Prepared By: Tim Wojo Revision - Date: 0 – 03232009 Page 7 of 15

40-6537 Service Manual

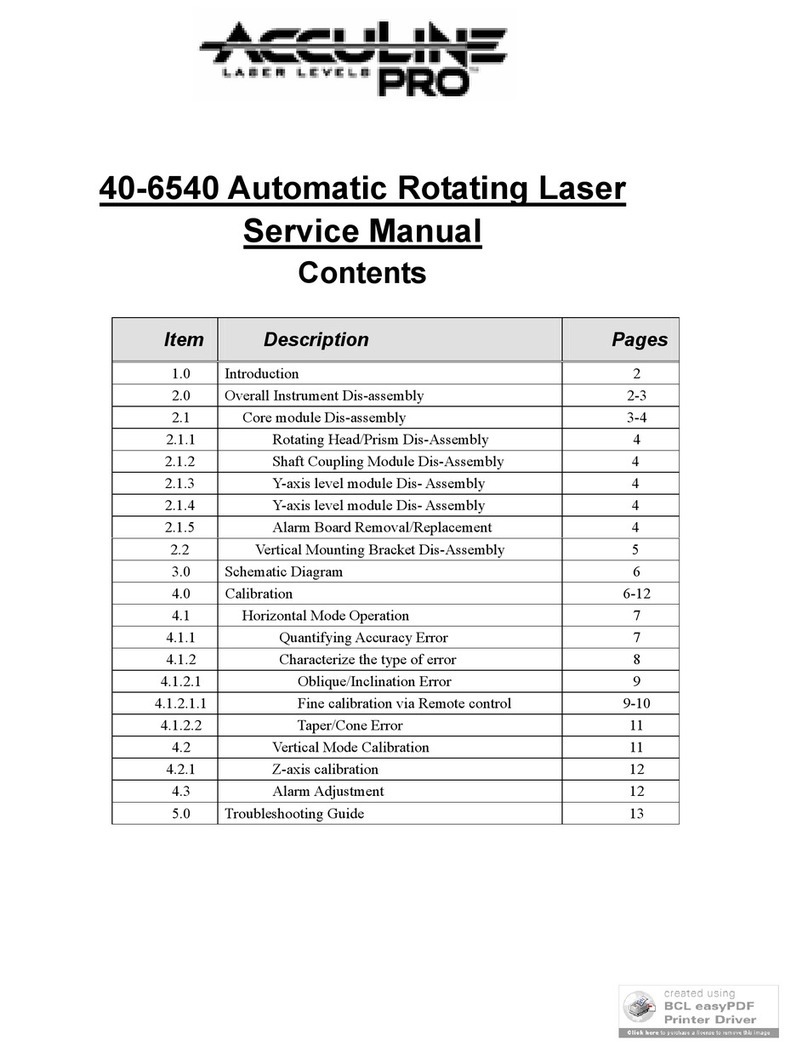

3.1. Horizontal Mode Operation

In this mode of operation, the instrument is self-leveling, where by a major factor of accuracy is how well the leveling

compensator is balanced. Different types of errors require different methods of calibration. These errors are easily characterized

by placing the instrument on a flat surface following the guidelines below, and running the instrument with the rotating head

continuously rotating 360°.

3.1.1. Quantifying Accuracy Error

Establish the test set-up shown in the following illustration and confirm that it meets the following requirements:

1) The debugging platform should be horizontal with a error less than 0.1°(6′);

2) The distance L from the center of the debugging clamp to the wall should be L≥10m;

3) The accuracy of the reference marking is no less than 0.05mm/m;

4) The adjacent-light ruler should be put within 0.3m (12”) of the instrument (the zero position of the ruler should be located at

the same height as that of the laser line at the emitting hole).

1. Place the instrument for test on the test stand (preconfigured from the illustration above) with handle facing the far target .

2. Power the laser and function in full rotation mode (head rotates 360°)

3. Note the errors in all four quadrants of the instrument as read on the far target (i.e. x axis A = 0° and B = 180°, y axis C = 90°

and 270°)

You should end up with 4 numbers

i. A (0°) = _____

ii. B (180°) = ______

iii. C (90°) = ______

iv. D (270°) = ______

4. Since all of the errors are referenced against “0” on the far target, essentially the largest number from the data collected (A – D)

/ the distance should be equal to or less than the published specification for the product. If not, characterize the error and

determine method of calibration as defined by section 4.1.2 of this document.

0

Flat Surface (Test Stand)

Far Target placed on wall at least 10m (33ft) from Test

Stand, where “0” corresponds to them same height as

“0” on the target next to the aperature of the instrument.

Accuracy (A) = Difference between laser line

height and reference line height, divided by the

distance that the laser is from the wall (L)

Instrument for test (laser spinning 36

0

Near Target placed within 0.3m (12”) of

instrument. Note that “0” of the target

corresponds to the height of laser line at the

aperature of the instrument.