1. Precaution

1. Read this manual carefully before installing or using the device.

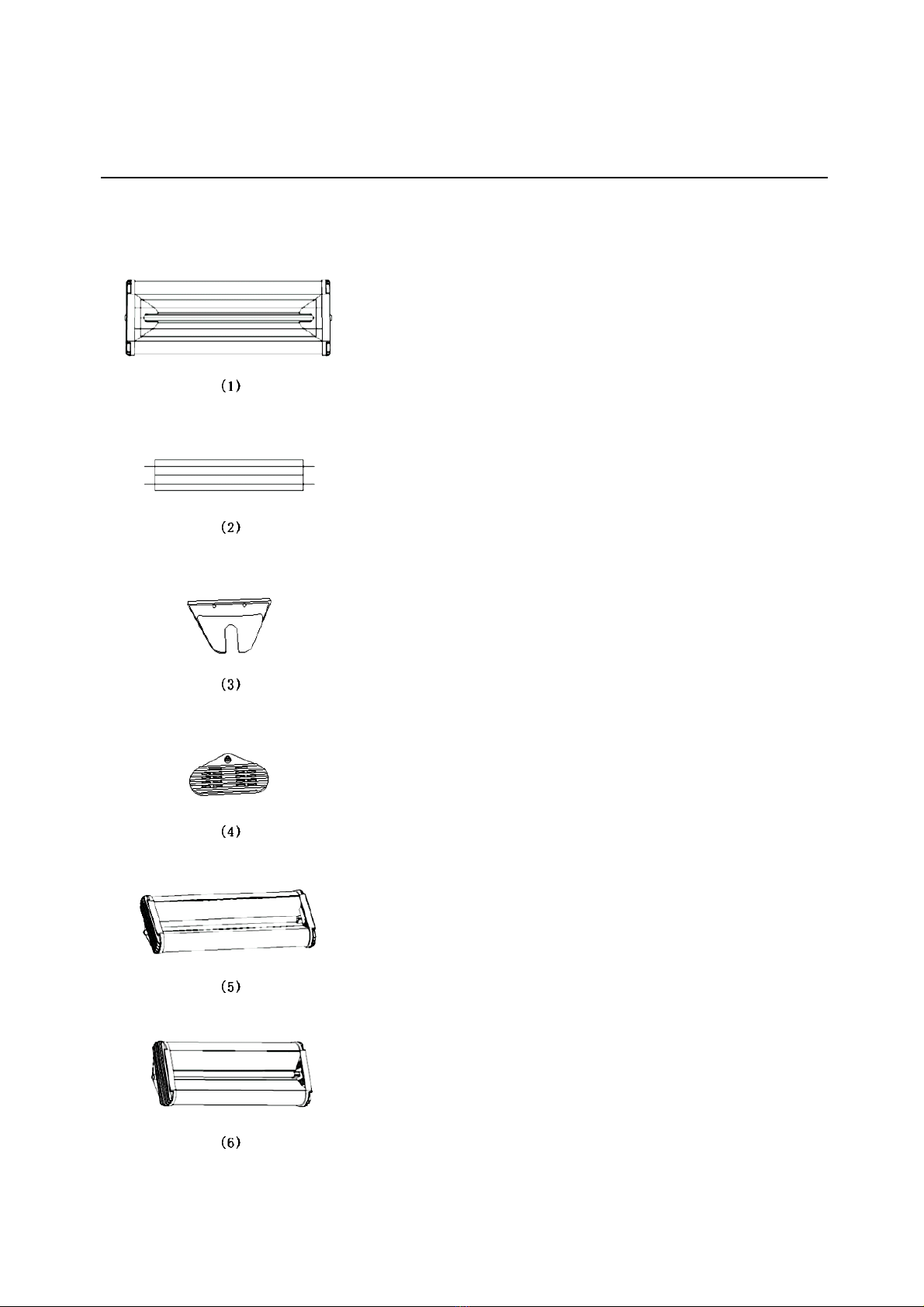

2.

Before first use, check / unscrew connections of the fluorescent tubes. If

the screw connection is too strong, the arc tube will break due to

temperature induced expansion.

3.

Attention! Device becomes hot, risk of injury and fire!

4.

This device is intended for paint drying applications. Set the correct

temperature and keep the minimum safe distance from the heat source during

operation. Improper use can lead to surface damage.

5. Installation and maintenance must be performed by a qualified installer

or service company.

6.

The system is designed for easy installation, low operating costs and

minimal maintenance. The warranty does not cover damage to the

fluorescent tube caused by incorrect handling or incorrect operation.

7.

The warranty does not cover damage caused by improper use.

8.

Disconnect the power source when the unit is not going to be used for a

long time.

9. The tubes should not be perpendicular to the ground when the device is

turned on. Otherwise, the life of the arc tube is shortened.

10.

Before use, make sure the cartridge connector is firmly connected.

1