1

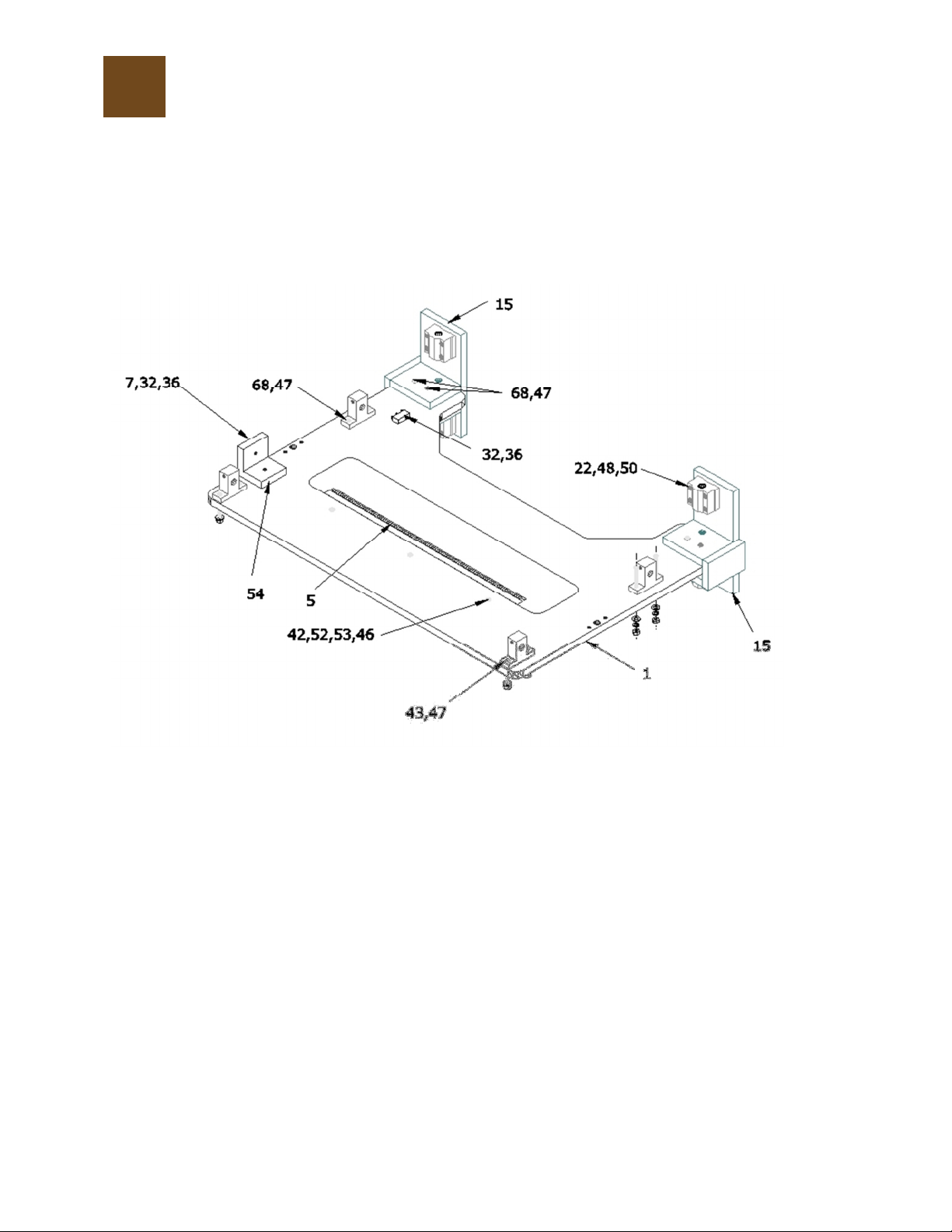

COPPERHEAD 3D PRINTER ASSEMBLY GUIDE

WELCOME

Thank you for choo ing the Copperhead 3D printer from Acadian

Robotic . Plea e read through thi manual fir t before etting up

your machine. If you have any que tion or comment regarding

thi guide plea e contact u at tech upport@acadianrobotic .com.

January 2015 ver ion

ASSEMBLY INSTRUCTIONS

Tool required:

Metric allen wrench et

Needle no e plier

Large and mall Philip head crewdriver

Large and mall flat head crewdriver

Grounding wri t trip (for PCB protection)

Small cre cent wrench

General note :

-

Keep the hardware (nut , bolt , wa her ) loo e until the machine i fully

a embled unle otherwi e noted in the individual tep .

-

When te ting the machine’ component and wiring all connection

hould be ecurely fa tened.

-

When in talling wiring loo ely ecure the zip trip or cable clap unle

otherwi e noted in the individual tep . Do not let the wiring hand loo e

from component without upporting the wire with zip trip or wire

clip .

-

When di connecting the motor grab the ide of the white motor plug

connector and gently jiggle the connector away from the motor. NEVER

grab the wire to di connect the motor .