4/28 NT00000849-UTBS-ECOWATT-AN-230623

Tripping of safety thermostats (EI model)

• UTBS ECOWATT® are equipped with 2 safety switch thermostats:

-A manual reset thermostat switches off the heater at 85°C.

-An automatic reset thermostat switches off the heater at 60°C.

• Any resetting or tripping information (via the BMS for example) involves looking for the cause of this

1.3 Reception – Storage

In the event of lack, non-compliance, total or partial damage to the products delivered, the Buyer must, in

accordance with article 133-3 of the Commercial Code, issue written reservations on the carrier's receipt and

conrm them in 72 hours by sending a registered letter to the transporter and a copy to the manufacturer.

The receipt without reservation of the equipment deprives the Buyer of any further recourse against us.

The product must be stored away from bad weather, shocks and dirt due to projections of any kind during its

transport from the supplier to the end customer, and on the site before installation.

1.4 Warranty

The equipment is guaranteed for 24 months from the invoice date. The warranty is limited to the replace-

ment of parts or equipment whose operation is recognized as defective by the manufacturer, excluding

any compensation or penalties. The costs of labor, removal and rest, travel related to the replacement are

the responsibility of the Customer. Excluded from our warranty are defects linked to abnormal use or not

in accordance with the recommendations in our instructions, defects observed as a result of normal wear

and tear, incidents caused by negligence, lack of monitoring or maintenance, defects due to incorrect ins-

tallation of devices or poor storage conditions prior to assembly.

In any case, manufacturer is not responsible for transformed material, even partially repaired.

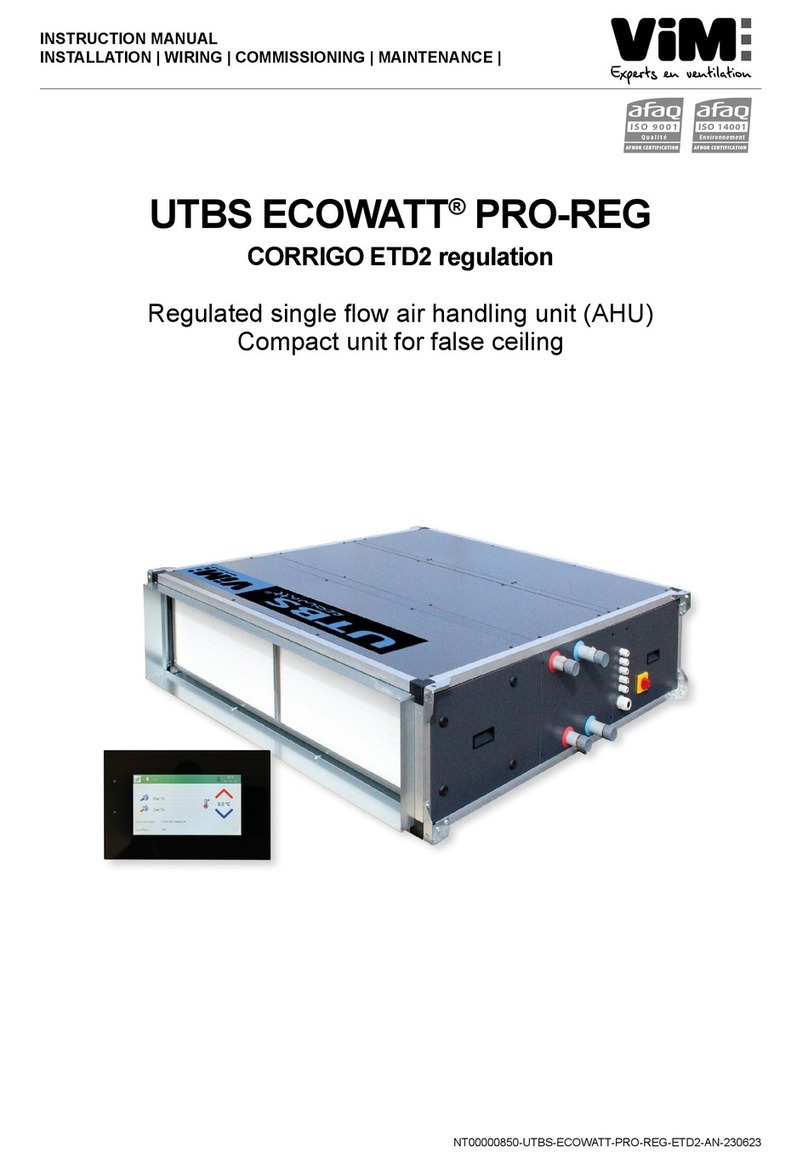

2. PRODUCT RANGE PRESENTATION

2.1 Range

Use:

• Introduction of fresh air, heating and air conditioning.

• Indoor or outdoor installation.

• Floor or ceiling mounting, or vertical see § "3.4 Location and mounting", page 13.

4 sizes:

UTBS ECOWATT® 2 (2,000 m3/h), UTBS ECOWATT® 3 (3,000 m3/h), UTBS ECOWATT® 5 (5,000 m3/h),

UTBS ECOWATT® 8 (8,000 m3/h),

Congurations according to the types of built-in coils or heater:

• UTBS ECOWATT®EI : integrated electric heater.

• UTBS ECOWATT®EC : integrated hot water coil.

• UTBS ECOWATT®ER : integrated reversible water coil.

• UTBS ECOWATT®ECF : integrated hot water coil + cold water coil.

• UTBS ECOWATT®EIF : integrated electric heater + cold water coil.

• UTBS ECOWATT®EX : integrated direct expansion coil.

Upward vertical air ow mounting possible for versions with hot water coil or electrical heater.

4 constructions - rectangular line connection:

• UTBS ECOWATT®D : indoor installation - Right hand side access

• UTBS ECOWATT®G : indoor installation - Left hand side access

• UTBS ECOWATT®EXD : outdoor installation with mounted roof - Right hand side access

• UTBS ECOWATT®EXG : outdoor installation with mounted roof - Left hand side access