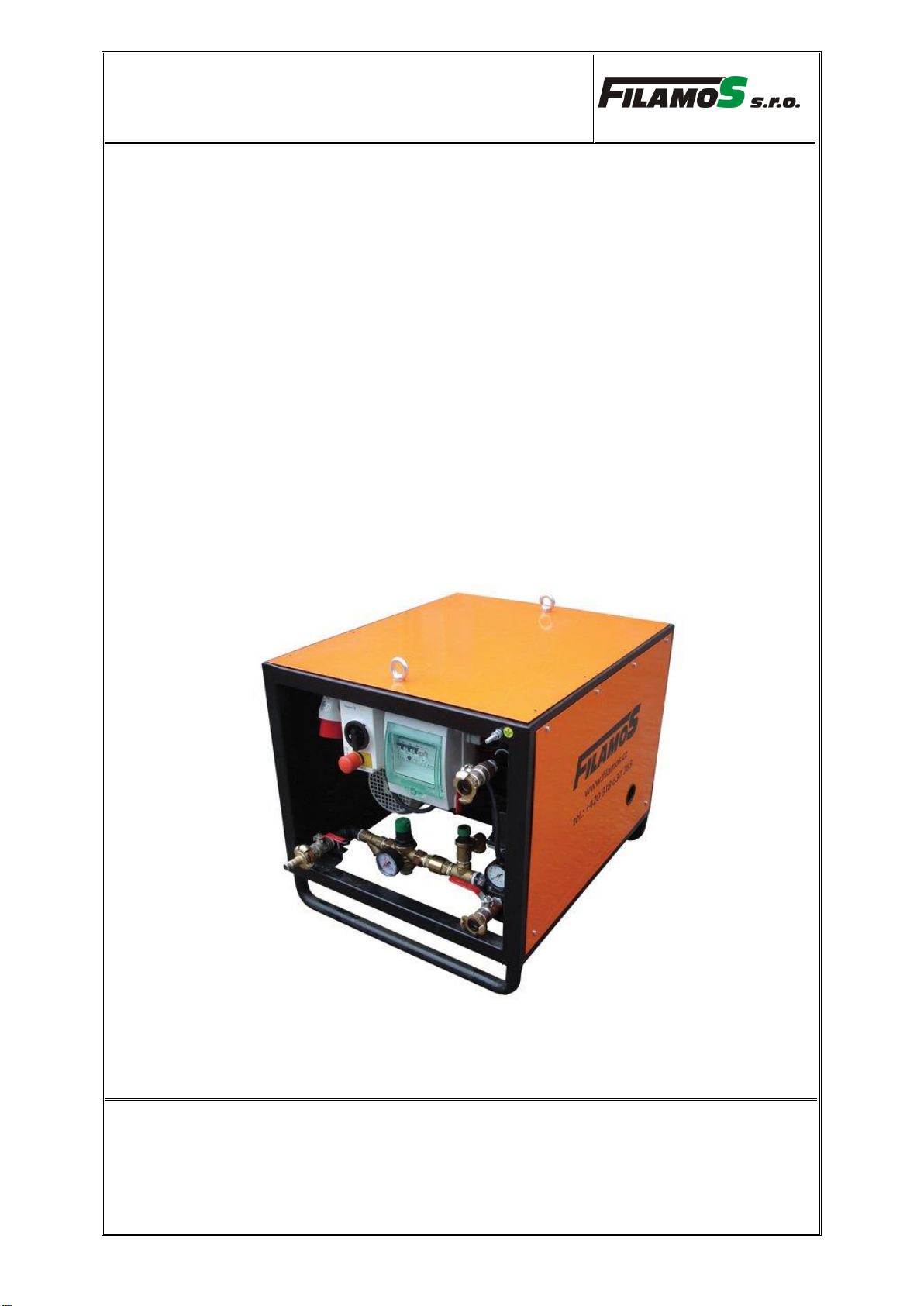

Filamos DC 50 User manual

Dosing pump DC 50 / DC 200

VÝROBCE: FILAMOS, s.r.o.

Hatě 546, 261 01 Příbram, Česká republika

Tel.: + 420 318 637 763, Fax: + 420 318 624 181

www.filamos.cz

User manual

Dosing pump

DC 50 / DC 200

Dávkovací čerpadlo DC 50 / DC 200

1

Obsah Strana

I. USE...............................................................................................2

III. SAFETY........................................................................................3

IV. TECHNICAL DATA.......................................................................3

V. OPERATION AND MAINTENANCE INSTRUCTIONS..................4

VI. APPENDICES...............................................................................5

Dávkovací čerpadlo DC 50 / DC 200

2

I. USE

Dosing pump, series DC, is used for dosing liquid additives to a concrete flow at realisation

of dry-sprayed or wet-sprayed concrete technology.

The additive is used for increasing speed of the concrete hardening process, increasing the

resistance at low temperatures, etc.

The pump may be used in the environment with outside temperatures of +5 ÷ +35 °C.

The source of electric power from the network 3 x 400V / 50Hz must be available.

The source carrying the minimum pressure of 0.3 MPa shall be used as the pressured water

intake.

The equipment is designated for the environment free of any danger of a methane explosion

(SNM-0) and flammable gases according to the Czech National Standard (ČSN) EN 1127-2.

II. PRINCIPLE OF FUNCTION; DESCRIPTION

The basic unit of the pump is a hose pump providing for accurate dosage, easy maintenance,

dry-operation, long service life, etc.

The pump is driven by the electric motor equipped with the ballast resister permitting the

dosed quantity be mechanically controlled.

The pressure switch situated within the circuit provides for the pump automatic switch-off

and switch-on according to a rise or drop of the pressure caused by closing and opening the

closure on the spraying nozzle of the concrete spraying machine.

The system of a reverse valve avoids any leak of chemical liquid additive into the water

distribution branch.

The control (regulation) of the dosed quantity is carried out by change of rotations of the

pump rotor. The rotations are controlled at the driving shaft and the number of them is

transferred to a display on the converter showing the quantity of supplied liquid additives in

litres. The operating staff may operatively adjust the optimum dosage at various and

changing conditions of spraying, e.g. output of water at the place of spraying.

Distributions water section:

-closing valve (1) at the input with a quick coupler (2) for connection of the pressured

water

-reduction valve (3) for setting the input pressure –set at 0.55 MPa

-reverse valve (4) avoiding the access of a liquid mix to the distribution water section

-safety valve (5) set at 0.6 MPa

-

The mixing section (6) is connected to the water supply and rising branch from the hose

pump (7).

Dávkovací čerpadlo DC 50 / DC 200

3

It is also provided with the controlling manometer (8) and pressure switch (9) controlling

the water and additives mix supply switch-on and switch-off. The pressure switch is set in

the following range 0.3 ÷ 0.55 MPa. Electric power to the pump motor is switched on at the

bottom and switched off at the top.

The sucking part of the distributions comprises a suction hose with basket. Such part is

connected to the closing valve (11) by the quick coupler (10) avoiding any leak of the liquid

additive back to the tank from which it is sucked.

The rising branch is provided with the closing valve (12) and quick coupler behind the

mixer for connection of the hose leading to the Machine nozzle for a concrete spraying.

In order to depressurise the hose, such connection is amended with a corner valve permitting

to loose the pressure in the rising branch at the pump stopping.

The electrical part comprises five-pin connector 16A/400V (13), motor starter (14) with a

stop button and box with the thermal and under-voltage trip (15).

The electric motor (16) with capacity of 550 W is in the set with a mechanical ballast

resistor (17) and worm gearbox (18) connected to the hose pump by the flexible connection

coupling (19).

III. SAFETY

The pump may be connected only to the approved media complying with the standards

(electric power, pressured water)

.

The operating staff must be older than 18 years of age and familiar with the User Manual,

observe any and all operating rules of a structure and the technological regulations and

measures set forth in the project documentation for the work subject to realisation.

They also must observe the safety regulations set forth by the liquid mix producer.

IV. TECHNICAL DATA

Type of the pump

DC 50

DC 200

Output (l/hod)

13-50

48-240

Max. pressure

(MPa)

0,75

Input (W)

550

Feeding system

3 NPE ~ 50 Hz

Weight (kg)

148

Length

80 cm

Width

70 cm

Height

65 cm

The DC 50 type is fitted for the shotcreting machine SSB 14 or SSB 05, DC 200 type for the

machines SSB 24 and SSB 02.

Dávkovací čerpadlo DC 50 / DC 200

4

The whole equipment is situated in a protective frame and covered with metal sheets and

one rubber wall.

The connecting and controlling elements are accessible from the equipment face side, a

display showing the supplied quantity is covered up with a lifting rubber cap.

The protection from any dangerous touch is provided by a self-activating disconnection

from the source and different progressive connections. The bolt for the interconnection with

the earthing network at a worksite is placed on the frame face side.

The equipment is made from materials of regular qualities.

The manufacturer tests the pump using clean water instead of the liquid additive, and all

elements are set and their sealing tested.

The equipment is marked with a type label of the manufacturer and supplied together with

the release inspection and the certificate of conformity.

The warranty is honoured for 12 months from the date of delivery. The warranty is not

honoured for a replaceable working hose of the pump itself.

The equipment is supplied on a pallet and the transport is carried out by usual transport

means.

V. OPERATION AND MAINTENANCE INSTRUCTIONS

Main principles for the equipment operation:

-the servicing and operating staff must be very careful and equipped with working

protective aids according to the additive producer instructions

-any and all repairs and adjustments may be done only if the equipment is

disconnected from the electric power source

-at realisation of the pump and distributions repair, the pressure must be lowered in

such areas and the pump rinsed with clean water

-the suction hose handling must always be done with an increased diligence

-any repairs on electric installation may be executed only by a worker certified to

perform such electrical installations

Preparation of operation:

-the equipment gets connected to the electric power and pressured water sources;

earthing is a must

-the tank containing the liquid additive is placed in a sufficient distance and then

hose-connected to the pump

-the rising hose is connected and check of all connection points and function of

closing valves is performed

-the sufficient space for the operating staff and its contact with the spraying nozzle

operator is provided

Dávkovací čerpadlo DC 50 / DC 200

5

Operation:

A) Dry-spraying

-upon agreement with the nozzle operator, the pressured water is released into the

distribution

-after the hose is filled, the pump is switched on to suck in the liquid additive to be

mixed with water in the mixer

B) Wet-spraying

-is done without any pressured water intake, only the hose pump is lowered

Operation interruption:

-caused either due to a closure of the cock at the spraying nozzle, increase of the

pressure or the pressure switch having bee turned off

-the operation is executed by switching off the motor starter (stop-button)

In order to prevent any leak of pressure, it is good to close the suction cock and delivery

cock

Operation termination:

-to clean the additive sucking part with clean water and rinse out the entire pump

distribution and pump as well

-by checking the manometer to verify that no pressure exists in the distribution and to

disconnect the hoses thereafter

The equipment works in a semi-automatic regime –despite, the permanent presence of

operating staff is required. The equipment operation must be monitored, primarily the

additive mix tank level.

At the time of maintenance, connection points must be checked according to the User

Manual one-by-one as well as the hose clips and hose pump BREDEL (supplied), the

lubricant level must be checked.

Also the dosing hose replacement is to be done following the User Manual.

The oil in the ballast resistor must be replaced after 3,000 hours in maximum –0.5 litre of

SHELL OIL DONAX TA.

The warm gearbox filling stays at all times over the entire service life of the pump –only

needs to be checked whether the oil level is not dropping due to a leak at the shaft sealing –

use SHELL OIL TIVELA SC 320 for refill, if any.

VI. APPENDICES

1. a 2. Description of the Dosing Pump Type DC

3. List of Spare Parts (for purchase, if needed)

Dávkovací čerpadlo DC 50 / DC 200

6

ANNEX 1. DESCRIPTION OF THE DOSING PUMP (chapter 2)

14 15

11

13

10

9

8

1

2

3 4 5 12

Dávkovací čerpadlo DC 50 / DC 200

7

ANNEX 2. DESCRIPTION OF THE DOSING PUMP (chapter 2)

6

16

17

7 19 18

21

20

Dávkovací čerpadlo DC 50 / DC 200

8

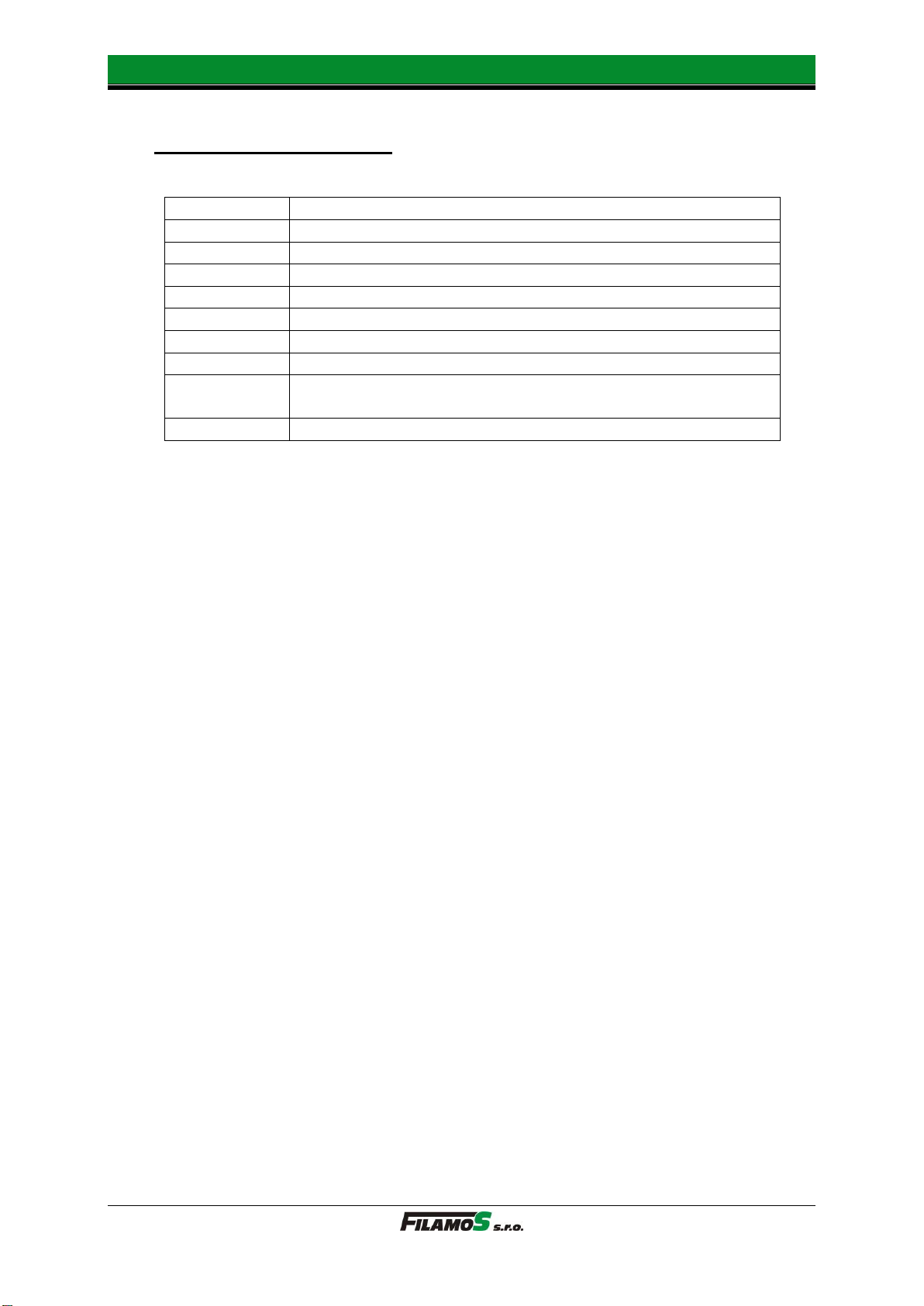

ANNEX 3. List of Spare Parts

1, 11, 12

Ball cock ¾“

2, 10

Quick coupler ¾“

3

Reduction valve D06F ¾ B

4

Reverse valve PN 16 –¾“

5

Safety valve PV KB ½“ x ¾“ KB 15

7

Hose pump

8

Manometer G1/4“, 0 – 1 MPa

9

Pressure limiter N 61216 0041

16, 17, 18

Electric motor, ballast variator, worm gearbox –

BONFIGLIOLI

19

Shaft coupling GE-T-24A-32B

This manual suits for next models

1

Table of contents

Popular Construction Equipment manuals by other brands

Manitowoc

Manitowoc 500E2 Operator's manual supplement

Manitowoc

Manitowoc Grove GRT880 Operator's manual

allen

allen WB1224 Assembly & parts manual

GSi

GSi VersaLoop 8 Installation and operation manual

JEKKO

JEKKO SPD265C+ Operating and maintenance manual

Trinity Highway

Trinity Highway QuadGuard M Wide Product Description Assembly Manual