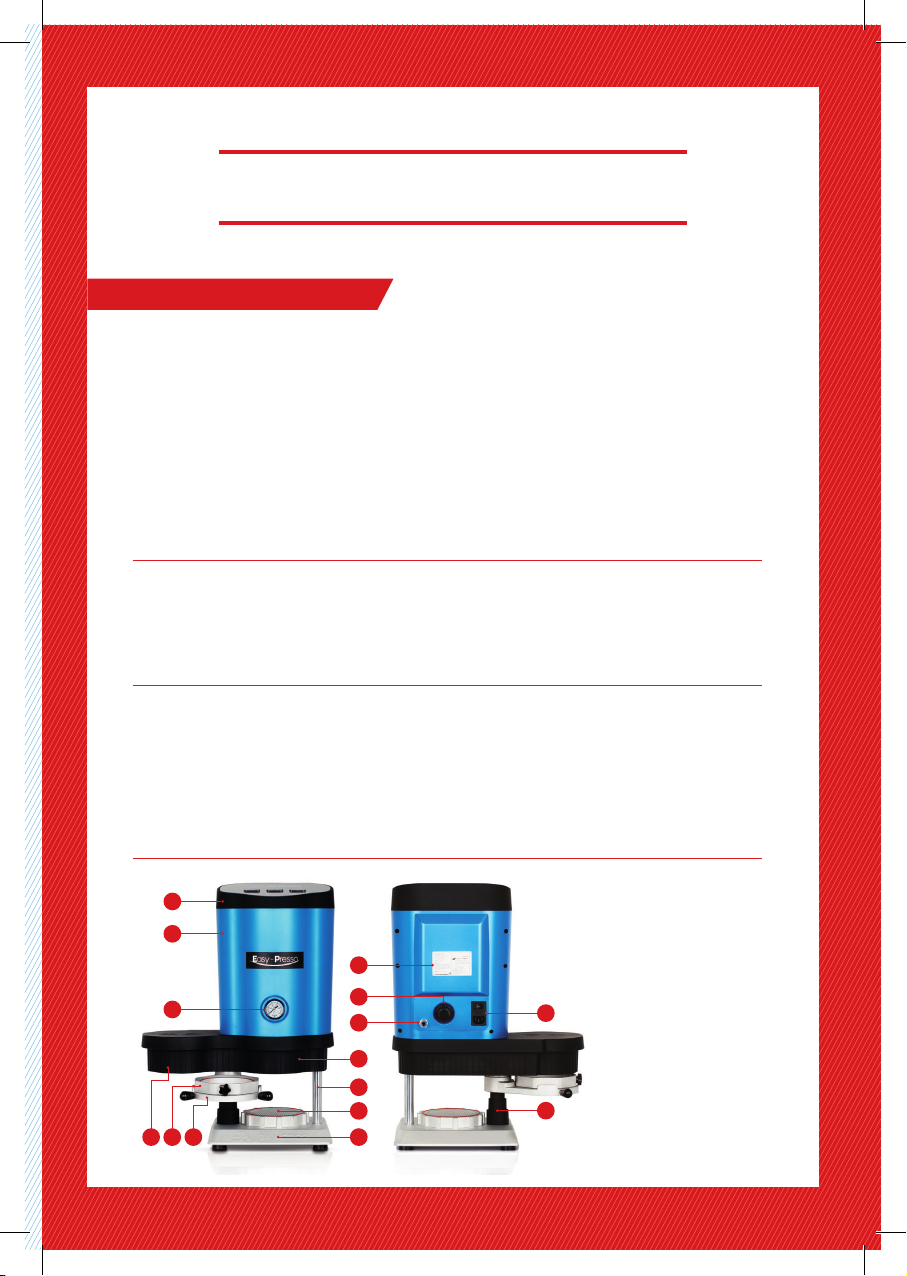

Front (Operating Switch)

•

Heater :

Sheet heating and softening

•

Cylinder :

Up & down operation and vacuum

•

Pressure

:

Pressure ejection and model moulding

Component

(구성품)

①

Product Name : EASY-PRESSO (Model: EP-100)

②

Power : AC 100~120V 50~60HZ, AC 220~240V 50~60HZ

③

Power Consumption : 450W

④

Pressure : 0.4~0.6

㎫

⑤

Dimension : 410x260x545

㎜

⑥

Weight : 15kg

Specication

04

A. Preparation before use

①

Connect the power cable to the main unit and the outlet.

②

Connect air tube(8

Ø

) to air connection of the main unit. (Check pressure gauge operation)

③

The factory setting is 0.5

㎫

. (If the pressure gauge does not work, check the air compressor in use.)

④

Rotate the lower sliding in the front direction and place the bead case on the bottom plate of the main unit.

B. How to use

①

Select the sheet that best suits your purpose. (Temporary, Splint, retainer, bleaching, and so on)

②

Place the model you want to make in the middle of the bead case.

③

Place a round ○or square □type sheet on the lower sliding to fit the guideline, and then put the upper sliding on.

④

Press the heater switch on the front top plate. (The lamp is turned on and the heater is in standby mode.)

⑤

Rotate the lower sliding to the left (90°). At this time, the heater automatically turns on.

⑥

Wait for the sheet to hit the model height or halfway. (Time range is between 50 to 90 seconds. The operating

time differs depending on the material and thickness.)

⑦

Rotate the lower sliding to the right (180°). (Model location in the center of the body)

⑧

Press the cylinder switch on the front top plate. (The lamp is turned on and the air case comes down and

presses the upper and lower sliding to create a vacuum standby state.)

⑨

Press the pressure switch on the front top plate. At this time, the air is injected into the air case and the sheet is

completely molded into the model. (The operating time is about 3 to 5 minutes depending on the material and

thickness.)

⑩

Turn off the front pressure switch and turn off the cylinder switch on the front top plate. (The sheet is fully seated

on the model and comes up.)

⑪

Rotate the lower sliding to the left(90°).

⑫

Remove the upper sliding and take out the molded model.

⑬

Turn off the heater switch on the front plate.

Operation

05