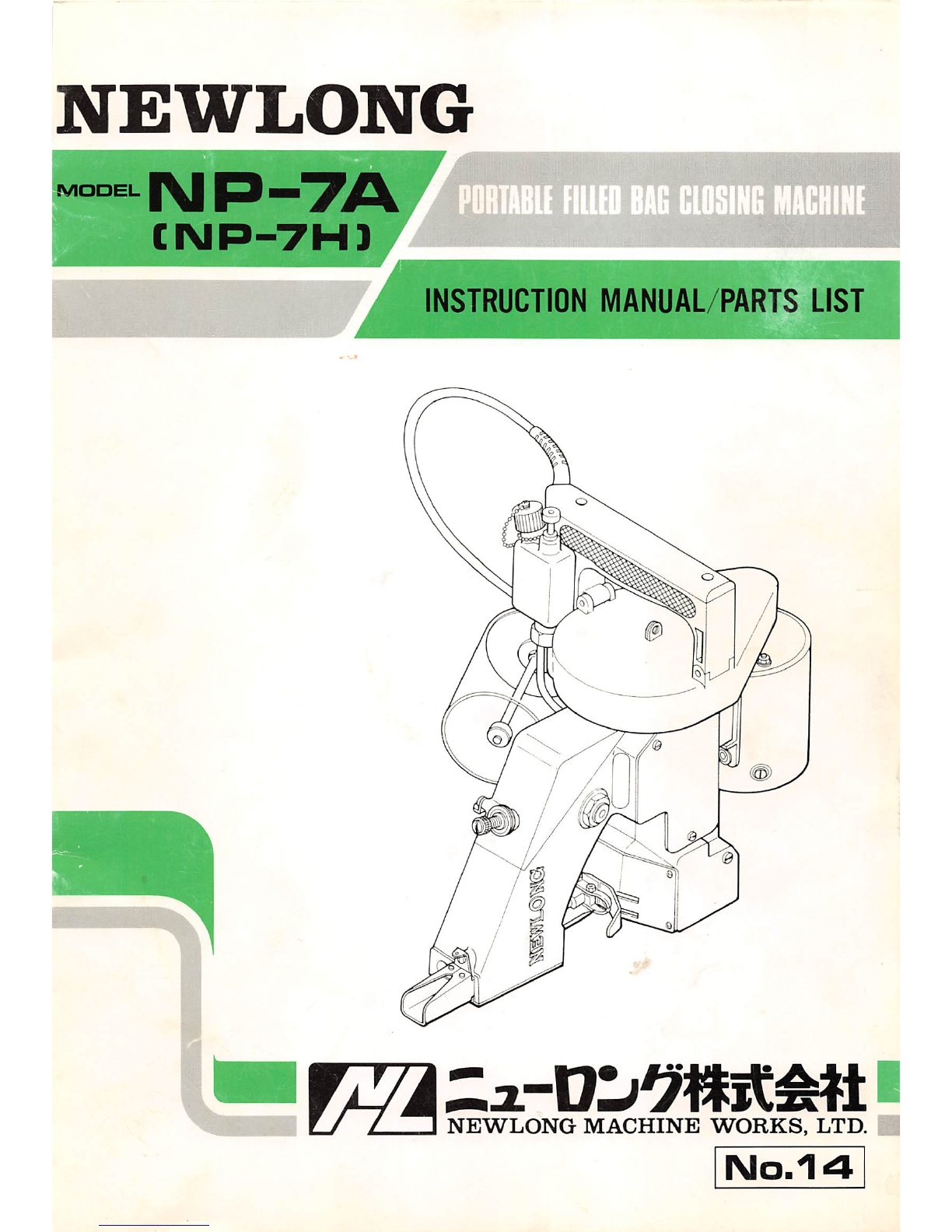

6.

MAINTENANCE

&

LUBRICATION

Clean the machine at the end

of

the day's work. Wipe

dust and other foreign matter

off

the Feed Dog teeth

Looper and Throat Plate evelets where they are easily

gathered.

Care should be taken to keep the machine free from rust,

especially when to leave it unused for some time.

Recommended lubricants are Shell X-100, Motor. Oil

lOW/30, Shell Vitria Oil 31 or the equivalent. For

operation and maintenance

of

the lubricator, refer to

Section

7.

Important

I

When adjusting

the

machine

or

replacing parts, always

disconnect

the

Electric Cord

from

the

power

source.

This

is

important

in

view

of

safety

to

the

operator

and

adjuster.

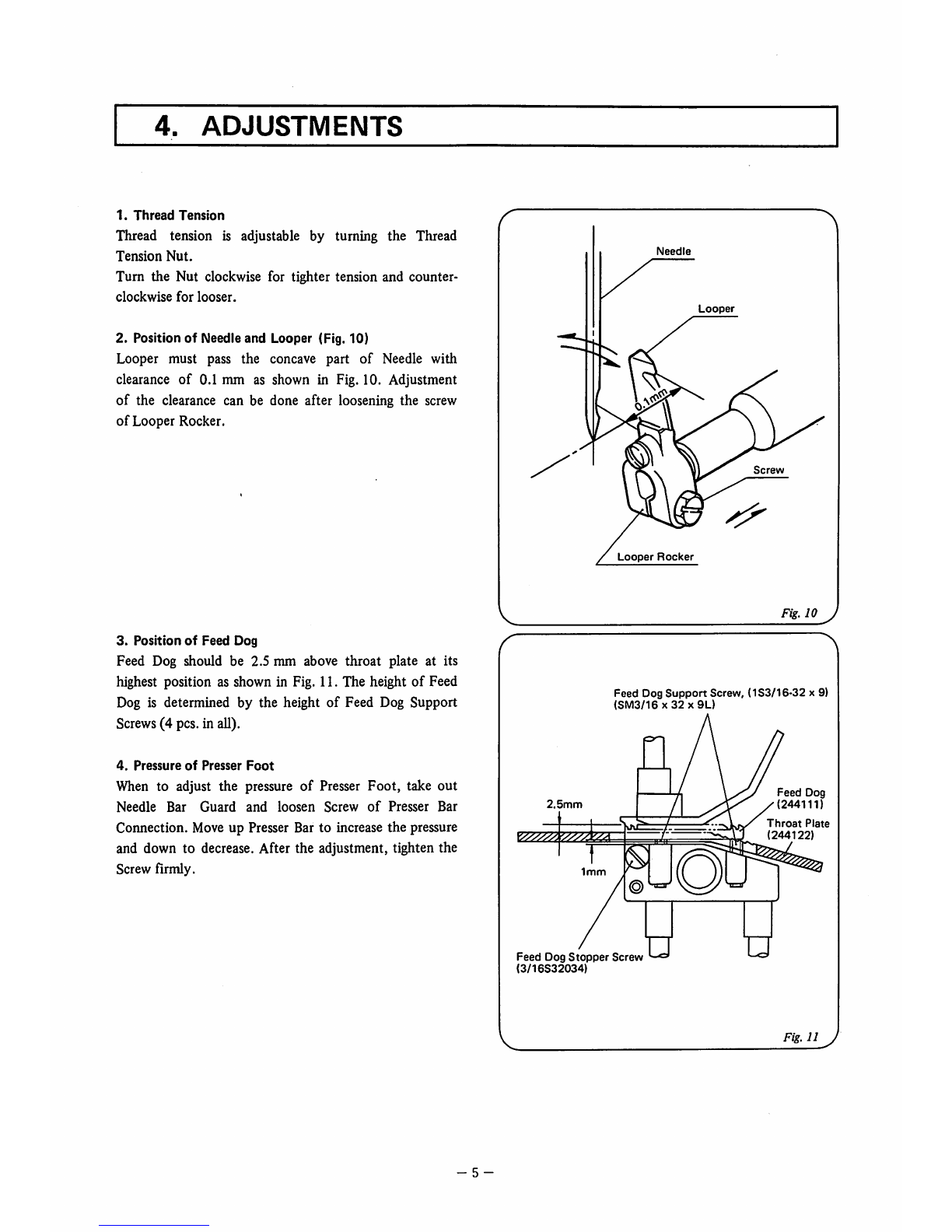

7.

LUBRICATOR

1.

Operation

The lubricator comprises a

pump

and a reservoir. The

reservoir holds max 45 cc

of

oil. (Effective oil volume

is 28 cc.)

To operate

the

lubricator:

1. First unscrew

the

reservoir cap

by

half

a

turn.

*

2. Push the button to its lowest position (stroke: 12mm).

3. When released,

the

button

will automatically return

to its original position.

4. Lastly, tighten the cap to prevent oil leak during

operation.

*

Repeated

working

on

the

button

without

first

loosening

the

cap

may

produce

negative

pressure

in

the

reservoir,

and

the

dust

in

the

atmosphere

may

be

easily

introduced

in it

when

the

cap

is

loosened.

2.

Maintenance

1. Keep

off

dust or foreign matter when to fill oil (They

may cause jamming

of

the piston arid the check valve).

2. Rate of discharge is fixed and not adjustable (0.08 cc

per push).

3. At high temperatures, grease may run along points .

This is normal, grease being used when the lubricator

was assembled in our plant.

4. Reservoir is made

of

high density polyethylene. Keep

off

fire and refrain from using organic, benzene, or

xylene chemicals for cleaning.

Check periodically for correct working of the pump.

(Repeat oil feed and look at the oil through the

discharge pipe.)

7 -