A/DA Vertical User manual

Инструкция

по эксплуатации

Прибор вертикального проектирования ADA Vertical

А00364

Цены на товар на сайте:

http://www.vseinstrumenti.ru/instrument/izmeritelnyj/teodolity/ada/pribor_vertikalnogo_proektirovaniya_

ada_vertical_a00364/

Отзывы и обсуждения товара на сайте:

http://www.vseinstrumenti.ru/instrument/izmeritelnyj/teodolity/ada/pribor_vertikalnogo_proektirovaniya_

ada_vertical_a00364/#tab-Responses

Operating manual

Instrument of vertical projection

Model: ADA Vertical

Manufacturer Address .

VERTICAL

Table of contents

1. Description and application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.

3. Construction features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Preparation before operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5. Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6. Adjustment of the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8. Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

9. Exceptions from responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Appendix 1. Warranty card

Appendix 2.

MEASUREMENT FOUNDATION

VERTICAL

3

ADA VERTICAL presents the instrument of vertical projection with laser emitter, class 2. Do not look into the laser beam

and do not aim at other persons.

1. Description and application

1) Transmission of planned position with the help of optical method or laser beam;

2) Bright visible red laser beam (635nm);

3) Brightness adjustment of laser beam;

5) Laser target with reticular division;

6) Bubble levels with LED backlight;

Laser beam is combined with axis of sight of telescope. Such alignment is very convenient when measuring. Because

it’s possible to make optical and laser measurements simultaneously. With the help of telescope it’s possible to control

the position of laser spot and transmit planned position of the dot in vertical direction.

Instrument of vertical projection is widely used by professionals for control when building elevator well, setting supports

for high-tension lines, building bridges and tunnels, skyscrapers, water towers, chimneys and for other works where it’s

necessary to have constant control.

Complete set

- instrument of vertical projection 1

- operating manual 1

- target plate 1

- calibrating pin 1

- case 1

- batteries 2

VERTICAL

MEASUREMENT FOUNDATION

4

Limit deviation of the plumb up

Limit deviation of the plumb down

Accuracy of tubular level

Optics and laser plumb (zenith)

Image inverted

Angle of view 1° 50’

Effective aperture of lens 36 mm

0,8 m

Laser wavelength 635 nm

Range of laser viewing 70 m

Laser range in the daytime<200m ; at night<250m

Laser power 5mW

Diameter of laser spot

Error of misalignmen of optical and

vertical axis is less than

5”

Error of misalignmen of optical and

laser axis is less than

5”

MEASUREMENT FOUNDATION

5

VERTICAL

Laser plumb (down point)

Source Laser diod

Laser wavelength 650 nm

Laser power 1mW

Effective laser range 2 m

Diameter of laser spot

Focusing range Not adjustable

Power supply

Operating temperature

Continuous usage 8 h

Dimensions

Weight 2,8 kg

VERTICAL

MEASUREMENT FOUNDATION

6

1

2

3

4

5

6

7

8

9

10

11

12

13

1) lens;

2) focusing screw;

3) battery compartment cover;

adjustment;

5) screw to switch on and brightness

adjustment of laser plumb down;

6) eyepiece;

7) circular bubble level;

8) foot screws of the tribrach;

9) graduated limb;

10) focusing screw of the plumb down;

11) handle for transportation;

12) adjusting screw of tubular level;

13) tubular level

3. Construction features

MEASUREMENT FOUNDATION

7

VERTICAL

4. Preparation before operation

Insert the batteries

Remove battery compartment cover (3) and insert 2 batteries type AA observing the polarity.

Mounting the instrument on the tripod

Place the tripod on the construction site. Place the instrument on the tripod and tighten the central screw

properly. Adjust the height of the tripod for convenient operation with instrument. Adjust legs of the tripod,

so that the bubble of circular level (7) is exactly in the center of the level.

Leveling of the instrument

Coarse leveling with circle bubble:

1) Turn the foot screws A and B to enable the bubble of circular level (7) to position itself on the line that is

parallel to the line that goes through the foot screws A and B (pic.2).

2) Turn the foot screw C to enable bubble to position itself in the center of circular level (7) (pic.3).

Note: Circular bubble level is only used for leveling the instrument when mounting on the tripod. Leveling before measurements

is made with tubular level.

Pic.1

Pic.2 Pic.3

A

B

C

A

B

C

VERTICAL

MEASUREMENT FOUNDATION

8

Fine adjustment with tubular level:

1) Turn the instrument in order to make the tubular level (13) parallel to the

2) Turn the foot screws A and B to make the bubble move into the middle

of tubular level (13);

3) Turn the instrument so that the tubular level (13) will be perpendicular

the line that goes through the foot screws A and B. Turn the foot screw C to

make the bubble move into the middle of tubular level (pic.5);

that the bubble will be in the center of tubular level.

Switch-on

1) Turn laser screw (5) to turn on laser dot of the marker of plumb down. Bright laser spot is projected on the target. Continue to

turn screw (5) to adjust the brightness of the laser spot;

2) Loosen central screw of the tripod. Move the instrument carefully on the tripod until the laser dot is on the reference point;

Preparation before vertical measurements

focusing screw (2) to get accurate image of laser dot and marking on the laser target. If you need to increase the accuracy you

can use the method of the measurement of diameter:

1) Turn the graduated limb so that zero on the scale coincide with hairline on the housing of the instrument;

2) Mark up the position of laser dot;

3) Turn the instrument by 180° and mark up new position of laser dot;

Middle point between these two points is the reference point.

Pic.4 Pic.5

MEASUREMENT FOUNDATION

9

VERTICAL

5. Measurements

Vertical measurements

1) Watch laser target and laser marker in the eyepiece of the instrument. If necessary, adjust sharpness of manual focusing;

2) Laser target can be moved vertically for transmission of reference point on desired height;

3) As a result you will get reference point. Line that connects these two points will be vertical.

Vertical measurements in wells

Such measurements can be used in mine survey and engineering surveying.

E.g. transfer of line (of given direction). As it is shown in the picture 6, lines A and B are known refer-

ence mark. Part of this line goes under well. There are two additional dots C and D on this line.

Transmission is made following way:

1) Place the instrument in the bottom of the well. Be sure, laser plumb (zenith) must coincide

with dot C;

2) Laser plumb down marks dot E, which will be the projection of dot C;

3) Do the same transmission of the dot D. Dot F is the projection of dot D;

6. Adjustment of the instrument

Adjustment of the tubular level

Axis of the level must be perpendicular to the rotation axis of the theodolite. Turn the alidade of the instrument, so that the axis

of tubular level will be parallel to the imaginary line, that connects centers of any 2 foot screws of the tribrach. Rotate these 2

screws in opposite directions, so that the bubble will be in the center of level. Rotate alidade of the instrument by 90° and with

the help of third screw place the bubble in the center.

Rotate alidade of the instrument by 90° once more. If necessary, place the bubble in the center of the level. Rotate alidade

Pic.6

A

C

D

B

EF

VERTICAL

MEASUREMENT FOUNDATION

10

of the instrument by 180°. It’s necessary to make further adjustment, if the offset of the bubble is more than 1 graduation. Half

of the value of bubble deviation is necessary to improve with the help of foot screws. Another half – with the help of adjustment

screw of tubular level.

Adjustment of circle level

After adjustment of tubular level, it’s necessary to adjust circular level. If the bubble deviate from the center, adjust its position with

the help of three adjusting screws, which are located under the level (pic.7).

Adjusting

screws of the

circle level

Pic.7

Pic.8

Adjusting

screws of the

reticule

Adjustment of collimation error

Rotate the alidade by 180°, observing the center of croosshair of the target in

the lens. If you see the offset of the crosshair of reticule relatively the crosshair

of the target, it’s necessary to make adjustment:

1) Place the instrument on the tripod or special stand;

3) Turn the alidade of the instrument by 180°, observing the offset of reticule;

the picture 8. Remove the offset by half;

5) Turn the alidade of the instrument by 180°. Repeat the adjustment by remov-

ing the offset completely.

Adjustment of the offset of laser beam

Collimation error between optical and laser axis occurs, If laser spot and the

center of reticule don’t coincide.

For adjustment :

1) Place the instrument on the tripod or special stand;

MEASUREMENT FOUNDATION

11

VERTICAL

3) Rotate the adjusting screw, as shown in the picture 9 with the help of pin.

Laser spot must coincide with the center of reticule.

Adjustment of the focus of laser beam

Otherwise adjust the size of the laser spot up to the minimum size with the help of adjusting screws, as shown in the picture 10.

7. Maintenance

1) Use handle for transportation (11) to take the instrument from the box. Never touch the lens to take it from the case;

2) Rotation of the alidade must be easy;

3) Avoid direct sunlight during operation;

dirt from the surface of the instrument and place it into the clean dry case;

5) Keep the instrument clean;

6) Put the instrument into the case to avoid damages during transportation; Keep case in the dry clean place;

7) Insert out the batteries if you are not going to use instrument for a long time;

8) Don’t leave the instrument without usage for a long time on the construction site. Vibration, dust, humidity can have negative

Pic.9

Adjusting

screw of

collimation

error

Adjusting

screws of

laser spot

Pic.10

VERTICAL

MEASUREMENT FOUNDATION

12

Warranty

This product is warranted by the manufacturer to the original purchaser to be free from defects in material and workman-

ship under normal use for a period of two (2) years from the date of purchase.

During the warranty period, and upon proof of purchase, the product will be repaired or replaced (with the same or similar

model at manufactures option), without charge for either parts of labour.

In case of a defect please contact the dealer where you originally purchased this product. The warranty will not apply to

this product if it has been misused, abused or altered. Without limiting the foregoing, leakage of the battery, bending or

dropping the unit are presumed to be defects resulting from misuse or abuse.

Exceptions from responsibility

The user of this product is expected to follow the instructions given in operators’ manual.

Although all instruments left our warehouse in perfect condition and adjustment the user is expected to carry out periodic

checks of the product’s accuracy and general performance.

The manufacturer, or its representatives, assumes no responsibility of results of a faulty or intentional usage or misuse

-

tions.

data, loss of data and interruption of business etc., caused by using the product or an unusable product.

other thsn explained in the users’ manual.

The manufacturer, or its representatives, assumes no responsibility for damage caused by wrong movement or action due

to connecting with other products.

WARRANTY DOESN’T EXTEND TO FOLLOWING CASES:

1. If the standard or serial product number will be changed, erased, removed or wil be unreadable.

2. Periodic maintenance, repair or changing parts as a result of their normal runout.

mentioned in the service instruction, without tentative written agreement of the expert provider.

5. Damage to products or parts caused by misuse, including, without limitation, misapplication or nrgligence of the terms of

service instruction.

6. Power supply units, chargers, accessories, wearing parts.

7. Products, damaged from mishandling, faulty adjustment, maintenance with low-quality and non-standard materials, pres-

ence of any liquids and foreign objects inside the product.

9. In case of unwarranted repair till the end of warranty period because of damages during the operation of the product, it’s

transportation and storing, warranty doesn’t resume.

For more information you can visit our website WWW.ADAINSTRUMENTS.COM

WARRANTY CARD

Name and model of the product ________________________________________________

Serial number ________________date of sale_______________________

Name of commercial organization _____________________stamp of commercial organization

During this warranty period the owner of the product has the right for free repair of his instrument in case of manufacturing defects.

occur in the result of the instrument outage.

The product is received in the state of operability, without any visible damages, in full completeness. It is tested in my presence. I have no

complaints to the product quality. I am familiar with the conditions of qarranty service and i agree.

purchaser signature _______________________________

Before operating you should read service instruction!

If you have any questions about the warranty service and technical support contact seller of this product

__________________________________________________________________________

__________________________________________________________________________

name and model of the instrument

Corresponds to ______________________________________________________________

designation of standard and technical requirements

Data of issue _______________________________________________________________

Stamp of quality control department

Price

Sold ___________________________________ Date of sale ______________________

name of commercial establishment

ADA

MEASUREMENT FOUNDATION

WWW.ADAINSTRUMENTS.COM

ADA Vertical

VERTICAL

MEASUREMENT FOUNDATION

18

1.

2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.

8.

9.

MEASUREMENT FOUNDATION

19

VERTICAL

Table of contents

Languages:

Other A/DA Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

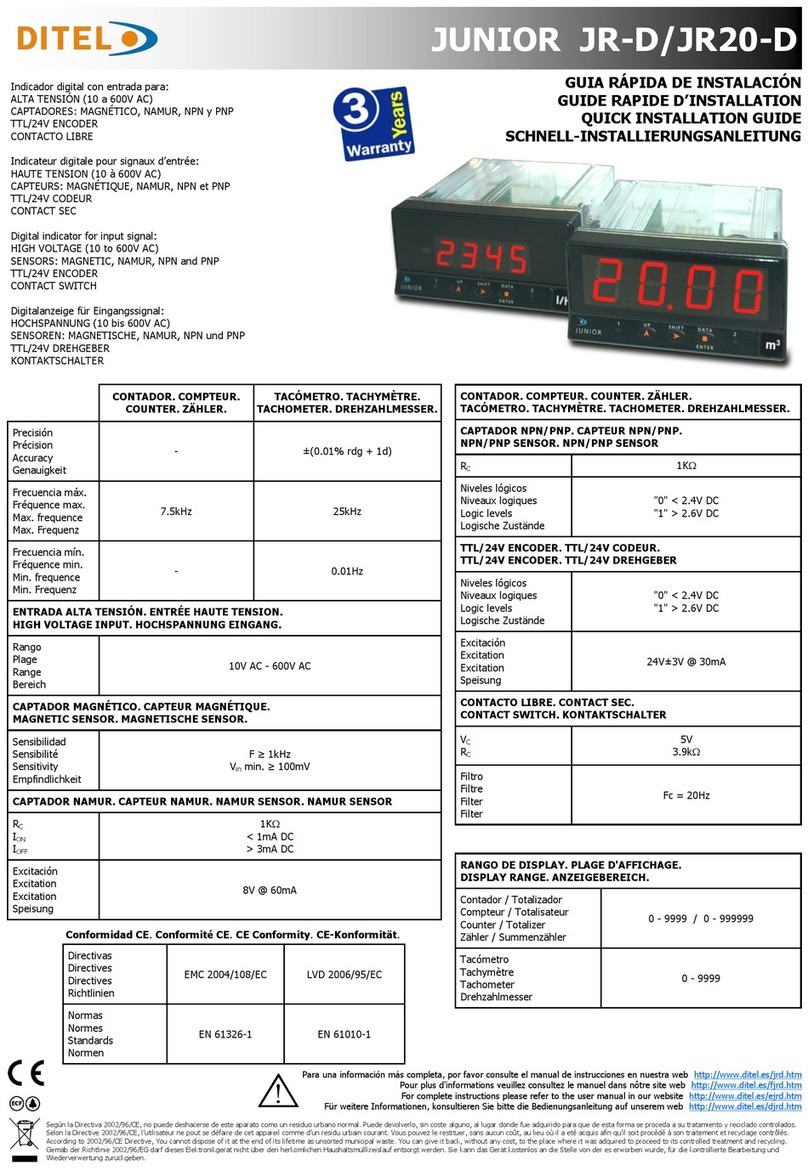

Ditel

Ditel JUNIOR JR-D Quick installation guide

ASAIR

ASAIR AF5485 user manual

Precision Digital Corporation

Precision Digital Corporation Survivor PD662 instruction manual

RKI Instruments

RKI Instruments CO-04 Operator's manual

JDS Uniphase

JDS Uniphase BACKREFLECTION METER RM3750 user manual

Fluke

Fluke 1630-2 user manual