A-M Systems 3

131 Business Park Loop, P.O. Box 850 Carlsborg, Wa 98324

Telophone: 800-426-1306 * 360-683-8300 * FAX: 360-683-3525

E-mail: amsys@a-msystems.com * Website: http://www.a-msystems.com

To accurately measure the impedance, verify at the OUTPUT connector that the signal

is a pure 1.0 kHz sine wave, and that the sine wave is at its maximum amplitude (the

point just before the signal becomes unstable).

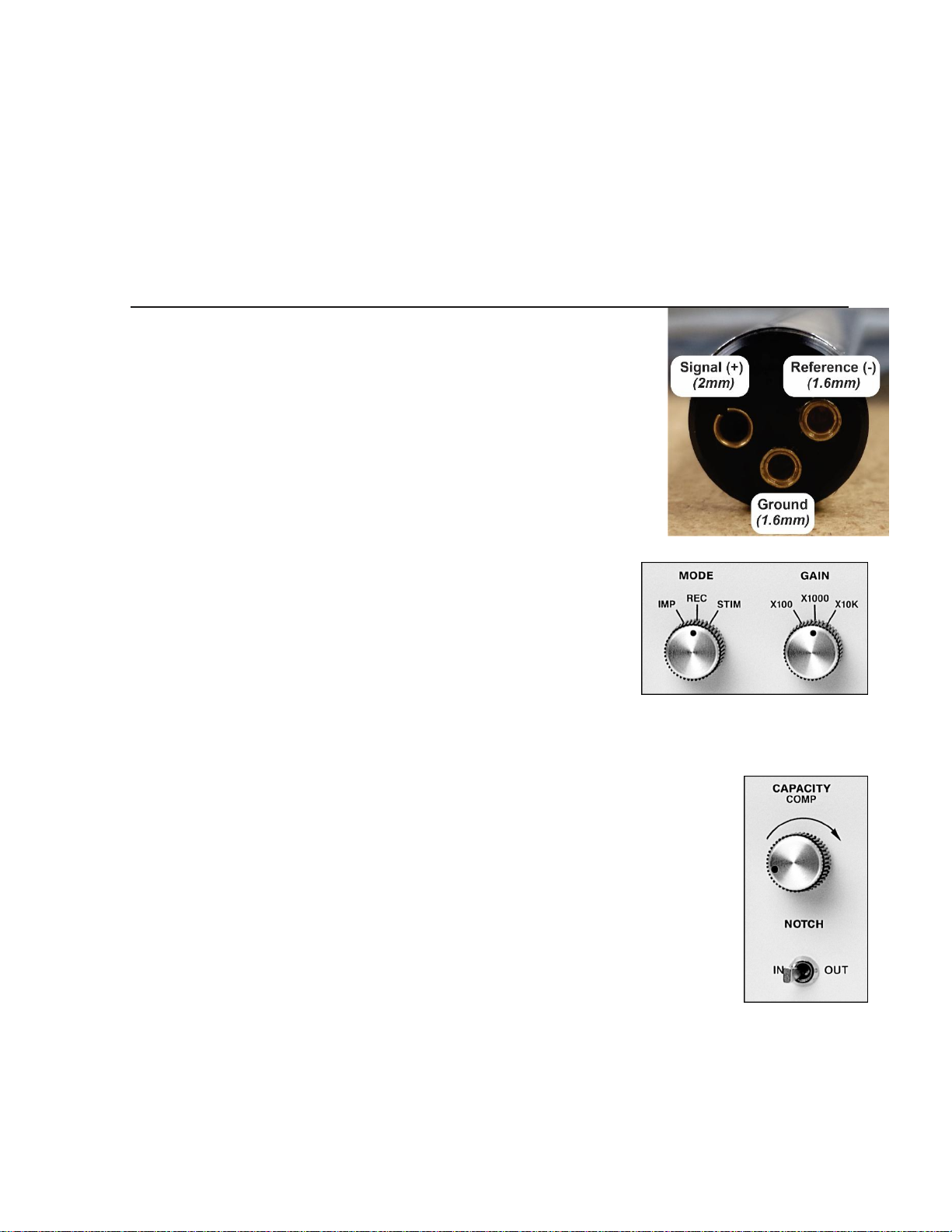

NOTCH: This switch allows the Notch Filter to be included (IN) in the signal processing

path or bypassed (OUT). Warning: Although the Notch Filter provided can

significantly reduce unwanted interference from the power source, it will cause some

distortion of the signal, especially in frequencies below 100 Hz. Therefore, the Notch

Filter should only be used if other noise reduction techniques such as proper

grounding and shielding are inadequate.

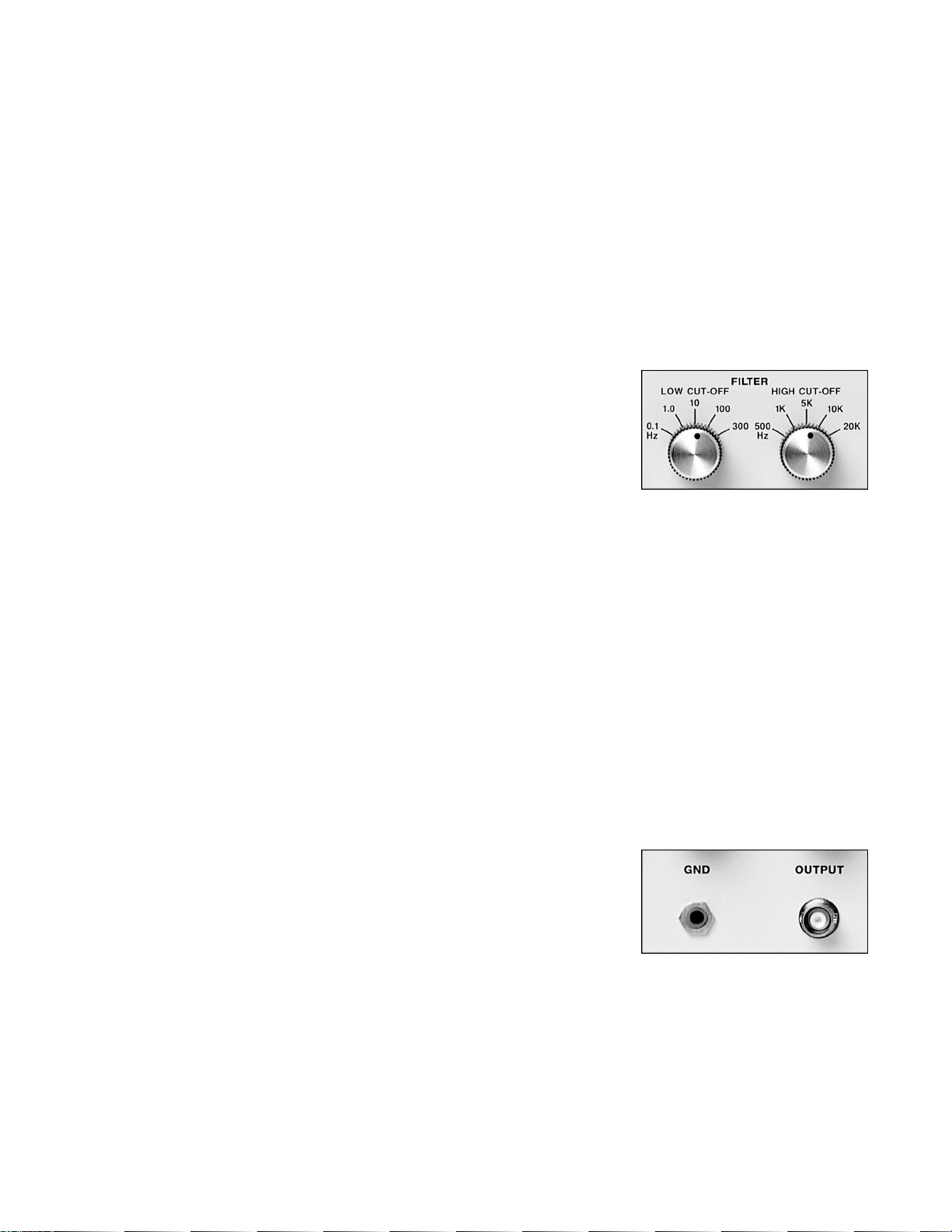

LOW CUT-OFF: This rotary switch enables the user to select the lower boundary

frequency at which point the channel’s input signal begins

to be cut-off. Signals below the cut-off frequency will be

attenuated by a factor of 100 (-40 dB) per decade decrease

in the input signal frequency. For example, if the LOW CUT-

OFF switch is set at 100 HZ, then a 10 Hz signal will be

attenuated by a factor of 100 while a 1 Hz signal will be

attenuated by a factor of 10,000.

The Low Cut-Off frequency should be selected based on the frequency content of the

signal to be recorded. One of the uses of this filter is to reduce slow variations or DC

levels in the input signal.

HIGH CUT-OFF: This rotary switch enables the user to select the upper boundary

frequency at which point the channel’s input signal begins to be cut-off. Signals above

the cut-off frequency will be attenuated by a factor of 100 (-40 dB) per decade

increase in the input signal frequency. For example, if the HIGH CUT-OFF switch is set

at 1 KHZ, then a 10 kHz signal will be attenuated by a factor of 100 while a 100 kHz

signal will be attenuated by a factor of 10 000. One of the uses of this filter is to

reduce high frequency noise that is above the frequency content of the signal being

recorded.

OUTPUT: This BNC connector provides the output signal from the amplifier channel.

GND: This connector on the front panel provides access to

the circuit ground for its channel. Either the PROBE GND

connector or the front panel GND must be connected for

proper operation. Usually the PROBE GND connector is tied

to the indifferent lead. If you desire to have the current constrained to a known path

you may want to place the GND elsewhere. Actual GND placement depends on the

application. For low-noise recordings a ground connection should be made in the

recording medium (i.e. bath ground, animal ground, etc.).