1

WARNING............................................................................................................................2

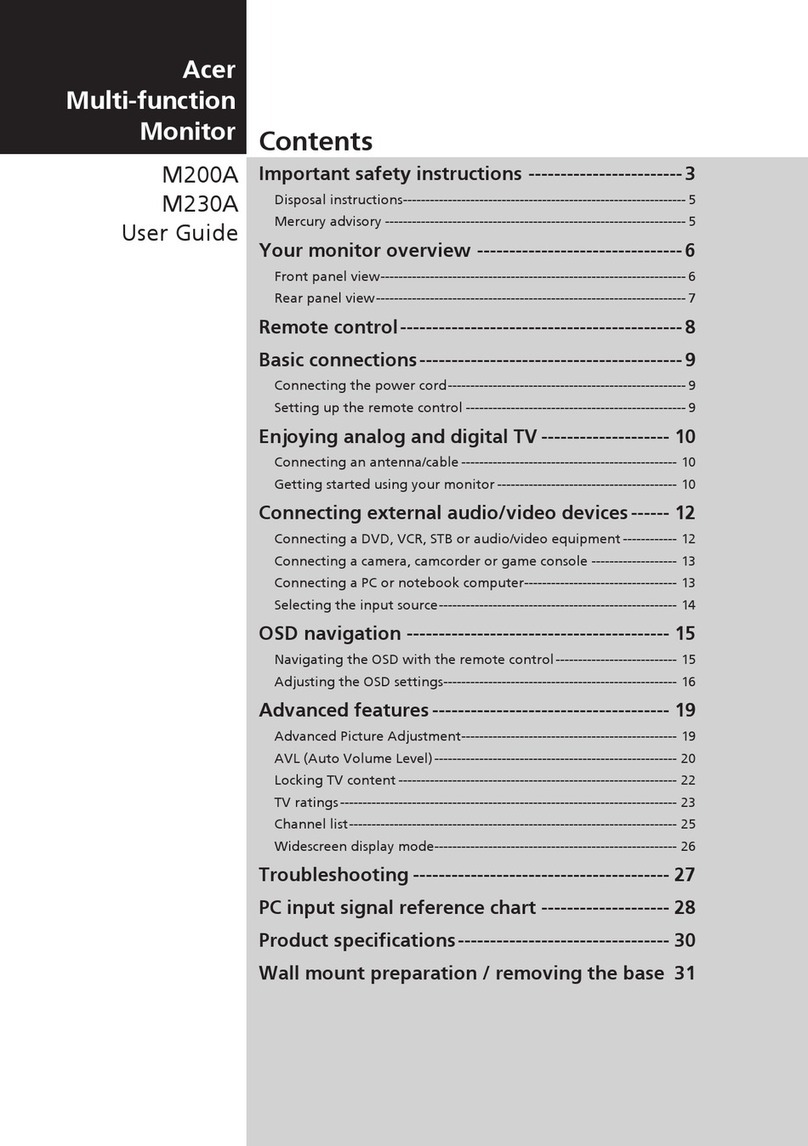

1. ALGNMENT PROCEDURE.............................................................................................3

A. Conditions................................................................................................................................3

B. Functions Alignment................................................................................................................3

C. Preset Timing:..........................................................................................................................6

2. OPERATION THEOREM ...............................................................................................12

A. Power Supply (1)...................................................................................................................12

B. Deflection...............................................................................................................................12

C. Video......................................................................................................................................12

D. Digital Controllable...............................................................................................................12

E. Function Block Diagram........................................................................................................13

F. Power Supply..........................................................................................................................14

G. Under Voltage Protection.......................................................................................................15

H. Degaussing CKT....................................................................................................................15

I. Deflection................................................................................................................................16

J. Video AMP. Circuit.................................................................................................................18

J-2. Video AMPLIFIER..............................................................................................................18

K. Digit Control..........................................................................................................................20

3. CONTROL AND CONMECT LAYOUT ..........................................................................21

A.Main PCB ...............................................................................................................................21

B.CRT PCB................................................................................................................................22

4. TROUBLE SHOOTING..................................................................................................23

A.Power Supply Check ..............................................................................................................23

B.Monitor Check Flow Chart.....................................................................................................24

APPENDIX A: PARTS LISTS .....................…………………………………………………...27

APPENDIX B: DISPLAY UNIT ASSEMBLY…………………………………………………...82

PPENDIX C: P.C.B. ASSEMBLY………………………………………………………………..96

APPENDIX D: CRT& YOKE ASSEMBLY…………………………………………………….106