HAWEKA AXIS 500 User manual

Operating Instructions

Laser Wheel Aligner

(Translation of the original manual)

D-30938 Burgwedel •Kokenhorststr. 4 • Phone: +49 / 5139 / 8996-0 • Fax: +49 / 5139 / 8996-222 •

www.haweka.com • [email protected]om

GEB 001 081

Wheel Alignment AXIS500

AXIS500 Manual Instructions

1

Table of contents

1 General safety precautions...........................................................................................3

1.1 Operator’s responsibility ........................................................................................... 3

1.2 Description of applied symbols ................................................................................. 3

1.3 General safety measures .......................................................................................... 4

2 Shipment.........................................................................................................................5

2.1 Dimensions and Weight ............................................................................................ 5

2.2 Information’s for general handling and storage ......................................................... 5

3 Product Description.......................................................................................................6

3.1 Agreed functionality .................................................................................................. 7

3.2 Design of laser measurement head .......................................................................... 8

3.3 Description ................................................................................................................ 9

3.4 Button assignment .................................................................................................... 9

3.5 Initiation .................................................................................................................. 10

3.6 Technical Data ........................................................................................................ 11

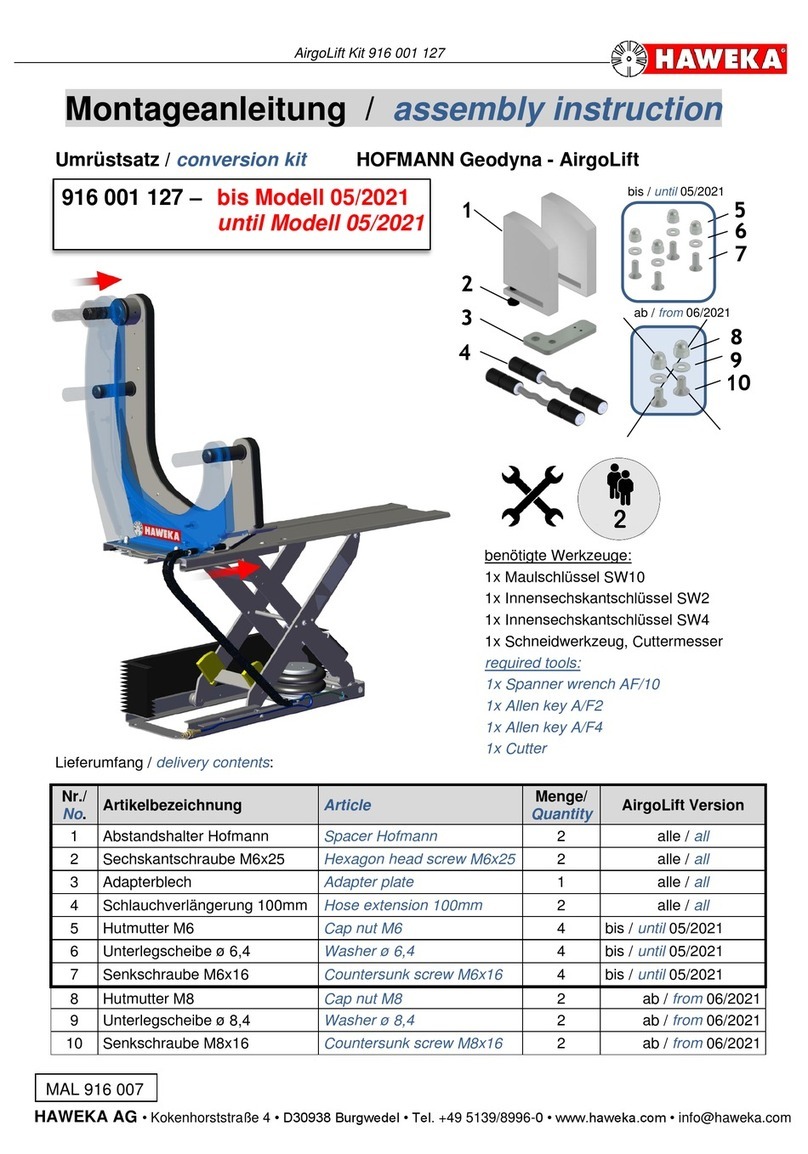

4 Equipment.....................................................................................................................12

4.1 Part list basic version of AXIS500 ........................................................................... 12

4.2 Accessories ............................................................................................................. 15

5 Front Wheel Alignment................................................................................................17

5.1 Preparations............................................................................................................ 17

5.2 Alignment of „Straight ahead position“ .................................................................... 18

5.3 Set-up of Toe Scales .............................................................................................. 19

5.4 Toe Measurement and Alignment ........................................................................... 20

5.5 Check of Steering Wheel Center Position............................................................... 22

5.6 Camber measurement ............................................................................................ 23

5.7 Caster and Inclination ............................................................................................. 24

5.8 Max. Steering Angle ................................................................................................ 25

5.9 Relative Steering Angle (toe out on turns) .............................................................. 26

5.10 Rim Run-Out Check ................................................................................................ 27

6 Rear Wheel Alignment.................................................................................................28

6.1 Camber Measurement of the Rear Wheels ............................................................ 28

6.2 Total Toe / Rear Axle .............................................................................................. 28

6.3 Measurement of Axle Mismatch in relation to the Frame: ....................................... 29

6.4 Axle Mismatch in relation to Vehicle’s Longitudinal Axis ......................................... 30

7 Alignment of Twin Steering Front Axles....................................................................31

7.1 Preparations............................................................................................................ 31

7.2 Reading of total toe ................................................................................................. 31

7.3 Toe Alignment of the Second Axle .......................................................................... 33

Wheel Alignment AXIS500

AXIS500 Manual Instructions

2

8 Trucks with independent suspensions .....................................................................35

8.1 Measurement of Individual Toe -Trucks with Two Adjustable Toe Rods ................ 35

9 Adjustment by Run-out compensation......................................................................37

10 Checking the Wheel Alignment Clamp......................................................................39

11 Maintenance.................................................................................................................40

11.1 Maintenance ........................................................................................................... 40

11.2 Replacing the batteries in the laser housing ........................................................... 40

11.3 Replacing the batteries in the inclinometer ............................................................. 41

12 Error description .........................................................................................................42

12.1 Error description and causes .................................................................................. 42

13 Annex............................................................................................................................43

13.1 Conversion Table from Millimetres into Degrees .................................................... 43

13.2 Diagram for Determination of Axle Mismatch (optical measurement) Dia. 1 .......... 45

13.3 Diagram for Determination of Axle Mismatch (optical measurement) Dia. 2 .......... 46

13.4 Measurement report ............................................................................................... 47

14 EC-Declaration of Conformity.....................................................................................48

HAWEKA AG

Kokenhorststraße 4

Germany - 30938 Burgwedel

Tel.: +49 5139 / 8996-0

Fax: +49 5139 / 8996-222

info@haweka.com

www.haweka.com

For version see page 7

Wheel Alignment AXIS500

AXIS500 Manual Instructions

3

1 General safety precautions

1.1 Operator’s responsibility

Laser Aligner AXIS500 has been designed and

manufactured in accordance with harmonized standards. It

is thus state of art and provides maximum security during

operation.

Structural changes of Laser Aligner require written approval

of manufacturer!

Operational safety can only be achieved, if all required

measures are carried out. It is due to the responsibility of

the operator to consider these measures and to control their

implementation.

In particular the operator has to ensure that

• the device is only used appropriately to its agreed

functionality

• the device is only used if proper functionality is provided

• complete operating instructions are provided in legible

form at point of location of device

• only suitably trained and authorized personnel operates

the device

• the personnel is regularly instructed in all aspects of

operational safety and familiar with operating

instructions and contained safety precautions

• all warning and safety precaution labels maintain

attached to the device in legible form

1.2 Description of applied symbols

These operating instructions con

tain accurate safety precautions, following symbols

have been applied for indication

This symbol indicates general risk for the device and

materials.

Warning of hazardous electric voltage

This symbol indicates risks for humans, device and

materials.

Wheel Alignment AXIS500

AXIS500 Manual Instructions

4

This symbol indicates no safety concerns but

information’s for a better understanding of operating

cycles.

Symbols attached to laser measuring heads are placed close to laser beam output

opening.

Laser radiation warning

This symbol indicates that, above all, dangers to

people are to be expected.

Information sign with the laser class markings

1.3 General safety measures

Laser Aligner AXIS500 must only be operated by suitably

trained and authorized personnel that is familiar with these

operating instructions and capable of proper

implementation.

Check Laser Aligner before any operation for visual damage

and ensure proper functionality of device! In case of defect

inform manager of workshop!

Laser

CLASS 2

TYP 1

Laser devices require general considerations:

- Do never look directly into laser beam!

- Define laser beam paths accurately, use laser absorbing

means to avoid stray laser irradiation! Hazardous

reflections are particularly caused by reflecting and

shining surfaces.

- Level laser beam path above or below eye level if

possible!

- Laser beam paths should not cross operational areas. If

this is inevitable mark laser operating area significantly

and set up required warning signs.

- Switch off laser after operation!

You can find more safety precautions in:

Safety of laser products; Part 1: Equipment classification,

requirements and user’s guide (IEC 825-1:1993)

It is the responsibility of the operator to ensure proper

operation and implementation of safety precautions.

Wheel Alignment AXIS500

AXIS500 Manual Instructions

5

2 Shipment

2.1 Dimensions and Weight

Length x Width x Height

120 cm x 80 cm x 90 cm

Shipment weight:

170 Kg

2.2 Information’s for general handling and storage

Avoiding damages and injuries during shipment:

• industrial trucks must be in accordance with regulations for

prevention of accidents

• shipment activities must only be carried out by suitably trained

and authorized personnel

• heavy impacts during shipment must be avoided

Keep device always dry.

This applies in particular to shipment and storage of complete

instrument cabinet.

Ensure that storage location is dry and dust free.

Wheel Alignment AXIS500

AXIS500 Manual Instructions

6

3 Product Description

Laser Aligner AXIS500

Part No. 922 000 050

These operating instructions are subject to alterations.

8. revised version 2019

Illustration: HAWEKA AG / 30938 Burgwedel

This publication may not be reproduced in any form or by any means.

Wheel Alignment AXIS500

AXIS500 Manual Instructions

7

3.1 Agreed functionality

• Laser Aligner AXIS500 is designed for wheel alignment of motor vehicles.

• Only for the fast measurement of the chassis geometry.

Front wheel alignment and steering axle:

- Total Toe / Single Toe

- Camber

- Caster

- KPI

- Relative steering angle

- Steering wheel centre position

Rear wheel alignment:

- Toe

- Camber

- Offset

- Out of square

• Laser Aligner AXIS500 enables measurements while in driven position. No lifting of

vehicle is required.

• Measurements can be taken fast and reliable on all types of motor vehicles ( with

specific accessories provided).

Safe operation of Laser Aligner AXIS500 cannot be ensured

if not used appropriately to its agreed functionality!

The operator-and not the manufacturer- is responsible for all

damages and injuries resulting from inappropriate use to its

agreed functionality.

Applied laser of laser measuring head is a class 2 laser. Short-

term laser beam impact ( up to 0,25 s) proves not to be harmful to

human eyes. Eye blink reflex prevents the eye from injury during

short-term, unintentional exposure to laser beam.

DO NEVER LOOK INTENTIONALLY INTO LASER BEAM!

In case of suspected eye injury through laser beam impact consult a ophthalmologist

immediately!

Wheel Alignment AXIS500

AXIS500 Manual Instructions

8

3.2 Design of laser measurement head

Laser head and main components:

Laser head is free rotatable. Ensure that laser beam output opening is

directed downward to the floor after mounting of laser heads and

before switch on of diode laser.

Inclinometer

Required for camber and caster measurement during

front wheel alignment. Electronic inclinometer is

mounted on measuring head shaft.

Grab arm assembly

Part No.912e008 140

3 arm star Pro Clamp

Part No. 912e008 265

Quick-socket magnetic

fool

Part No. 913 027 007

Star grip screw M8 x 40

Part No.DU ST08040

Measuring head shaft

Part No.913 005 015

Laser head

Part No.913 001 042

Magnetic fool 100

Part No.913 027 012

Wheel Alignment AXIS500

AXIS500 Manual Instructions

9

3.3 Description

The electronic inclinometer is used to record angle values on the vehicle geometry.

This device enables the camber, caster and included angle to be determined.

Angles can be measured in the horizontal and vertical plane depending on the attachment

face.

Display symbols:

Camber display

Request for value recording

Caster / KPI

Angle value display:

Upper line: Caster

Lower line: KPI

3.4 Button assignment

ON/

OFF

On / Off button

Light

Switch on background lighting for 30 seconds.

Switches between the camber measurements, caster / KPI and max. steering. The first mode is the

camber measurement, where the result of the angle is directly shown. In caster / KPI mode, LED's light

signals confirm the recorded angle changes and after the procedure has ended the display automatically

switches to the display values for caster (upper line) and KPI (lower line).The third mode is for calculating

the max. steering angle. Press the button again to switch back to the camber display.

Tara

Press this button to adjust the angle measurement to an inclined plane. The angles in both measuring

directions are thus adjusted to zero. This operating state is indicated by a symbol in the bottom right-hand

corner. Press this button again to switch back to display of the absolute angle.

Hold/

Save

Press this button to "freeze" the angles in the display. This operating state is indicated by a symbol in the

bottom left-hand corner. If the button is pressed again the display switches back to continuous display of

the measured values.

On / Off switch

Display lighting

For angle

measurement

in an

inclined plane.

Illuminated LC display

Switches between the

angle measurements

Keep angle values in

the display

LED indicator light

Wheel Alignment AXIS500

AXIS500 Manual Instructions

10

Initiation

Initial operation of Laser Aligner requires following measures:

Mounting of rolls and scale holding device on mobile instrument cabinet.

Fit in fastening screws M8 x 65 from top and tighten

with nut and washer.

For each roll

4 x Carriage bolt M8

4 x Washer M8

4 x Nut M8

3 x Carriage bolt M8 x 30

3

x Washer M8

3 x

Nut M8

Wheel Alignment AXIS500

AXIS500 Manual Instructions

11

3.5 Technical Data

Measuring Accuracy:

Toe < 0,5 mm

Camber

Caster

Steering

Relative steering angle +/- 15 min.

Axle mismatch +/- 1 mm

Axle torsion +/- 5 min.

Toe measurement range +/- 28 mm

Camber measurement range to 5 degrees

KPI measurement range to 18 degrees

Castor measurement range to 12 degrees

Turning plate carrying capacity 6 t / piece

Laser:

Model LG650-7 (80)

Operating voltage 3 Volt (2 x Mignon Typ AA 1,5 Volt)

Power Po 0,91 mW

Wave range

λ

650 nm

Range 20 m

Laser class 2 DIN EN 60825-1:1994-07

Electronic inclinometer:

Operating voltage 6 volt (4 x Mignon Type AA Batteries 1.5 volt)

Current input during operation 10 mA (without lighting), 60 mA (with lighting)

Closed-circuit current (unit switched off) < 10 µA

Running time with one set of batteries without lighting: approx. 50 - 60 h.

with lighting: approx. 30 h.

Specified measuring range +/- 45° for both axles

Extended measuring range +/- 90° for both axles

Accuracy of the specified measuring range 0... 10°: +/-0° 03’

10 ... 45°: +/-0° 12’

Resolution 0° 01’

Temperature range -5 to +50 °C (in use) -20 to 65 °C (storage)

Shock resistance of the sensor 3.500g

0 ... 10°: +/- 0° 03’

10 ... 45°: +/- 0° 12’

Wheel Alignment AXIS500

AXIS500 Manual Instructions

12

4 Equipment

4.1 Part list basic version of AXIS500

2 pcs. Laser measuring heads with magnetic feet (100 mm) 1 pcs. Part No. 922 001 006

4 pcs. Grab arms for trucks 1 pcs. Part No. 912e008 303

1 pcs. Electronic inclinometer

Part No. 913 009 048

1 pcs. Alignment block for uneven floors

Part No. 913 010 000

Wheel Alignment AXIS500

AXIS500 Manual Instructions

13

2 pcs. 20° scales 1 pcs. Part No. 913 018 000

2 pcs. Turning plates

Left and Right

1 pcs. Part No. 913 011 000

6 pcs. Magnetic feet for rear-axle measuring (315mm)

1 pcs Part No. 913 030 012

6 pcs. Magnetic feet for front-axle measuring (100 mm) with quick socket

1 pcs. Part No. 913 027 011

Wheel Alignment AXIS500

AXIS500 Manual Instructions

14

2 pcs. Toe scales (min 3.110 – max. 4.440) mm

1 pcs. Part No. 913 051 000

2 pcs. Magnetic scales

1 pcs. Part No. 913 013 000

1 pcs. mobile instrument cabinet and fastening material 1 pcs Part No. 913 052 009

4 pcs. Rolls 2 pcs. holding device

for scale

Part No. for 1 piece: Part No. 912e008 212 (1 piece)

913 019 002 (brake roll)

913 019 003 (w/o brake)

1 pcs. CD Rom

1pcs. Tape measure “Test-Record”

Part No. 900 008 041 Part No. VID 922 002

Wheel Alignment AXIS500

AXIS500 Manual Instructions

15

4.2 Accessories

Upgrade kit for double steering axles Part No. 922 000 002

2 pcs. Additional turning plates 2 pcs. Laser heads with magnetic feet and grab

arms for trucks

Upgrade kit for special truck wheels (Trilex / Dayton)

6 pcs. Adapters for rim run-out compensation Part No. 922 000 004

Upgrade Kit for trailer and semitrailer alignment

Scale unit with king pin and king pin adaptor incl. 6 special magnets (265 mm)

Part No. 922 000 001

Wheel Alignment AXIS500

AXIS500 Manual Instructions

16

Upgrade Kit for passenger car alignment

12 passenger car adaptors, 2 measuring heads, 8 telescoping cross arms

Part No. 922 000 016

Wheel Alignment AXIS500

AXIS500 Manual Instructions

17

5 Front Wheel Alignment

5.1 Preparations

• Carry out alignment on level ground.

• Remove protective caps of wheel nuts or caps

respectively.

• Clean rim between wheel nuts.

• Check tire pressure and, if necessary, adjust as

specified.

Drive vehicle onto turning plates

• Place turning plates centrally in front of the wheels.

• Fasten turning plates with bolt to avoid torsion.

• Drive vehicle on turning plates. The wheel centre

shall be positioned in the turning plate centre.

Mounting of laser measuring heads (Illustration 1)

• The magnetic feet of the 3-arm-star have to be

adjusted to the proper rim diameter. It is

recommended to fix the laser measuring head onto

a mounting stand of instrument cabinet (Illustration

1).

• Adjust magnetic cams by turning and shifting to

achieve all-over attachment of rim flange diameter

between wheel nuts.

• Put the measuring heads with the magnets onto the

rim flange. Two magnets shall be placed above the

wheel centre and one below. (Illustration 2).

Fitting of magnetic scales

• Put the front wheels in the straight ahead position by

turning the steering wheel. (Illustration 2)

• Fix the first scale on the right-hand side of the

frame, if possible in the middle (regarding

lengthwise direction).

• Switch on laser on the right-hand side.

(left hand drive vehicles, vice versa for RTA)

Pay attention to laser beam output

opening before switch on!

• Turn right-hand laser until the laser point gets visible

on the magnetic scale.

• Adjust scale with wing nut until the laser point

indicates »0«.

• Repeat the same procedure with the second scale

on the right-hand side. Now the magnetic scales

have the same length and must not be changed

again!

• Attach one of the two scales on the left-hand

side, if possible in the same place (Illustration 3). (Illustration 3)

Wheel Alignment AXIS500

AXIS500 Manual Instructions

18

Front Wheel Alignment

Fitting of magnetic scales (continued)

• Switch on left-hand laser.

Pay attention to laser beam output

opening before switch on!

• Turn left-hand laser until the laser point gets

visible on the scale.

5.2 Alignment of „Straight ahead position“

• Should the laser point on the left-hand scale not

point at zero, turn steering wheel until the value

indicated on the scale is halved. Laser points on

the same value on both scales.

Example:

Indication right: 0

Indication left: 4 scale lines out

Turn steering wheel until both laser points

point

at 2 scale lines outward(Illustration 4)

Now the front wheels are in alignment with the

frame, seen in driving direction.

• Adjust magnetic scales with the wing nuts

until both laser points point at zero.

This procedure is important for all following measurements.

(Illustration 4)

Table of contents

Other HAWEKA Measuring Instrument manuals