AC Tech Lenze RS-485 User manual

CMVMB401B

SMVector

RS-485 Modbus Communication Module

Communications Interface Reference Guide

This documentation applies to the RS-485 / Modbus communications option for the

SMVector inverter and should be used in conjunction with the SMVector Operating

Instructions (Document SV01) that shipped with the drive. These documents should be

read carefully as they contain important technical data and describe the installation and

operation of the drive and this option.

WARNING!

The information in this document is based on RS-485 Modbus Communication Module

software version 1.01. If a future revision of software contains differences in the

register numbering or register definitions, drive operation could be seriously affected.

If drive parameter P494 does not display 1.01, then writing to any drive register over

the Modbus® network MUST NOT BE ATTEMPTED as it would have the potential

for unexpected consequences potentially resulting in damage to the equipment or

harm to personnel. Future releases of module software require that the appropriate

documentation be used for implementation.

© 2007 AC Technology Corporation

No part of this documentation may be copied or made available to third parties without the

explicit written approval of AC Technology Corporation.

All information given in this documentation has been carefully selected and tested for

compliance with the hardware and software described. Nevertheless, discrepancies

cannot be ruled out. We do not accept any responsibility nor liability for damages that may

occur. Any necessary corrections will be implemented in subsequent editions.

About these instructions

1

ENGLISH

Contents

1 Safety information ................................................................2

2 Introduction ..........................................................................4

2.1 Overview ...................................................................................................4

2.2 SMVector Modbus RTU Implementation Specifications ...........................4

3 Installation ............................................................................5

3.1 Installing the Module into the Terminal Cover ..........................................5

3.2 RS-485 / Modbus RTU terminal block ......................................................5

3.3 Installing the Terminal Cover ....................................................................6

4 Extended Parameters for RS-485/Modbus RTU ................7

4.1 Parameter Menu .......................................................................................7

5 Modbus Protocol Details .....................................................9

5.1 Data Transmission ....................................................................................9

5.2 Register Numbering ..................................................................................9

5.3 Modbus Function Codes Supported ........................................................9

6 Modbus Message Details ...................................................10

6.1 Register Reading ....................................................................................11

6.2 Register Writing ......................................................................................12

6.3 No Response Conditions ........................................................................13

6.4 Exception Responses .............................................................................13

7 Commissioning ..................................................................14

7.1 Drive Monitoring ......................................................................................14

7.2 Drive Programming and Control .............................................................14

7.3 Unlocking & Locking of Drive Controls and Parameters ........................14

7.4 Network Watchdog Timer .......................................................................15

7.5 Watchdog Timer Controls .......................................................................15

8 Typical Network Applications ...........................................16

8.1 Controlling the Drive (e.g. starting the drive) ..........................................16

8.2 Changing Drive Parameters ...................................................................16

8.3 Controlling the Drive Frequency, PID or Torque Setpoint ......................16

9 Drive Registers ...................................................................17

9.1 Data Internal vs. Display Representation ...............................................17

9.2 Configuration and Control Registers ......................................................17

10 Programming Parameters .................................................25

10.1 Negative Number Transmission .............................................................25

10.2 Terminal and Protection Status (P530) ...................................................25

10.3 Keypad Status (P531) .............................................................................26

11 Troubleshooting and Fault Elimination ............................27

11.1 Faults ......................................................................................................27

11.2 Troubleshooting ......................................................................................27

2ENGLISH

Safety information

1 Safety information

General

Some parts of Lenze controllers (frequency inverters, servo inverters, DC controllers) can be live,

moving and rotating. Some surfaces can be hot.

Non-authorized removal of the required cover, inappropriate use, and incorrect installation or operation

creates the risk of severe injury to personnel or damage to equipment.

All operations concerning transport, installation, and commissioning as well as maintenance must

be carried out by qualified, skilled personnel (IEC 364 and CENELEC HD 384 or DIN VDE 0100 and

IEC report 664 or DIN VDE0110 and national regulations for the prevention of accidents must be

observed).

According to this basic safety information, qualified skilled personnel are persons who are familiar with

the installation, assembly, commissioning, and operation of the product and who have the qualifications

necessary for their occupation.

Application as directed

Drive controllers are components which are designed for installation in electrical systems or machinery.

They are not to be used as appliances. They are intended exclusively for professional and commercial

purposes according to EN 61000-3-2. The documentation includes information on compliance with

the EN 61000-3-2.

When installing the drive controllers in machines, commissioning (i.e. the starting of operation as

directed) is prohibited until it is proven that the machine complies with the regulations of the EC Directive

98/37/EC (Machinery Directive); EN 60204 must be observed.

Commissioning (i.e. starting of operation as directed) is only allowed when there is compliance with

the EMC Directive (89/336/EEC).

The drive controllers meet the requirements of the Low Voltage Directive 73/23/EEC. The harmonised

standards of the series EN 50178/DIN VDE 0160 apply to the controllers.

The availability of controllers is restricted according to EN 61800-3. These products can cause

radio interference in residential areas. In this case, special measures can be necessary.

Installation

Ensure proper handling and avoid excessive mechanical stress. Do not bend any components and

do not change any insulation distances during transport or handling. Do not touch any electronic

components and contacts.

Controllers contain electrostatically sensitive components, which can easily be damaged by inappropriate

handling. Do not damage or destroy any electrical components since this might endanger your

health!

Electrical connection

When working on live drive controllers, applicable national regulations for the prevention of accidents

(e.g. VBG 4) must be observed.

The electrical installation must be carried out according to the appropriate regulations (e.g. cable cross-

sections, fuses, PE connection). Additional information can be obtained from the documentation.

The documentation contains information about installation in compliance with EMC (shielding, grounding,

filters and cables). These notes must also be observed for CE-marked controllers.

The manufacturer of the system or machine is responsible for compliance with the required limit values

demanded by EMC legislation.

Operation

Systems including controllers must be equipped with additional monitoring and protection devices

according to the corresponding standards (e.g. technical equipment, regulations for prevention

of accidents, etc.). You are allowed to adapt the controller to your application as described in the

documentation.

3

ENGLISH

Safety information

DANGER!

• After the controller has been disconnected from the supply voltage, live components

and power connection must not be touched immediately, since capacitors could be

charged. Please observe the corresponding notes on the controller.

• Do not continuously cycle input power to the controller more than once every three

minutes.

• Please close all protective covers and doors during operation.

WARNING!

Network control permits automatic operation of the inverter drive. The system design

must incorporate adequate protection to prevent personnel from accessing moving

equipment while power is applied to the drive system.

Pictographs used in these instructions

Pictograph Signal word Meaning Consequences if ignored

DANGER! Warning of Hazardous

Electrical Voltage.

Reference to an imminent

danger that may result in death

or serious personal injury if the

corresponding measures are not

taken.

WARNING! Impending or possible danger

for persons Death or injury

STOP! Possible damage to equipment Damage to drive system or its

surroundings

Note Useful tip: If observed, it will

make using the drive easier

4ENGLISH

Introduction

2 Introduction

This reference guide assumes that the reader has a working knowledge of the Modbus

RTU Protocol and familiarity with the programming and operation of motion control

equipment. This guide is intended as a reference only.

2.1 Overview

Modbus is an internationally accepted asynchronous serial protocol designed for

commercial and industrial automation applications. The Modbus RTU architecture is

based upon a PLC to device communication structure and, as such is Master-Slave

in orientation. The SMV drive, in this case, always acts as the slave in this network,

responding to commands and requests from the Master.

While the Modbus RTU protocol does not specify the physical layer, the ESVZAR0

module uses the RS-485 physical interface which is quite common and well suited for the

industrial environment. The ESVZAR0 module provides both galvanic and optical isolation

of this physical interface.

2.2 SMVector Modbus RTU Implementation Specifications

Typical communications between master and slave would be:

• Write commands from Master

- Run command

- Frequency Reference

- Modification of Drive operating parameters

• Requests from Master

- Reporting of drive status

- Fault status (and fault history)

The SMVector drive most nearly conforms to the Modicon® Micro 84 in capabilities. This

may be of importance when configuring networks for DDE Servers.

The following table identifies the Modbus serial communication specifications. If

the specification is fixed (non-adjustable) the value is shown under “Range”, if the

specification is selectable, the table identifies the Parameter and available range of

selections.

Description Type Range

Baud Rate Selectable P411 (2400, 4800, 9600, 19200, 38400, 57600, or 115200 bps)

Data Bits Fixed 8

Parity / Stop Bits Selectable P412 (None/1, None/2, Even/1, Odd/1)

Network Address Selectable P410 (1 - 247)

5

ENGLISH

Installation

3 Installation

3.1 Installing the Module into the Terminal Cover

7mm

<_ 2.8 mm²

(12-22 AWG)

0.5 Nm/ 4.5 lb-in

12345

3.2 RS-485 / Modbus RTU terminal block

Terminal Description Important

1 Earth ground / shield

For reliable communication make sure terminal

is connected to the Modbus network

GND/common. If only two wires are used (TXA

and TXB) in the network, connect Terminal 1 to

chassis/earth ground.

2 TXA

If controller is located at either end of the network,

a terminating resistor (120ohm typical) should be

connected across TXA and TXB

3

4 TXB

5

Protection against contact

• All terminals have basic isolation (single insulating distance)

• Protection against contact can only be ensured by additional measures (i.e. double insulation)

6ENGLISH

Installation

3.3 Installing the Terminal Cover

7

ENGLISH

Commissioning

4 Extended Parameters for RS-485/Modbus RTU

In addition to the drive parameters that are detailed in the Installation and Operation

manual, the installation of the RS485/Modbus RTU module will give access to the 400

series parameters that are exclusive to this communication module.

4.1 Parameter Menu

Code Possible Settings IMPORTANT

No. Name Default Selection

RS485/Modbus: Modbus Module Specific parameters

p400 Network Protocol 0 Not Active

1 Remote Keypad

2 Modbus RTU

P401 Module Revision 01.0.0 Display reads 01.x.x where:

01 = RS485/Modbus Module

x.x = Module Revision

Read only

P402 Module Status 0 0 Not Initialized

Read only

Online state “3” indicates that the

communications between the drive and

module are working properly.

1 Initialization: Module to EPM

2 Initialization: EPM to Module

3 Online

4 Failed Initialization Error

5 Time-out Error

6 Initialization Failed Module type mismatch (P401)

7 Initialization Error Protocol Selection mismatch (P400)

P403 Module Reset 0 0 No Action

1 Reset Module parameter values

to default.

Returns module parameters 401…499 to

the default values shown in this manual.

P404 Module Time-out

Action

3 0 Ignore • Action to be taken in the event of a

Module/Drive Time-out.

• Time-out is fixed at 200ms.

• Selection 1 (STOP) is by the method

selected in P111.

1 STOP (see P111)

2 Quick Stop

3 Fault (f.ntf)

P405 Network Fault 0 0 No Fault

Read only, see P425 and P426

1 Network Time-out, F.nF1

P406 Proprietary Manufacturer specific Read only

8ENGLISH

Commissioning

Code Possible Settings IMPORTANT

No. Name Default Selection

RS485/Modbus: System bus parameters

P410 Network address 1 1 247 The Drive does not support the Modbus

“broadcast” function.

P411 Network

Baud Rate

2 0 2400 bps

1 4800 bps

2 9600 bps

3 19200 bps

4 38400 bps

5 57600 bps

6 115200 bps

P412 Network Data

Format

0 0 8 Data bits, No Parity, 2 stop bits

1 8 Data bits, No Parity, 1 stop bit

2 8 Data bits, Even Parity, 1 stop bit

3 8 Data bits, Odd Parity, 1 stop bit

P425 Network Message

time-out

10.0 0.0 {s} 300.0

P426 Network Message

time-out action

4 0 Not active

1 STOP (see P111)

2 Quick stop

3 Inhibit

4 Trip fault, F.nF1

P427 Valid Network

messages

Received

0 0 {messages} 9999 • Read-only

• When number of messages exceed

9999, counter resets to 0 and continues.

RS485/Modbus: Module Specific parameters

P494 Communication

Module software

version

• Read only

• Format: x.yz

P495 Internal Code • Read only

• Alternating Display: xxx-; -yy

P498 Missed Messages

Drive to Module

• Read only

P499 Missed Messages

Module to Drive

• Read only

9

ENGLISH

Commissioning

5 Modbus Protocol Details

5.1 Data Transmission

This drive uses the RTU (Remote Terminal Unit) transmission mode of the Modbus

Protocol and operates as a Slave device on the network. All devices communicating with

the drive(s) must be a Modbus Master.

5.2 Register Numbering

Modbus 3X and 4X register numbers are always one greater than the actual drive

register numbers. For example: drive register #24 would correspond to Modbus 3X / 4X

register #25.

All the register numbers referred to in this document are drive register numbers.

5.3 Modbus Function Codes Supported

Function codes supported by the drive are:

The function codes supported by the drive are:

03 - Read Holding Register (4X references)

04 - Read Input Register (3X references)

Note

We do not differentiate between 4X and 3X references. Therefore, function codes 03

and 04 are treated identically.

Typically only one register (or one word of data) can be read at a time.

Exceptions to this rule are:

• Register #24 (Command Frequency) can be read as a single register or as a group

of 6 drive status registers (#24-29).

• Register #32 (low word of Total kWh) can be read as a single register or as a group

of 2 registers (#32-33).

• Register #60 (low word of Total Runtime Hours) can be read as a single register or

as a group of 2 registers (#60-61).

• Register #64 (low word of Total Power On Hours) can be read as a single register or

as a group of 2 registers (#64-65).

10 ENGLISH

Commissioning

In some instances, multiple words can be read for a single register. When this is done for

the registers below, the response from the drive will be for the number of words, rather

than the number of registers, requested:

• Register #500 (Fault History) can be read as 1 word (returning the two most recent

faults) or as 4 words (returning the entire fault history).

• Register #511 (Total kWh) can be read as 1 word (returning only the low word of the

32-bit register value) or as 2 words (returning the complete 32-bit register value).

• Register #540 (Total Runtime Hours) can be read as 1 word (returning only the low

word of the 32-bit register value) or as 2 words (returning the complete 32-bit register

value).

• Register #541 (Total Power On Hours) can be read as 1 word (returning only the low

word of the 32-bit register value) or as 2 words (returning the complete 32-bit register

value).

06 - Preset Single Register (4X references)

Write a single register.

16 - Preset Multiple Registers (4X references)

While code 16 is supported it’s implementation is limited to addressing only one register

per write.

6 Modbus Message Details

The following abbreviations will be used throughout this section when illustrating the

message structure:

R Read

W Write

RS Response

SA Slave Address (01 ... F7 hex)

EC Exception Code

RH Register Address (high byte)

RL Register Address (low byte)

DxH Data (high byte)

DxL Data (low byte)

CRCH CRC (high byte)

CRCL CRC (low byte)

11

ENGLISH

Commissioning

6.1 Register Reading

6.1.1 Message structure for reading one 16-bit register

All registers except #1

RSA 03 RH RL 00 01 CRCH CRCL

RS SA 03 02 DH DL CRCH CRCL

6.1.2 Message structure for reading two 16-bit registers

Registers 32, 60 and 64 only

RSA 03 RH RL 00 02 CRCH CRCL

RS SA 03 04 D1H D1L D2H D2L CRCH CRCL

D1H and D1L are the high and low bytes of the first 16-bit register value

(32, 60, 64)

D2H and D2L are the high and low bytes of the second 16-bit register value

(33, 61, 65)

Example:

Total Run-time Hours = 305419896 (12345678h)

Register #60 (low word of total run-time hours) = 5678h

Register #61 (high word of total run-time hours) = 1234h

RSA 03 00 3C 00 02 CRCH CRCL

RS SA 03 04 56 78 12 34 CRCH CRCL

6.1.3 Message structure for reading one 32-bit register

Registers 511, 540 and 541 only

RSA 03 RH RL 00 02 CRCH CRCL

RS SA 03 04 DHH DHL DLH DLL CRCH CRCL

DHH and DHL are the high and low bytes of the high word (i.e. the first 16 bits)

of the 32-bit register value

DLH and DLL are the high and low bytes of the low word (i.e. the last 16 bits) of

the 32-bit register value

Example:

Total Run-time Hours (Register #540) = 305419896 (12345678h)

RSA 03 01 FF 00 02 CRCH CRCL

RS SA 03 04 12 34 56 78 CRCH CRCL

12 ENGLISH

Commissioning

6.1.4 Message structure for reading one 4 word register

Register 500 only

RSA 03 01 F4 00 04 CRCH CRCL

RS SA 08 D1 D2 D3 D4 D5 D6 D7 D8 CRCH CRCL

D1 holds the value of Fault 1 (the most recent fault in the fault history)

D2 holds the value of Fault 2 in the fault history

…

D8 holds Fault 8 (the oldest fault in the fault history).

6.1.5 Message structure for reading six 16-bit registers

Register 24 only

RSA 03 00 18 00 06 CRCH CRCL

RS SA 0C D1H D1L D2H D2L D3H D3L

D4H D4L D5H D5L D6H D6L CRCH CRCL

Command Frequency D1H D1L Register #24 (DH DL)

Actual Frequency D2H D2L Register #25 (DH DL)

Load D3H Register #26 (DH)

Operation Status D3L Register #26 (DL)

Rotational Direction D4H Register #27 (DH)

Control Mode D4L Register #27 (DL)

Speed Command Source D5H Register #28 (DH)

Auto/Manual Status D5L Register #28 (DL)

Present Fault D6H Register #29 (DH)

Command Rotation D6L Register #29 (DL)

6.2 Register Writing

6.2.1 Message structure for reading one word

All writable registers

WSA 06 RH RL DH DL CRCH CRCL

RS SA 06 RH RL DH DL CRCH CRCL

13

ENGLISH

Commissioning

6.3 No Response Conditions

The drive will not respond to any message that…

• contains one or more parity errors

• has an invalid CRC value

• was not directed to the drive’s network address.

This drive does not support the broadcast function of the Modbus protocol.

• is not at least 8 bytes long (minimum required for the supported functions)

• is more than 18 bytes long (maximum allowed before input buffer overflow occurs)

6.4 Exception Responses

If a valid message is received (i.e. parity, crc, address and message length all pass

validity checks), but the message contents are somehow invalid, the drive will respond

with a Modbus exception.

6.4.1 Message structure for an exception response to a read request (03)

WSA 83 EC CRCH CRCL

6.4.2 Message structure for an exception response to a write request (06)

WSA 86 EC CRCH CRCL

6.4.3 Exception Codes (EC):

EC Description

01 Command rejected; Illegal function

02 Invalid register number

03 Data value is out-of-range

04 Wrong data format

06 Slave device (drive) busy

14 ENGLISH

Commissioning

7 Commissioning

7.1 Drive Monitoring

The network can always read drive parameters as long as the Modbus communications

are enabled (i.e. P400 = 2) and configured properly (see P410-412).

7.2 Drive Programming and Control

Network Control must be enabled for the network to program drive parameters or take

control of an actual drive. This is done by …

1) Setting P121…P123 equal to 09 (NET ENABLE) and asserting the corresponding

TB-13x terminal

2) Setting P100 to 00, 01, 03 or 04. Network control cannot be enabled when P100 is

set to 02 (REMOTE KEYPAD ONLY) or 05 (TERMINAL STRIP/REMOTE KEYPAD).

Once network control is enabled, the drive must unlock controls and/or parameters in

order to write to any of the drive registers.

7.3 Unlocking & Locking of Drive Controls and Parameters

Writing to Register #48 (Unlock Controls) with a value of 0 will unlock write access to the

Drive Control register (#1) only. Write commands to any other drive registers will not be

allowed.

Writing to Register #48 (Unlock Controls) with a value equal to the drive’s programming

password (P194) will unlock the Drive Control register (#1) and all other writable drive

registers. This enables the writing of any drive register that is not designated as read-

only.

Note

The factory default password is 225

Writing to Register #49 (Unlock Parameters) with a value equal to the drive’s

programming password (P194) will unlock all writable drive registers EXCEPT for the

Drive Control register (#1). This enables the writing of any drive register that is not

designated as read-only, except for Register #1.

Once write access to the drive registers has been unlocked, it will remain unlocked until

any of the following conditions occur …

• Register #1 (Drive Control) is written with bit 1 (Lock Security) set

• A network watchdog time-out occurs (see Sections 7.4 and 7.5)

• The TB-13x terminal assigned to NETWORK ENABLE is de-asserted or is assigned

to a function other than NETWORK ENABLE.

Writing to Register #1 (Drive Control) with bit 1 (Lock Security) set will lock both Drive

Controls and Parameters, disabling the watchdog timer and preventing any further writing

to drive registers (other than #48 and #49).

15

ENGLISH

Commissioning

When the Lock Security (bit 1) is set, the drive drops out of NETWORK control and

switches to the normal source of control. If P100 = 3 (NETWORK ONLY) and the drive is

running, the drive will also be stopped (according to P111).

Drive parameters and status registers can always be read, even when P100=2,5 and/or

drive control and parameters are locked.

Stop commands (STOP, QUICK STOP, INHIBIT) will always be accepted, even when

network control is not enabled or drive controls are locked.

7.4 Network Watchdog Timer

The drive is equipped with a network communications watchdog timer. If the Modbus

Master wishes to control the drive (start, forward, reverse, etc.) it must first Unlock

Controls (see Section 7.3). If the watchdog timer is enabled (i.e. P426 is not set

to IGNORE) and drive controls have been unlocked, the Master must periodically

communicate with the drive or a watchdog time-out will occur. The watchdog timer does

not operate unless Controls have been UNLOCKED via Register #48 and a time-out

action (other than IGNORE) has been specified using parameter P426.

7.5 Watchdog Timer Controls

7.5.1 Watchdog Time-out Period (P425)

The maximum amount of time that should be allowed to pass between network messages

to a specific drive will vary from one network to the next. Therefore, we have made the

watchdog time-out period user settable via Drive Programming Parameter P425 (see 4.1

for details).

7.5.2 Watchdog Time-out Action (P426)

The appropriate action to be taken when a watchdog time-out occurs will also vary from

one application to the next. Therefore, we have provided five user selectable time-out

actions which can be set via Drive Programming Parameter P426 (see 4.1 for details).

If the Watchdog Timer has been disabled (i.e. P426 is set to IGNORE), Controls and/or

Parameters must still be unlocked in order to gain write access to the drive control and/or

program parameter registers. However, there are no longer any constraints on how often

the Master must communicate with the drive.

16 ENGLISH

Commissioning

8 Typical Network Applications

8.1 Controlling the Drive (e.g. starting the drive)

The following is the sequence of events for starting the drive via the network:

1) Unlock the Drive Control register (#1) by writing a 0 (or the drive password) to

Register #48.

2) Control drive operation with various commands to Register #1 (Start, Stop, Forward,

Reverse, etc.). To start the drive, a value of 0x0008 should be sent to Register #1.

3) If the watchdog timer is enabled, keep it from timing out by assuring that a read

command (to any register) is performed within the time specified by P426.

4) Lock Control when drive operations are complete by writing a 0x0002 (i.e. setting the

Lock Security bit) to Register #1.

Note

If P100 = 3 (NETWORK ONLY) and the drive is still running when the Lock

Security bit is set, it will be brought to a stop by the method specified in Drive

Programming Parameter P111 (STOP).

5) The drive will return to its normal control mode.

8.2 Changing Drive Parameters

The following is the sequence of events for changing drive parameters:

1) Unlock write access to the drive parameters by writing the drive password (P194) to

Register #49. The drive will remain in its normal control mode.

2) Write to all necessary drive configuration or parameters registers.

3) The watchdog timer is not enabled when only the parameters have been unlocked

so there is no need to send repeated read commands to prevent it from timing out.

4) Lock Control when drive operations are complete by writing a 0x0002 (i.e. setting the

Lock Security bit) to Register #1.

8.3 Controlling the Drive Frequency, PID or Torque Setpoint

The following is the sequence of events for changing the drive frequency, PID or torque

setpoint:

1) Configure the setpoint reference for NETWORK.

The network can be set as the frequency, PID or torque setpoint reference in any of

the following ways:

a) Set P101 (Standard Reference Source) to NETWORK (06) and make sure that

no AUTO source has been selected.

b) Set P121…P123 to AUTO: NETWORK (07) and assert the corresponding TB-

13x terminal.

c) Unlock drive controls and write a value of 0xC000 to Register #1 (see Section

9.2.1).

2) Unlock parameters by writing the drive password (P194) to Register #49. The drive

will remain in its normal control mode. The watchdog timer is not enabled when

only parameters have been unlocked so there is no need to send repeated read

commands to prevent it from timing out.

17

ENGLISH

Commissioning

3) Modify the appropriate NETWORK setpoint register.

Register #44 - Network Speed Command

Register #45 - Network PID Setpoint Command

Register #46 - Network Torque Command

4) Lock Control when drive operations are complete by writing a 0x0002 (i.e. setting the

Lock Security bit) to Register #1.

9 Drive Registers

9.1 Data Internal vs. Display Representation

Register data passed across the Modbus communications link is always in INTERNAL

units, although the drive itself may show the information in some alternate DISPLAY units.

For register values with 1 or more decimal places, the actual value sent over the Modbus

communications will be the value times 10DP, where DP is the number of decimal places.

Example

An actual frequency of 34.3Hz would be sent over the network as 343 (34.3*101).

If the drive is setup to display the actual frequency in RPM using P178 = 29.17, the

actual speed would be displayed on the drive as 1000 (RPM) but would still be sent

over the Modbus communications as 343 (or 01 57 hex).

9.2 Configuration and Control Registers

Registers #1 through #99 are reserved for configuration and control over the network and

cannot be accessed via the drive’s local keypad.

Reg # Register Name Default Range of Adjustment Important

1 Drive Control (write only) See Sections 8.1 and 9.2.1

19 Drive Family Read only, drive family is 72

21 Drive Size Read only. See section 9.2.2

23 Drive Status Read only. See section 9.2.3

24 Command Frequency 0.0 Hz 0.0 … 500.0 Read only.

25 Actual Frequency 0.0 Hz 0.0 … 500.0 Read only.

26 Load (DH)

Run Status (DL) Read only. See section 9.2.4

27 Actual Direction (DH)

Control Mode (DL) Read only. See section 9.2.5

28 Speed Source (DH)

Auto/Manual (DL) Read only. See section 9.2.6

29 Present Fault (DH)

Commanded Direction (DL) Read only. See section 9.2.7

30 Motor Voltage Read only. See P506 in drive manual

18 ENGLISH

Commissioning

Reg # Register Name Default Range of Adjustment Important

32 Total kWh (low word)

Read only. See P511 in drive manual

33 Total kWh (high word)

37 Actual PID setpoint 0.0 -999.0 … 3100.0 Read only. See section 9.2.8

38 PID Setpoint Command 0.0 -999.0 … 3100.0 Read only. See section 9.2.8

39 PID Feedback 0.0 -999.0 … 3100.0 Read only. See section 9.2.8

40 Keypad Speed Command 20.0 Hz P102 … P103

41 Keypad PID Setpoint Command 0.0 -999.0 … 3100.0 Read only. See section 9.2.8

42 Keypad Torque Command 100% 0.0 … 400.0

44 Network Speed Command 0.0 Hz P102 … P103 See Section 8.3

45 Network PID Setpoint Command 0.0 -999.0 … 3100.0 Read-only See Sections 8.3 and 9.2.8

46 Network Torque Command 0% 0.0 … 400.0 See Sections 8.3

48 Unlock Controls See Sections 7.3

49 Unlock Parameters See Sections 7.3

50 Parameter Version Read only. See section 9.2.9

60 Total Run Time hours (low word)

Read only. See P540 in drive manual

61 Total Run Time hours (high word)

64 Total Power-on Hours (low word)

Read only. See P541 in drive manual

65 Total Power-on Hours (high word)

70 Network Controlled Digital Output

(TB14) + Relay

0: de-energized, 1: energized

bit 9: TB-14 state

bit 10: Relay state

other bits are not used

See section 9.2.10

71 Network Controlled Analog Output 0.0% 0.0 … 100.0 See section 9.2.11

Table of contents

Other AC Tech Control Unit manuals

Popular Control Unit manuals by other brands

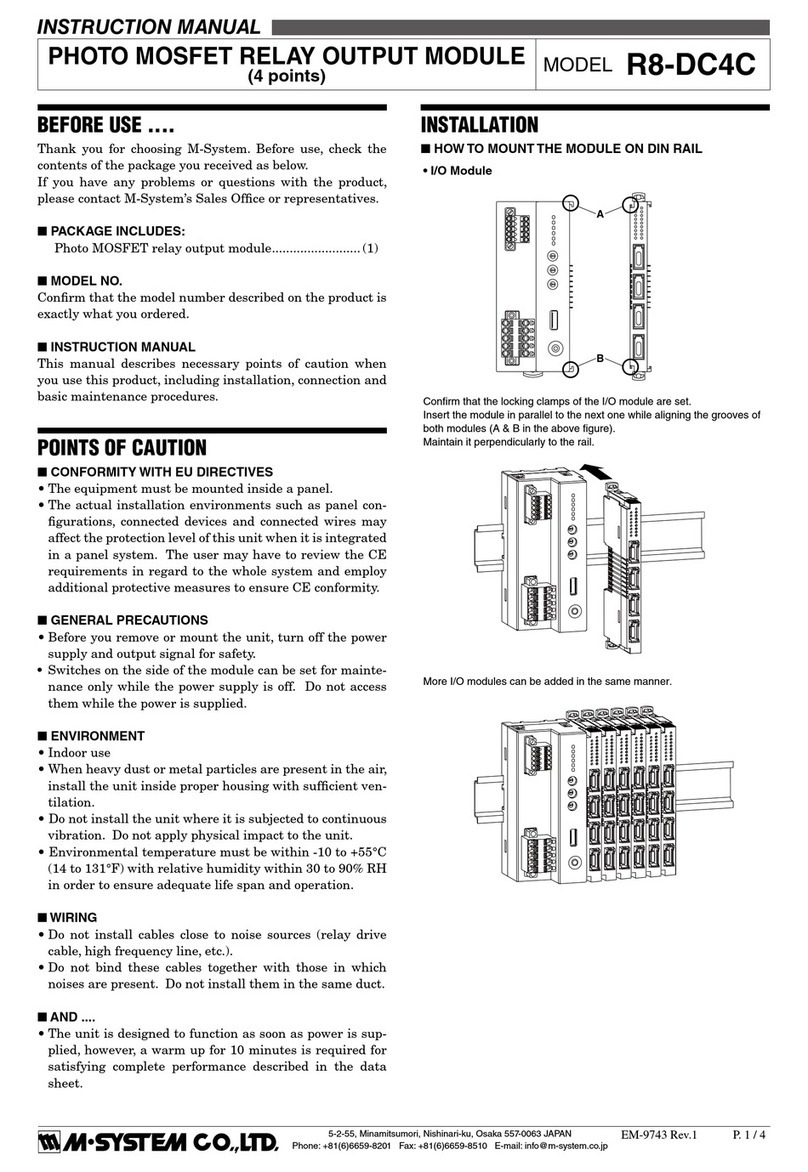

M-system

M-system R8-DC4C instruction manual

ITT

ITT Engineered Valves EnviZion Installation, operation and maintenance manual

Siegenia

Siegenia IO module operating instructions

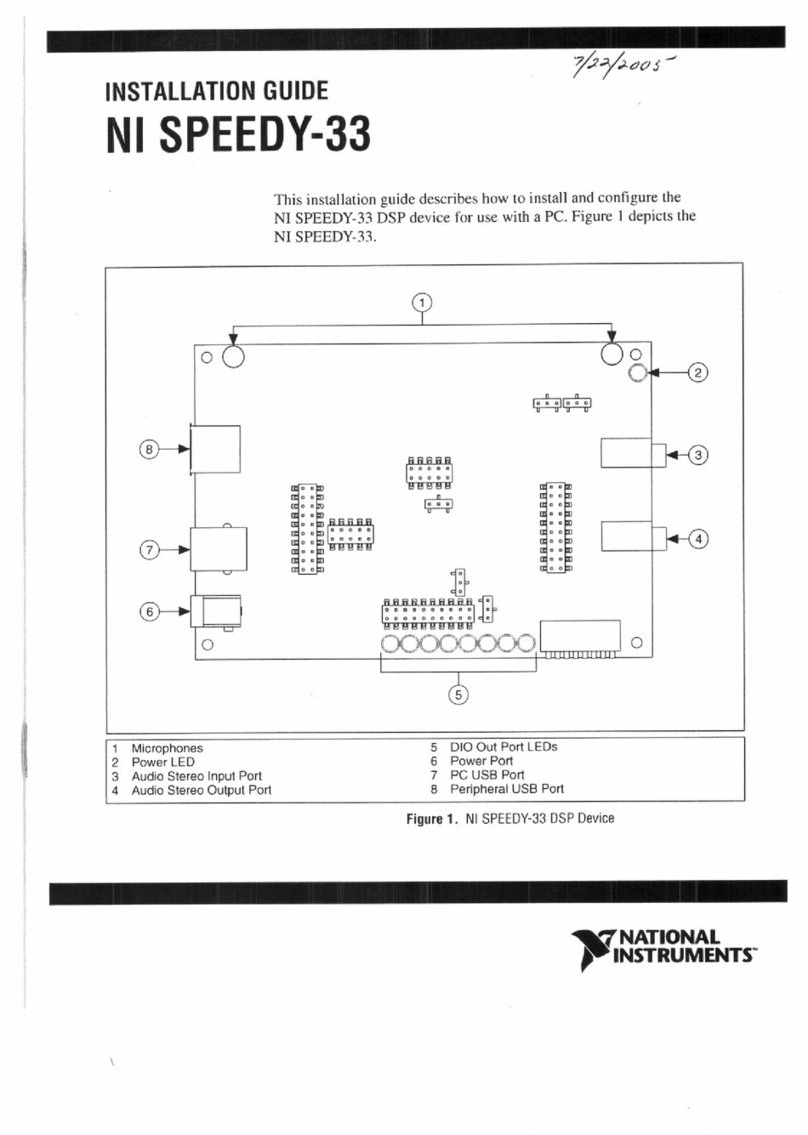

National Instruments

National Instruments NI-SPEEDY-33 installation guide

Vogtlin

Vogtlin M-Flow Series instruction manual

Eizo

Eizo JC-100 user manual

Regulus

Regulus VZK R 3 230-1P Series Installation and operation manual

Harvia

Harvia Pro D IP65 Supplement Note

NI

NI PXIe-4304 CALIBRATION PROCEDURE

National Instruments

National Instruments PXIe-4310 user manual

Linear Technology

Linear Technology DC1198A-B Demo Manual

Viessmann

Viessmann EA1 Installation and service instructions