3

Air handling units

Application, working conditions, construction

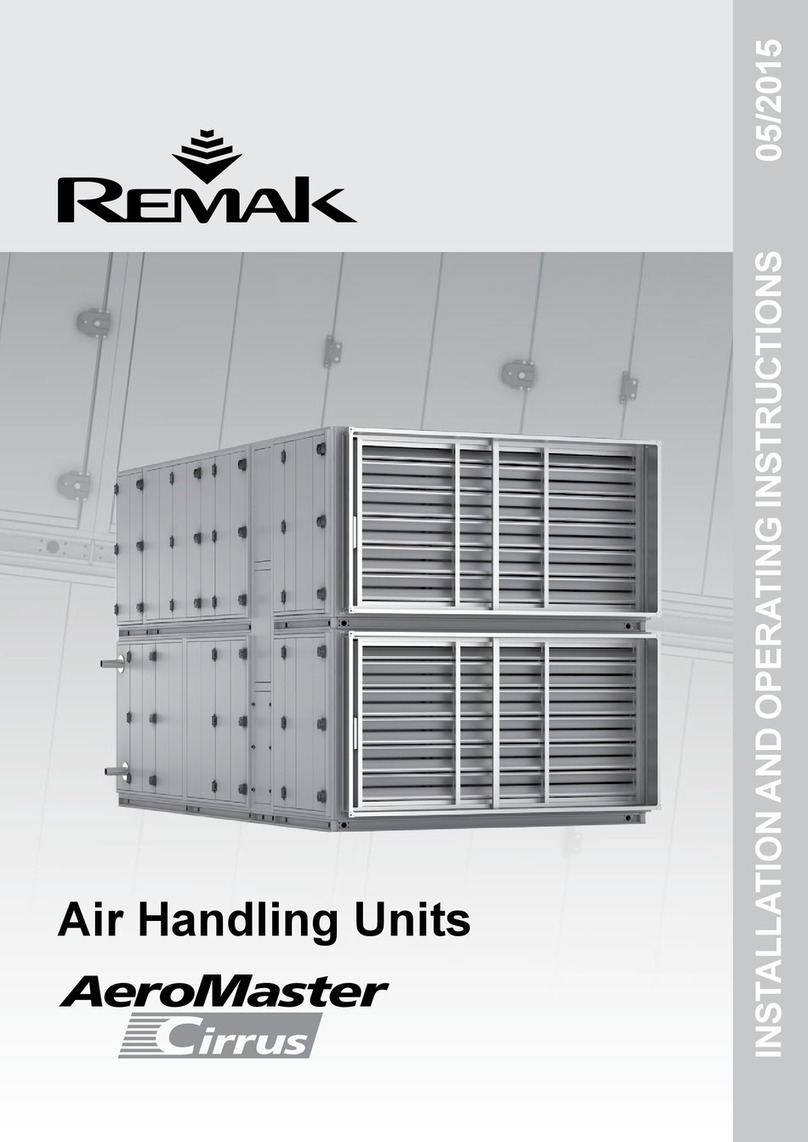

Picture 1 – service access to units (left/right)

Service panel of electric heating section, separate wiring

boxes and service panels covering electric devices are

provided with label with warning symbol meaning „Warning

– Danger of Electric Shock“

Information from the producer

AeroMaster FP air-handling units are produced

according to valid czech and european technical

regulations and technical standards. Units can only be

installed and used according to this documentation.

Installation and service instructions must be accessible

to service attendance and therefore it is useful to place

it close to the unit.

Application and working conditions

AeroMaster FP air-handling units are intended for com-

fortable air-handling and air-conditioning of smaller

rooms. They are manufactured in two dimensional ran-

ges, FP 2.7 and FP 4.0, for air ow ranges from

500 m3/h to 4,500 m3/h at air pressure deference of the

fan of up to 1200 Pa. AeroMaster FP air-handling units

are designed to transport air without solid, brous, stic-

ky, aggressive, respectively explosive impurities. The

transported air must be free of corrosive chemicals or

chemicals aggressive to zinc and steel, respectively

aluminium. When designing the air-handling assembly,

it is necessary to take into account the temperature and

humidity of the inlet and outlet air in relation to the am-

bient temperature and humidity. It is especially necessa-

ry to analyze the relation of the unit's casing classica-

tion pursuant to EN 1886 and the risk of condensation

respectively, ice build-up. AeroMaster FP air-handling

units can be used in normal rooms (IEC 60364-5-51,

resp. ČSN 332000-5-51 ed.2, ČSN 332000-1 ed.2) and

in rooms with extended ambient temperature range ran-

ging from -30 °C to +40 °C without additional measures.

Degree of protection - IP 40. The unit's accessories

(M&C) are not included - they must be assessed sepa-

rately.

Construction of air handling unit

Unit construction is sectional, modular. Casing is com-

posed of panels and connecting bars between them.

Panels are attached to connecting bars and by thread-

ed joints between each other. For cases of regular

maintenance or inside checks (change of ltration

inserts, cleaning etc.), the sections are equipped with

service panels which have the same construction as

stationary panels but they are equipped with handles

and xed by turning thrust latches.

All panels have sandwich construction with total width

of lateral insulation of 40 mm, upper and bottom of 25

mm with quality anticorrosive treatment. Panels are pro-

vided with PE seal sticked to panel surfaces of contact.

Complete air handling unit Viking FP is composed of

sections. The sections are (mechanically) separate

while the lateral panel of the section is compact (panel

without bars). The section is functionally dened by a

casette.

Unit labelling

Every section (except the frame) is provided with type

(production) label of section, with following data:

producer name

type, size and code identication of the section

order number /year of production

weight

wiring (electric system)

electric protection

The label also includes technical parameters of given

section. The user must make sure, that all labels on the

machine are readable and undamaged during whole

operation time. In case of damage of label conserning

safe use, repair it at once.

Informative and safety labels

FP units and separate sections are further provided with

informative labels showing the function of the device,

wiring schemes, media inlets and outlets and producer

labelling.

service lter

connection

RIGHT

service

connection fan

LEFT

heater

damper

heater

eliminator fan

cooler

cooler

Service access to units

Unit construction provides

combinations of sides of ener-

gy connection and service

accesses. Connection side is

always given according to the

direction of air ow. (picture 1)

Meaning of symbols

elastic connection

air damper

air lter

heater

cooler

drop eliminator

fan

Warning symbol „Other danger“ is placed on the outside of

the unit on the service door and it calls attention to hazard

of interception with moving objects.