ACPro AWHD(18)ND3GO User manual

AC Pro Multi-Zone Outdoor

18-24K Service Manual

AWHD(18)ND3GO

AWHD(24)ND3GO

(Refrigerant R410A)

Part Ⅰ : Technical Information 1

1. Summary 1

2. Specifications 2

3. Outline Dimension Diagram 6

4. Refrigerant System Diagram 7

5. Electrical Part 8

5.1 Wiring Diagram 8

5.2 PCB Printed Diagram 10

6. Function and Control 12

Part Ⅱ : Installation and Maintenance 14

7. Notes for Installation and Maintenance 14

8. Installation Manual 16

8.1 Electrical Connections 17

8.2 Installing the Outdoor Unit 18

8.3 Installation Dimension Diagram 19

8.4 Check after Installation 20

9. Troubleshooting 21

9.1 Flashing LED of Indoor/Outdoor Unit and Primary Judge-

ment

21

9.2 Malfunction Checking and Elimination 22

9.3 Maintenance Method for Normal Malfunction 35

10. Exploded View and Parts List 37

11. Removal Procedure 43

Appendix 56

Appendix 1: Reference Sheet of Celsius and Fahrenheit 56

Appendix 2: Configuration of Connection Pipe 56

Appendix 3: Pipe Expanding Method 57

Appendix 4: List of Resistance forTemperature Sensor 58

Table of Contents

1Technical Information

PART I : TECHNICAL INFORMATION

Outdoor Unit

AWHD(18)ND3GO

AGWHD(24)ND3GO

1. SUMMARY

1

Technical Information

Service Manual

1. Summary

Part Ⅰ: Technical Information

Outdoor Unit

GWHD(18)ND3EO

GWHD(18)ND3FO

GWHD(18)ND3GO

GWHD(24)ND3EO

GWHD(24)ND3FO

GWHD(24)ND3GO

2

Technical Information

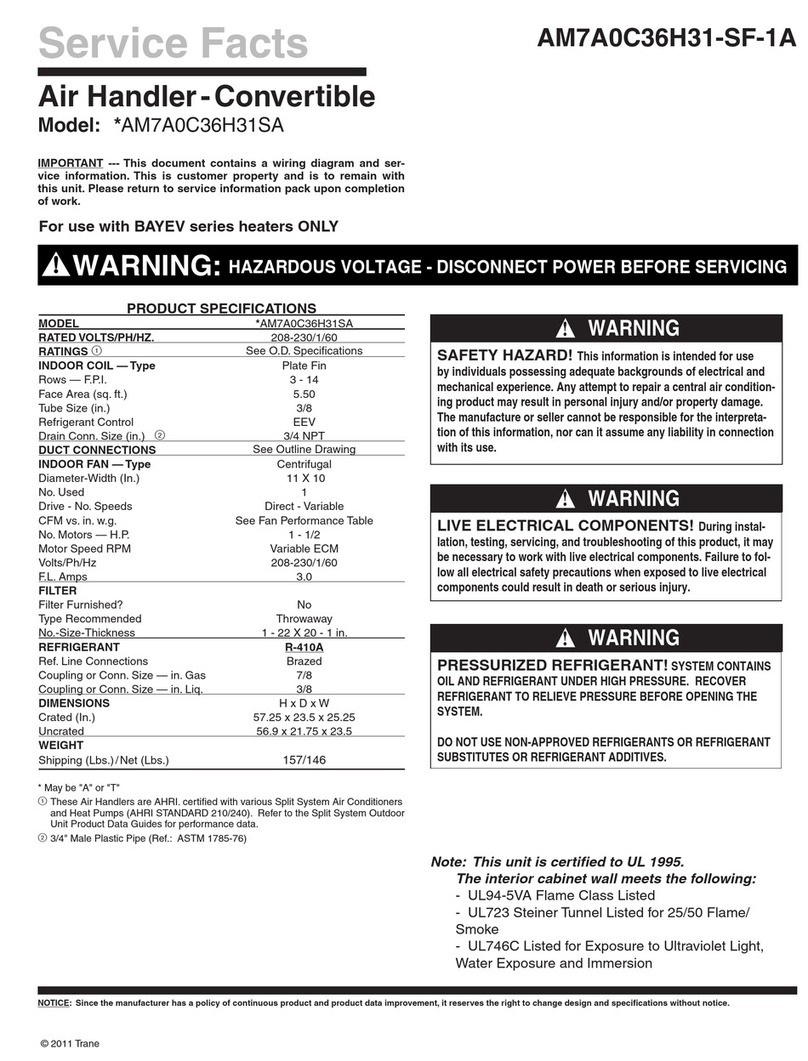

2. SPECIFICATIONS

Model AWHD(18)ND3GO

Product Code CB228W07700

Power Supply

Rated Voltage V~ 208/230

Rated Frequency Hz 60

Phases 1

Cooling Capacity (max~min) Btu/h 18000(6155~6998)

Heating Capacity (max~min) Btu/h 19000(8530~22600)

Cooling Power Input (max~min) W 1440

Heating Power Input (max~min) W 1520

Cooling Current Input A6.62

Heating Current Input A6.61

Rated Power Input W 2800

Current Breaker A 25

EER (Btu/h)/W 12.50

COP (Btu/h)/W 12.50

Outdoor Unit

CompressorTrademark ZHUHAI LANDA COMPRESSOR CO.LTD

Compressor Model QXA-B141zF030A

Compressor Refrigerant Oil Type RB68EP

CompressorType Inverter Rotary

L.R.A A /

Compressor Rated Load Amp (RLA) A 10.82

Compressor Power Input W 1440

CompressorThermal Protector 1NT11L—6233

Throttling Method Electron expansion valve

Cooling Operation Ambient

Temperature Range F -0.4~118.4

Heating Operation Ambient Temperature Range F -4~75.2

Condenser Material Aluminum Fin-copperTube

Condenser Pipe Diameter inch Φ9/32

Rows-Fin Gap(mm) inch 2-1/18

Coil length (l) X height (H) X coil width (L) inch 33 1/2X1 /12X26

Fan Motor Speed (rpm) (H/M/L) rpm 630

Output of Fan Motor W 60

Fan Motor RLA A0.62

Fan Motor Capacitor μF /

Air Flow Volume of Outdoor Unit 1883

Fan Type-Piece CFM Axial-flow

Fan Diameter Φ20 1/2

Defrosting Method inch Automatic Defrosting

ClimateType T1

Isolation I

Moisture Protection IPX4

Permissible Excessive Operating Pressure for the

Discharge Side MPa 4.3

Permissible Excessive Operating Pressure for the

Suction Side MPa 2.5

Dimension (WXHXD) inch 38X27 9/16X15 39/64

Dimension of Package (LXWXH) inch 40 13/32X18X29

Dimension of Package (LXWXH) inch 40 1/2X18X29 1/2

Net Weight lb 114.7

Gross Weight lb 124.6

Refrigerant Charge R410A

Refrigerant Charge oz 56.45

3Technical Information

Outdoor Unit

Cross-sectional Area of Power Cable Conductor sq in 0.0062

Recommended Power Cable(Core) N 3

Connection Pipe Connection Method - Flare Connection

Not Additional Gas Connection Pipe Length ft 131.2

Connection Pipe Gas Additional Charge oz/ft. 0.2

Outer Diameter of Liquid Pipe1(AC Pro Allocation)

(Metric) inch 1/4

Outer Diameter of Liquid Pipe2(AC Pro Allocation)

(Metric) inch 1/4

Outer Diameter of Gas Pipe1(AC Pro Allocation)(Metric) inch 3/8

Outer Diameter of Gas Pipe2(AC Pro Allocation)(Metric) inch 3/8

Connection Pipe Max. Height Distance(indoor and

indoor) ft 32.8

Connection Pipe Max. Height Distance(indoor and out-

door and indoor up) ft 32.8

Connection Pipe Max. Height Distance(indoor and out-

door and outdoor up) ft 32.8

Max. equivalent connection pipe length(outdoor to last

indoor) ft 32.8

Connection Pipe Max. Length Distance(total lenght) ft 65.6

The above data is subject to change without notice; please refer to the nameplate of the unit.

4

Technical Information

Model AWHD(24)ND3GO

Product Code CB228W07800

Power Supply

Rated Voltage V~ 208/230

Rated Frequency Hz 60

Phases 1

Cooling Capacity (max~min) Btu/h 24000(7500~33000)

Heating Capacity (max~min) Btu/h 26000(7500~35000)

Cooling Power Input (max~min) W 1920

Heating Power Input (max~min) W 2050

Cooling Current Input A 8.35

Heating Current Input A8.9

Rated Power Input W 4550

Current Breaker A 35

EER (Btu/h)/W 12.5

COP (Btu/h)/W 12.7

Outdoor Unit

CompressorTrademark ZHUHAI LANDA COMPRESSOR CO.LTD

Compressor Model QXAS-D23zX090B

Compressor Refrigerant Oil Type RB68EP

CompressorType Inverter Rotary

L.R.A A /

Compressor Rated Load Amp (RLA) A 15.82

Compressor Power Input W 2550

CompressorThermal Protector 1NT11L—6233

Throttling Method Electron expansion valve

Cooling Operation Ambient

Temperature Range F -0.4~118.4

Heating Operation Ambient Temperature Range F -4~75.2

Condenser Material Aluminum Fin-copperTube

Condenser Pipe Diameter inch Φ2/7

Rows-Fin Gap(mm) inch 2-1/18

Coil length (l) X height (H) X coil width (L) inch 38 21/32X1 1/2X29 7/16

Fan Motor Speed (rpm) (H/M/L) rpm 800

Output of Fan Motor W 90

Fan Motor RLA A0.59

Fan Motor Capacitor μF /

Air Flow Volume of Outdoor Unit 2354

Fan Type-Piece CFM Axial-flow

Fan Diameter Φ21 43/64-2 39/64

Defrosting Method inch Automatic Defrosting

ClimateType T1

Isolation I

Moisture Protection IPX4

Permissible Excessive Operating Pressure for the

Discharge Side MPa 4.3

Permissible Excessive Operating Pressure for the

Suction Side MPa 2.5

Dimension (WXHXD) inch 38 37/64X31 7/64X17 21/64

Dimension of Package (LXWXH) inch 42 1/2X19X33

Dimension of Package (LXWXH) inch 42 43/64X19 13/64X33 43/64

Net Weight lb 153.2

Gross Weight lb 164.3

Refrigerant Charge R410A

Refrigerant Charge oz 77.6

5Technical Information

Outdoor Unit

Cross-sectional Area of Power Cable Conductor sq in 0.0051

Recommended Power Cable(Core) N 3

Connection Pipe Connection Method - Flare Connection

Not Additional Gas Connection Pipe Length ft 98.4

Connection Pipe Gas Additional Charge oz/ft. 0.2

Outer Diameter of Liquid Pipe1(AC Pro Allocation)

(Metric) inch 1/4

Outer Diameter of Liquid Pipe2(AC Pro Allocation)

(Metric) inch 1/4

Outer Diameter of Liquid Pipe2(AC Pro Allocation)

(Metric) inch 1/4

Outer Diameter of Gas Pipe1(AC Pro Allocation)(Metric) inch 3/8

Outer Diameter of Gas Pipe2(AC Pro Allocation)(Metric) inch 3/8

Outer Diameter of Gas Pipe2(AC Pro Allocation)(Metric) inch 3/8

Connection Pipe Max. Height Distance(indoor and

indoor) ft 32.8

Connection Pipe Max. Height Distance(indoor and out-

door and indoor up) ft 32.8

Connection Pipe Max. Height Distance(indoor and out-

door and outdoor up) ft 32.8

Max. equivalent connection pipe length(outdoor to last

indoor) ft 65.6

Connection Pipe Max. Length Distance(total lenght) ft 196.8

The above data is subject to change without notice; please refer to the nameplate of the unit.

6

Technical Information

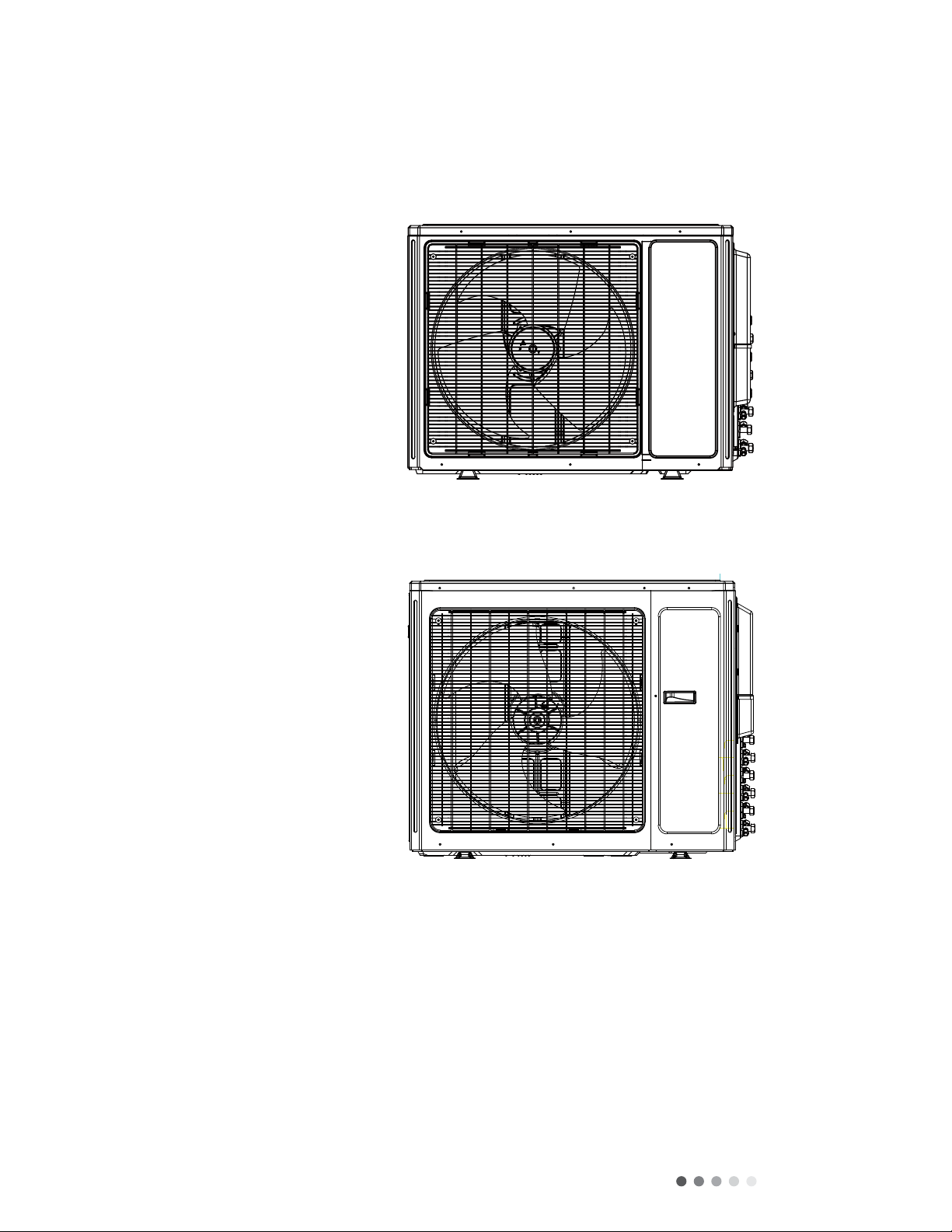

3. OUTLINE DIMENSION DIAGRAM

AWHD(18)ND3GO

10 Technical Information

Service Manual

3. Outline Dimension Diagram

35 1/8

38

27 9/16

15 39/64

13 27/64

22

14 1/2

Unit:inch

Unit:inch

GWHD(18)ND3EO GWHD(18)ND3FO GWHD(18)ND3GO

GWHD(24)ND3EO GWHD(24)ND3FO GWHD(24)ND3GO

38 37/64

35 1/8 13 27/64

17 21/64

31 7/64

22

14 1/2

AWHD(24)ND3GO

7Technical Information

4. REFRIGERANT SYSTEM DIAGRAM

A1:A-unit electronic expansion valve

B1:B-unit electronic expansion valve

C1:C-unit electronic expansion valve

D1:D-unit electronic expansion valve

11

Technical Information

Service Manual

4. Refrigerant System Diagram

outdoor

indoor

D1

C1

B1

A1

filter

A heat exchanger

gas -liquid separator

inverter compressor

discharge silencer

discharge temperature

sensor

SP

4-way valve

outdoor heat exchanger

fan

high pressure switch

B heat exchanger

C heat exchanger

D heat exchanger

filter

filter

filter

filter

Note: Not available for 14K/18K

model

C2

C3

D3

D2

B3

B2

A2

A3

A1:

A-unit electronic expansion valve B1:B-unit electronic expansion valve

C1:C-unit electronic expansion valve D1:D-unit electronic expansion valve

A2:A-unit gas pipe temperature sensor B2:B-unit gas pipe temperature senso

r

C2:C-unit gas pipe temperature sensor D2:D-unit gas pipe temperature senso

r

A3:

A-unit liquid pipe temperature sensor B3:B-unit liquid pipe temperature sensor

C3:C-unit liquid pipe temperature sensor D3:D-unit liquid pipe temperature senso

r

Note: Not available for 14K/18K model

A2:A-unit gas pipe temperature sensor

B2:B-unit gas pipe temperature sensor

C2:C-unit gas pipe temperature sensor

D2:D-unit gas pipe temperature sensor

A3:A-unit liquid pipe temperature sensor

B3:B-unit liquid pipe temperature sensor

C3:C-unit liquid pipe temperature sensor

D3:D-unit liquid pipe temperature sensor

8

Technical Information

5. ELECTRICAL PART

5.1 WIRING DIAGRAM

Instruction

Symbol Symbol Color Symbol Symbol Color Symbol Name

WH White GN Green COMP Compressor

YE Yellow BN Brown Grounding wire

RD Red BU Blue / /

YEGN Yellow/Green BK Black / /

VT Violet OG Orange / /

OUTDOOR UNIT

AWHD(18)ND3EO AWHD(18)ND3FO AWHD(18)ND3GO

12 Technical Information

Service Manual

5. Electrical Part

5.1 Wiring Diagram

Symbol Symbol Color Symbol Symbol Color Symbol Name

WH White GN GREEN COMP Compressor

YE Yellow BN Brown Grouding wire

RD Red BU Blue

YEGN Yellow/Green BK Black

VT Violet OG Orange

● Outdoor Unit

●Instruction

GWHD(18)ND3EO GWHD(18)ND3FO GWHD(18)ND3GO

63610000144

N(1)

2

3

L2

3

2

L1

N(1)

3

2

N(1)

BLOCK

TERMINAL

BLOCK

TERMINAL

N(1)

2

3

θ

θθθ

INDOOR UNIT A

RT1

RT2

RT3 OUTTUBE

TEMP.SENSOR

OUTROOM

TEMP.SENSOR

EXHAUST

TEMP.SENSOR

4YV

COMP

M1

FAN MOTOR

EKV 5

5

BK

FB

YEGN

G

OFAN

G

G

EH

COMPRESSOR

BAND HEATER RD

RD

HEAT-C

BN

EKV

WH

55FA

RDBK

RT7RT6

TEMP.SENSORTEMP.SENSOR

RDBK

TEMP.SENSOR

LIQUID PIPE

TEMP.SENSOR

GAS PIPE

RT4 RT5

θ

BK

GY COM-INNER

BU

BN

BU

BU

BN

BU

YEGN

G

BU

N1

AC-L2

N2

E(PE)

AP2

N1

AC-L1

BN

AP1:Main Board

U

V

WRD

BU

YE

BU

RD

YE

L1

L1

G

W

X1

VU

4WAY

T-SENSOR

POWER

YEGN

XT1

XTA

XTB

L1

L2

COMP.

TERMINAL

BLOCK

L1

OVC-COMP

SAT

WH

WH

BLOCK

TERMINAL

TERMINAL

BLOCK

N(DC-) at AP1 is higher than 30V to

the voltage of terminal P(DC+) and

Please don't touch any terminal when

WARNING

prevent the risk of electrical shock!

N1

AC-L

N2

4-WAY VALVE

GAS PIPE LIQUID PIPE

BK

WH

VT

VT

QA YA QB YB

CONNECTOR

OVERLOAD

PROTECTOR

RD

RD

BOTTOM HEAT-B

EH

BOND HEATER

G

G

G

X2

X3 X4

X5

X6

ELECTRONIC

EXPANSION

VALVE B

VALVE A

EXPANSION

ELECTRONIC

L5

L5

L2 L3

L4

2L3L

θ

θ

TUBE-A TUBE-B

INDOOR UNIT B

WH BK

YEGN

9Technical Information

AWHD(24)ND3EO AWHD(24)ND3FO AWHD(24)ND3GO

13

Technical Information

Service Manual

GWHD(24)ND3EO GWHD(24)ND3FO GWHD(24)ND3GO

63633609

3OHDVHGRQWWRXFKDQ\WHUPLQDOZKHQ

WKHYROWDJHRIWHUPLQDO3'&DQG

1'&DW$3LVKLJKHUWKDQ9WR

SUHYHQWWKHULVNRIHOHFWULFDOVKRFN

5'

%27720

%$1'+($7(5(+

0

*

2)$1

<(*1

*02725

/

/

/

/

*

32:(5

$30$,1%2$5'

7(036(1625

7(036(1625

7(036(1625

(;+$867

2875220

28778%(

35(6685(

6:,7&+

+,*+

3527(&725

29(5/2$'

&203

6(16256(1625

7(03

%8

%1 %.

:+

%8

<(

:+

:+

5'

<(

%8

5'

<(

%8

5'%.

5'

%.

%. 5'5'%.

:+

:+

*<

%.

<(*1

%8

%1

%1

%8

%1

%8

%1

%8

7(50,1$/

7(50,1$/%/2&.

)$

)%

)&

(.9

(.9

(.9

;

;

;

(/(&7521,&

(;3$16,21

9$/9($

*

,1'22581,7$

1

*

,1'22581,7%

1

*

1

1

*

$&/

$30$,1%2$5'

$&/

1

(3(

1

;7%

1

;7$

/

/

;7

4$ <&4&<%4%

<$

5757

,1'22581,7&

1

5($&725

2*

:+

/;

/;

%/2&.

%/2&.

7(50,1$/

%/2&.

7(50,1$/

9$/9(%

(;3$16,21

(/(&7521,&

(/(&7521,&

(;3$16,21

9$/9(&

;

78%(&

78%(%

57

575757

78%($

&20,11(5

1

57

57

;

*

::

9

/

8

9

29&&203

8

&203

3

+36

+33

57

76(1625

$&/

1

;7&

+($7&

5'

%$1'+($7(5

&2035(6625

:$< <99$/9(

:$<

%8

&211(&725

97

97

*

; ;

<(*1

)$1

*$6

3,3(

7(03

3,3(

/,48,' /,48,'

3,3(

7(03

3,3(

*$6

7(03

6(1625 6(1625 6(16256(1625

7(03

*$6

3,3(

7(03

3,3(

/,48,'

5'

%.

:+

7(50,1$/

%/2&.

%/2&.

7(50,1$/

7(50,1$/

%/2&.

+($7%

5'

5'

These circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

These circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

10

Technical Information

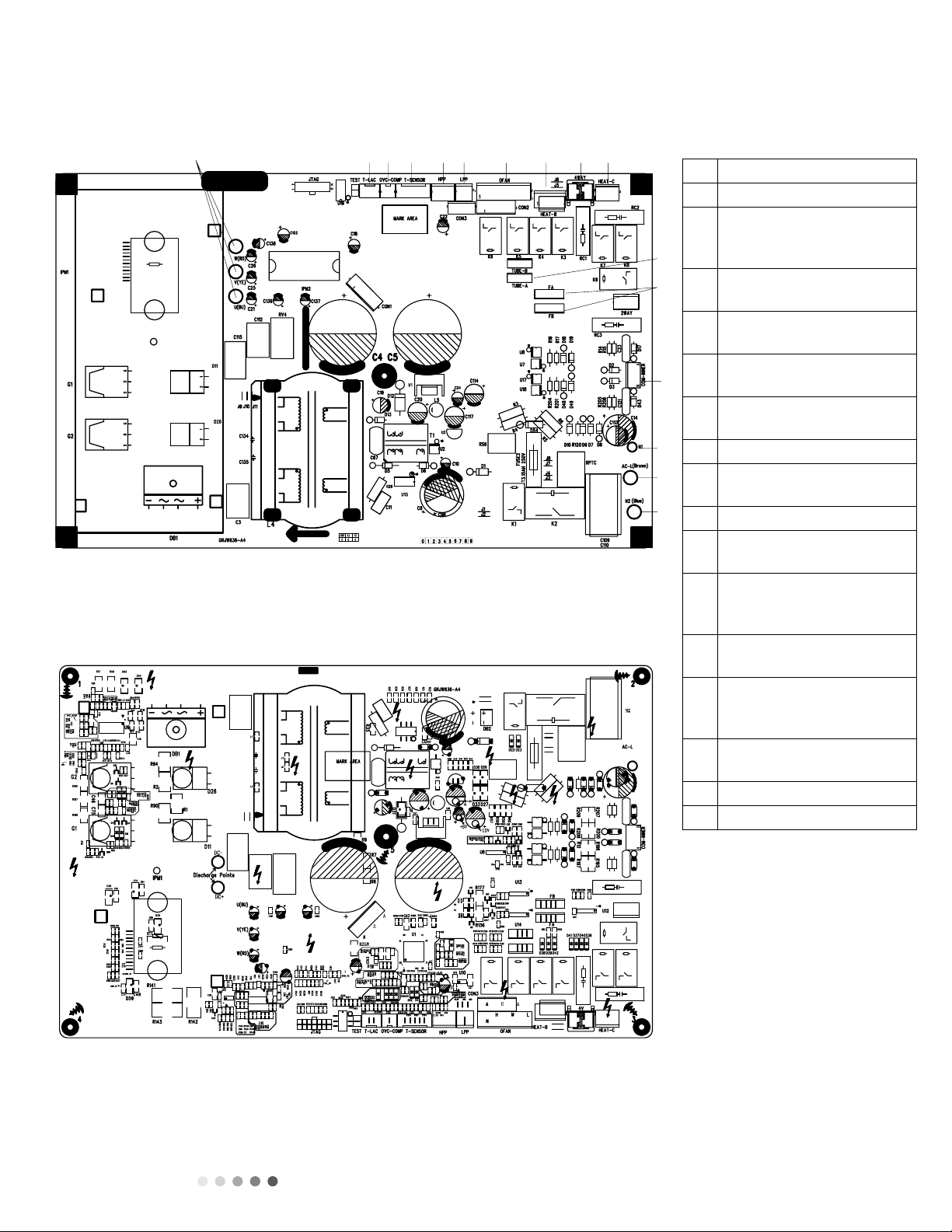

5.2 PCB PRINTED DIAGRAM

AWHD(18)ND3EO AWHD(18)ND3FO AWHD(18)ND3GO

14 Technical Information

Service Manual

1

1

23 45678910

11

12

13

14

15

16

1 Terminal of compressor

2Terminal of low-temperature

cooling temperature sensor

3Overload protection terminal

of compressor

4Temperature sensor terminal

of outdoor unit

5High pressure protection

terminal

6Low pressure protection

terminal

7 Terminal of outdoor unit

8Electric heating belt terminal

of chassis

9 Terminal of 4-way valve

10 Electric heating belt terminal

of compressor

11

Terminal of temperature

sensor wire for liquid valve

and gas valve

12 Terminal of electronic

expansion valve

13

Terminal of communication wire

for indoor unit and outdoor unit

14 Neutral wire terminal for

communication

15 Live wire terminal

16 Neutral wire terminal

5.2 PCB Printed Diagram

● TOP VIEW

● BOTTOM VIEW

GWHD(18)ND3EO GWHD(18)ND3FO GWHD(18)ND3GO

No Name

1Terminal of compressor

2Terminal of low-

temperature cooling

temperature sensor

3 Overload protection

terminal of compressor

4 Temperature sensor

terminal of outdoor unit

5 High pressure protection

terminal

6Low pressure protection

terminal

7Terminal of outdoor unit

8 Electric heating belt

terminal of chassis

9Terminal of 4-way valve

10 Electric heating belt

terminal of compressor

11 Terminal of temperature

sensor wire for liquid valve

and gas valve

12 Terminal of electronic

expansion valve

13 Terminal of communication

wire for indoor unit and

outdoor unit

14 Neutral wire terminal for

communication

15 Live wire terminal

16 Neutral wire terminal

11 Technical Information

AWHD(24)ND3EO AWHD(24)ND3FO AWHD(24)ND3GO

15

Technical Information

Service Manual

1234 8756 9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

● TOP VIEW

● BOTTOM VIEW

GWHD(24)ND3EO GWHD(24)ND3FO GWHD(24)ND3GO

1 Terminal of compressor

2 Low pressure protection terminal

3 High pressure protection terminal

4Overload protection terminal of

compressor

5Temperature sensor terminal of

outdoor unit

6 Electric heating terminal of chassis

7Electric heating terminal of

compressor

8 Terminal of outdoor unit

9 Terminal of 4-way valve

10 Temperature sensor for liquid valve

and gas valve for unit A

11 Temperature sensor for liquid valve

and gas valve for unit B

12 Temperature sensor for liquid valve

and gas valve for unit C

13 Temperature sensor for liquid valve

and gas valve for unit D

14 Electronic expansion vale for unit A

15 Electronic expansion vale for unit C

16 Electronic expansion vale for unit B

17 Electronic expansion vale for unit D

18 Communication wire with indoor unit

19 Neutral wire for counication

20 Live wire

21 Neutral wire

22 Reactor wire 1

23 Reactor wire 2

No Name

1Terminal of compressor

2Low pressure protection

terminal

3 High pressure protection

terminal

4 Overload protection

terminal ofcompressor

5Temperature sensor t

erminal of outdoor unit

6Electric heating terminal of

chassis

7Electric heating terminal of

compressor

8Terminal of outdoor unit

9Terminal of 4-way valve

10 Temperature sensor for

liquid valve and gas valve

for unit A

11 Temperature sensor for

liquid valve and gas valve

for unit B

12 Temperature sensor for

liquid valve and gas valve

for unit C

13 Temperature sensor for

liquid valve and gas valve

for unit D

14 Electronic expansion vale

for unit A

15 Electronic expansion vale

for unit C

16 Electronic expansion vale

for unit B

17 Electronic expansion

vale for unit D

18 Communication wire

with indoor unit

19 Neutral wire for

communication

20 Live wire

21 Neutral wire

22 Reactor wire 1

23 Reactor wire 2

12

Technical Information

6. FUNCTION AND CONTROL

FUNCTION CONTROL

1. Cooling mode

• If the compressor is stopped and the indoor unit reaches the cooling operation condition; the electronic expansion

valve, the outdoor fan and the compressor will all begin to operate.

• If the compressor stops suddenly, the outdoor fan will stop within 1 minute.

• When the unit converts to heating mode, the 4-way valve will be energized after the compressor has been at a

full stop for 2 minutes.

• The outdoor fan starts 5 seconds before the compressor turns on. When powering up the unit, the outdoor fan

will run 3 minutes on high speed and then it will run at set speed. The fan runs for a minimum period of 80

seconds for each setting adjusted by the user.

• When the compressor stops, the outdoor fan will run at present speed for 1 additional minute before stopping.

• Should the outdoor unit malfunction or should it go into Protection Mode, the indoor unit will maintain

operational status.

1.2. Dry mode (dehumidification mode)

• The dry mode process is the same as those in cooling mode.

• The 4-way valve shall be closed.

• Temperature setting range is 60.8F - 86.0F.

• Protection function will be the same as in cooling mode.

• If the compressor is stopped and the indoor unit reaches the cooling operation condition; the electronic expansion

valve, the outdoor fan and the compressor will all begin to operate.

If the compressor stops

1.3. Heating mode

• Temperature setting range is 60.8F - 86.0F.

• When the compressor stops, the outdoor fan will run at present speed for 1 additional minute before stopping.

• While in Heating Mode, the indoor unit will enter into cold air prevention status. When the unit stops (or is turned

off), the indoor unit enters into residual heat blowing status.

• The outdoor fan starts 5 seconds before the compressor turns on. When powering up the unit, the outdoor fan

will run 3 minutes on high speed and then it will run at set speed. The fan runs for a minimum period of 80

seconds for each setting adjusted by the user.

1.4 Fan mode

• Temperature setting range is 60.8F - 86.0F.

• The fan will operate at its user set speed on the indoor unit.

• Indoor fan can operate at HIGH, MEDIUM, LOW, or AUTO fan speed.

Protection Function

2.1 Mode Conflict Protection of Indoor Unit

• When the indoor unit is in basic mode, compare the mode of other indoor units to see if there is a conflict – such

as cooling mode in conflict with dry or heating mode(s).

• No matter which indoor unit operates first, the unit will run in heating mode.

2.2 Mode Conflict Protection of Indoor Unit

• When the tube temperature is low, the compressor raises the operational frequency. When the tube temperature

is high, the compressor frequency is restricted or lowers the operational frequency; when the tube temperature is

too high, the compressor protection stops running.

• If the discharge temperature protection continuously runs for 6 cycles, the compressor will shut down and fail

to run. The compressor will be able to run after cutting off power to the unit and restoring it after the capacitors

have been effectively rid of any residual charge. If the running time of the compressor is longer than 7 minutes,

the protection time record will be cleared.

13 Technical Information

2.3 Discharge Protection Function

• When the discharge temperature is low, the compressor raises the operational frequency. When the discharge

temperature is high, the compressor frequency is restricted or lowers the operational frequency; when the

discharge temperature is too high, the compressor protection stops running.

• If the discharge temperature protection continuously runs for 6 cycles, the compressor will shut down and fail

to run. The compressor will be able to run after cutting off power to the unit and restoring it after the capacitors

have been effectively rid of any residual charge. If the running time of the compressor is longer than 7 minutes,

the protection time record will be cleared.

2.4 Communication Malfunction

• If the outdoor unit does not receive communication from the indoor unit after 3 minutes of being powered-up,

the outdoor unit will infer that the indoor unit is not installed and will power down.

2.5 Overcurrent Protection

• Overcurrent protection of complete unit, phase wire protection, and compressor phase current protection.

2.6 Compressor High-Pressure Protection

• If the high-pressure switch is isolated for 3 seconds, the compressor will enter high-pressure protection mode

and will come to a complete stop. Simultaneously, the outdoor unit will send the signal – high pressure protection

engaged – to the indoor unit(s).

• Once high pressure protection mode has been engaged, the high pressure switch will be closed for 6 seconds and

the compressor will resume running after the power has been cutoff and restored.

2.7 Compressor Overload Protection

• When the compressor overload switch detects movement, the indoor unit will display malfunction and it will stop

the indoor unit from reaching the set temperature. When the compressor stops for more than 3 minutes and

the overload switch is reset, the unit will resume normal operating status automatically. If overload protection is

activated more than 6 times, the unit will fail to resume normal operation. It will only resume running after the

power has been cutoff and restored.

2.8 Compressor Phase-Lacking Protection

• If one of three phases is detected as open during power up of the compressor, the compressor will enter phase

lacking protection. The malfunction will automatically clear after 1 minute, the unit will restart and then attempt

to detect is phase lacking protection is still needed. If phase lacking protection is detected 6 times, the

compressor will not restart but will be able to run after power has been cutoff and restored. At this point, if the

run time of the compressor is 7 minutes without interruption, the protection record will be cleared and the system

will run under normal conditions.

2.9 IMP Protection

• When the IMP module protection is detected, the outdoor unit will stop the indoor unit from reaching the set

temperature. After the compressor has stopped for 3 minutes, the unit will resume normal operational status

automatically. If the IMP protection occurs more than 6 times, the system will completely stop and the send the

signal of module protection to the indoor unit. The unit cannot resume operational status automatically, it will

only resume running after the power has been cutoff and restored.

14

Technical Information

PART II : TECHNICAL INFORMATION

7. NOTES FOR INSTALLATION AND MAINTENANCE

SAFETY PRECAUTIONS:

IMPORTANT!

Please read the safety precautions carefully before

installation or prior to performing any maintenance.

Please follow instructions below.

• Maintenance or installation MUST be in accordance with

instructions.

• Comply with ALL local and national electrical codes.

• Pay attention to ALL warnings and cautions in this

manual.

• Any maintenance and/or installation shall be performed

by distributors or licensed and qualified individual.

• Electrical work MUST be performed by licensed

technician according to local regulations and the

instructions given in this manual.

• Use extreme caution when performing electrical

installation tasks – Electric shock can result in severe

injury or death.

WARNINGS!

ELECTRICAL SAFETY PRECAUTIONS

1. Disconnect power supply prior to ANY work.

2. The air conditioner is a specialized circuit that requires

its own power supply – this is not to be shared with ANY

other electrical appliances.

3. The air conditioner should be installed in a suitable

location and the power supply should be easily reachable

by ALL users.

4. During maintenance and installation, make sure wiring

terminals are securely fastened.

5. Ground wire MUST be firmly connected and NOT used

for other purposes.

6. Use protective accessories as necessary, (IE: protective

boards, cable-cross loop, wire clips, etc.).

7. Live wire, neutral wire, and ground wire MUST

correspond to the live wire, neutral wire, and ground wire

of the air conditioner.

8. Power cord and power connections MUST be free of

obstruction and CANNOT be compressed.

9. Should power cord or power connection become severed,

they MUST be repaired/replaced by qualified technician.

10. If the power cord or power connection wire is not

long enough, replace with specialized cable from

manufacturer before proceeding with installation or

repair. DO NOT elongate these wires.

11. An air switch MUST be installed if there is no plug found

on the air conditioner. The air switch MUST be all-pole

parting and the contact parting distance MUST be at

1/8” or greater.

12. All wires and pipes MUST be connected firmly prior to

supplying the unit with power.

13. Eliminate any electric leakage on the unit body.

14. Fuses MUST be replaced with fuse of the same

specification(s). DO NOT replace with copper wire or

conducting wire.

15. If the unit is being installed in a humid climate, a circuit

breaker MUST also be installed.

INSTALLATION SAFETY PRECAUTIONS

1. Select installation location according to the requirements

of this manual. (See the requirements of installation

section in this manual.).

2. Handle unit with care. If unit exceeds 44.09 pounds, use

the two-person lift technique to transport.

3. Use a sufficient fixing bolt when installing both the

indoor and outdoor unit(s). Ensure installation support is

firm.

4. Use safety belt and personal protection equipment

(PPE) while working above a height of 6’.

5. Use equipped components or appointed components

during installation.

6. Make sure to clear the unit of any/all foreign objects prior

to completion of installation.

REFRIGERANT SAFETY PRECAUTIONS

1. Avoid contact of fire and refrigerant as the combination

creates poisonous gas.

2. Use only specified refrigerant. DO NOT mix refrigerant

types. DO NOT allow air to remain in refrigerant lines as

this may lead to pipe rupture or other hazards.

3. Check entire system for refrigerant leaks prior to

completing installation.

Improper installation may lead to fire hazard,

explosion, electric shock or injury.

15 Technical Information

MAIN TOOLS FOR INSTALLATION AND MAINTENANCE

1. Level meter, measuring

tape

2. Screwdrivers 3. Impact drill, drill head, electric drill

4. Electroprobe 5. Universal meter 6.Torque wrench, open-end wrench, inner

hexagon spanner

7. Electronic leakage detector 8. Vacuum pump 9. Pressure meter

10. Pipe pliers, pipe cutter 11. Pipe expander, pipe bender 12. Soldering appliance, refrigerant container

16

Technical Information

Start installation

Preparation before installation

Read the requirements for

electric connection Select installation location Prepare tools

Select indoor unit

installation location

Select outdoor unit

installation location

Install wall-mounting frame,

drill wall holes

Connect pipes of indoor unit

and drainage pipe

Connect wires of

indoor unit

Bind up pipes and hang

the indoor unit

Install the support of

outdoor unit

(select it according to the

actual situation)

Fix outdoor unit

Make the bound pipes pass

through the wall hole and then

connect outdoor unit

Install drainage joint of

outdoor unit (only for cooling

and heating unit)

Connect pipes of outdoor unit

Connect wires of outdoor unit

Neaten the pipes

Vacuum pumping and leakage detection

Check after installation and test operation

Finish installation

8. INSTALLATION MANUAL

INSTALLATION PROCEDURE

17 Technical Information

8.1 ELECTRICAL CONNECTIONS

1. Remove the handle at the right side plate of the outdoor

unit (one screw).

2. Remove the cable clamp, connect the power connection

cable with the terminal at the row of connection and

fix the connection.The fitting line distributing must be

consistent with the indoor unit. terminal of line bank.

Wiring should meet that of indoor unit.

3. Fix power connection wire by wire clamp.

4. Ensure wire has been fixed well.

5. Install the handle.

Including an air switch with suitable capacity,

please note the following table. Air switch should

be included magnet buckle and heating buckle

function, it can protect the circuit-short and

overload. (Caution: please do not use thefuse only

for protect the circuit)

An all-pole disconnection switch having a contact

separation of at least 3mm in all pole should be

connected in fixed wiring.

Wrong wire connection may cause malfunction of

some electric components.After fixing cable, ensure

that leads between connection to fixed point have

some space.

The connection pipes and the connectiong wirings

of the unit A and unit B must be corresponding to

each other respective.

The appliance shall be installed in accordance with

national wiring regulations.

Note: the above figures are only intended to be

a simple diagram of the appliance and may not

correspond to the appearance of the units that have

been purchased.

!

!

!

!

!

22 Installation and Maintenance

Service Manual

8.1 Electrical Connections

1. Remove the handle at the right side plate of the outdoor

unit (one screw).

2. Remove the cable clamp, connect the power connection

cable with the terminal at the row of connection and fix the

connection. The tting line distributing must be consistent with

the indoor unit. terminal of line bank. Wiring should meet that of

indoor unit.

3. Fix power connection wire by wire clamp.

4. Ensure wire has been xed well.

5. Install the handle.

Wrong wire connection may cause malfunction of some

electric components.After xing cable, ensure that leads

between connection to xed point have some space.

An all-pole disconnection switch having a contact

separation of at least 3mm in all pole should be connected

in xed wiring.

The connection pipes and the connectiong wirings of

the unit A and unit B must be corresponding to each

other respective.

The appliance shall be installed in accordance with

national wiring regulations.

Note: the above gures are only intended to be a simple

diagram of the appliance and may not correspond to the

appearance of the units that have been purchased.

Including an air switch with suitable capacity, please note

the following table. Air switch should be included magnet

buckle and heating buckle function, it can protect the

circuit-short and overload. (Caution: please do not use

thefuse only for protect the circuit)

GWHD(18)ND3EO GWHD(18)ND3FO

GWHD(18)ND3GO

L1

L2

To the power supply

To unit B

Power cord

To unit A

connecting

cable

L1

L2

Power cord

L1 L2

L1 L2

L1

L2

To the power supply

To unit A

L1 L2

GWHD(24)ND3EO GWHD(24)ND3FO

GWHD(24)ND3GO

connecting

cable

connecting

cable

To unit B

connecting

cable

To unit C

connecting

cable

C

C

AWHD(18)ND3EO AWHD(18)ND3FO

AWHD(18)ND3GO

AWHD(24)ND3EO AWHD(24)ND3FO

AWHD(24)ND3GO

This manual suits for next models

1

Table of contents

Other ACPro Air Handler manuals

Popular Air Handler manuals by other brands

Johnson

Johnson SUIT VRV Series instruction manual

Trox Technik

Trox Technik X-CUBE X2 compact 2 Transport and installation manual

Salda

Salda Smarty 2R VE User and Service Technical Manual

Greenheck

Greenheck IG Installation, operation and maintanance manual

Nortek

Nortek U-match Series Owner's Manual & Installation Instructions

MrCool

MrCool Olympus Series Installation & owner's manual