9308735

Setup

Calibration Factor

In this menu, you can recalibrate the meter for different

fluids.

1. If you have not already entered the dispensing

options menus, do steps 1 and 2 in Selecting

Dispensing Options on page 8.

2. Press the Auto/Reset button repeatedly until CAL

blinks and the current calibration factor is

displayed to indicate that you are in the Calibration

menu.

3. With CAL blinking, you can press the Auto/Reset

button and choose not to change the calibration

factor, which advances to the Auto Preset Amount

menu.

OR

You can recalibrate the meter as follows:

3a. If the unit of measurement is liters, dispense

exactly one liter of fluid into a calibrated

1-liter container. If the unit of measurement

is gallons, pints, or quarts, dispense exactly

one quart of fluid into a calibrated 1-quart

container. For proper calibration, you must

dispense the exact amount, according to the

markings on the container.

After dispensing, the displayed number is the

new calibration factor. The new calibration

factor must be within 20 percent of the

factory default value [in the range of 294 gal.

(310 liters) to 442 gal. (467 liters)], or it will

not be accepted.

The following table lists approximate

calibration factors for different fluids. Your

calibration number may vary slightly due to

temperature or flow rate.

Calibration Number

Fluid Quarts Liters

oil (10W–30) 368 389

gear lube 368 389

automatic

transmission

fluid

368 389

antifreeze 347 367

Calibration factors at 70_F (21_C) at 2.0 gpm (7.6 lpm).

3b. Press the Auto/Reset button to store the new

calibration factor and advance to the Auto

Preset Amount menu.

Auto Preset Amount

In this menu, you can specify an amount to be

displayed when you enter the Auto dispense mode.

Typically, you would enter the amount you most

frequently dispense.

1. If you have not already entered the dispensing

options menus, do steps 1 and 2 in Selecting

Dispensing Options on page 8.

2. Press the Auto/Reset button repeatedly until

AUTO blinks and the auto preset amount in

memory is displayed to indicate that you are in the

Auto Preset Amount menu. This is the amount

that is displayed when the Auto/Reset button is

pressed during normal operation.

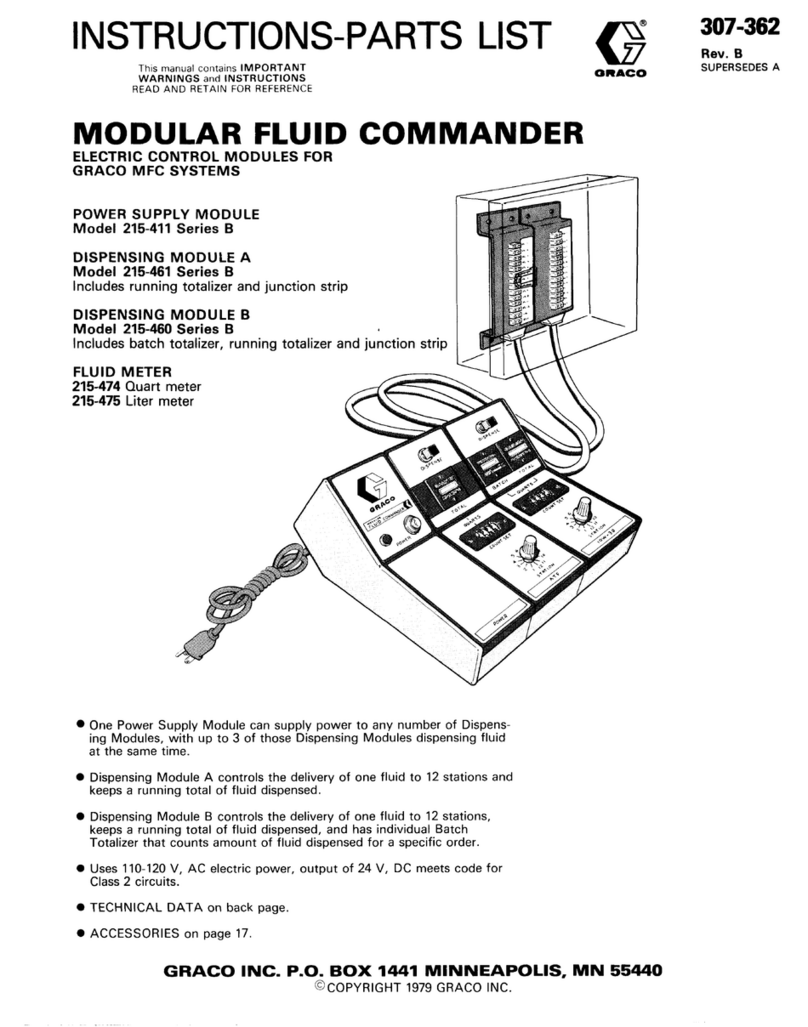

3. With AUTO blinking and the stored auto preset

amount displayed, as shown below, do ONE of the

following two options:

DEnter a new auto preset amount by pressing

the 10 button to change the 10s digit,

the 1.0 button to change the 1s digit, and

the 0.1 button the change the first decimal

digit.

In the figure below, the arrows point from the

numbered buttons on the keypad to the

corresponding digits in the display.

NOTE: If you press and hold the 10, 1.0, or

0.1 buttons, the digits advance rapidly.

To store the displayed auto preset amount in

memory and advance to the Shut-Off Default

Amount menu, press the Auto/Reset button.

OR

DPress the Auto/Reset button.

The currently displayed auto preset amount is

retained, and the display advances to the

Shut-Off Default Amount menu.

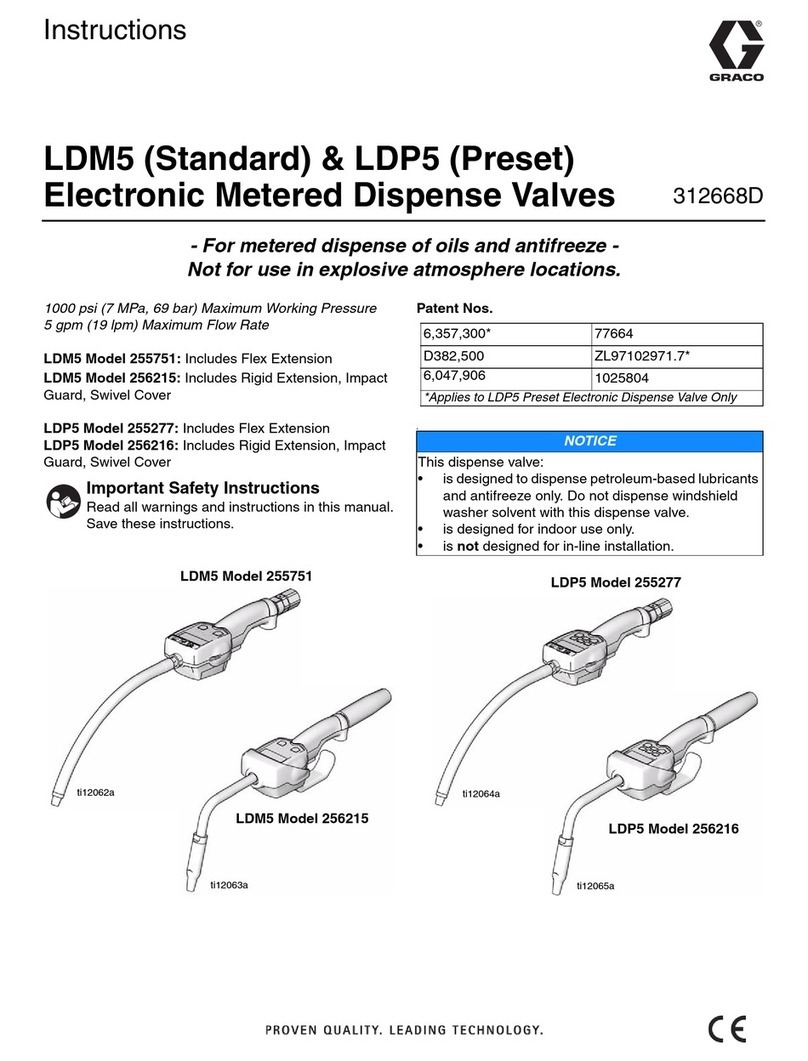

! CAUTION

To prevent overfills and spills

Maximum Working Pressure 7 MPa (70 bar, 1000 PSI)

DDo not obstruct the trigger

DDo not leave unattended DDo not operate below 32_F (0_C)

DRead instruction manual

06044A

AUTO

GAL