ABTQ-74 rev 01 (Last review: 05 Oct 06)

1/2

A B Controls and Technology Ltd

Sanderson Street, Lower Don Valley, Sheffield

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS FOR

ABTECH ‘HVJB’ series – SIRA06ATEX4280

Marking

The maximum power dissipation and

voltage permitted in this terminal box are

marked on the label and identified as

***W and __kV. The ambient temperature

range for which this product is suitable is

–20 to +40oC

Installation

1) Using the mounting dimensions data provided, either in the product catalogue data sheets or

on the drawings supplied, (as part of the project documentation), mark out the positions for the

mounting holes on the surface where installation is required.

2) Drill the mounting holes for either M8 or M9 fixing studs.

3) Insert the top two studs leaving 8 to 10mm protruding and lift the enclosure into position using

such assistance as may be necessary to avoid injury and hang the top fixing brackets of the

box onto the studs. Ensuring that the box is secure, insert and tighten the bottom two studs.

Now complete tightening the top two studs.

4) Unfasten the lid securing screws and remove the enclosure lid. Put the lid in a safe place.

5) Install and secure the cable glands in accordance with the manufacturers instructions.

6) Remove the top half on each cable clamp and put safely aside.

7) Remove the terminal post lock nuts, washers and the upper current bars and put safely aside.

8) Pull the cables into the box leaving trailing leads long enough to reach their respective crimp

lugs after routing through the cable clamps.

9) Trim each cable core so that the conductor end will reach the inside stop of the crimp lug on

which it is to be terminated.

10)Strip the insulation of each cable core by the length of the crimping barrel plus 2mm.

11)Remove each crimping lug in turn from the terminal post and place the securing nuts to one

side.

12)Crimp each lug onto the respective conductor ensuring that the crimp die set used is suitable

for the conductor size and is not damaged or excessively worn. The crimp die set may produce

either a hexagon type crimp or an indent type crimp. With hexagon die sets execute at least

two crimps on each lug.

13)The finished crimp should meet the tensile strength requirements of Table 2 of BS4579:Part

1:1970.

14)Route the cable core through the appropriate cable clamp and place the hole in the palm of the

now attached cable lug on to its respective terminal post, on top of the lower current bar.

15)Replace the upper current bar and secure it in place with the flat washer, spring washer and

two locknuts provided. Ensure that the spring washer is fully compressed by the first lock nut

then apply a further 1/8 to ¼ turn. Secure the fitting with the second lock nut.

16)When all the cable lugs have been attached and correctly tightened replace the top halves of

the cable clamps and tighten each one to secure the cables.

17)Replace the lid and secure it by closing the lid and tightening the lid fixing screws. Ensure that

all gland-plate securing screws are tightened.

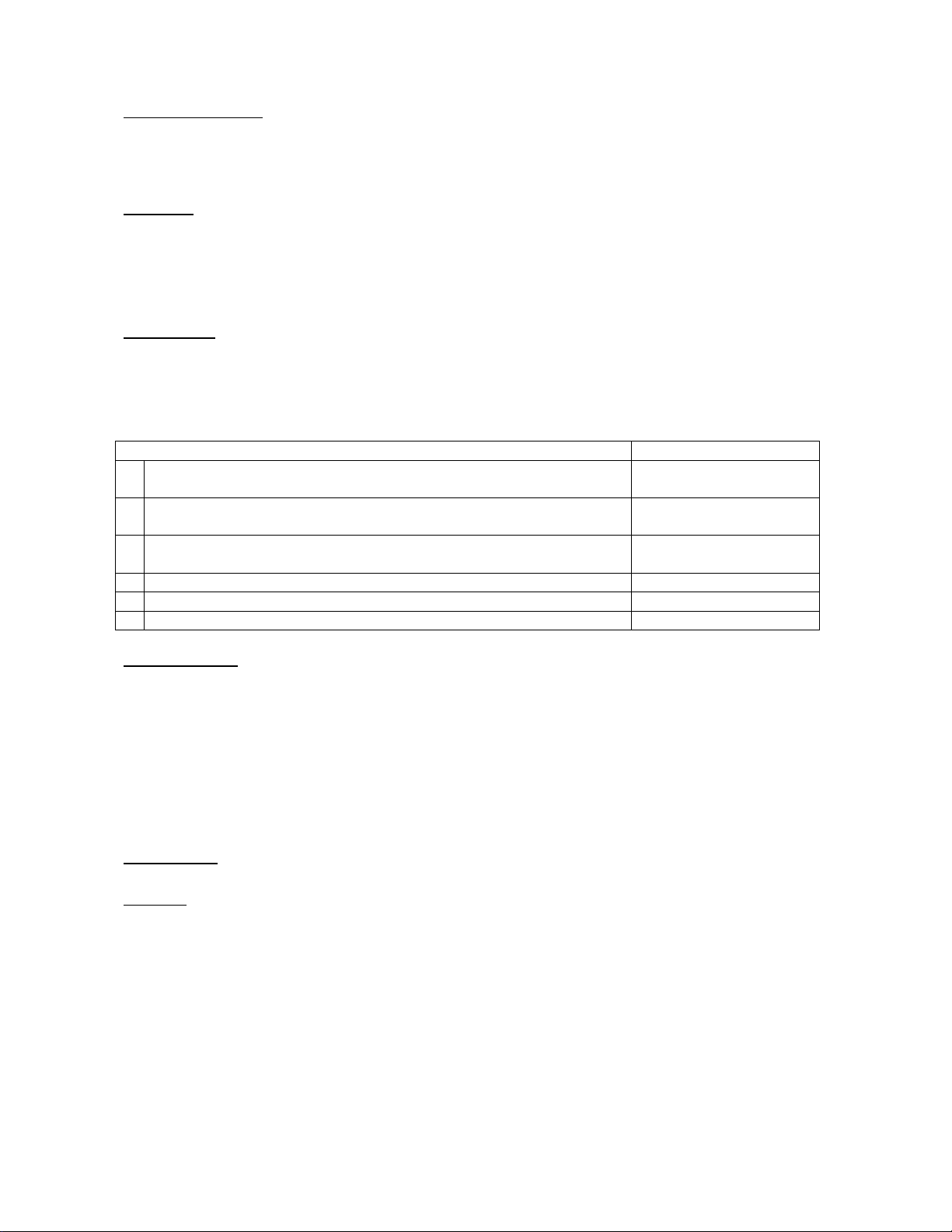

??

CABLE AT ENTRY POINT EXCEEDS 70 deg C

WARNING! ISOLATE ELSEWHERE BEFORE OPENING

SERIAL No. S***** / 20**

HVJB __________ *** W ___kV ?????

A B CONTROLS & TECHNOLOGY LTD SHEFFIELD S9 2UA ENGLAND

www.ab-tech.co.uk

ABTECH

II 3 GD-IP66 - T70 C EEx nA II T4

SIRA06ATEX4280