P/N 800-1090-104 Rev L102012 Page 4 of 44

Table of Contents

SECTION 1 GENERAL INFORMATION.............................................................6

INTRODUCTION.............................................................................................................6

SPECIFICATIONS1.........................................................................................................7

SECTION 2 PROPANEL OPERATION ..............................................................8

INITIAL SET-UP.............................................................................................................8

CALIBRATION ...............................................................................................................9

OUTSIDE MEASURING:..................................................................................................9

INSIDE MEASURING ......................................................................................................9

CORNER-TO-CORNER MEASURING:.............................................................................10

HOLE-TO-HOLE MEASURING.......................................................................................10

EDGE-TO-HOLE MEASURING.......................................................................................10

GENERAL MAINTENANCE.............................................................................................11

BATTERY REPLACEMENT.............................................................................................11

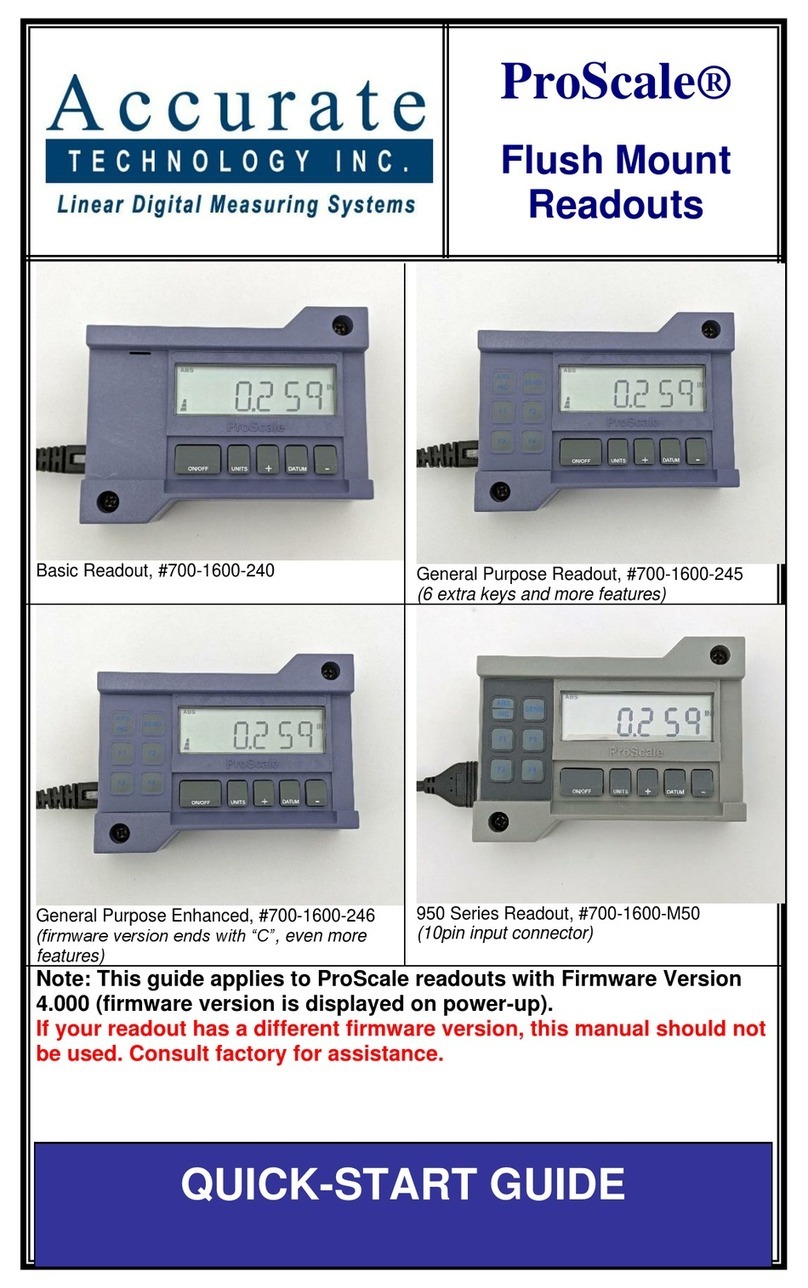

SECTION 3 READOUT OPERATION ................................................................12

KEY TIMING ...............................................................................................................12

KEYS ........................................................................................................................13

On/Off Key ..........................................................................................................13

Units Key.............................................................................................................13

Plus (+) & Minus (–) Keys....................................................................................14

Datum Key ..........................................................................................................14

FUNDAMENTAL READOUT FUNCTIONS ..........................................................................15

Auto on/off...........................................................................................................15

Reading Direction................................................................................................15

Resolution...........................................................................................................15

Measurement Units.............................................................................................16

Key Lock .............................................................................................................16

Linear Scaling......................................................................................................17

Upper/Lower Limits .............................................................................................17

ADVANCED READOUT FUNCTIONS................................................................................18

Absolute / Incremental.........................................................................................18

Absolute (ABS)................................................................................................18

Incremental (INC)............................................................................................18

Send....................................................................................................................19

Offset Addition.....................................................................................................19

Input/Output Connections....................................................................................20

ADVANCED PROGRAMMING FUNCTIONS........................................................................23

Monitor................................................................................................................23

Hold.....................................................................................................................24

Delete..................................................................................................................24

Go/NoGo.............................................................................................................25

Measurement Accumulator .................................................................................26

Statistics..............................................................................................................27

Compensation.....................................................................................................29

Circuit Board Jumpers.........................................................................................30

SECTION 4 PROGRAMMING ............................................................................31