Dillon ED-2000plus User manual

ED-2000plus Electronic Dynamometer

with HR-2000 Remote

User’s Manual

2

03/17/04 ED2000_U.P65 PN 29641-0012F e3 Printed in USA

Risk of electrical shock. Do not remove cover. No user service-

able parts inside. Refer servicing to qualified service personnel.

Weigh-Tronix reserves the right to change

specifications at any time.

CAUTION

EUROPEAN COUNTRIES

WARNING

This is a Class A product. In a domestic environment this product may cause radio

interference in which the user may be required to take adequate measures.

3

Table of Contents

Table of Contents ............................................................................................ 3

Specifications ................................................................................................. 4

ED-2000plus Introduction ................................................................................ 5

Normal Operation Mode ....................................................................... 6

RS-232 Operation ................................................................................ 7

Device Information Mode ...................................................................... 8

Configuration Mode .............................................................................. 9

Disabling the Radio-Link Software to Save Battery Power ........ 10

Sleep Mode .............................................................................. 10

Battery Replacement .......................................................................... 11

HR-2000 Introduction and Operation .............................................................. 12

Introduction ......................................................................................... 12

Addresses .......................................................................................... 12

Operation ........................................................................................... 13

Powering Up ....................................................................................... 13

For Radio Communication ........................................................ 13

Radio Operation with RS-232 ............................................................. 14

For Wireline Communication ..................................................... 15

Addressing Mode ............................................................................... 15

Appendix - Weighing and Force Measurement Practice ................................ 18

Load Centering ................................................................................... 18

Good Pin Fit ....................................................................................... 18

Torque and Bending ........................................................................... 18

Certified Gear ..................................................................................... 18

Safety ................................................................................................. 18

Good Force Measurement Practice .................................................... 19

—This manual is for reference only.—

Pages are numbered consecutively beginning with the cover page.

4

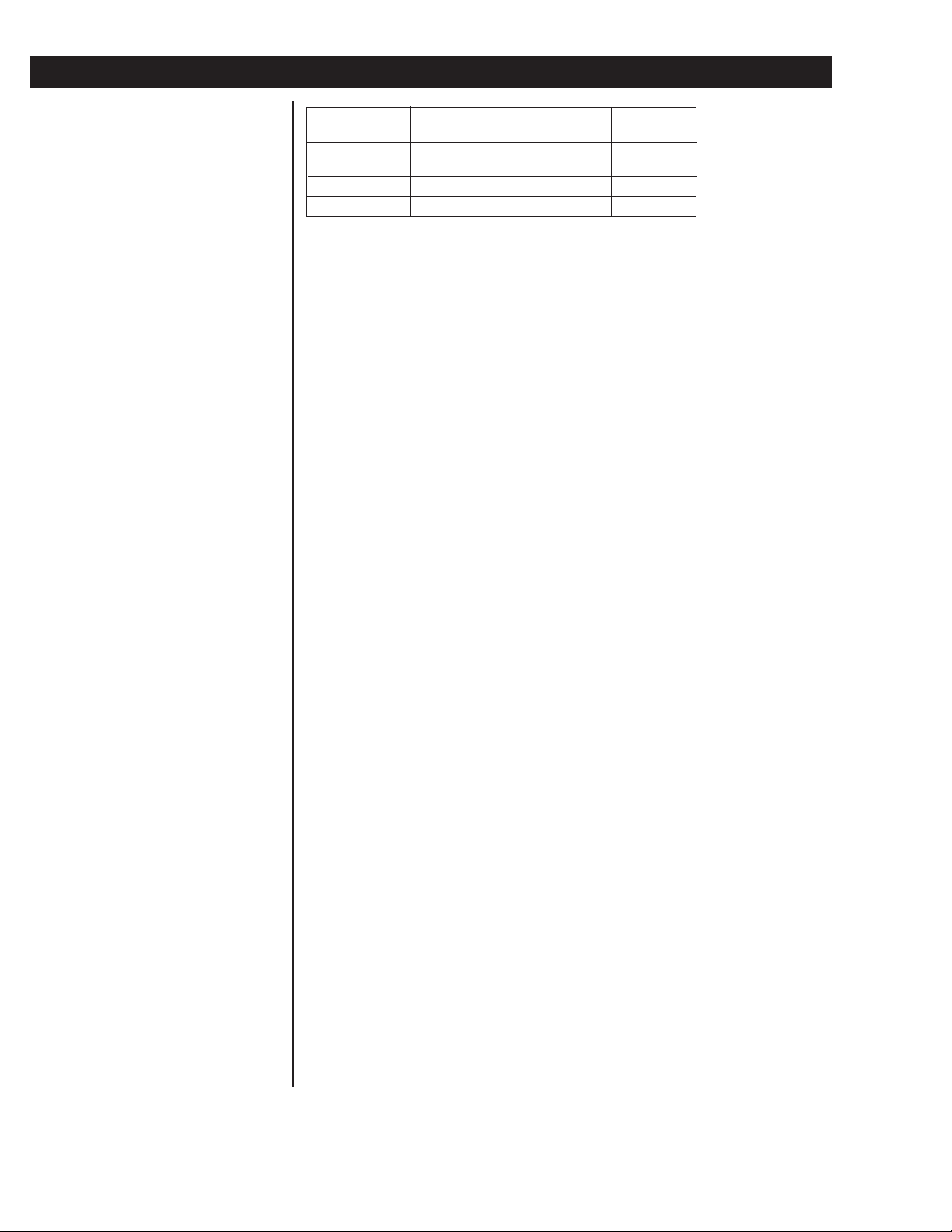

2,000 x 0.5 lb 1,000 x 0.2 kg 10 x 0.002 kN 1 x 0.0002 T

5,000 x 1 lb 2,000 x 0.5 kg 20 x 0.005 kN 2 x 0.0005 T

10,000 x 2 lb 5,000 x 1 kg 50 x 0.01 kN 5 x 0.001 T

20,000 x 5 lb 10,000 x 2 kg 100 x 0.02 kN 10 x 0.002 T

50,000 x 10 lb 20,000 x 5 kg 200 x 0.05 kN 20 x 0.005 T

100,000 x 20 lb 50,000 x 10 kg 500 x 0.1 kN 50 x 0.01 T

Aluminum alloy (2-, 5-, and 10,000 lb)

Stainless steel (20-, 50-, and 100,000 lb)

NEMA 4X / IP66 (sealed against dust, hosedown, and corrosive agents)

Selectable pounds, kilograms, kiloNewtons, metric tons. The selected unit of

measure is saved when the power is switched off.

0.1% of rated capacity

0.1% of rated capacity

2 times per second

Normal mode: 8 times per second

Peak hold: 60 times per second

5:1

6 LCD digits, 0.9" (22.5 mm) height

RS-232 output from dynamometer or Radio-Link remote display unit.

LB, KG, KN, TONN, PH (peak hold), BAT (low battery)

On/Off, Test, Clear/Zero, Peak hold, Function key, Units

Standard 9V battery, alkaline or lithium. The ED-2000plus has approximately

200 hours of use with the 9V alkaline battery. Battery life can be extended

with the use of a 9V lithium battery. These values represent “average” use;

mode of operation, typical period of use, battery recovery, and other variables

determine the ultimate battery life. With the optional radio link installed, the

9V battery life is approximately 36-48 hours.

-4° to 140°F (-20° to 60°C)

Traceable to the National Institute of Standards and Technology (NIST).

Calibration Certificate with each unit.

Open air range: Up to 300 feet

Update rate: 2 times per second

RF signal output: 0 dBm in 50 at 25 C in accordance to FCC Part 15.249,

and in Canada under TRS RSS-210.

Frequency: 916.5 MHz

ED-2000plus Specifications

Capacities:

Construction:

Enclosure:

Units of measure:

Accuracy:

Repeatability:

Display update rate:

Internal update rate:

Ultimate safety factor:

Display:

Outputs:

Annunciators:

Control keys:

Power:

Operating temp:

Calibration:

Optional Radio link:

5

ED-2000plus Introduction

The ED-2000plus dynamometer is an electronic portable force or weight

measurement instrument.

The ED-2000plus is available with low-power radio communications. This

option permits wireless communication between the ED-2000plus and an

HR-2000 handheld remote display. The ED-2000plus system offers additional

flexibility by the ability to have several (up to 255) devices controlled by a

single HR-2000 display. This is called a multidrop system.

Data can be extracted from either the ED-2000plus or the HR-2000. This data

can be sent to a computer by pressing the DATA SEND key or requested by

the computer by sending an ENQUIRE code.

This guide describes the operation of the ED-2000plus series of Dillon elec-

tronic dynamometers and the procedures for configuring the device to your

specific needs.

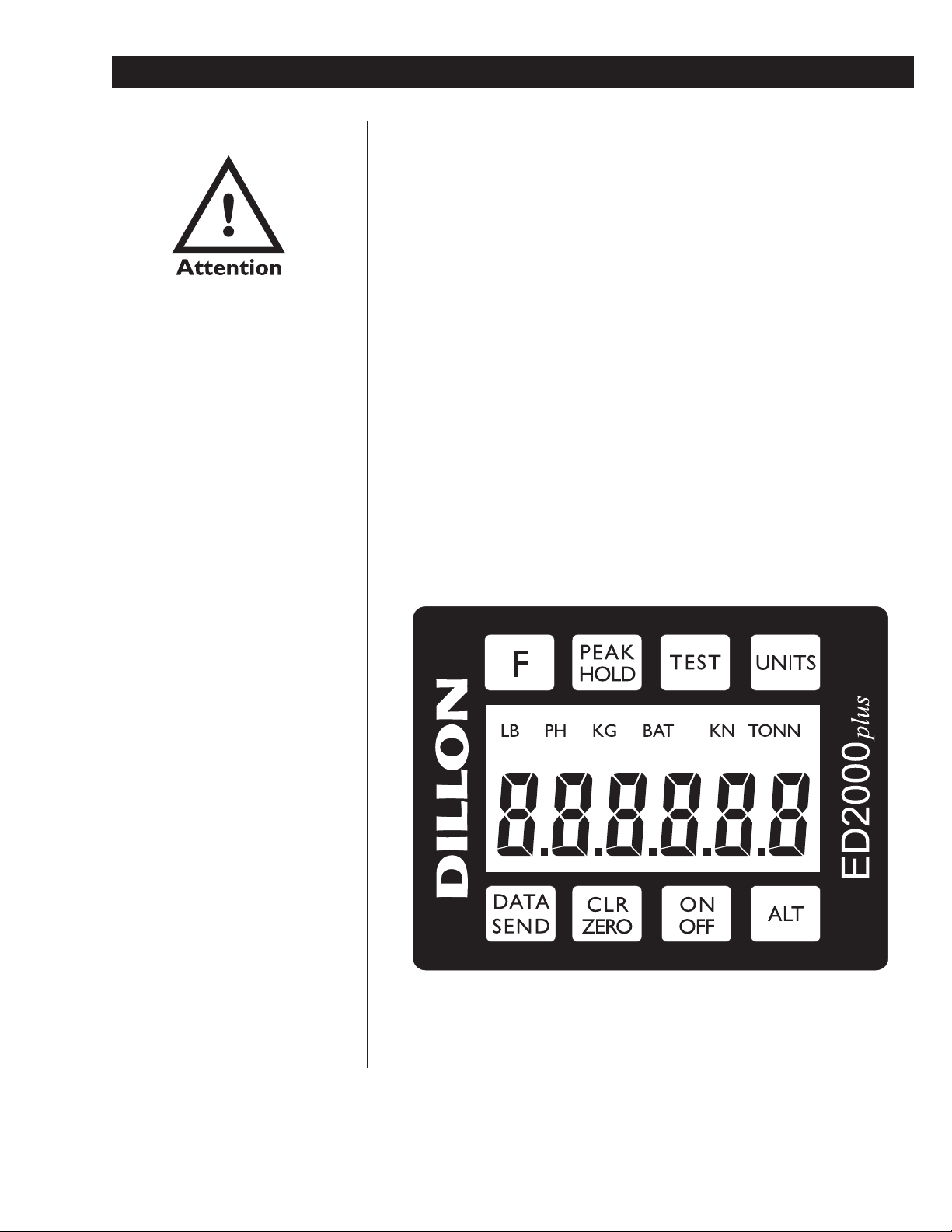

The display consists of six 7-segment digits and six annunciators which

appear when appropriate. See Figure 1 below.

There are three modes of operation:

• Normal operating mode, which covers the daily use of the device.

• Device information mode, allows information about the device to be

viewed but not edited. Information that can be viewed includes serial

number, range, date of last calibration, etc.

• Configuration mode, which enables the user to configure the device.

Figure 1

Electronic Dynamometer Front Panel

The ED-2000plus is not suit-

able for use in magnetic

environments.

6

Shows the current gross value with the

appropriate annunciator visible (LB, KG,

KN or TONN). With Version 3.0 software

the display will show OFF 3A when turning

the unit off.

Reads net force value. Can be positive or

negative. Can tare up to 100% of capacity.

No change in the display.

Shows the gross force value.

The units legends will change in the

sequenceLB->KG->KN->TONN->LB etc.,

and the display will update accordingly.

Activates the "PH" annunciator if in peak

hold mode. The annunciators will flash and

the top segment of the left most digit will

illuminate to indicate maximum is being

displayed.

The top segment of the left most digit

illuminates if maximum reading is being

displayed. The bottom segment illumi-

nates if the minimum reading is being

displayed.

A value is displayed that is within ±0.1% of

capacity in the currently selected measur-

ing units. If displayed value is greater than

±0.1%, recalibrate the unit. Depending on

the filter value currently selected (see

Configuration Mode), the display may take

some time to settle to a stable reading.

Hold for ½ second to turn unit on. On start-up

the device is initialized and starts measuring with

previous units selected. ON/OFF key is disabled

in peak hold, device information and configuration

modes.

Tare the device and show net reading.

Send displayed information via RS-232

Not used with the ED-2000plus

Reverts to gross reading.

Scrolls through the four possible units of mea-

sure and converts the reading to the selected

unit. Selected unit of measure is saved when

power is switched off.

Toggles the device between normal and peak

hold mode. In peak hold mode it will update the

reading at 60 times per second.

If the device is in peak hold mode, toggles

between minimum and maximum readings.

Performs an internal shunt test of the measuring

bridges. (You must hold the key down until the

display stabilizes.)

Switches device from normal operating mode to

device information mode.

Switches device from operating mode to configu-

ration mode.

Puts device in RS-232 mode. This function also

conserves battery life. If you are not using the

radio function, we recommend placing the device

in RS-232 mode.

ON/OFF

CLR/ZERO

SEND DATA

ALT

F+CLR/ZERO

UNITS

F+PEAK

HOLD

PEAK HOLD

TEST

F+UNITS

F+TEST

F+ON

(from power

off)

Normal Operation

Mode

Key Function Display

Table 1

Key Functions in Normal Operation Mode

During normal operation mode most of the basic functions are available by

pressing one key. Some of the functions require that the F-key is pushed

simultaneously. This is indicated by F+[key]. Table 1 explains the key

functions.

7

RS-232 Operation You can operate the ED-2000plus with a computer or other data logging

device via RS-232. To place the ED-2000plus in RS-232 mode, use one hand

to press and hold the F key and use the other hand to press the ON key.

This operation is transparent to the user. It is important that the ED-2000plus

and the external device are set at a baud rate of 2400 for RS-232 communica-

tion.

When you press the DATA SEND key in RS-232 mode, or send an enquire

code from the external device to the ED-2000plus, the following information is

sent to the external device:

xxxxx.x uu CR/LF

x= force value

u= unit of measure (LB, KG, KN or T)

CR/LF = carriage return and line feed

The enquire code is a single question mark (?). When the ED-2000plus

receives this code from the external device, the above information is sent.

If your RS-232 port is receiving garbled data, check to be sure you are in

RS-232 mode or that an HR-2000 is not trying to communicate with the

ED-2000plus by radio.

The force value received is right

justified with any leading zeroes

replaced by spaces. Negative

values will show a minus sign

before the first digit. The

decimal point will not be printed

if it follows the significant

digits.

8

To acitvate the device information mode from normal operating mode use one

hand to press and hold the F key and use the other hand to press the UNITS

key. Return to normal operations by using one hand to press and hold the F

key and use the other hand to press the CLR/ZERO key.

Upon entering device information mode, the selected unit annunciator will

flash (indicating that the device is out of the normal operating mode) and the

display will show the device serial number. Use the keys described in Table 2

to view the information fields described in Table 3.

Device Information

Mode

The "label" for the field is shown briefly

when the key is kept depressed. The

actual information value is then shown.

Same as for PEAK HOLD

Same as for PEAK HOLD

Scroll down the list of information fields, i.e. the

next field in the list.

Scroll up the list of information fields, i.e. the

previous field in the list

Show the label of the current information field.

Return to normal operating mode.

PEAK HOLD

TEST

UNITS

F+CLR/ZERO

Key Function Display

Table 2

Key Function in Device Information Mode

The device serial number (6 digits).

Load element number.

The software release number.

Device range in 1,000s of pounds.

Year, Month and Day of last calibration.

Reference to calibration document number (6 digits).

Total number of calibrations performed.

Number of times the device has been overloaded beyond 125% of full

capacity.

The communication address assigned to the device in multidrop

applications.

SErno

Eltno

SoFt

rAnGE

C-dAt

C-rEF

C-cnt

OLOAd

Addr

Label Typical Display Description

512056

201360

2.60

201Lb

96.08.02

100123

3

0

100

Table 3

Device Information Fields

Table 3 contains the information fields and typical values you can view in the

device information mode. The fields appear in the sequence shown. Scrolling

past the last item in the list will return the display to the first item in the list.

9

To activate the configuration mode from normal operation, use one hand to

press and hold the F key and use the other hand to press the TEST key.

Return to normal operations by using one hand to press and hold the F key

and use the other hand to press the CLR/ZERO key.

Upon entering configuration mode, the selected unit annunciator will flash

(indicating that the device is out of the normal operating mode) and the

display will show the current value for setpoint 1.

The configuration values may be changed and permanently stored in nonvola-

tile memory within the device. Consequently, use these functions with care.

Note that the values will be changed immediately in the EEPROM, but some

changes will only take effect when the unit is switched off and then back on.

These values are noted with an asterisk in the "Label" column of Table 5

Table 4 shows the keys you use to set configuration to your needs. Table 5

contains the configuration items you can view and change.

Table 5 contains the information fields and typical values you can view in the

configuration mode. The fields appear in the sequence shown. Scrolling past

the last item in the list will return the display to the first item in the list.

Configuration Mode

Key Function Display

The "label" for the field is shown briefly

when the key is kept depressed. The

actual information value is then shown.

Same as for PEAK HOLD.

Same as for PEAK HOLD.

Dependent upon function selected.

Dependent upon function selected.

Scroll down in list of information fields, i.e. the

next field in the list.

Scroll up in list of information fields, i.e. the

previous field in the list.

Show the label of the current information field.

Increment the value shown with wraparound.

Decrement the value shown with wraparound.

Return to basic function mode.

PEAK HOLD

TEST

UNITS

F+PEAKHOLD

F+TEST

F+CLR/ZERO

Table 4

Key Functions in Configuration Mode

10

Typically not used.

Typically not used.

Filter values (damping factors) on the load cell signal. Acceptable

values are from 0 (no damping) to 7 (maximum damping).

Changes the serial communication link between RS-485 and radio

link. Press F + TEST key to toggle between the two choices. Select

RS-232 communication by depressing F+ON/OFF at power up and

RS-485 and radio will be bypassed.

The communication address assigned to the device in multidrop

applications. Values should be between 33 and 255.

Communication baud rate. Available values are 300, 1200, 2400,

4800, 9600, and 19,200 baud. System default is 2400 baud. Radio

communication at 2400 baud by default.

SEt-1**

SEt-2**

FiLt

SErch*

Addr*

bAud*

Label Typical Display Description

100

110

2

rS-485

rAdio

100

2400

*Change takes effect only after the unit has been switched off and then back on.

** Used only in special software applications

Table 5

Configuration Items

Sleep mode is a non-configurable battery saving feature of the ED-2000plus. It

functions all the time. If signal changes from the strain gages are not received

by the microprocessor, certain high drain functions are shut down. The

display does not change and any communication with the unit or signal from

the gages reactivates the unit instantly. The function of the sleep mode is

transparent to the user.

The ED-2000plus software allows you to use the Radio-Link option. If the

Radio-Link option is installed but not being used, disable the radio portion of

the software to increase battery life. Also, if your system is not equipped with

the Radio-Link option, disable the software.

To disable the Radio-Link software see the SErch section in Table 5 below.

Notice that the change will not take effect until the ED-2000plus has been

switched off and then back on.

Disabling the Radio-Link

Software to Save Battery

Power

Sleep Mode

11

When the low battery annunciator appears, you have approximately five hours

of usage left. To change the nine-volt battery in the ED-2000plus, follow these

steps:

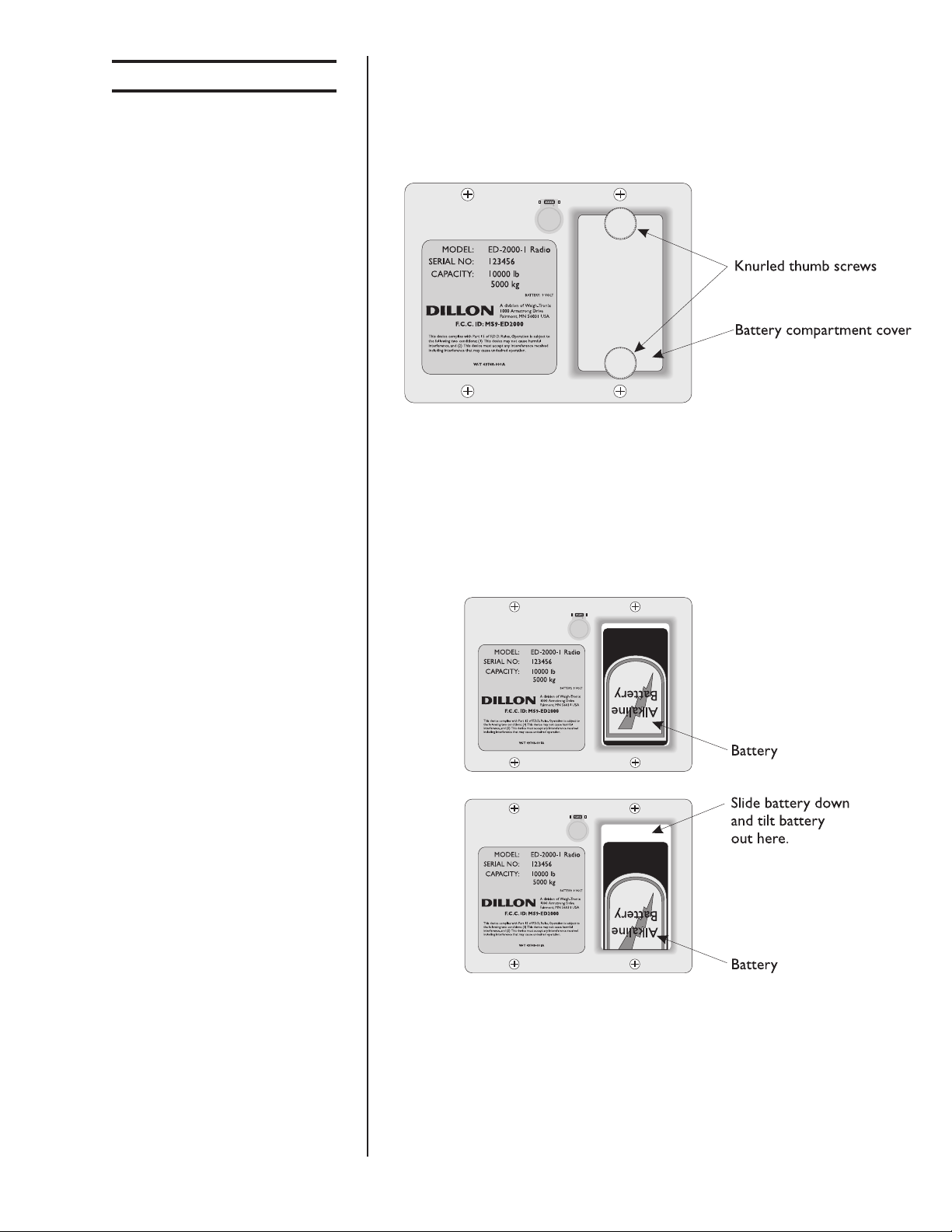

1. Remove the two knurled thumb screws from the battery compartment

cover. (Be careful not to lose these screws.) See Figure 6.

Figure 6

Battery compartment cover

2. Remove the battery compartment cover.

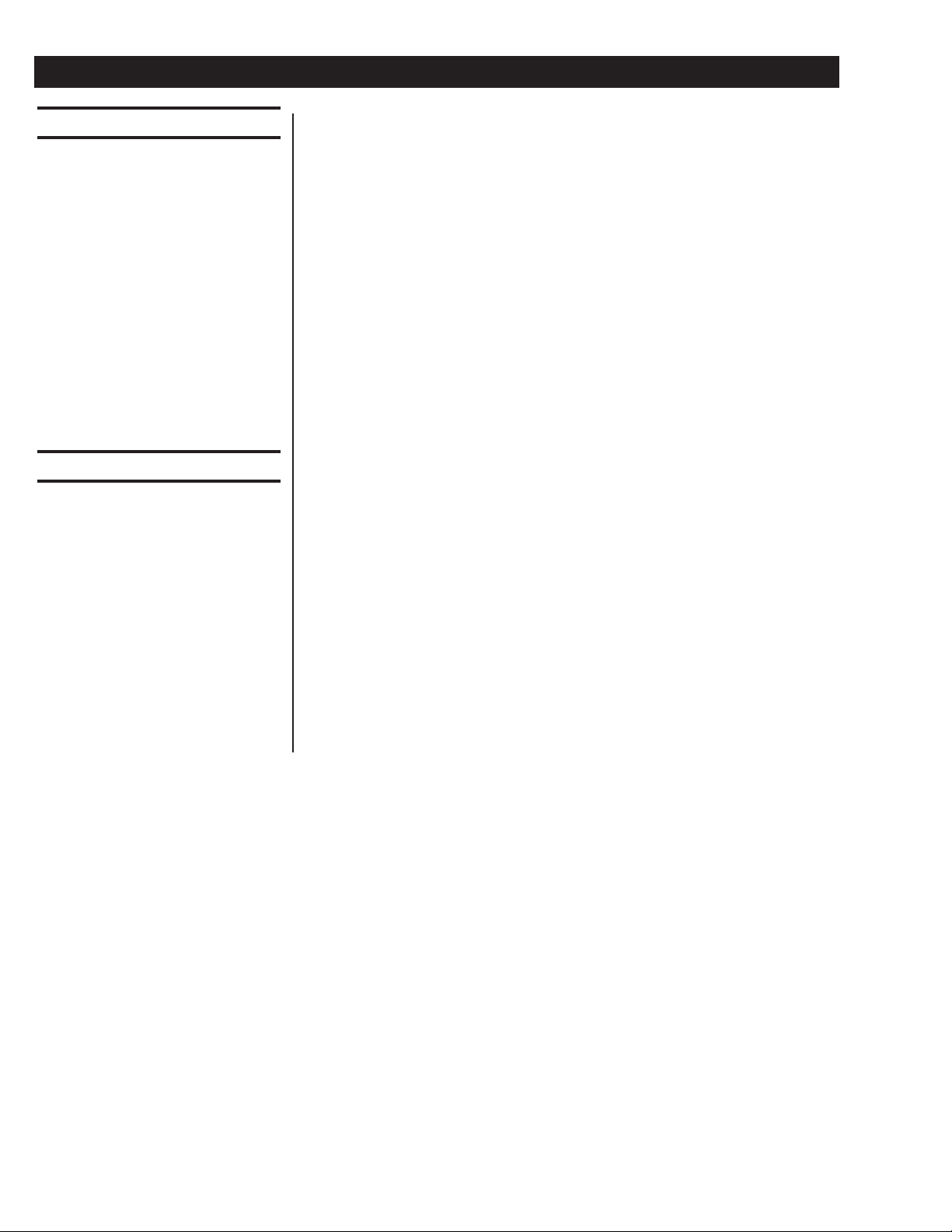

3. Slide the battery down and pry the free end of the battery out of the

compartment opening. See Figure 7.

Figure 7

Battery removal

4. Pull the battery out of the compartment and disconnect the battery from

the battery lead.

5. Connect new battery to the lead and reverse the disassembly procedure.

ED-2000plus connected to

an HR-2000 by wire

receives power from the

HR-2000. A battery is not

recommended in the

ED-2000plus in this

situation.

Battery Replacement

The HR-2000 does not contain

a low battery detector. It merely

displays the low battery warning

from the loadcell. Because of

this, change batteries in both

the ED-2000plus and HR-2000

when the battery warning lights

up. (Radio-Link systems only)

12

HR-2000 Introduction and Operation

To reduce battery drain when

not using the Radio-Link option,

with the HR-2000 unit on, press

both the PEAK/HOLD and the

ON/OFF key. This disables the

radio portion of the software

and will increase battery life.

Introduction

Addresses

High frequency signals are

subject to absorption by the

ground and the atmosphere, as

well as reflections from metallic

surfaces. For low power sys-

tems, it is normal that varia-

tions of range will be experi-

enced, even in “open air”

conditions in different environ-

ments. Due to combinations of

absorption and reflection,

pockets with weak and strong

signals will be experienced

inside the range.

The dominant absorption factor

is the ground. As a general

rule, the higher the antennas

are above the ground, the

better the signal.

The HR-2000 operates as a remote keyboard and display for the ED-2000plus

electronic dynamometer. Communication between the HR-2000 and the

ED-2000plus takes place in RS-485 format via cable or low power radio

communication.

The HR-2000 has the following communication parameters "hardwired" into

the device.:

• Communication mode: RS-485 half duplex

• Baud rate: 2400 bits per second

• Own address: Configurable

• Initial remote address: Last address used

Addresses are important with the ED-2000plus and HR-2000 because of the

manner in which they communicate. The HR-2000 sends out a signal (poll

signal) requesting that the instrument with a specific address send its display

reading. The ED-2000plus looks at the poll signal that the remote sent and

determines if the address matches. If it does match, the ED-2000plus re-

sponds with its reading.

The concept of addresses is relatively transparent if the system consists of a

single ED-2000plus and an HR-2000. The system will communicate with little

(if any) addressing ever required. However, if several ED-2000plus instruments

are in the same area, they each need to be uniquely identified so that the

HR-2000 knows which ED-2000plus it is talking to.

If several HR-2000 remotes are in the same area, each remote needs to know

when it is its turn to use the airwaves. This is also accomplished by assign-

ing the remote a unique address, and by telling it how many other remotes

are in the area.

The following pages describe the operation of the HR-2000, both in one-on-

one and multiple applications.

13

Turns the unit on in radio mode. RS-485 wireline communi-

cation will also function.

Press these two keys to power up the unit in RS-485

wireline mode. This disables radio function and preserves

battery life.

Puts the unit into addressing mode and shows the address

that is to be polled.

Increments the address by 1 count.

Decrements the address by 1 count

Increments the address by 10

Decrements the address by 10

Returns unit to normal display mode.

Turns the unit off

Forces unit into RS-232 mode

Places remote in LISTEN mode. The remote waits for a poll

signal from the attached peripheral, requests the reading

from the ED-2000plus and returns the reading to the periph-

eral.

Press this to save changes and move to the next item.

Hold the UNITS key to see the item name, release it to see

the value.

Key Function Display

rAdio

rS-485

SEtuP-100

101

99

110

90

-donE-

OFF

-duAL-

LiStEn

See Table 7

headings

ON/OFF

F + ON/OFF

(while unit is off)

F+ ON/OFF

(while unit is on)

PEAK HOLD

TEST

F + PEAK/HOLD

F + TEST

F + ON/OFF

ON/OFF

ALT + ON (while unit is off)

F + ALT

UNITS

Table 6

Key Functions for HR-2000

Operation

Powering Up

For Radio Communication

While operating the HR-2000,

the lower part of the leftmost

digit may be observed to flash.

This occurs when the HR-2000

wants to transmit a message

and is waiting for access or for

an answer. Operating under

good radio conditions, this will

be rarely seen.

The key functions for the HR-2000 are listed in Table 6.

To power up for use with the radio link, press the ON/OFF key on the

ED-2000plus then the press the ON/OFF key on the HR-2000.

When you turn on the HR-2000 for radio use, the display will show the

software revision number (probably hr2001), then the word rAdio. Until the

corresponding ED-2000plus is powered up and communicating with the

HR-2000, the letter rwill flash back and forth between inverted and upright.

When communication is established and working properly the display will

mirror the ED-2000plus display and the leftmost decimal point will blink every

½ second. If communication is broken, the display will flash a small o in the

lower left corner of the display. If communications are not resumed within ten

seconds, the display will show rAdio and the letter rwill flash back and forth

between inverted and upright.

14

Radio Operation with

RS-232

You can connect the HR-2000 with a computer or other data logging device

via RS-232. There are two communication modes for the HR-2000; normal

operation mode and listen mode. It is important that the ED-2000plus, the

HR-2000 and the external device all be set at a baud rate of 2400 for RS-232

communication.

In normal operating mode, the ED-2000plus and HR-2000 are in constant

contact and the HR-2000 screen reflects what the ED-2000plus screen

shows. Information can be sent to an external device by pressing the DATA

SEND key on the HR-2000.

In listen mode, the HR-2000 waits to receive an enquire code from the exter-

nal device, polls the ED-2000plus for the information, then returns it to the

external device.

To enter listen mode, use one hand to press and hold the F key and use the

other hand to press the ALT key. In listen mode the display shows the word

LISTEN and keys are nonfunctional.

Following is the format of the information sent to the external device:

xxxxx.x uu CR/LF (if in LISTEN mode, a less than symbol (>), ASCII

code 62, is also sent after the line feed)

x= force value

u= unit of measure (LB, KG, KN or T)

CR/LF = carriage return and line feed

The enquire code for the HR-2000 is a question mark plus a carriage return

(?,CR or ASCII Codes 63,13). When the HR-2000 receives this code from the

external device, the above information is sent.

The action of sending information or polling for information can introduce

delays in communication between the HR-2000 and ED-2000plus.

If your HR-2000 does not automatically detect the RS-232 connection, turn off

the unit, then power up by using one hand to press and hold the ALT key

and using the other hand to press the ON key. This forces the unit into RS-

232 operation.

The force value received is right

justified with any leading zeroes

replaced by spaces. Negative

values will show a minus sign

before the first digit. The

decimal point will not be printed

if it follows the significant

digits.

WARNING!

HR-2000 is intended to send

only force/weight readings.

Although the HR-2000 can

remotely configure an

ED-2000plus, unpredictable

output may result if Print or

Enquire actions occur while the

ED-2000plus is in configuration

mode.

15

To power up for use with wired communication, use one hand to press and

hold the F key and use the other hand to press the ON/OFF key. Powering

up this way will turn off the radio communication and save battery power in

the HR-2000.

When you turn on the HR-2000 for wireline communication, the display will

show the software revision number (probably hr2001), then rS-485. When

communication with the connected ED-2000plus is established the display

will mirror the ED-2000plus display and the leftmost decimal point will blink

every ½ second. If communication is broken with the ED-2000plus, the

display will show a small oin the lower left of the display. If communication is

not resumed within ten seconds the display will show rS-485 and the letter r

will flash back and forth between inverted and upright.

You can set the address for each HR-2000 and ED-2000plus operating in a

given area so that they can work without interference. If several systems are

operating in the same airspace each HR-2000 and ED-2000 must have a

unique address. Since more instruments must share the same airwaves, the

update time for each unit will increase. Approximate times are shown in Table

7.

It is recommended to keep the ED-2000plus instrument addresses at 100 or

higher.

In multiple system environments the remotes must have their Source ad-

dresses and Poll parameters set appropriately. The source address must

start from address 32 and increase sequentially. The poll value must be equal

to the number of HR-2000s in the area.

You need to set the addresses according to the number of systems you have

operating in the area. See Table 7 below for the proper settings.

Addressing Mode

For Wireline Communication

Number of HR-2000 Poll value ED-2000plus Update time

HR-2000s Source address Destination address

2 32 2 100 1 second

33 2 101 1 second

3 32 3 100 1.5 second

33 3 101 1.5 second

34 3 102 1.5 second

4 32 4 100 2 second

33 4 101 2 second

34 4 102 2 second

35 4 103 2 second

Table 7

Addresses for multiple systems

16

To assign the correct address for each part of the system, you must access

the address mode. Follow these steps to access and set the proper ad-

dress.

1. With one hand, press and hold

the F key and use the other hand

to press the ON/OFF key. . . SEtuP is displayed then 100. This is

the Destination address currently

assigned to the ED-2000plus.

2. Increment or decrement the

address number using the keys

described in Table 6 until the

address you want is on the

screen. Remember to follow the recommen-

dations in Table 7.

3. Press the UNITS key to save the

change and move to the next

item in the address mode. . . SourcE is displayed while the UNITS

key is held then the Source address

is displayed when the key is re-

leased. This is the address currently

assigned to the HR-2000.

4. Increment or decrement the

address number using the keys

described in Table 6 until the

address you want is on the

screen. Remember to follow the recommen-

dations in Table 7.

5. Press the UNITS key to save the

change and move to the next

item in the address mode. . . POLL is displayed while the UNITS

key is held then the poll value is

displayed when the key is released.

This value identifies the number of

remotes that may be operating in a

given airspace. This value has a

default of one. Changing the value will

have the effect of increasing the time

between display updates.

6. Increment or decrement the

address number using the keys

described in Table 6 until the

address you want is on the

screen.

Entering a destination address

of 0 will cause the remote to

send a signal called a “Broad-

cast signal”. The first

ED-2000plus that responds with

its value will then be locked in.

The Destination address must

match with the address entered

in the ED-2000plus. This value

has a default of 100.

17

Two special modes can be flagged with the Poll value:

· A Poll value of zero places the remote in Manual Poll mode. The remote

will only poll the instrument when the UNITS key is pressed by the

operator. The ED-2000plus will reply and the HR will display the reading

until the unit is polled again (or until the screen blanks after ten seconds

of non communication). Manual poll mode is designed for situations in

which constant updates are not necessary, to conserve battery life or

reduce airwave clutter.

· A Poll value of 255 places the unit in Monitor mode. The instrument is

completely passive and only ON/OFF or F+ON/OFF keys are functional.

It will need a second HR-2000 operating actively, and the dEStin and

SourcE address must match the active HR-2000 exactly. The passive

HR-2000 will display any traffic FROM the ED-2000 TO the active

HR-2000, as long as it is within receiving distance. Monitor mode is

designed for situations where a second remote is required for the same

ED-2000plus.

7. Press the UNITS key to save the

change and move to the next

item. . . dEStin is displayed while the key is

pressed then the destination value.

You are now back at the top of the

list of items in address mode.

18

Torque and Bending

Appendix - Weighing and Force Measurement Practice

The basis for all electronic force measurement or weighing is measurement of

stress in a loadcell body. To obtain optimal results it is necessary to estab-

lish a few basic rules, otherwise the effect may be a nonlinear or

nonrepeatable response. Read and follow these tips and see the illustrations

on the next page.

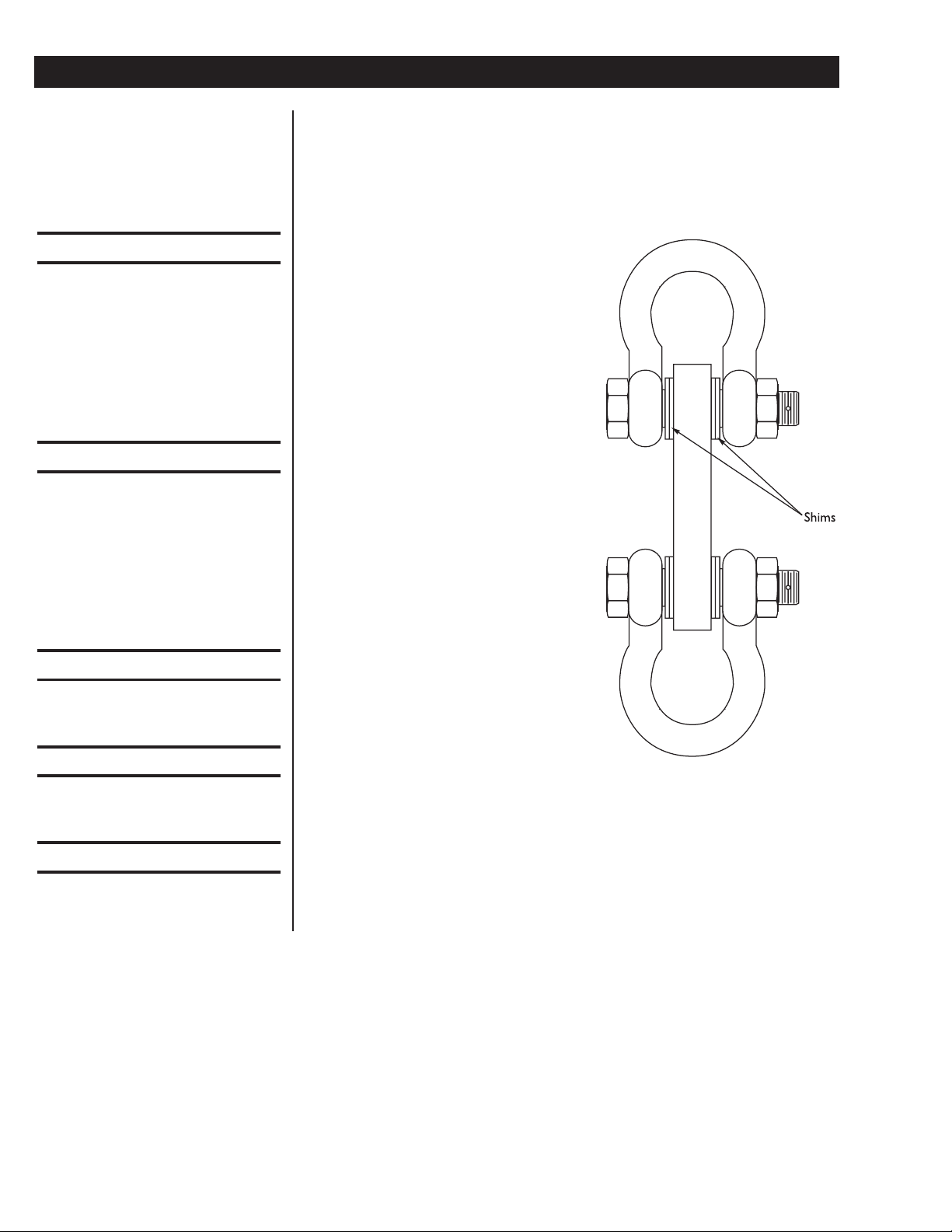

For accurate performance the force

acting on the unit must be in line with

the unit. Centering the load is accom-

plished by using the shims on each side

of the load cell so that it is centered on

the shackle pin. See the illustration at

right. The 20, 50, and 100 Klb

ED-2000plus also include spacers

supplied with shackles.

A good fitting pin is important in order to

generate an even stress distribution and

avoid yield stresses. The ED-2000plus

are designed with the recommended

shackle pin hole sizes for the Crosby

shackle capacity. To achieve published

accuracy you must use the shackle

pins and centering spacers provided by

Dillon.

Torque and bending should be avoided.

Use swivels on the lifting wire for

antitorque and avoid side forces.

Certified shackles and lifting gear

should always be used in accordance to

local laws and federal legislation.

Safety is always a concern in overhead lifting and tensioning applications. To

limit your liability always insist upon factory supplied shackles and pins and

factory tested and certified safe optional equipment. All DILLON products are

designed to meet the published Safe Working Load (SWL) and Ultimate

Safety Factor (USF) standards of the United States Military.

Load Centering

Good Pin Fit

Certified Gear

Safety

19

Good Force Measurement Practice

A division of Weigh-Tronix Inc.

1000 Armstrong Dr.

Fairmont, MN 56031 USA

Telephone: 507-238-4461

Facsimile: 507-238-8258

e-mail: [email protected]

www.dillon-force.com

Force Measurement Products & Systems

Dillon

Table of contents

Other Dillon Measuring Instrument manuals

Dillon

Dillon AP User manual

Dillon

Dillon AP User manual

Dillon

Dillon Quantrol BFG 10 User manual

Dillon

Dillon EDjunior User manual

Dillon

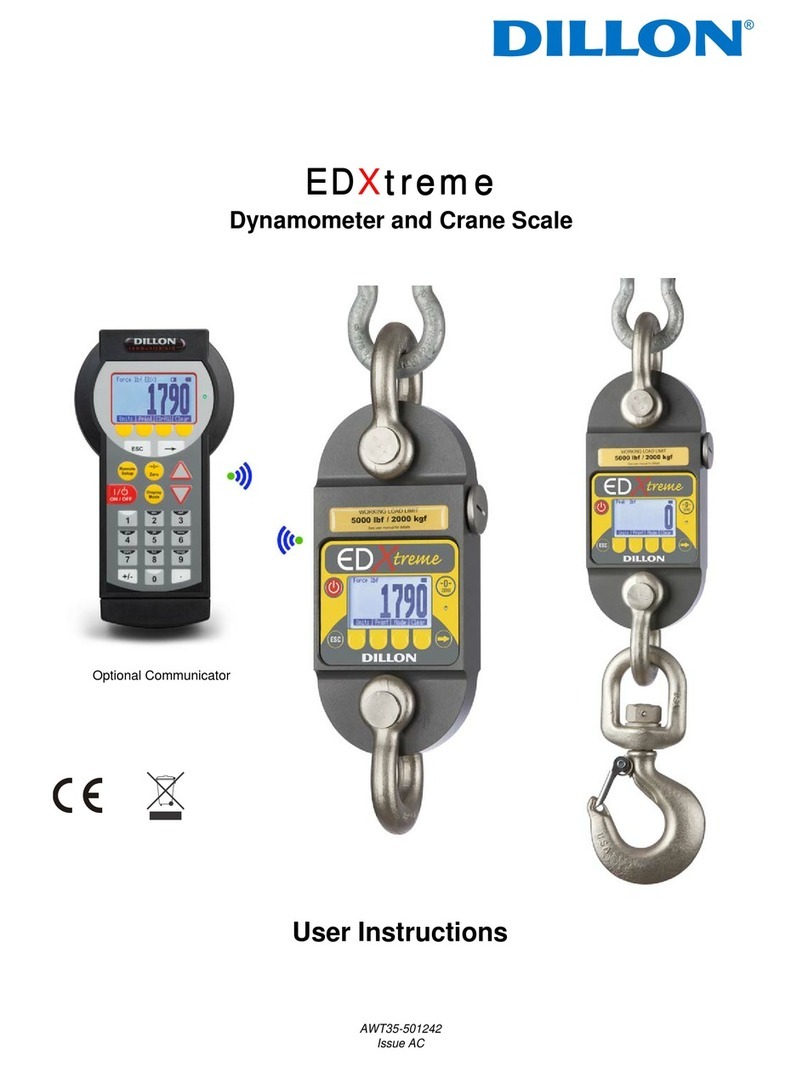

Dillon EDXtreme EDX-1T User manual

Dillon

Dillon EDXtreme User manual

Dillon

Dillon AFG Series User manual

Dillon

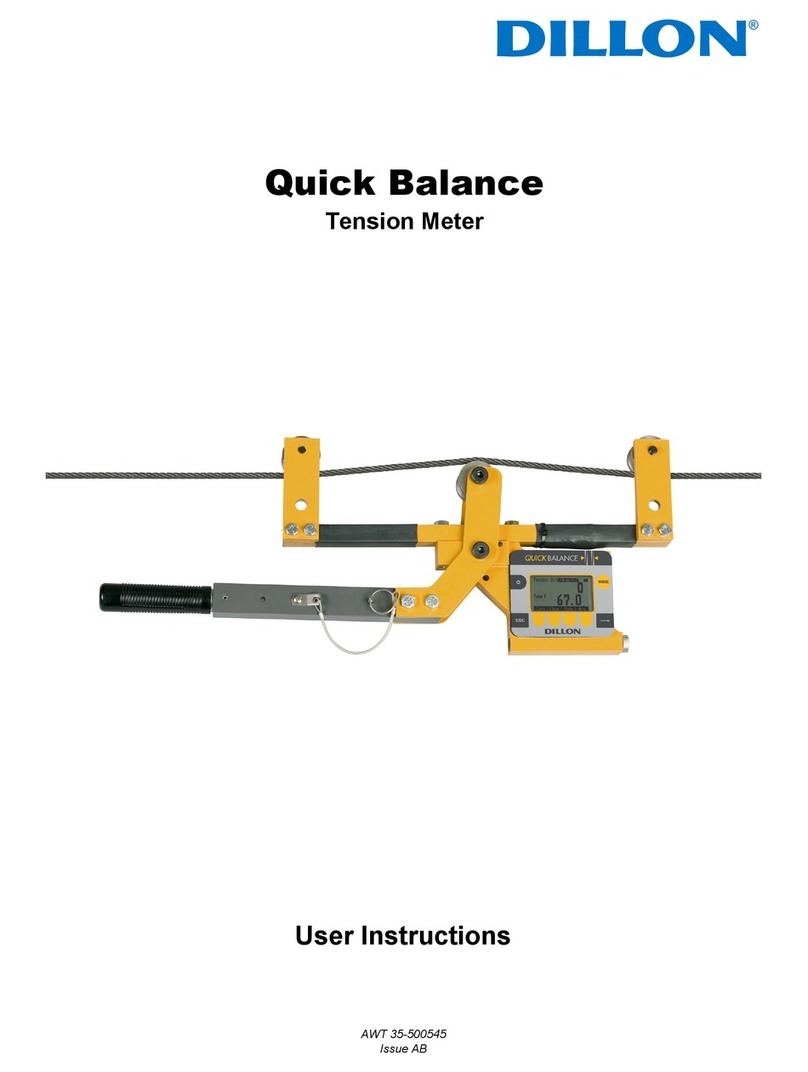

Dillon Quick Balance User manual

Dillon

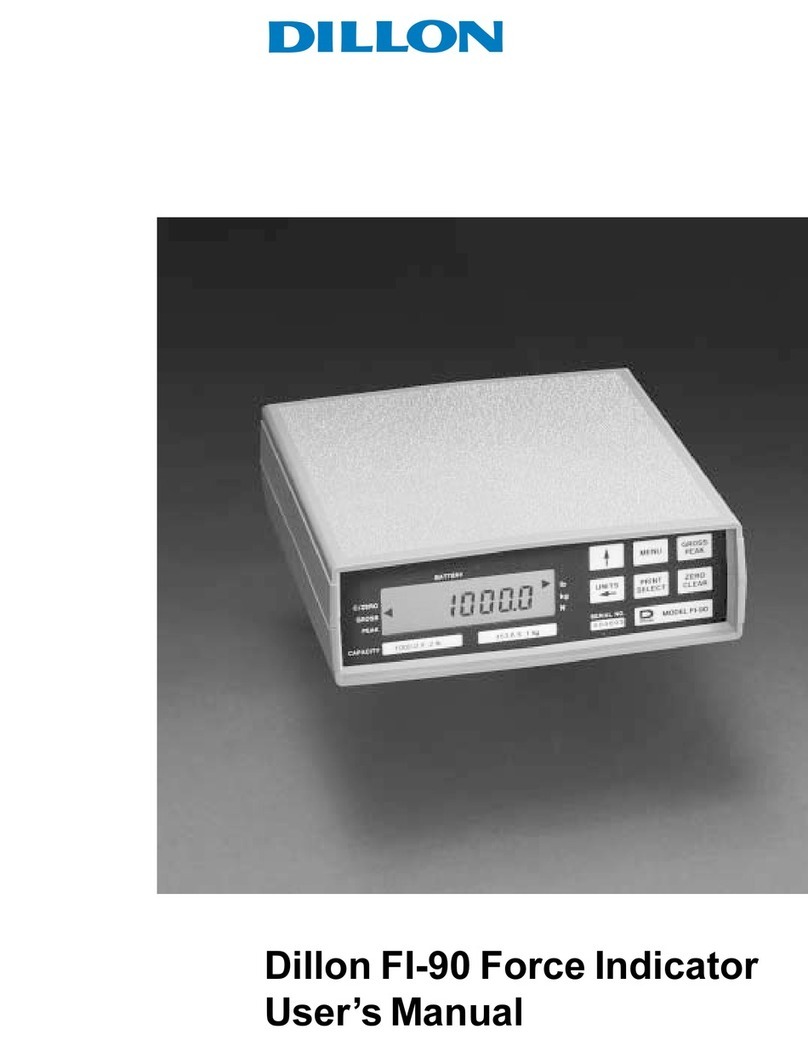

Dillon FI-90 User manual

Dillon

Dillon AP Dynamometer User manual