the or inary laboratory place. The Bath must be

locate in the horizontal position (for proper operation of the apparatus). Plug the Bath with the help of 2

stan ar ize single-phase plugs into el.socket. Connect each bath (col an hot) with its own cor .

Before plugging in the technician has to check the con ition of the el.circuit that will be use for the Water Bath

operation. If the result of the el.circuit inspection is positive, the Water Bath can be plugge in.

Plug wiring (front view):

L1-phase230 V, 50Hz protective earth con uctor PE

(black con uctor) (siskin-green con uctor)

Neutral wire

(blue)

3

Co d Bath SU6.2. connection:

3.

S

AFETY RECOMMENDATIONS

Water Bath may be operate only by person who became completely acquainte with its function within the

framework of the training, or who became thoroughly acquainte with the user’s gui e of this evice. The Water Bath

must be plugge in with the help of a stan ar ize plug into single-phase el.socket with circuit breaker. Before

plugging in the technician has to check the con ition of the el.circuit that will be use for the Water Bath operation. If

the result of the el.circuit inspection is positive, the Water Bath can be plugge in.

There is the Main Switch locate on front panel. The Main Switch has two positions ON - 1, OFF - 0.

In case of anger switch off the Main Switch an isconnect fee el.cor out of the socket. Switch off the Main

Switch, isconnect fee el.cor out of the socket an contact the qualifie service personnel who provi es service for

elivere evice if necessary.

Warning! It is hazar ous for anyone except for the pro ucer an authorize service company to repair the apparatus.

4

4.

T

ECHNICAL DATA

E ectric data:

- voltage system TN-S 1+PE+N

- voltage 230V/50 Hz or 110V/60 Hz

- protection IP 20

- the equipment can be use in neutral me ium

- the equipment output : hot bath 1500W, col bath 1800W

- circuit breaker–10A fusible cut out

- plugging in el. network: with the help of flexible cor LYS 3x1,5

-average plug an socket outlet protecte with 16A circuit breaker

Adjustab e data:

- type of metho : THERMOSTAT, PROFILE, CALIBRATION

- temperature range: from 25

0

C to +90

0

C, col bath from - 10

0

C to +30

0

C with the help of membrane keyboar

an isplay

- time since the begining of test

Accuracy:

- accuracy of temperature measurement: +-0,01

0

C

- accuracy of temperature regulation: : +-0,1

0

C

Data represented on LCD disp ay:

- type of metho : THERMOSTAT, PROFILE

- instantaneous temperature of bath or suspension, require temperature of bath

- time since the begining of test

- communication of the instrument with the service

5

5.

U

SER

’

S GUIDE

Picture of the coo ing bath - SU6.2:

Control panel Mixer engine Removable top

Cooling thermostat Cooling on-off switch Cooling exchanger Air inlet

First switch on the Main Switch locate on the front panel of the equipment.

NOTICE: It is forbi en to use the evice without filling it with water. It coul cause evice estruction an staff injury.

The evice warns you if there is not enough water insi e the bath. It is necessary to use electrically con uctive liqui .

If wou use non electrically con uctive liqui then the evice will notify all the time that there is not enough water

insi e the bath even if it isn’t true. If you use istille water in the laboratory just a a pinch of salt (NaCl) an you

will get electrically con uctive liqui .

Switch on the cooling on-off switch except for the main switch in the cooling bath. There is a cooling thermostat just

next to cooling on-off switch an we o reccomen to leave its value as prea juste „value 5“

Warning! Do not exceed the temperature+30 degrees Ce sius in the coo ing bath otherwise the coo ing system can

be irreversib y damaged!!!!!

6

The bottles can be put in only into the bottle hol er which makes part of the supply. If you put them insi e without

the bottle hol er the bottles may move in the bath an the stirrer can be amage .

The stirrer is controlle with the help of the switch „Stirrer“. We reccommen to leave the stirrer always switche on

(in the position I) in this way the stirrer will be controlle (switch on/switch off) with "Main switch". Once the main

switch is switche on the stirrer is switche on automatically too.

One chip microprocessor is use to control the evice. The algorithm is save in the program. Program is controlle

with the help of 7 keys of the membrane keyboar which is locate on the front panel of the equipment. The report

about the operating con ition can be observe on the 2 lines of the isplay.

Contro Pane Scheme – front view:

Key F1 Display Key mius (-) Key plus (+) Key ROTATION

Key OFF Key ON Key ENTER Main Switch

7

Contro Pane Scheme – rear view :

Fee cor Fan Stirrer connection Safety fuse 10 A Connector RS232

After switching on the equipment there is 1-CUBE name an the version of the control programme appears on the

isplay, they isappear after a while an the the text THERMOSTAT appears on the isplay. Once you finish working

switch off the evice with the help of the Main switch.

Control algorithms:

The following control algorithms PROFILE, THERMOSTAT, CALIBRATION can be run with the Water Bath

During the process the following information are automatically isplaye on the isplay.

1. ine:

The require temperature is isplaye .

2. ine:

Information about time given in minutes an instantaneous real working temperature.

8

Adjustment of the required temperature or time:

The require temperature or time in the metho s (menu) THERMOSTAT, CALIBRATION an PROFILE are a juste by

pressing keys plus + (to increase the value) or minus – (to ecrease the value). First the require value is change of

tenths of egree or 1 secon s, after ten changes (ten presses of key) the require value is change of egrees or 10

secon s, after ten following changes (ten presses of key) the require value is change of 10 egrees or 100 secon s

etc. Once you have a juste the require ata push the key OFF to save it into the memory, after this step the text

THERMOSTAT appears again on the isplay.

Metho Thermostat:

This algorithm allows to a just any require temperature an the Water Bath maintains the temperature for the

require time. The evice has save the last value a juste temperature that was regulate . If you o not want to

change the value of the temperature start the algorithm itself by pressing the key ON. The text: REQ.CONTROL:

appears on the first line of the isplay, there is the time in minutes „min=“an the real temperature „T=“ in

0

C

on the

secon line.

If the set temperature oesn’t suit you an you nee to change it you have to a just the require temperature before

you press the key ON. The require temperature is set with the help of keys plus + (to increase the value) or minus –

(to ecrease the value) – see the paragraph above: Adjustment of the required temperature or time: in the chapter

Contro a gorithms. After setting the require temperature press the key OFF an in that way the require

temperature is save an the text THERMOSTAT appears again on the isplay. Now you can start the temperature

control running by pressing the key ON. The algorithm is stoppe by pressing the key OFF. If there is not enough

water in the Bath the text „add water“ appears automatically on the isplay an it will isappear once the water is

a e .

Method PROFILE:

This algorithm allows to a just any require time behaviour of temperatures. It is possible to a just as many as 7

points efine with time an temperature coor inates. After choice of the item PROFILE in the main menu with the

help of the key ROTATION one can start the algorithm itself by pressing the key ON.

After 1 sec the text: START ON:

OTHER PARAMETERS: appears on the isplay.

If there has been alrea y set the temperature curve before, one can use it again (because it is save in the internal

memory) by hol ing the key ON at the time when the text: START ON:

OTHER PARAMETERS: appears on the isplay.

If there hasn’t been set the temperature curve yet or it is necesary to set it in a ifferent way, one waits about 1 sec

till the text SET UP THE CURVE appears on the isplay. After that the text: time of point 1= appears on the first line an

one sets the time in minutes on the secon line. Time is set with the help of keys plus + (to increase the value) or

minus – (to ecrease the value) – see paragraph: A justment of the require temperature or time: in the chapter

Control algorithms. After setting the time of point 1 press the key OFF an in that way time of point 1 is save in the

internal memory an after that the text: time of point 2= appears on the first line an one sets in the same way the

time of point 2, the time of point 3, the time of point 4, the time of point 5, the time of point 6, the time of point 7.

After setting the time of point 7 press the key OFF an the text: temp. of point 1= appears on the first line an one

sets the temperature in

c

C. on the secon line. Temperature is set with the help of keys plus + (to increase the value)

or minus – (to ecrease the value) – see paragraph: A justment of the require temperature or time: in the chapter

Control algorithms. After setting the temperature of point 1 press the key OFF an in that way temperature of point 1

is save in the internal memory an after that the text: temp. of point 2= appears on the first line an one sets in the

9

same way the temperature of point 2, the temperature of point 3, the temperature of point 4, the temperature of

point 5, the temperature of point 6, the temperature of point 7 an by pressing the key OFF the control of the

a juste curve starts running. There is isplaye the require temperature on the first line of the isplay an the time

runne off from the beginning of the test an real temperature on the secon line of the isplay. The algorithm is

stoppe by pressing the key OFF.

Temperature (

0

C)

40

0

C

34

0

C

30

0

C

25

0

C

10 30 40 65 80 105 125

Time(min.)

Examp e of the curve adjustement according to picture:

time of point 1=10, time of point 2=30, time of point 3=40, time of point 4=65, time of point 5=80, time of point

6=105, time of point 7=125,

temperature of point 1=30, temperature of point 2=30, temperature of point 3=34, temperature of point 4=34,

temperature of point 5=40, temperature of point 6=40, temperature of point 7=25,

Method Ca ibration:

It is necessary to check the measurement accuracy with the help of etalon once in a six months. If the temperature of

the bath oes not correspon to the temperature measure with the etalon it is necessary to recalibrate the

temperature sensor. The temperature sensor is calibrate only if it is really necessary because the equipment is

optimally calibrate by manufacturer.

Ca ibration Procedure:

It is necessary to calibrate two temperatures in the opposite en s within evice temperature range for the right

measurement of the Water Bath - The lower temperature (for example about 5 egrees Celsius) an the upper

temperature (about 70 egrees Celsius).

10

Ca ibration of the ower temperature 5 degrees Ce sius (point 1) :

First check if the temperature in bath is about 5 egrees Celsius an if it is not use the metho Thermostat to reach it.

Once temperature of 5 egrees Celsius is reache use the following proce ure:

1) Press the keys OFF an ENTER at the same time

2) There is text „ ig value of tem“ on the first line an the value on the secon line. Write own the igital value.

3) There is text „point 1 - igital“ on the first line an the value on the secon line. Overwrite the value with the

help of keys + (increase ) or – ( ecrease) to put the igital value that you have written own before. Press the

key „OFF“ to set the require value.

4) There is text „point 1 - temp“ on the first line now an the value on the secon line. Overwrite the value with the

help of keys + (increase ) or – ( ecrease) to put the value that you have measure before with the etalon in

the water of the water bath. Press the key „OFF“ to set the require value.

5) There is text „point 2 - igital“ on the first line now an the value on the secon line. Do not set the point 2 at this

moment therefore press the key „OFF“.

6) There is text „point 2 - temp“ on the first line now an the value on the secon line. Do not set the point 2 at this

moment therefore press the key „OFF“.

7) There is text „HYSTER1_0= “ on the first line now an the value on the secon line. Do not set HYSTER1_0= at

this moment therefore press the key „OFF“.

8) There is text „HYSTER1_100= “ on the first line now an the value on the secon line. Do not set HYSTER1_100=

at this moment therefore press the key „OFF“.

9) There is text „HYSTER2_0= “ on the first line now an the value on the secon line. Do not set HYSTER2_0= at

this moment therefore press the key „OFF“.

10) There is text „HYSTER2_100= “ on the first line now an the value on the secon line. Do not set HYSTER2_100=

at this moment therefore press the key „OFF“.

11) There is text „HYSTER3_0= “ on the first line now an the value on the secon line. Do not set HYSTER3_0= at

this moment therefore press the key „OFF“.

12) There is text „HYSTER3_100= “ on the first line now an the value on the secon line. Do not set HYSTER3_100=

at this moment therefore press the key „OFF“.

The lower temperature (point 1) is calibrate now.

11

Ca ibration of the upper temperature 70 degrees Ce sius (point 2) :

First check if the temperature in bath is about 70 egrees Celsius an if it is not use the metho Thermostat to reach

it. Once temperature of 70 egrees Celsius is reache use the following proce ure:

1) Press the keys OFF an ENTER at the same time

2) There is text „ ig value of tem“ on the first line an the value on the secon line. Write own the igital

value.

3) There is text „point 1 - igital“ on the first line an the value on the secon line. Do not set the point 1 at

this moment therefore press the key „OFF“.

4) There is text „point 1 - temp“ on the first line now an the value on the secon line. Do not set the point 1 at

this moment therefore press the key „OFF“.

5) There is text „point 2 - igital“ on the first line now an the value on the secon line. Overwrite the value

with the help of keys + (increase ) or – ( ecrease) to put the igital value that you have written own

before. Press the key „OFF“ to set the require value.

6) There is text „point 2 - temp“ on the first line now an the value on the secon line. Overwrite the value with

the help of keys + (increase) or – ( ecrease) to put the value that you have measure before with the

etalon in the water of the water bath. Press the key „OFF“ to set the require value.

7) There is text „HYSTER1_0= “ on the first line now an the value on the secon line. Do not set HYSTER1_0=

at this moment therefore press the key „OFF“.

8) There is text „HYSTER1_100= “ on the first line now an the value on the secon line. Do not set

HYSTER1_100= at this moment therefore press the key „OFF“.

9) There is text „HYSTER2_0= “ on the first line now an the value on the secon line. Do not set HYSTER2_0=

at this moment therefore press the key „OFF“.

10) There is text „HYSTER2_100= “ on the first line now an the value on the secon line. Do not set

HYSTER2_100= at this moment therefore press the key „OFF“.

11) There is text „HYSTER3_0= “ on the first line now an the value on the secon line. Do not set HYSTER3_0=

at this moment therefore press the key „OFF“.

12) There is text „HYSTER3_100= “ on the first line now an the value on the secon line. Do not set

HYSTER3_100= at this moment therefore press the key „OFF“.

The upper temperature (point 2) an temperature sensor are calibrate now

12

Hysteresis adjustment to achieve the most accurate regulation

Very complicate regulation algorithm is use to achieve the require temperature. 3 hysteresis ranges are use an

the heating output is regulate accor ing to them, in a ition its amplitu e is change linearly in epen ence on

temperature an on cooling compressor closing. Hol generally – if the volume of the bath is bigger, one has to a just

smaller hysteresis. Proce ure of hysteresis a justment is following:

1) Press the key s OFF an ENTER at the same time

2) There is text „ ig value of tem“ on the first line an the value on the secon line.

3) There is text „point 1 - igital“ on the first line an the value on the secon line. We o not calibrate the

temperature sensor now therefore press the key „OFF“.

4) There is text „point 1 - temp“ on the first line now an the value on the secon line. We o not calibrate the

temperature sensor now therefore press the key „OFF“.

5) There is text „point 2 - igital“ on the first line now an the value on the secon line. We o not calibrate the

temperature sensor now therefore press the key „OFF“.

6) There is text „point 2 - temp“ on the first line now an the value on the secon line. We o not calibrate the

temperature sensor now therefore press the key „OFF“.

7) There is text „HYSTER1_0=“ on the first line now an the value on the secon line. Overwrite the value

with the help of keys + (increase ) or – ( ecrease) to a just „HYSTER1_0“ as require . Press the key

„OFF“ to set the require value. Hysteresis „HYSTER1_0 is prea juste by the manufacturer as 000.30.

8) There is text „HYSTER1_100=“ on the first line now an the value on the secon line. Overwrite the value

with the help of keys + (increase ) or – ( ecrease) to a just „HYSTER1_100“ as require . Press the key

„OFF“ to set the require value. Hysteresis „HYSTER1_0 is prea juste by the manufacturer as 000.10.

9) There is text „HYSTER2_0=“ on the first line now an the value on the secon line. Overwrite the value

with the help of keys + (increase ) or – ( ecrease) to a just „HYSTER2_0“ as require . Press the key

„OFF“ to set the require value. Hysteresis „HYSTER2_0 is prea juste by the manufacturer as 000.15.

10) There is text „HYSTER2_100=“ on the first line now an the value on the secon line. Overwrite the value

with the help of keys + (increase ) or – ( ecrease) to a just „HYSTER2_100“ as require . Press the key

„OFF“ to set the require value. Hysteresis „HYSTER2_100 is prea juste by the manufacturer as 000.05.

11) There is text „HYSTER3_0=“ on the first line now an the value on the secon line. Overwrite the value

with the help of keys + (increase ) or – ( ecrease) to a just „HYSTER3_0“ as require . Press the key

„OFF“ to set the require value. Hysteresis „HYSTER3_0 is prea juste by the manufacturer as 000.05.

12) There is text „HYSTER3_100=“ on the first line now an the value on the secon line. Overwrite the value

with the help of keys + (increase ) or – ( ecrease) to a just „HYSTER3_100“ as require . Press the key

„OFF“ to set the require value. Hysteresis „HYSTER3_100 is prea juste by the manufacturer as 000.02.

The hysteresis is a juste now.

13

6.

M

ONITORING

RS232

During all the metho s Heating Immersion Circulator

the recor s of the temperature curves in PC are possible. Switch

off the evice an connect the PC com port with the RS232 com port with the help of supplie communicating cable.

Switch on the evice an start any metho . Use any program which makes possible the RS232 communication to

recor the temperatures in PC. Program Hyperterminal (which is part of WINDOWS) or program Serial Watcher (which

is part of Monitoring Mash Bath supply) can be use . Note. It is necessary to a just the program for ASCII signs

reception.

7.

M

AINTENANCE

Throughout the operation the scale can be se imente on the heating elements. It is important to remove these

se iments. Pour the water with either the acetic aci or citric aci into the bath an heat up an hol the

temperature of 65 egrees Celsius for one hour in the bath. Then isconnect fee el.cor out of the socket, suck the

se iments with the help of a hose an clean the vessel.

8.

I

MPORTANT WARNINGS

The Cooling Bath must be always locate on the nibs an mustn’t be tilte or turne upsi e own

in any case!!!!

If the evice is transporte at temperature below freezing point, it is necessary to leave the instrument for about 2

hours at room temperature before you start to work with it.

The fuses are locate on the back panel of the Water Bath. It is forbi en to replace the fuse by fuse with ifferent

value than the value in icate on the equipment.

Service:

For service contact the manufacturer: 1-CUBE, Hamry 3567, 580 01 Havl.Bro , Czech Rep.

tel. 00 420- 569 433 620

fax .00 420-569 422 144

NOTICE: It is forbi en for anyone except for the manufacturer or authorize company to repair the apparatus.

At the en of the apparatus life we recommen that it is accor ing to correspon ing waste categorization.

Take the metallic parts ma e of iron, brass, plastic elements an packing material to the separate collection as a

secon ary raw material. You can also or er the apparatus liqui ation at the above mentione company that ensures

the liqui ation of the waste accor ing to Waste Act.

Table of contents