7General installation aid for complete packages

The brochures are a good installation aid

and provide a way of finding out which

parts belong together.

Please follow the instructions

enclosed with the individual devices.

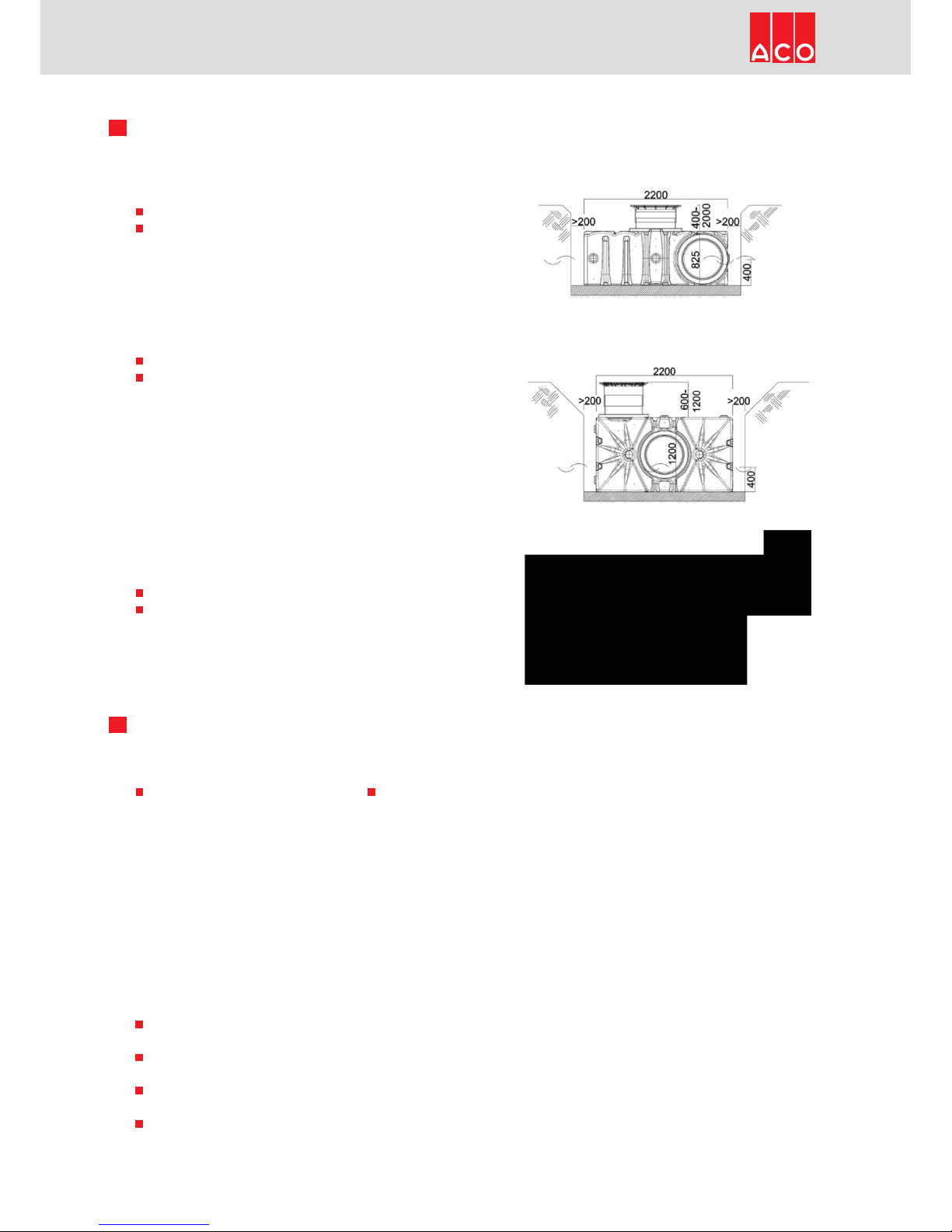

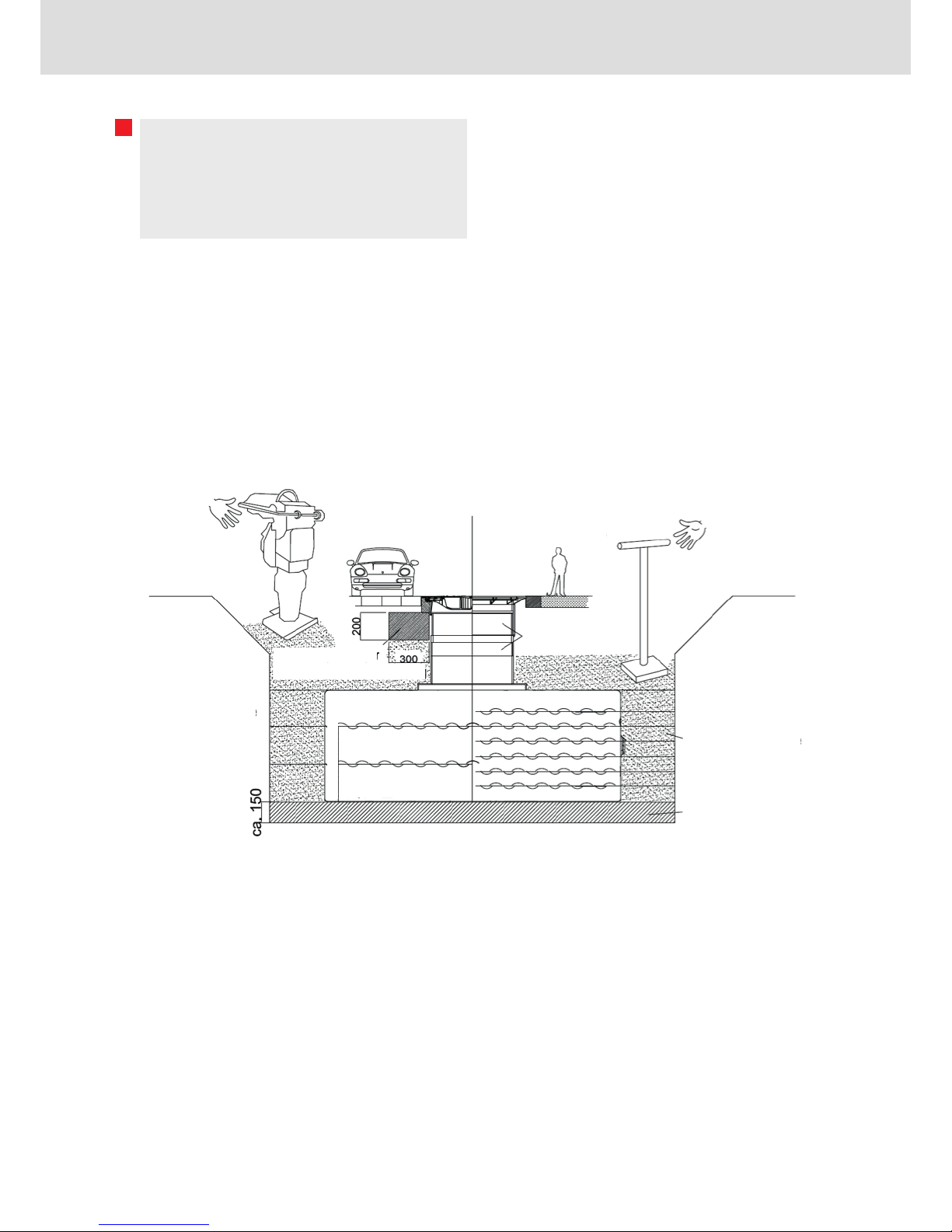

Install the underground tank as

described in the installation

instructions.

Connect the downpipes, which are to

be connected to the underground

tank, to the rainwater inlet at the

underground and connect the overflow

to the drainage sewer, the infiltration

system or other drainage systems.

If you have purchased a house system,

to supply your toilet and/or washing

machine with rainwater, or you would

like to install a level indicator in the

house for your garden system, lay a

DN 100 KG pipe/KG 2000 pipe from

the house connection at the

underground tank to the house service

connection room in the building.

Please ensure that the blank pipe is

laid with at least 2% gradient to the

underground tank, so that

condensation cannot run into the

building. If possible, use max. 30° or

45°bends and branches (e.g. to the

water extraction box), so that the

rainwater hoses do not kink.

A wall penetration seal/gland should

be used to seal the KG pipe in the

house; the seal is inserted directly in

the DN 100 KG pipe.

In the House and Garden packages,

the opening for the water connection

box (if it is not ordered separately)

must be closed off using an

appropriate KG pipe and cover.

The emergency overflow at the top of

the tank must be shortened if

necessary, so that the skimmer edge

lies below any other openings. This

ensures that the surface water flows

away, rather than standing, for

example, in the top tank connection or

in one of the blank pipes

(e.g. to the water extraction box of the

garden packages).

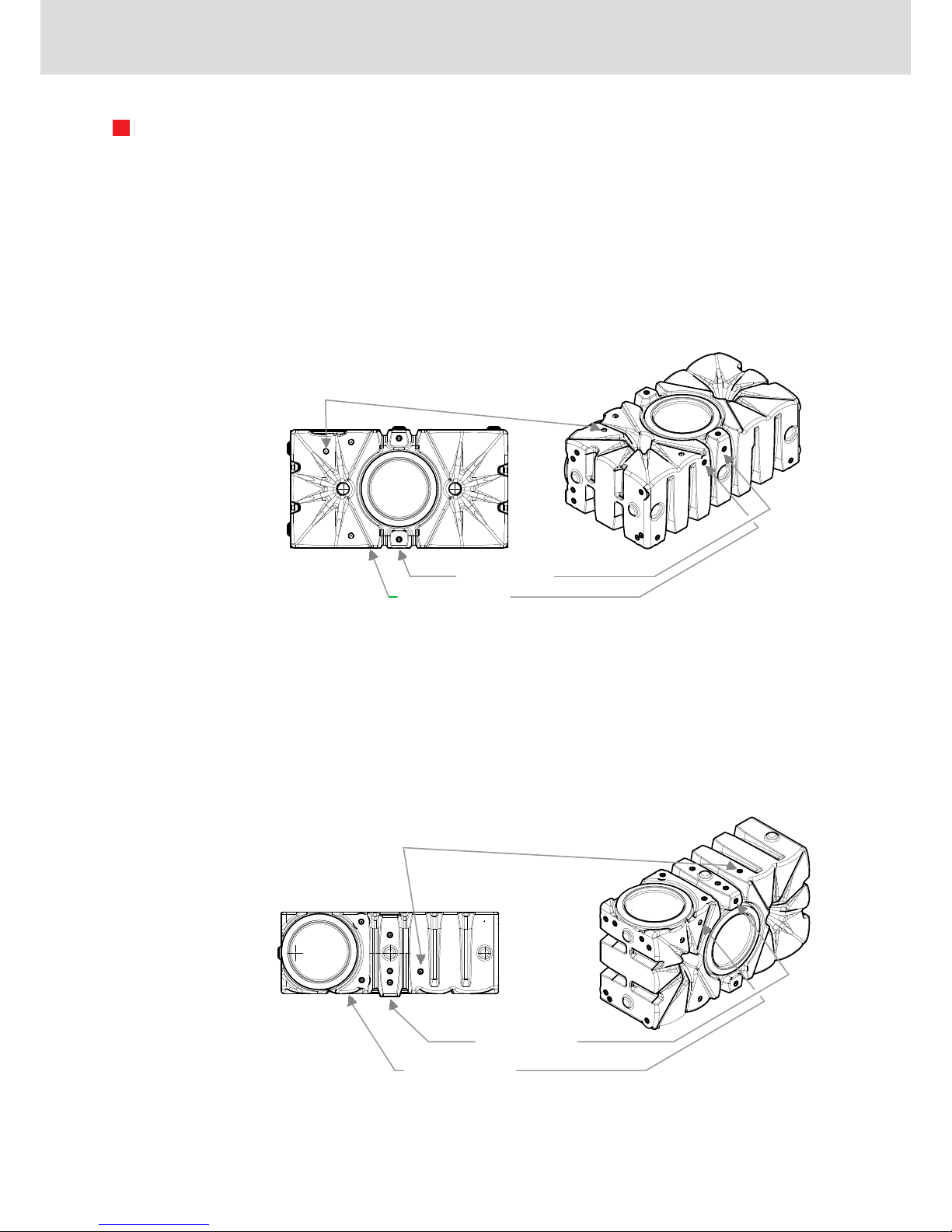

Depending on the features included in

the package, the installation

procedure is as follows:

a) House and Garden Professional:

install the fully automatic rainwater

control in the plant room/service

connection room in the house and lay the

suction (intake) hose from here to the

underground tank (through a correspond-

ing blank pipe)

b) House and Garten Compact:

place the underwater pressure pump in

the underground tank. Use a rotproof

rope or similar to secure the pump from

above in the neck section and to place it

upright in the tank. It also makes it easier

to remove the pump from the tank if

necessary.

Lay the rainwater pressure hose (through

a blank pipe with slope to the

underground tank) from the pump to the

service connection room in the hose and

connect it via a shut-off ball valve to the

rainwater pressure pipe to your toilet,

washing machine, etc.

In the next step you connect the drinking

water pressure pipe to the free drinking

water pressure pipe and connect the inlet

socket of the topup supply to the

underground tank using HT and KG pipes.

IMPORTANT: Ensure slope to the

underground tank! It is advisable to form

a trap as an odour trap. If the top-up pipe

is not positioned with adequate backflow

protection, a backflow safety valve

should be installed. (e.g. ACO Triplex

DN 50, mounted on the wall in front of

the wall penetration). Lay the pump cable

and the cable from the float switch of the

drinking water topup from the under-

ground tank to the service connection

room in the house.

IMPORTANT: Now plug the intermediate

connector of the float switch in the

socket and the connector of the solenoid

valve on the intermediate connector.

IMPORTANT: If there is no water in

the underground tank, water runs

into it until the float switch in the

underground aligns upwards and the

solenoid valve closes.

As soon as there is sufficient water in the

underground tank (pump completely

covered) please plug the connector of

the underwater pressure pump into a

power socket. The system begins to

operate and the pump fills all rainwater

pressure pipes in the house.

IMPORTANT: Check beforehand that

all threaded fasteners, connections,

and hose clamps are properly

tightened. Please ensure that after

all pipes have been filled, the pump

in the underground tank switches off

and only switches on again if you

open a load (toilet flushing).

c) Garden Plus:

Find a suitable place for your water

connection box near the underground

tank and lay a protective pipe/blank pipe,

e.g. KG pipe DN 100/KG 2000 from the

tank to the water connection box. When

laying the blank pipe, it is advisable to lay

the rainwater pressure hose from the

underwater pressure pump to the water

connection box at the same time through

the blank pipe and to connect it to the

ball valve. Now connect the hose to the

pump and lay the pump cable in a reserve

blank pipe to a power socket. Please use

a rotproof rope or similar to secure the

pump at the top of the neck section in the

underground tank. It also makes it easier

to remove the pump if necessary. As

soon as you have tightened all

connections and hose clamps, the ball

valve in the water connection box is

closed and the underground tank is filled

with water, plug the pump connector into

a power socket.

IMPORTANT: The pump starts up and as

soon as the pressure has built up in the

pipe the pump switches off again. If you

now open the ball valve, the pump is

switched on automatically and vice

versa. To make the system winterproof,

disconnect the pump plug from the

power socket and open the ball valve in

the water connection box. Your system is

now winterproof.

d) Garden Basic:

Find a suitable place for your water

connection box near the underground

tank. Lay the suction hose through a KG

pipe/KG 2000 pipe DN 100 laid for this

purpose to the water connection box.

Feed the suction hose through the

perforated bottom of the water

connection box and fix a hose coupling

above the bottom. This prevents the

hose from slipping into the tank. Fill the

pump and the entire suction hose with

water and connect the hose in the water

connection box to the short hose piece

with coupling at the pump (intake side at

front). Connect, e.g. a garden hose, to

the discharge side at the top. As soon as

you now plug the connector into a power

socket and if necessary throw the switch,

the pump pumps water. Disconnect the

connector or throw the switch back to

switch off the pump. To make the system

winterproof, disconnect the suction hose

from the hose piece of the pump and

stow it in the water connection box.

Remove the pump, drain it completely

and place the pump in a dry, frost-free

and well ventilated place. Your system is

now winterproof.