AC Tech Lenze MotionView OnBoard User manual

PositionServo DeviceNet Communications Module

Communications Interface Reference Guide

Copyright ©2008 by AC Technology Corporation.

All rights reserved. No part of this manual may be reproduced or transmitted in any form without written

permission from AC Technology Corporation. The information and technical data in this manual are subject to

change without notice. AC Tech makes no warranty of any kind with respect to this material, including, but not

limited to, the implied warranties of its merchantability and fitness for a given purpose. AC Tech assumes no

responsibility for any errors that may appear in this manual and makes no commitment to update or to keep

current the information in this manual.

MotionView®, PositionServo®, and all related indicia are either registered trademarks or trademarks of Lenze

AG in the United States and other countries.

DeviceNet™ , EtherNet/IP™, CIP™ and all related indicia are either registered trademarks or trademarks of

the ODVA (Open DeviceNet Vendors Association).

About These Instructions

This documentation applies to DeviceNet communications for the PositionServo drive and should be used

in conjunction with the PositionServo User Manual (S94PM01) and the PositionServo Programming Manual

(PM94M01). These documents should be read in their entirety as they contain important technical data and

describe the installation and operation of the drive.

iP94DVN01A

Contents

1. Safety Information...................................................................................................1

1.1 Warnings, Cautions & Notes.............................................................................................1

1.1.1 General ............................................................................................................... 1

1.1.2 Application .......................................................................................................... 1

1.1.3 Installation .......................................................................................................... 1

1.1.4 Electrical Connection........................................................................................... 2

1.1.5 Operation ............................................................................................................ 2

2. Introduction.............................................................................................................3

2.1 Fieldbus Overview ........................................................................................................... 3

2.2 Module Specification ....................................................................................................... 3

2.3 Module Identification Label ..............................................................................................3

3. Installation ..............................................................................................................4

3.1 Mechanical Installation .................................................................................................... 4

3.2 DeviceNet Terminal Block................................................................................................ 4

3.3 Electrical Installation........................................................................................................ 5

3.3.1 Cable Types ........................................................................................................ 5

3.3.2 Network Limitations ............................................................................................ 5

3.3.3 Connections and Shielding .................................................................................. 6

3.3.4 Network Termination........................................................................................... 6

4. Configuring Drive for DeviceNet Communication .....................................................8

4.1 Connect to the Drive with MotionView OnBoard................................................................ 8

4.2 Set up the CAN network................................................................................................... 9

4.2.1 Enable DeviceNet Communication ...................................................................... 10

4.2.2 Set CAN Parameters...........................................................................................10

4.2.3 Set CANOpen Parameters................................................................................... 11

4.2.4 Set DeviceNet Parameters.................................................................................. 12

4.3 Configuration Parameters ............................................................................................... 12

4.4 Drive-Specific Error Codes.............................................................................................. 13

5. Polled I/O ...............................................................................................................14

5.1 Command Output Assembly............................................................................................ 14

5.1.1 Byte 0 – Control Word ........................................................................................ 15

5.1.2 Byte 2 - Command Type.....................................................................................15

5.1.3 Byte 3 - Response Type ..................................................................................... 16

5.1.4 Bytes 4 through 7 - Data ....................................................................................16

ii

P94DVN01A

Contents

5.2 Response Input Assembly ............................................................................................... 16

5.2.1 Byte 0 - Status Byte 1 ........................................................................................ 17

5.2.2 Byte 1 - Data Scale Factor..................................................................................17

5.2.3 Byte 2 - Status Byte 2 ........................................................................................ 17

5.2.4 Byte 3 - Response Type ..................................................................................... 18

5.2.5 Bytes 4 through 7 - Data ....................................................................................18

6 Explicit Messaging .................................................................................................19

6.1 Objects 64h and 65h ......................................................................................................19

6.2 Example Explicit Message...............................................................................................19

7. Reference ..............................................................................................................20

7.1 Reference Documents..................................................................................................... 20

7.2 Common Terms .............................................................................................................. 20

7.3 Parameter Quick Reference ............................................................................................ 21

1P94DVN01A

Safety Information

1. Safety Information

1.1 Warnings, Cautions & Notes

1.1.1 General

Some parts of Lenze controllers (frequency inverters, servo inverters, DC controllers) can be live, with the

potential to cause attached motors to move or rotate. Some surfaces can be hot.

Non-authorized removal of the required cover, inappropriate use, and incorrect installation or operation creates

the risk of severe injury to personnel or damage to equipment.

All operations concerning transport, installation, and commissioning as well as maintenance must be carried

out by qualified, skilled personnel (IEC 364 and CENELEC HD 384 or DIN VDE 0100 and IEC report 664 or DIN

VDE0110 and national regulations for the prevention of accidents must be observed).

According to this basic safety information, qualified skilled personnel are persons who are familiar with the

installation, assembly, commissioning, and operation of the product and who have the qualifications necessary

for their occupation.

1.1.2 Application

Drive controllers are components that are designed for installation in electrical systems or machinery. They

are not to be used as appliances. They are intended exclusively for professional and commercial purposes

according to EN 61000-3-2. The documentation includes information on compliance with the EN 61000-3-2.

When installing the drive controllers in machines, commissioning (i.e. the starting of operation as directed)

is prohibited until it is proven that the machine complies with the regulations of the EC Directive 98/37/EC

(Machinery Directive); EN 60204 must be observed.

Commissioning (i.e. starting of operation as directed) is only allowed when there is compliance with the EMC

Directive (89/336/EEC).

The drive controllers meet the requirements of the Low Voltage Directive 73/23/EEC. The harmonised standards

of the series EN 50178/DIN VDE 0160 apply to the controllers.

The availability of controllers is restricted according to EN 61800-3. These products can cause radio

interference in residential areas.

1.1.3 Installation

Ensure proper handling and avoid excessive mechanical stress. Do not bend any components and do not

change any insulation distances during transport or handling. Do not touch any electronic components and

contacts.

Controllers contain electrostatically sensitive components, that can easily be damaged by inappropriate

handling. Do not damage or destroy any electrical components since this might endanger your health!

When installing the drive ensure optimal airflow by observing all clearance distances in the drive's user manual.

Do not expose the drive to excessive: vibration, temperature, humidity, sunlight, dust, pollutants, corrosive

chemicals or other hazardous environments.

2

P94DVN01A

Safety Information

1.1.4 Electrical Connection

When working on live drive controllers, applicable national regulations for the prevention of accidents (e.g. VBG

4) must be observed. The electrical installation must be carried out according to the appropriate regulations

(e.g. cable cross-sections, fuses, PE connection).

Additional information can be obtained from the national regulatory documentation. In the United States,

electrical installation is regulated by the National Electric Code (nec) and NFPA 70 along with state and local

regulations.

The documentation contains information about installation in compliance with EMC (shielding, grounding, filters

and cables). These notes must also be observed for CE-marked controllers. The manufacturer of the system or

machine is responsible for compliance with the required limit values demanded by EMC legislation.

1.1.5 Operation

Systems including controllers must be equipped with additional monitoring and protection devices according to

the corresponding standards (e.g. technical equipment, regulations for prevention of accidents, etc.). The user

is allowed to adapt the controller to his application as described in the documentation.

DANGER!

After the controller has been disconnected from the supply voltage, do not touch the

live components and power connection, since capacitors could still be charged. Wait

at least 60 seconds before servicing the drive Please observe the corresponding

notes on the controller.

Do not continuously cycle input power to the controller more than once every three

minutes.

Please close all protective covers and doors during operation.

WARNING!

Network control permits automatic operation of the drive. The system design must

incorporate adequate protection to prevent personnel from accessing moving

equipment while power is applied to the drive system.

Table 1: Pictographs used in these instructions:

Pictograph Signal Word Meaning Consequence if Ignored

DANGER! Warning of Hazardous Electrical

Voltage.

Reference to an imminent danger that

may result in death or serious personal

injury if the corresponding measures

are not taken.

WARNING! Impending or possible danger to

personnel

Death or injury

STOP! Possible damage to equipment Damage to drive system or its

surroundings

NOTE Useful tip: If note is observed, it will

make using the drive easier

NOTE:

The complete list of variables can be found in the PositionServo Programming Manual

(PM94M01).

3P94DVN01A

Introduction

2. Introduction

The following information is provided to explain how the PositionServo drive operates on a DeviceNet network;

it is not intended to explain how DeviceNet itself works. Therefore, a working knowledge of DeviceNet is

assumed, as well as familiarity with the operation of the PositionServo drive.

2.1 Fieldbus Overview

The DeviceNet Fieldbus is an internationally accepted communications protocol designed for commercial and

industrial installations of factory automation and motion control applications. High data transfer rates combined

with it’s efficient data formatting, permit the coordination and control of multi-node applications.

2.2 Module Specification

Group 2 Server Device

Supported baudrates: 125kbps, 250kbps, 500kbps

Supported input/output polled data words: Polled, Bit Strobe, COS, Cyclic

Explicit communication for parameter access

2.3 Module Identification Label

Figure 1 illustrates the labelson the DeviceNet communications module. The PositionServo DeviceNet module

is identifiable by:

One label affixed to the side of the module.

The TYPE identifier in the center of the label: E94ZADVN1.

P23 Connector Designation

TYPE: E94ZADVN1

ID-NO: 13127865

SN: 13127865012345678

E94ZADVN1000XX1B11

Made in USA

940/941 DeviceNet

Communication

Option

P23

Figure 1: PositionServo DeviceNet Module Label

•

•

•

•

•

•

•

4

P94DVN01A

Installation

3. Installation

3.1 Mechanical Installation

1. Ensure that for reasons of safety, the AC supply and +24V DC backup supply have been disconnected

before opening the bay cover plate.

2. Remove the two COMM module screws that secure Option Bay 1 and with the aid of a flat head screw

driver, gently pry up the Option Bay 1 cover plate and remove.

3. Install the DeviceNet Module and replace screws as illustrated in Figure 2.

S921a

Figure 2: Installation of DeviceNet Communications Module

3.2 DeviceNet Terminal Block

Table 2 and Figure 3 illustrate the pinout of the PositionServo DeviceNet Module connector. This connector

provides 5-wire connection to the network.

Table 2: DeviceNet Interface Pin Assignments

Terminal Name Wire Color Description

1 V- Black 0V

2 CAN L Blue CAN Bus Low (Negative data line)

3 Shield Bare

4 CAN H White CAN Bus High (Positive data line)

5 V+ Red 11-25VDC power supply; current consumption 100mA @ 11VDC max

12345

Figure 3: DeviceNet Interface Pinout

5P94DVN01A

Installation

3.3 Electrical Installation

3.3.1 Cable Types

Due to the high data rates used on DeviceNet networks, it is paramount that correctly specified cable is used.

The use of low quality cable will result in excess signal attenuation and data loss. Several types of cable are

available for DeviceNet networks: flat cable, thicknet, mid cable and thinnet. Installation is typically done

with thicknet for trunk cable and thinnet for drop cable. Thicknet has a 3” minimum bend radius. Thinnet is

more flexible, with a 2” minimum bend radius, and as such is easier to install. Thinnet can be used for the

entire installation. The type of cable used, the lengths of the overall network and the drop cables all affect the

maximum baud rate.

Cable specifications and approved manufacturers are available from the official DeviceNet website at: http://

www.ovda.org.

3.3.2 Network Limitations

There are several factors that must be taken into consideration when designing a DeviceNet network. For full

details refer to the official “DeviceNet Planning and Installation Manual” available on the http://www.ovda.org

website. However, here is an abbreviated checklist:

DeviceNet networks are limited to a maximum of 64 nodes. Devices default to node 63 so leave node 63

open to avoid duplicate node addresses when adding devices.

Maximum total network length is governed by the data rate and cable type used. Refer to Table 3.

Table 3: Network Length, Drop Cable Length and Baud Rate

Data Rate MAXIMUM Network Length Sum of all Drop Cable Lengths

Flat Cable Thicknet Mid Cable Thinnet

125 kbps 420m 500m 300m 100m 156m

250 kbps 200m 250m 250m 100m 78m

500 kbps 75m 100m 100m 100m 39m

Cumulative drop line does not exceed the network specified limit.

Network drops/spurs must not exceed 6 meters (19’ 8.2”).

Use fiber optic segments to:

Extend networks beyond normal cable limitations

Overcome different ground potential problems

Overcome very high electromagnetic interference

Ground at only one location, prferably in the center of the network.

•

•

•

•

•

•

•

•

•

6

P94DVN01A

Installation

3.3.3 Connections and Shielding

ODVA specifies to ground the DeviceNet network at one location only.

The ground location should be done on the node that is closest to the physical center of the network to

maximize the performance and minimize the effect of outside noise.

The grounding connection method with regards to the network “V-” connections depends upon the cable

type used (see cable data sheet or OVDA “DeviceNet Planning and Installation Manual” for further details.

123 4 5

123 4 5

Connect to

cubical panel/earth

as close to the drive

as possible

Figure 4a: Network Daisy Chain Connection Figure 4b: Ground Connection of Network Center Node

3.3.4 Network Termination

In high speed fieldbus networks such as DeviceNet it is essential to install the specified termination resistors,

i.e. one at both ends of a network segment. Failure to do so will result in signals being reflected back along

the cable which will cause data corruption. The method of termination varies with the type of network cable

available. If terminating using an open-style resistor on the drive connection, use a 120W1/4W 1% resistor

and fit as illustrated in Figure 5.

123 4 5

Figure 5: Network Termination on Drive Connector

•

•

•

7P94DVN01A

Installation

DeviceNet

Master

PositionServo

DeviceNet

Slave

PositionServo

DeviceNet

Slave

+HL

120Ω

120Ω

DeviceNet

Network

DeviceNet

Network

- + HL - +HL -

+-

Power

Supply

Figure 6: DeviceNet Network Wiring

8

P94DVN01A

Commissioning

4. Configuring Drive for DeviceNet Communication

4.1 Connect to the Drive with MotionView OnBoard

With the drive power disconnected, install the DeviceNet module and connect the network cable as instructed

in the preceeding sections. Ensure the drive Run/Enable terminal is disabled then apply the correct voltage to

the drive (refer to drive's user manual for voltage supply details).

Refer to the PositionServo User Manual, section 6.2 for full detail on configuring & connecting a drive via

MotionView OnBoard (MVOB) software. Contained herein is a brief description of launching MVOB and

communicating with the drive.

Open your PC’s web browser. Enter the drive’s default IP address [192.168.124.120] in the browser’s

Address window.

The authentication screen may be displayed if the PC does not have Java RTE version 1.4 or higher. If so,

to remedy this situation, download the latest Java RTE from http://www.java.com.

When MotionView has finished installing, a Java icon entitled [MotionView OnBoard] will appear on your

desktop and the MVOB splash screen is displayed. Click [Run] to enter the MotionView program.

Once MotionView has launched, verify motor is safe to operate, click [YES, I have] then select [Connect]

from the Main toolbar (top left). The Connection dialog box will appear.

Select [Discover] to find the drive(s) on the network available for connection.

[Discover] may fail to find the drive’s IP address on a computer with both a wireless network card and a

wired network card. If this happens, try one of the following remedies:

Disable the wireless network card and then use [Discover].

Type in the drive’s IP address manually at the box [IP Address].

Then click [Connect]

Highlight the drive (or drives) to be connected and click [Connect] in the dialog box.

Figure 7 Connection Box with Discovered Drive

In the lower left of the MotionView display, the Message WIndow will contain the connection status message.

The message “Successfully connected to drive B04402200450_192.168.124.120” indicates that the drive

B04402200450 with IP address 192.168.124.120 is connected.

A connection needs to be setup only once per session or any time the communication settings are changed. If

the work is saved to a project file then the connection does not need to be setup unless different communication

settings are used.

1.

2.

3.

4.

5.

6.

9P94DVN01A

Commissioning

Figure 8: Successfully Connected

4.2 Set up the CAN network

To configure the PositionServo drive for DeviceNet communication, the drive must first be configured for a CAN

network. Several parameters need to be set to enable the PositionServo to operate on a CAN network. These

parameters are listed under the [Communication], [CAN] and [DeviceNet] folders in the MotionView OnBoard

software. Alternatively these parameters can be reached from the drive’s front display and keypad. CAN related

parameters are explained herein:

CAN Control Enabled/Disabled: Use this parameter to enable or disable CAN followed by reboot.

This parameter takes effect after the drive has been re-booted (power cycled).

CAN baud rate 10k- 1000k: Parameter takes effect after drive has been re-booted (power cycled).

Note: DeviceNet baud rate: 125k, 250k or 500k bps only.

CAN address 1-127: sets drive’s CAN ID. This parameter takes effect after the drive has been re-

booted (power cycled). Note: DeviceNet valid addresses = 0-63.

CAN Boot Up Mode Pre-Operational, Operational or Pseudo Master modes are available after power up.

Pre-Operational default mode for CAN Open slave. Drive will await message from master to enter

Operational mode

Operational drive will enter Operational mode immediately after power up without receiving

activation message from master. This feature is useful in a master-less network.

Pseudo Master in this mode drive will send activation message (with specified delay, see below) for

all CAN slaves waiting in Pre-Operational mode. This mode is useful when emulating

master functionality and activating passive slaves. Only one drive can be configured

as the pseudo master and only when there is no other master device.

CAN Boot up delay If drive is configured for Pseudo Master mode it will send activation message with

delay specified in this parameter. Delay is used to allow specified slaves to boot up

and configure their hardware to listen to the Master messages.

•

•

•

•

•

•

•

•

10

P94DVN01A

Commissioning

4.2.1 Enable DeviceNet Communication

Click on the [Communications] folder in the Node Tree and click on the down arrow next [q] to [Fieldbus

Selection]. Select [DeviceNet] from the pull down menu.

Figure 9: Enable DeviceNet Fieldbus Protocol

To activate any changes made the drive has to be reinitialized. Hence the warning within MotionView

Figure 10: REBOOT Message

This can be done by cycling the power to the drive.

4.2.2 Set CAN Parameters

The [CAN] folder contains the configuration parameters for the CAN interface. To change a CAN parameter,

use the pull-down menu to select a pre-defined value or click in the box adjacent to the parameter and enter a

numeric value that is within the parameter’s specified range. Table 4 lists the range and default value for each

CAN parameter.

Table 4: CAN Parameters

Parameter Range Default Value

CAN Baud Rate 10k, 25k, 50k, 125k, 250k, 500k, 800k, 1000k 125k

CAN Address 1 - 127 63

11 P94DVN01A

Commissioning

Figure 11: Set CAN Baud Rate & Address

4.2.3 Set CANOpen Parameters

The [CANOpen] folder contains the configuration parameters for the CANOpen Industrial Protocol. To change a

CANOpen parameter, use the pull-down menu to select a pre-defined value or click in the box adjacent to the

parameter and enter a numeric value that is within the parameter’s specified range. Table 5 lists the range and

default value for each CANOpen parameter.

Table 5: CANOpen Parameters

Parameter Range Default Value

CAN Bootup Mode Pre-operational, Operational, Pseudo master mode Operational

CAN Bootup Delay 0 - 5 seconds 5 sec

CAN Heart Beat Time (0x1017) 0 - 65535 milliseconds 2000 msec

Figure 12: Set CANOpen Parameters

12

P94DVN01A

Commissioning

4.2.4 Set DeviceNet Parameters

The [DeviceNet (CIP)] folder contains the configuration parameters for the DeviceNet Industrial Protocol. To

change a DeviceNet parameter, use the pull-down menu to select a pre-defined value or click in the box

adjacent to the parameter and enter a numeric value that is within the parameter’s specified range. Table 6

lists the range and default value for each DeviceNet parameter.

Table 6: DeviceNet (CIP) Parameters

Parameter Range Default Value

DeviceNet Poll I/O Scaling** 100, 101, 102, 103, 104101= 10

Figure 13: Set DeviceNet I/OScaling

4.3 Configuration Parameters

All standard CAN parameters are reused by DeviceNet.

To enable DeviceNet functionality, set variable 238 (VAR_CAN_ENABLE_EPM) = 3.

Variable 276 (DNET_SCALE_POLL_IO ) is a new parameter that determines the scale factor for the data of the

Polled I/O messages. (Refer to section 5). Variable 276 can be set from 0-4 and the default value is 1. Variable

276 is accessible through the MotionView program.

All Polled I/O messages have Integer 32 bit data values that are scaled by the value of the 10^DNET_SCALE_

POLL_IO.

Example:

For DNET_SCALE_POLL_IO = 1.

A. If the value of 14.7 needs to be sent, then it must send the integer value of 14.7 * (10^DNET_SCALE_POLL_

IO) = 147

B. If the received value is 156, then it must be divided by (10^DNET_SCALE_POLL_IO) to find the real value.

Actual Value = 156 / (10^DNET_SCALE_POLL_IO) = 15.6

13 P94DVN01A

Commissioning

4.4 Drive-Specific Error Codes

The description of the standard PositionServo Fault Codes can be found in the drive’s user manual (S94PM01).

The DFAULT parameter (PID 9) indicates the last drive fault. In addition, a new error code (43) is introduced to

indicate a problem in the DeviceNet Polled I/O message format.

Refer to section 5.2.4. The polled I/O response type 0x14 is used for error response.

14

P94DVN01A

Cyclic Data Access

5. Polled I/O

“OUT data and “IN data” describe the direction of data transfer as seen by the DeviceNet master controller.

For polled I/O messaging, there are two assemblies: the Command (Output) Assembly - Instance 1, and the

Response (Input) Assembly - Instance 2.

The poll operation works as follows:

The DeviceNet Master (PLC) sends an I/O Command Poll Assembly initialized with the desired command

and the desired response types.

The DeviceNet Slave (PositionServo drive) receives the Command I/O Poll Assembly.

The PositionServo Drive executes the command specified in the Command assembly.

The PositionServo Drive replies by sending the requested Response Assembly.

NOTE:

All Polled I/O messages have Integer 32 bit data values scaled by the value of the 10^DNET_

SCALE_POLL_IO.

NOTE:

The Enable bit takes precedence over the rest of the command bits and the command type.

If the drive is disabled (Enable bit = 0) no motion command can be executed and the move

command will be ignored. The response assembly will be issued as requested.

5.1 Command Output Assembly

Table 7 lists the bit assignments of the Polled I/O Command also known as the Output Assembly. Byte 0 is the

Control Byte, Byte 1 is not used, Byte 2 is the Command Type, Byte 3 is the Response Type and Bytes 4 through

7 contain the actual command data.

Table 7: Output Assembly

Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

0 Enable Reg Arm Hard Stop Smooth Stop NA Relative NA Start Motion

1 NA

2 Command Axis = 001 Command Assembly Type

3 Response Axis = 001 Response Assembly Type

4 Data Low Byte

5 Data Low Middle Byte

6 Data High Middle Byte

7 Data High Byte

1.

2.

3.

4.

15 P94DVN01A

Cyclic Data Access

5.1.1 Byte 0 – Control Word

Table 8: Ouput Assembly - Control Word

Bit Name Description Note

7 Enable 0 – disable drive

1 – enable drive

This bit controls PID 52

The Enable bit takes precedence over the

rest of the command bits and the command

type. If the drive is disabled (Enable bit =

0) no motion command can be executed

and the move command will be ignored.

The response assembly will be issued as

requested.

6 Reg Arm The change from 0 to 1 arms the registration input C1 It is equivalent to the REGISTRATION ON

language statement. (Internally this is the

RegistrationOn function).

5 Hard Stop 1 – The drive stops the motion quickly

using the QDECEL and QACCEL values.

This bit controls PID 136 and sets it to 2

4 Smooth Stop 1 – The drive stops motion

using the normal DECEL and ACCEL values.

This bit controls PID 136 and sets it to 1

3 NA 0 – default setting (bit not used)

2 Relative 1 – Relative motion will be executed.

0 – Absolute motion will be executed

1 NA (0) 0 – default setting (bit not used)

0 Start Motion Change from 0 to 1 starts a motion command equivalent to the

MOVED or MOVEP language commands

This bit in combination with the Relative bit

controls PID’s 92 and 93.

5.1.2 Byte 2 - Command Type

Command Axis (bits 7 to 5)

The values of these bits should always be 001 since the PositionServo has only 1 axis per drive.

Command Assembly Type

The Command Assembly Type ranges from 0x0 to 0x9 as listed in Table 9.

Table 9: Command Assembly Type

Type Command Description Note

0x0 NOP

0x1 Start Trapezoidal Move Initiates trapezoidal motion Should be used together with the Start Motion

and Relative control bits

0x2 Set Target Reference Sets the target reference PID 139 (IREF) Target reference in RPS for velocity mode and

in phase Amps (RMS) for current mode.

0x3 Set Acceleration Sets the acceleration PID 181 (ACCEL)

0x4 Set Deceleration Sets the deceleration PID 182 (DECEL)

0x5 Set Maximum Velocity Sets the maximum profile velocity PID 180 (MAXVEL)

0x6 Set Quick Deceleration Sets the quick deceleration PID 183 (QDECEL)

0x7 Set Velocity Profile Sets the velocity for profiled velocity mode PID 185 (VEL) Profiled velocity is the special operation of

Position mode. To set profiled velocity mode

set PID 138 to 1. To return back to normal

positioning mode set PID 138 to 0.

0x8 Start S-curved Move Initiates S-curve motion Should be used together with the Start Motion

and Relative control bits

0x9 Set User Variable V0 Sets PID 100 (V0)

16

P94DVN01A

Cyclic Data Access

5.1.3 Byte 3 - Response Type

Response Axis (bits 7 to 5)

The values of these bits should always be 001 since the PositionServo has only 1 axis per drive.

Response Assembly Type (bits 4 to 0)

This field specifies the type of the response assembly that this command requests. For list of all available

response assembly types refer to section 5.2.

5.1.4 Bytes 4 through 7 - Data

These 4 bytes contain the actual command data in little endian format. For the receiving node to reconstruct

the 32-bit data value as it was originally transmitted, parameters are transmitted in four 8-bit bytes in the order

of the lowest byte first and the highest byte last. Said another way, in little endian format, the least significant

byte is stored at the lowest address.

Endian Format 16-bit Value 32-bit Value

Byte Order Word Order Byte Order

Little Low byte first

High byte second

Low word first

High word second

Low byte first

Mid low byte second

Mid high byte third

High byte fourth

5.2 Response Input Assembly

Table 10 lists the Polled I/O Response also known as the Input Assembly.

Table 10: Input Assembly

Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

0 Enable State Reg Level Home Level NA (0) General Fault In Position NA (0) In Motion

1 Data Scale Factor

2 NA (1) NA (0) NA (0) NA (0) NA (0) Negative

HW Limit

Positive

HW Limit

NA (0)

3 Response Axis = 001 Response Assembly Type

4 Data Low Byte

5 Data Low Middle Byte

6 Data High Middle Byte

7 Data High Byte

Table of contents

Other AC Tech Control Unit manuals

Popular Control Unit manuals by other brands

Deif

Deif GCU 100 installation instructions

Asco

Asco 8210 series Installation & maintenance instructions

EVERSPRING

EVERSPRING AD132-1 manual

Cervis

Cervis MRF450 user manual

Vixen

Vixen Polar Fine Adjustment Unit DX instruction manual

Motorline professional

Motorline professional MC61SE installer and user manual

Fuji Electric

Fuji Electric P633A Series Mounting instruction

Sony

Sony BKS-R3219 Operation manual

Continental Hydraulics

Continental Hydraulics VSD08M Service manual

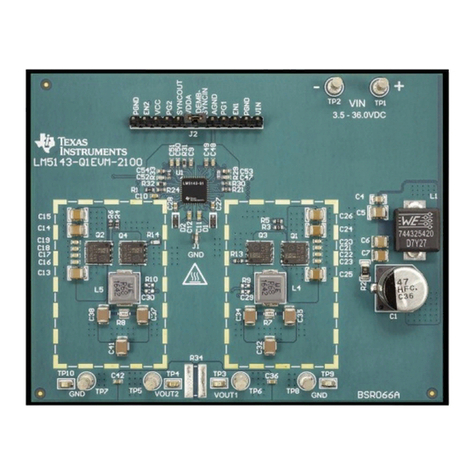

Texas Instruments

Texas Instruments LM5143-Q1 user guide

Tecnoma

Tecnoma Novatec Isobus Operating handbook

National Instruments

National Instruments 9759 user manual