Pag. 1 di 26

INDEX

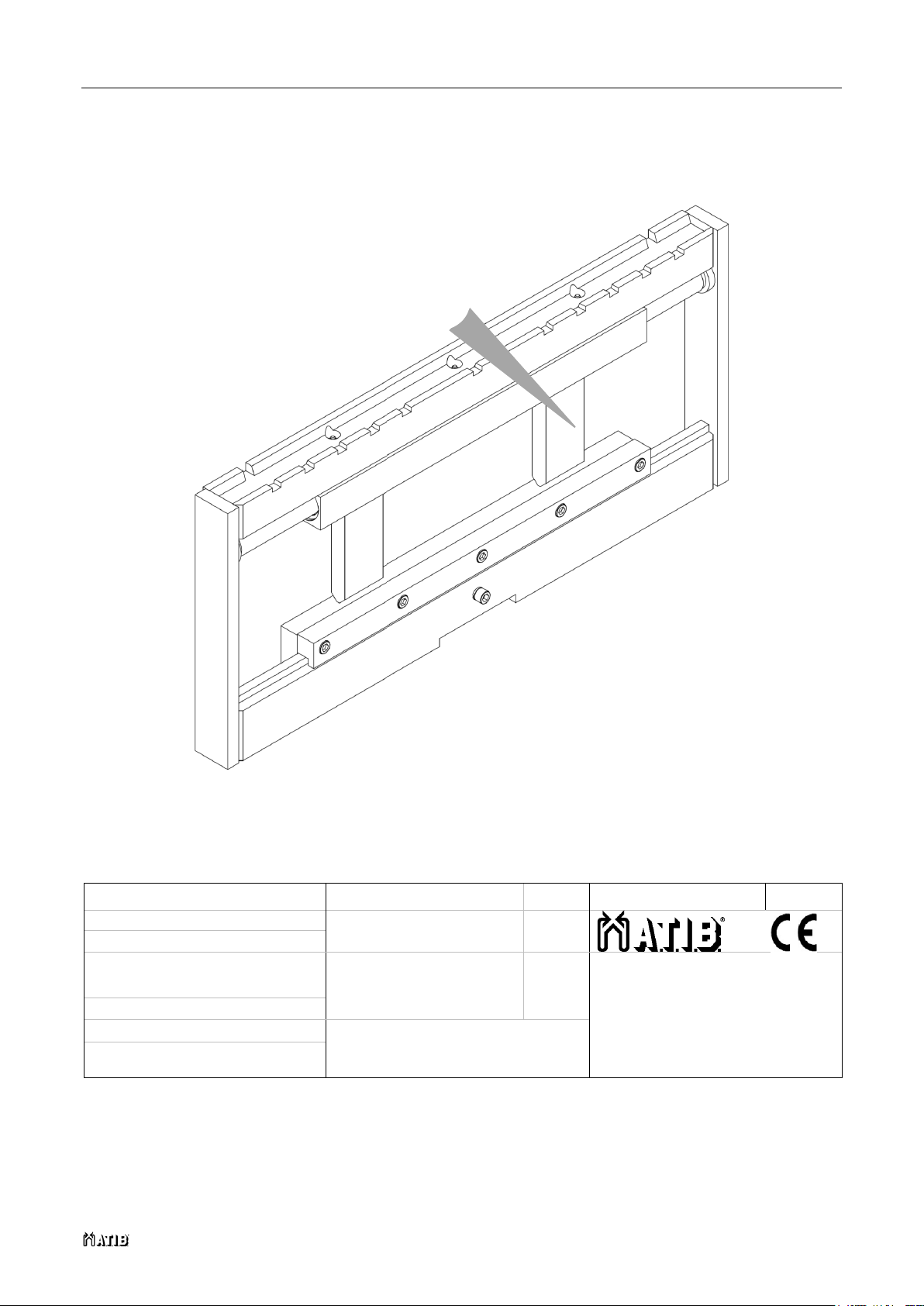

INTEGRAL SIDESHIFT TYPE 122

INDEX ......................................................................................................................................................1

1SAFETY RULES ...............................................................................................................................2

2INTRODUCTION ...............................................................................................................................3

2.1 Use and upkeep of this manual .........................................................................................3

2.2 Description of equipment...................................................................................................4

3INSTALLATION ................................................................................................................................8

3.1 Installation ...........................................................................................................................9

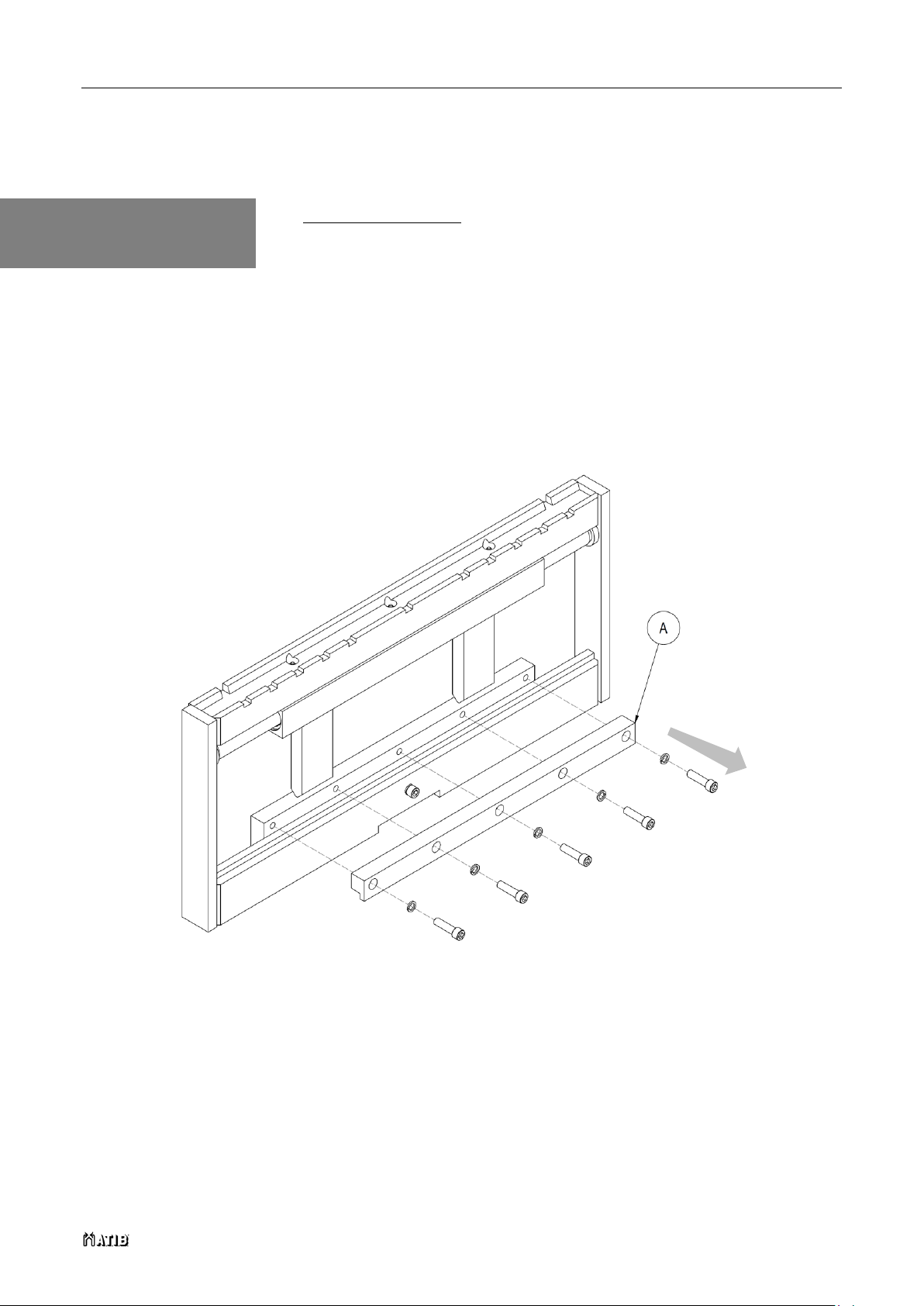

3.1.1 Installation the attachment without welded brackets................................................ 9

3.1.2 Installation the attachment with welded brackets ....................................................15

4USE RULES....................................................................................................................................17

5PERIODIC MAINTENANCE............................................................................................................20

5.1 Maintenance every 100 hours ..........................................................................................20

5.2 Maintenance every 300 hours ..........................................................................................20

5.3Maintenance every 1000 hours ........................................................................................21

5.4 Maintenance every 2000 hours ........................................................................................21

6DISASSEMBLY PROCEDURE.......................................................................................................22

6.1 Cylinder removal...............................................................................................................22

7BREAKDOWNS AND SOLUTIONS................................................................................................24

7.1 Breakdowns and solutions...............................................................................................24

7.2 Lubricate............................................................................................................................25