Contents:

1. About this manual .................................................................................. 5

1.1. Copyrights ...................................................................................... 5

1.2. Trademarks .................................................................................... 5

1.3. General .......................................................................................... 5

1.4. Document conventions .................................................................. 6

1.5. Use of symbols .............................................................................. 7

1.6. Terminology .................................................................................... 7

1.7. Abbreviations ................................................................................. 9

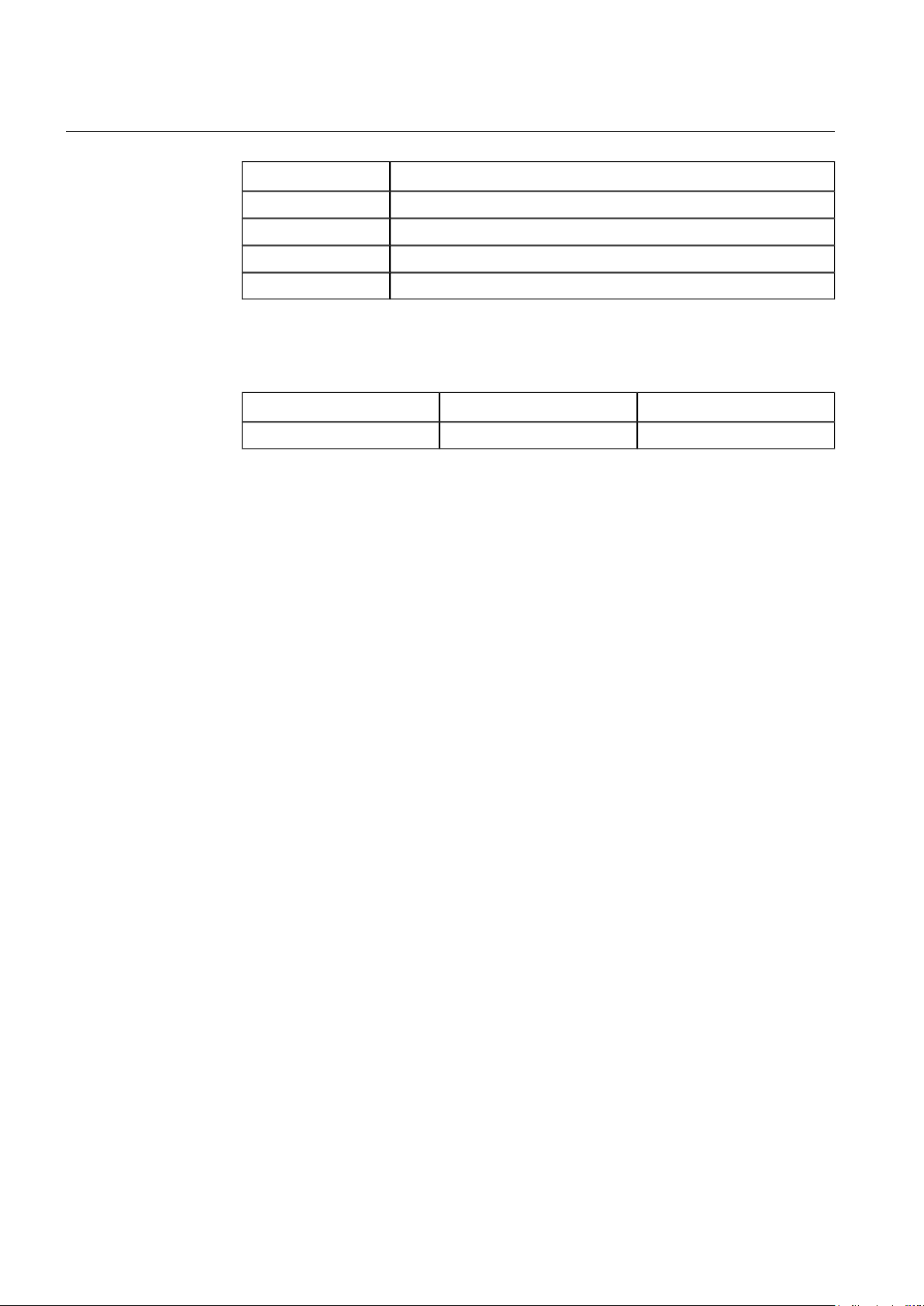

1.8. Document revisions ..................................................................... 10

2. Introduction ........................................................................................... 11

2.1. Functional overview ..................................................................... 11

2.2. External OPC Server features ..................................................... 12

3. Configuration ........................................................................................ 13

3.1. About this section ......................................................................... 13

3.2. Overview of configuration ............................................................ 13

3.3. Building object tree ...................................................................... 15

3.3.1. General about building object tree ................................ 15

3.3.2. Adding Gateway object ................................................. 16

3.3.3. Adding External OPC Server object .............................. 16

3.3.4. Adding External OPC Subnetwork objects .................. 16

3.3.5. Adding External OPC IED objects ............................... 16

3.3.6. Adding Logical Device objects ..................................... 17

3.3.7. Adding Logical Node objects ....................................... 17

3.3.8. Adding data objects ..................................................... 17

3.4. OPC Browser tool ........................................................................ 17

3.5. Configuring objects ...................................................................... 21

3.5.1. General about configuring objects ................................ 21

3.5.2. Configuring External OPC Server properties ................ 22

3.5.3. Configuring External OPC Server Subnetwork

properties ...................................................................... 22

3.5.4. Configuring External OPC IED Device .......................... 22

3.5.5. Configuring Logical Device properties .......................... 23

3.5.6. Configuring Logical Node properties ............................. 23

3.5.7. Configuring data objects for Internal OPC Data ............ 24

3.5.7.1. General about configuring data objects for

Internal OPC Data ...................................... 24

3.5.7.2. Integer status (INS) ................................... 25

3.5.7.3. Single point status (SPS) ........................... 25

3.5.7.4. Controllable single point (SPC) for OPC

internal data ................................................ 26

3.5.8. Configuring data objects for External OPC Client ......... 27

3

Station Automation COM600 3.51MRS757274

External OPC Server User's Manual

Issued: 30.6.2011

Version: A/30.6.2011