7

2 VV. Creating innovative solutions for you and your business since 1995.

RESET button

(use after replacing

lters)

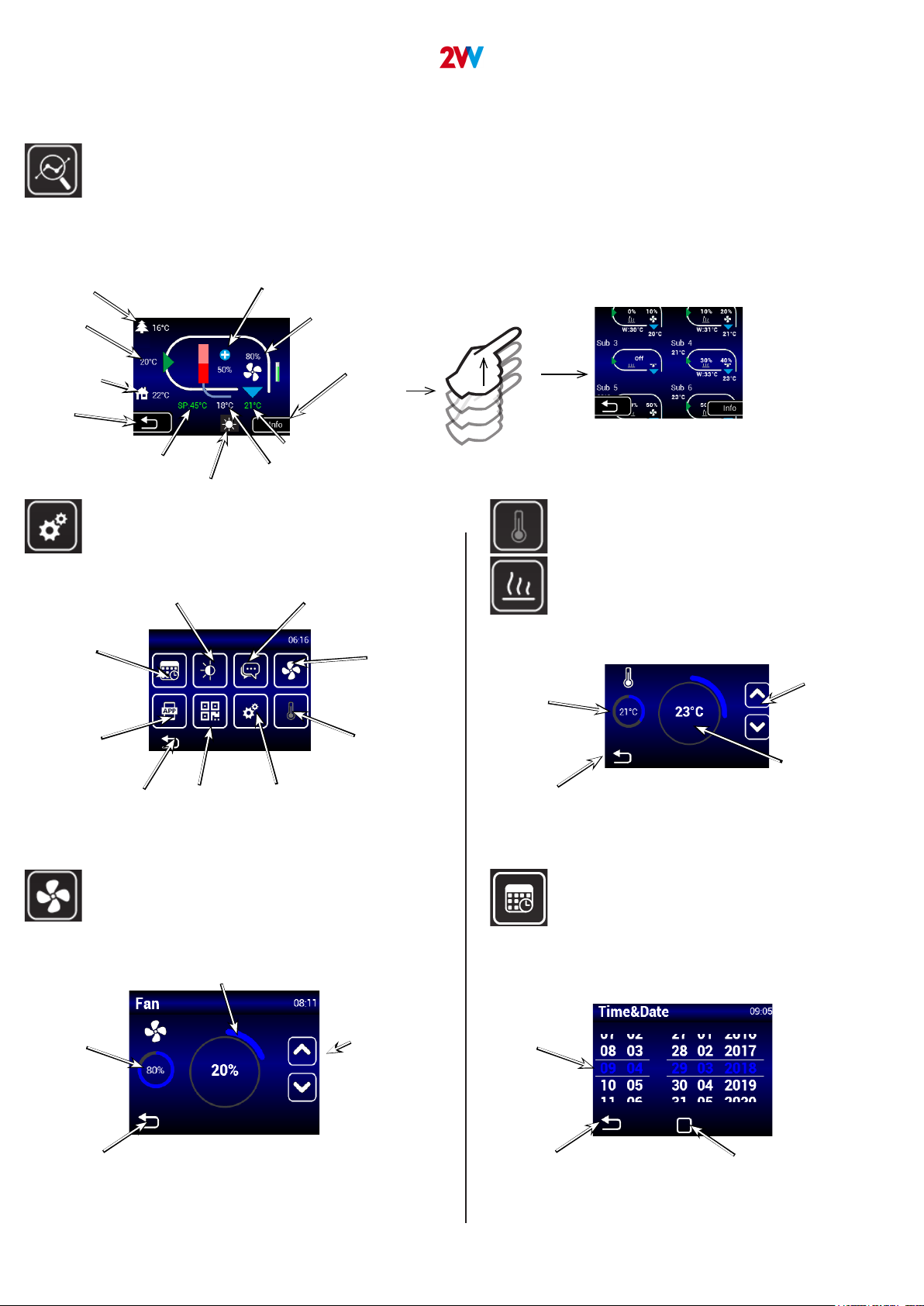

MENU - OUTLET TEMP LIMITS

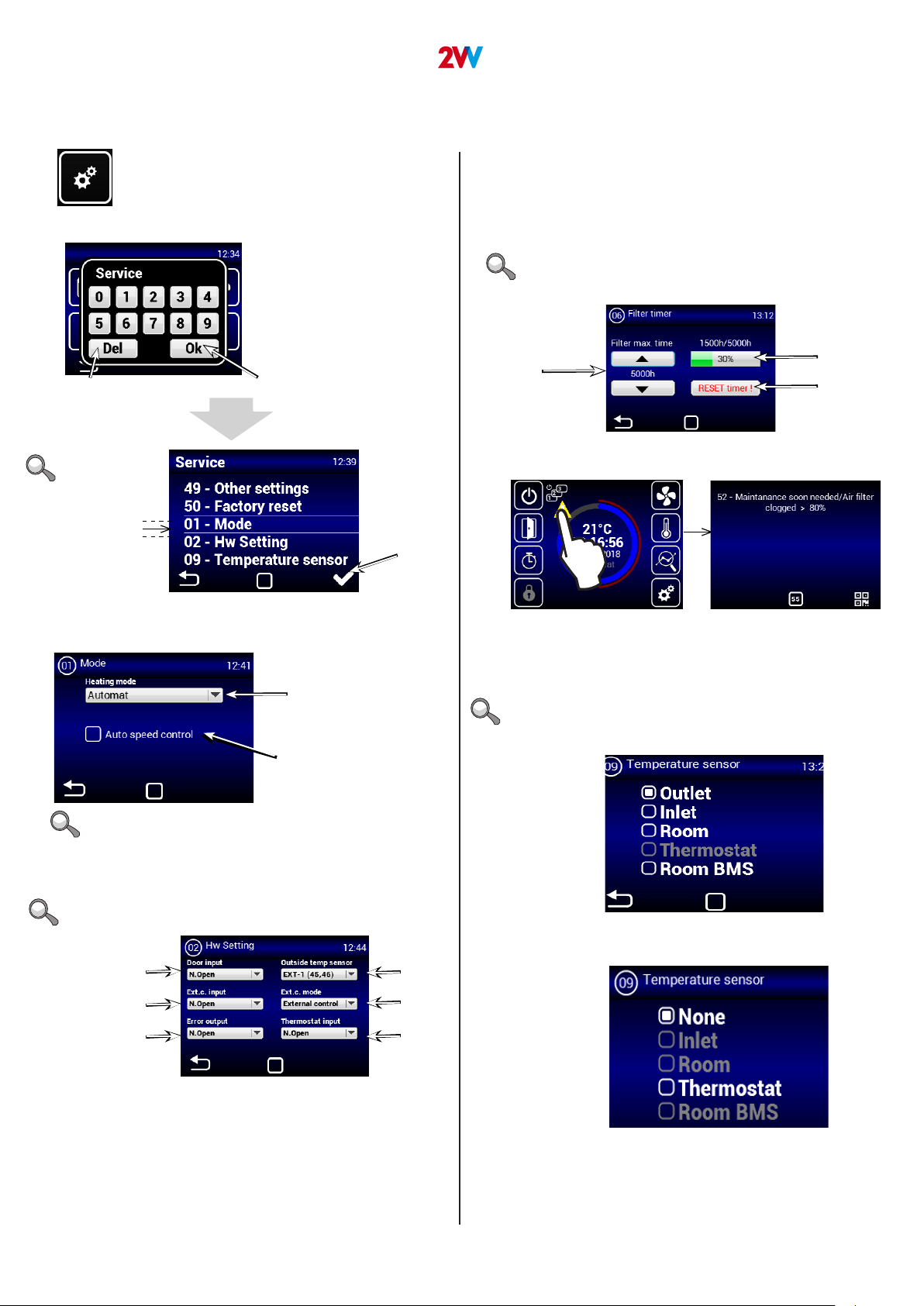

MENU - MODBUS RTU

MENU - NETWORK

Maximum temperature limit: 25°C - 45°C

Address

1~247

Parity

None

Odd

Even

DHCP blocked/enabled

Regulator network settings to

be entered manually:

IP address

Mask

Gate

Communication speed:

4800 Bd

9600 Bd

14400 Bd

19200 Bd

38400 Bd

Minimum temperature limit: 15°C - 20°C

Use this menu to set the limits of the exhaust

Use this menu to set the Modbus RTU communication

parameters

Use this menu to set the communication parameters of

the network interface

An incorrect setting may prevent communication with

the regulator

An incorrect setting may prevent communication with the

regulator

If “OUTLET” is selected in the TEMPERATURE SENSOR

MENU, it will not be possible to set values as they are

already dened by the sensor. You will see this screen:

1. CONTROL

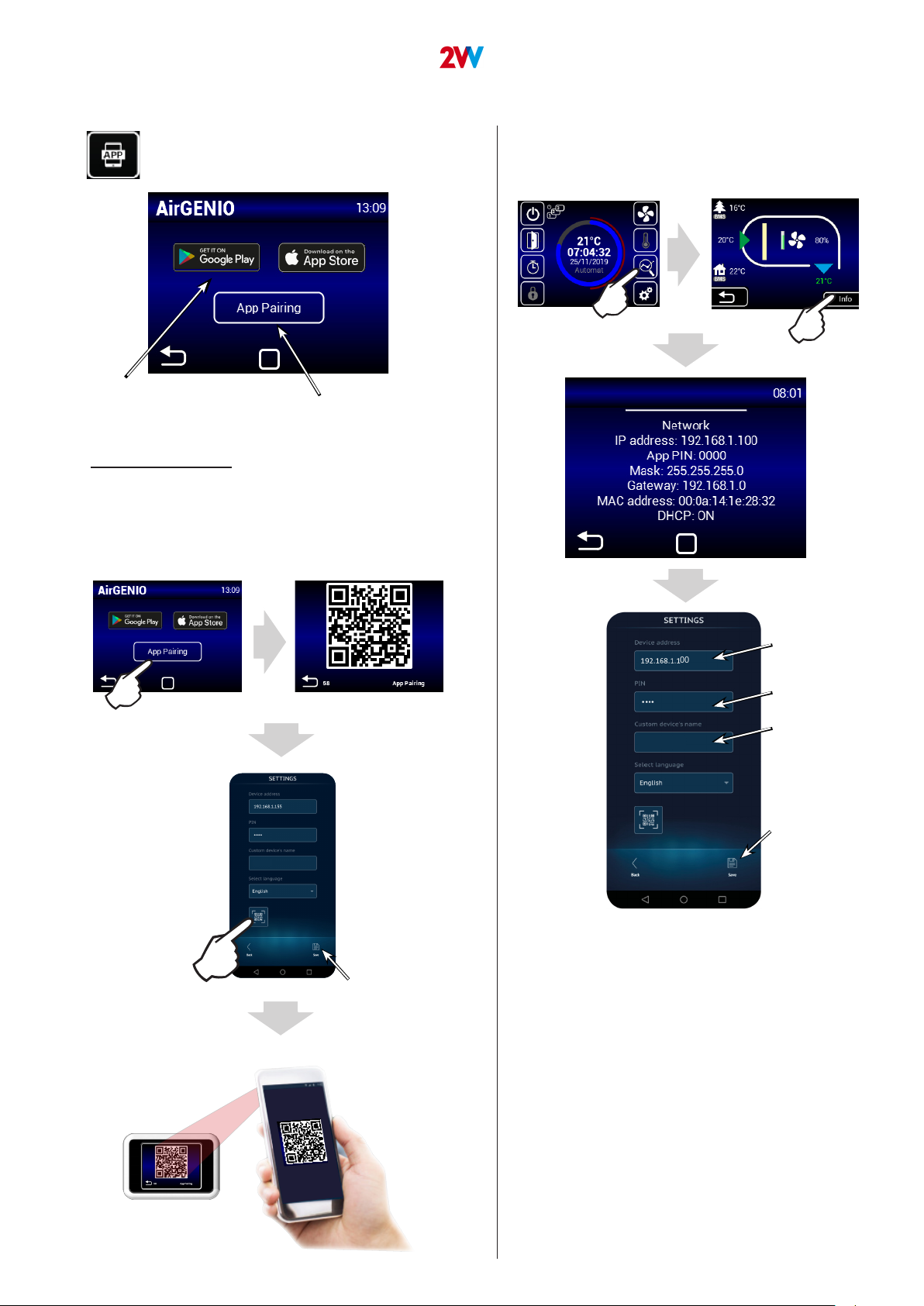

MENU - USER LOCK

MENU - SUMMER HEATING

Limit level – see Ad1)

Enter PIN 0000~9999

(numeric values only)

Use this menu to set the limits to control the regulator

with a multi-level panel

Use this menu to set heating limits in summer months

If the outside temperature sensor is not set,

the “summer heating” mode will operate only according

to the selected time and the temperature will not be taken

into account

Options:

None – Limit inactive

On/O – Only On/O and access to the information menu are

enabled in the main screen

On/O, Temp, Flow – On/O, the information menu, and temperature and air ow

settings can be accessed without password.

Full – Only the information menu can be accessed without password

User mode – Special user mode, see image below

End of winter period

(month number)

Start of winter

period (month number)

Enable/disable

function

Temperature limit – the

heating is disabled if the

temperature on the “Outdoor”

sensor is higher than the one

set here

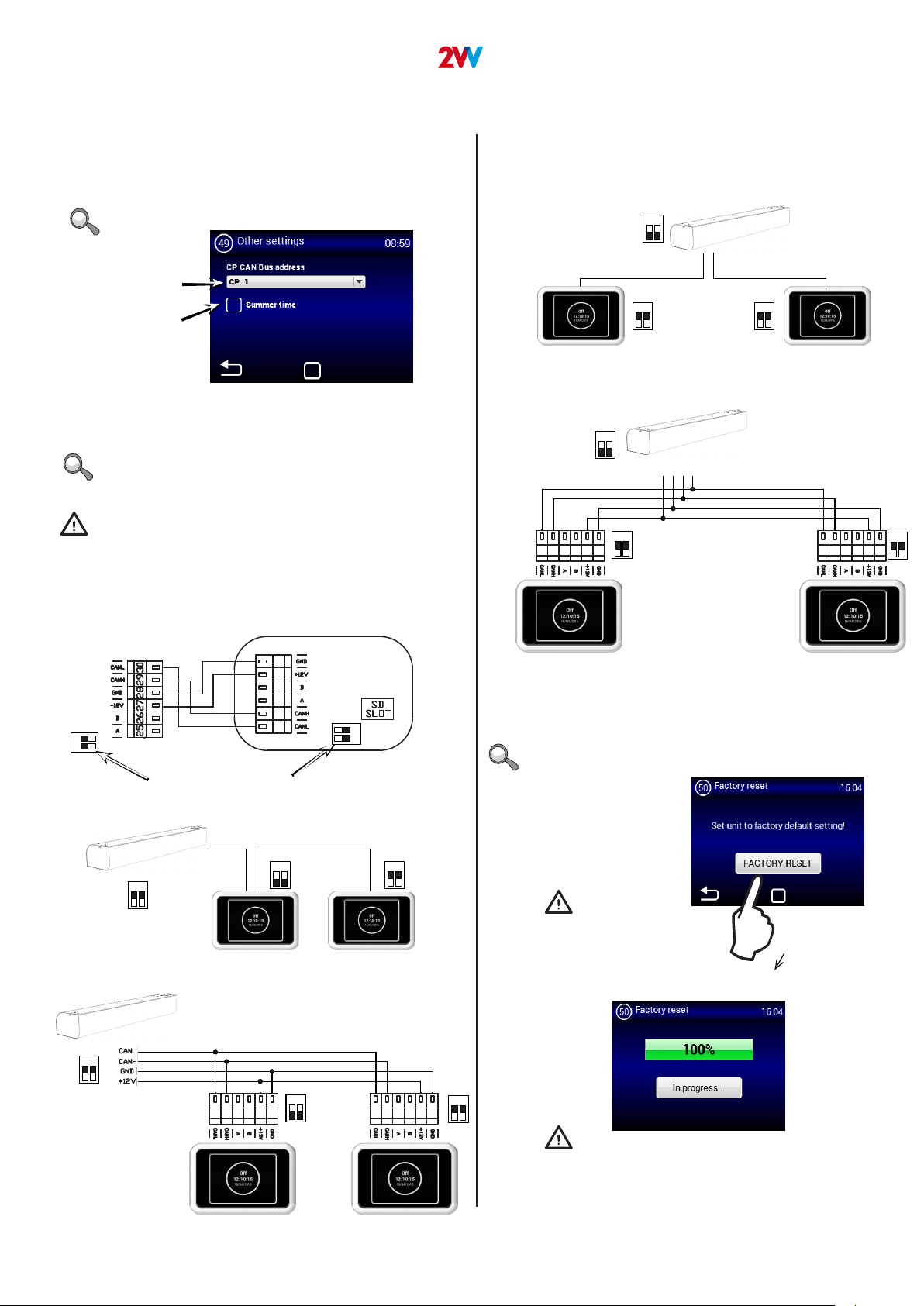

MENU - Night Reduction

This MENU allows for setting reduced temperatures dur-

ing night hours with closed doors.

In this menu, the reduction of temperature may be set

only by ve degrees at the set time compared to the

set (required) temperature.

Setting reduced

temperature range -1~-5°C

Setting start time

for reduced

temperature

Setting time for ending

reduced temperature.

Activating function