Acromag ES2163 User manual

EtherStax™ Stackable Industrial I/O Family

Modbus TCP/UDP/IP 10/100MB Ethernet I/O

Model ES2163 & ES2164

64-Ch Single-Ended Analog Current/Voltage Input

USER’S MANUAL

ACROMAG INCORPORATED Tel: (248) 295-0880

30765 South Wixom Road Fax: (248) 624-9234

Wixom, MI 48393-7037 U.S.A.

Copyright 2009, Acromag, Inc., Printed in the USA.

Data and specifications are subject to change without notice.

8500-825-B10A001

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

__________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

2

IMPORTANT SAFETY CONSIDERATIONS

You must consider the possible negative effects of power, component,

wiring, sensor, or software failure in the design of any type of monitoring or

control system. This is very important where property loss or human life is

Involved. It is important that you perform satisfactory overall system design

and it is agreed between you and Acromag, that this is your responsibility.

GETTING STARTED

QUICK START………………………………………….. 3

MOUNTING AND DIMENSIONS……………………… 5

CONTROLS & INDICATORS..………………………… 12

ISOLATION BARRIERS..………………………………. 13

CONNECTIONS…………………………………………. 14

Network…………………………………………….. 14

Redundant Media Connections………………... 21

Power……………………………………………….. 23

Earth Ground..………………………………….…. 23

Alarm Relay………………………………………... 24

Analog Inputs.…………………………………….. 25

Analog Common..………………………………… 26

WEB BROWSER………………………………………... 26

Home Page………………………………………… 26

Password Configuration Page.………………... 27

Network Configuration Page…………………… 27

Input Configuration Page……………………….. 31

Test Page………………………………………….. 37

Calibration Page………………………………….. 38

Utility Page………………………………………… 46

TROUBLESHOOTING………………………………….. 47

Diagnostics Table……………………………..…. 47

Getting Out Of Trouble………………………….. 50

TECHNICAL REFERENCE

KEY FEATURES………………………………………… 51

HOW IT WORKS………….…………………………….. 52

Key Observations…..……………………………. 53

MODBUS REGISTERS………………………………… 54

Register Functions………………………………. 54

Register Mirroring……………………………….. 55

Register Map……………………………………… 57

SPECIFICATIONS………………………………………. 81

Model Numbers….……………………………….. 81

Mounting Options………………………………... 81

Analog Input Specifications…….……………… 82

General Input Specifications…….…………….. 84

Reliability Prediction…………………………….. 85

Alarm Relay Output…………………………….… 86

Memory…………………………………………….. 86

Agency Approvals…..……………………………. 86

Enclosure and Physical…………………………. 87

Environmental…………………………………….. 88

Ethernet Interface………………………………… 89

Controls & Indicators……………………………. 90

CABLES & CONNECTORS..………………………….. 92

TABLE OF

CONTENTS

Symbols on equipment:

Means “Refer to User’s

Manual (this manual) for

additional information”.

The information of this manual

may change without notice.

Acromag makes no warranty

of any kind with regard to this

material, including, but not

limited to, the implied

warranties of merchantability

and fitness for a particular

purpose. Further, Acromag

assumes no responsibility for

any errors that may appear in

this manual and makes no

commitment to update, or

keep current, the information

contained in this manual. No

part of this manual may be

copied or reproduced in any

form without the prior written

consent of Acromag, Inc.

For additional information,

please visit our web site at

www.acromag.com and

download our whitepaper

8500-765, Introduction To

Modbus TCP/IP, or 8500-648,

Introduction to Modbus.

Windows® is a registered

trademark of Microsoft

Corporation.

!

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

___________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

3

If you already know the basics of connecting power, connecting a network

cable, and using a web-browser, and you only need some help establishing

communication, here is a brief outline of what you must do to start

communicating with this device right away and where to go for help.

This is a web-enabled Ethernet device that allows you to use your web-

browser to set it up and operate it. All Ethernet devices have a unique IP

address that you are required to know in order to communicate with them

using your web-browser.

What if you do not already know the IP address of the unit?

All Acromag Ethernet devices include an alternate default mode of operation

with a fixed IP address set to 128.1.1.100. Additionally, the user-

programmable IP address that is used outside of default mode is also initially

set to 128.1.1.100 from the factory. If this unit is fresh from the factory, you

can talk to it at this address in either mode.

If your unit is not as shipped from the factory and may have another IP

address set, then…

You need to place the unit in its Default Mode, which allows you to address it

at IP address 128.1.1.100 (http://128.1.1.100).

You place this unit into Default Mode by depressing the toggle switch to the

position marked “DFT” for about 4 seconds (see front figure at right), just

until the yellow STATUS LED (opposite side of unit) starts blinking slowly to

indicate the unit is in the Default Mode. Let go of DFT toggle when Status

LED starts blinking. If you hold it depressed for too long, it will pass back out

of Default Mode.

Try browsing the unit with your web browser address at http://128.1.1.100.

If your unit is in default mode, you should be presented with the home page

(and your Status LED should continue to blink).

If you are using IP address 128.1.1.100, and you still can’t talk to the unit…

You cannot talk to this device at IP address 128.1.1.100 if the Network

Interface Card you are using to connect to this device is set to an IP address

outside of the address domain established by this default address. You

must set the IP address of your network interface to an address like

128.1.1.x, where x is an integer from 1 to 254, except 100 (our default

address). This procedure is covered in document 8500-815 shipped with

your unit. It is also detailed in Application Note 8500-734, which you can

obtain from the CDROM shipped with your unit, or optionally via download

from our web site at www.acromag.com.

You managed to browse to the unit’s Home Page, but now you need to get

to the Network Configuration Page to set your own IP address…

In order to access any of the other web configuration pages, like the Network

Configuration Page, you will need to first enter a Username = User, and

Password = password to gain access (these are the default username and

password settings for all EtherStax models and these entries are case-

sensitive).

QUICK START

Guide to Quickly

Establishing

Communication

2

PORT 1

1RST

DFT

LED Column 2

PORT 2

ETHERNET 10/100M

LED Column 1

COM Port Status

Default Mode

& System Reset

Toggle Switch

Acromag

COM

STAT US

FRONT OF UNIT

+ -

+ -

B

STATUS

RELAY

G

RLY

A

RUN

GND

G

Alm Relay

(RED)

UNIT STATUS LED's

PWR

Op Status

(YELLOW)

BACK OF UNIT

Run/Power

(GREEN)

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

__________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

4

Your unit is not as shipped from the factory and you do not know the

Username and Password settings…

If you forget your user name & password, you can always toggle the unit into

default mode via the DFT toggle switch at the front of the unit (hold this

toggle 4 seconds to invoke default mode). In this mode, the password and

username will revert to the original defaults of “User” and “password” (unit

assumes an IP address of 128.1.1.100 in its default mode), allowing you to

re-invoke the Password Configuration Page and change the username and

password settings as required.

If after applying power, your green RUN LED is not solid ON after 25

seconds and is blinking continuously, you need to do the following:

Normally on power-up, the green RUN LED will blink for about 25 seconds

during initialization, then stay ON. But if you powered the unit up without

making your network connection, the green RUN LED will continue to blink.

If RUN continues to blink, first check that your network cable is connected to

the unit and to your PC. If you replaced the network cable after powering-up,

the RUN LED should stop blinking after about 10 seconds once a network

link has been established. Once the link is established, the green RUN LED

should not continue to blink and should stay ON, even if you later remove the

cable while still powered up.

If you have checked your network connections and the green RUN LED

continues to blink…Reset, Restore, Return:

Reset: Try resetting the unit by momentarily depressing the DFT/RST toggle

switch to the RST position. After about 25 seconds, the green RUN LED

should remain ON.

Restore: If you’ve tried resetting the unit and the green RUN LED still

continues to blink, then you may need to follow the procedure for restoring

the EtherStax to its initial configuration. This procedure is located at the end

of the Trouble-Shooting section of this manual under “Getting Out Of

Trouble” on page 50. Note that this is also the procedure used to sanitize

the unit for de-commissioning. You should only do this as a last resort, as

this procedure restores everything to its default state—all holding registers,

network settings, i2o settings, including any calibration you may have

performed.

If you do use restore and want to return the unit to service, the calibration

reference will additionally have to be “restored” separately via the Restore

Factory Voltage Reference Value button of the Input Calibration Page.

Inputs will be calibrated automatically by default, but any manual calibration

you may have done to improve accuracy is lost after restore and may need

to be rechecked.

Return: At this point, if the green RUN LED continues to blink after resetting

and after restoring, then you may need to return the unit for repair.

If you need additional help and you have already reviewed the material in

this manual, please contact the factory.

QUICK START

Guide to Quickly

Establishing

Communication

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

___________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

5

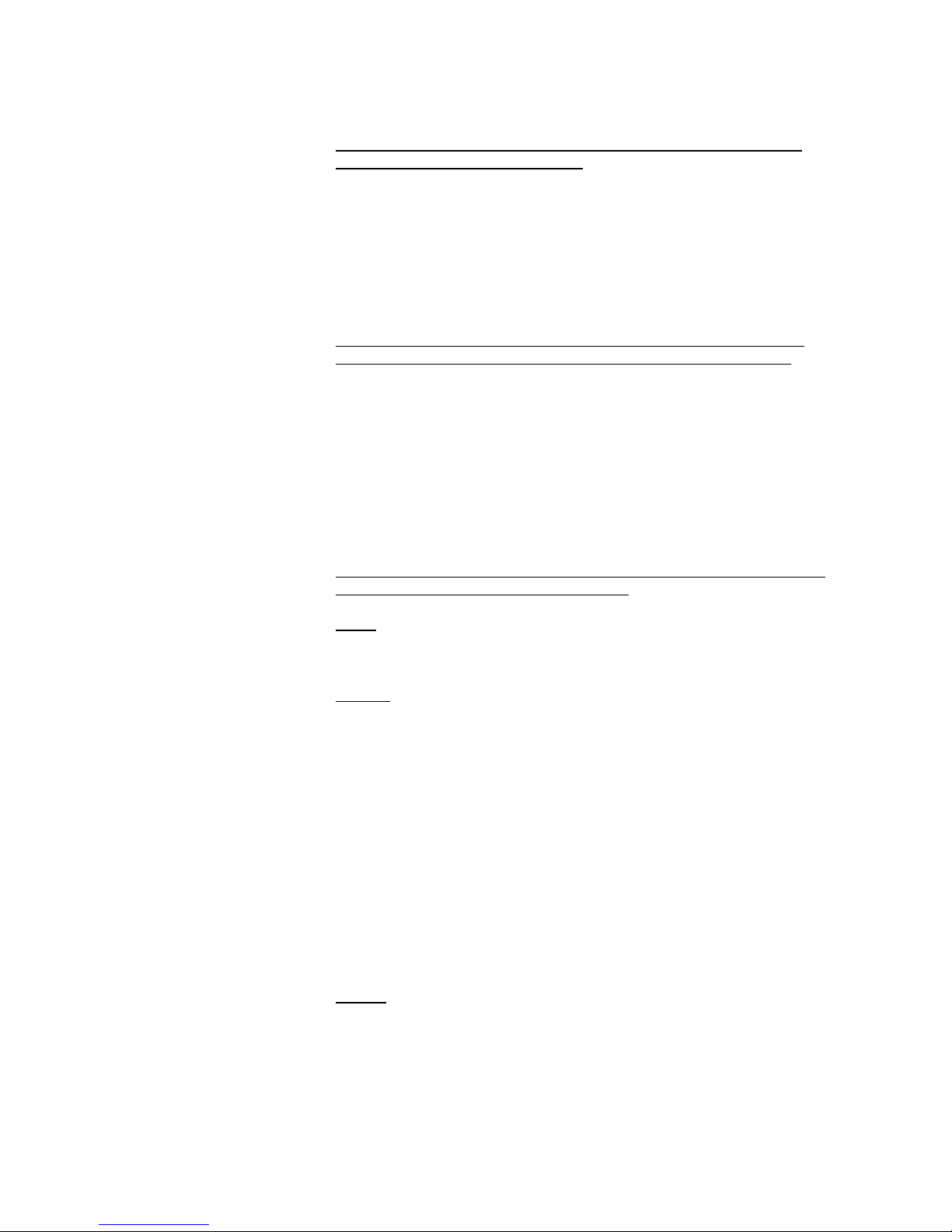

ESA-DIN-VMK TOP VIEW

NOTE: ESA-DIN-VMK CONTAINS

TWO OF THESE PIECES.

ESA-DIN-VMK SIDE VIEW

7.625

GROUND

SCREW

8.226

2.444

6.125

GROUND

SCREW

GROUND

SCREW

DIMENSIONS ARE IN INCHES.

THE ES2163/2164 IS SHOWN AT LEFT.

ETHERSTAX DIMENSIONS

A SINGLE UNIT STANDS 2.444 INCHES TALL.

EACH ADDITIONAL UNIT ADDS 2.229 INCHES.

A TWO UNIT STACK IS 4.673 TALL.

A THREE UNIT STACK IS 6.902 TALL.

THE OPTIONAL SURFACE-MOUNT BASE-PLATE

ESA-SMK ADDS 0.25" TO HEIGHT.

THE OPTIONAL DIN RAIL CLIP ESA-DIN-VMK

ADDS 1.0" TO HEIGHT WHEN MOUNTED ON

35mm x15mm DIN RAIL.

THE OPTIONAL BASEPLATE AND HEAVY DUTY

DIN RAIL MOUNT ESA-DIN-HMK ADDS 0.84" TO

HEIGHT WHEN MOUNTED ON 35mm x15mm DIN RAIL.

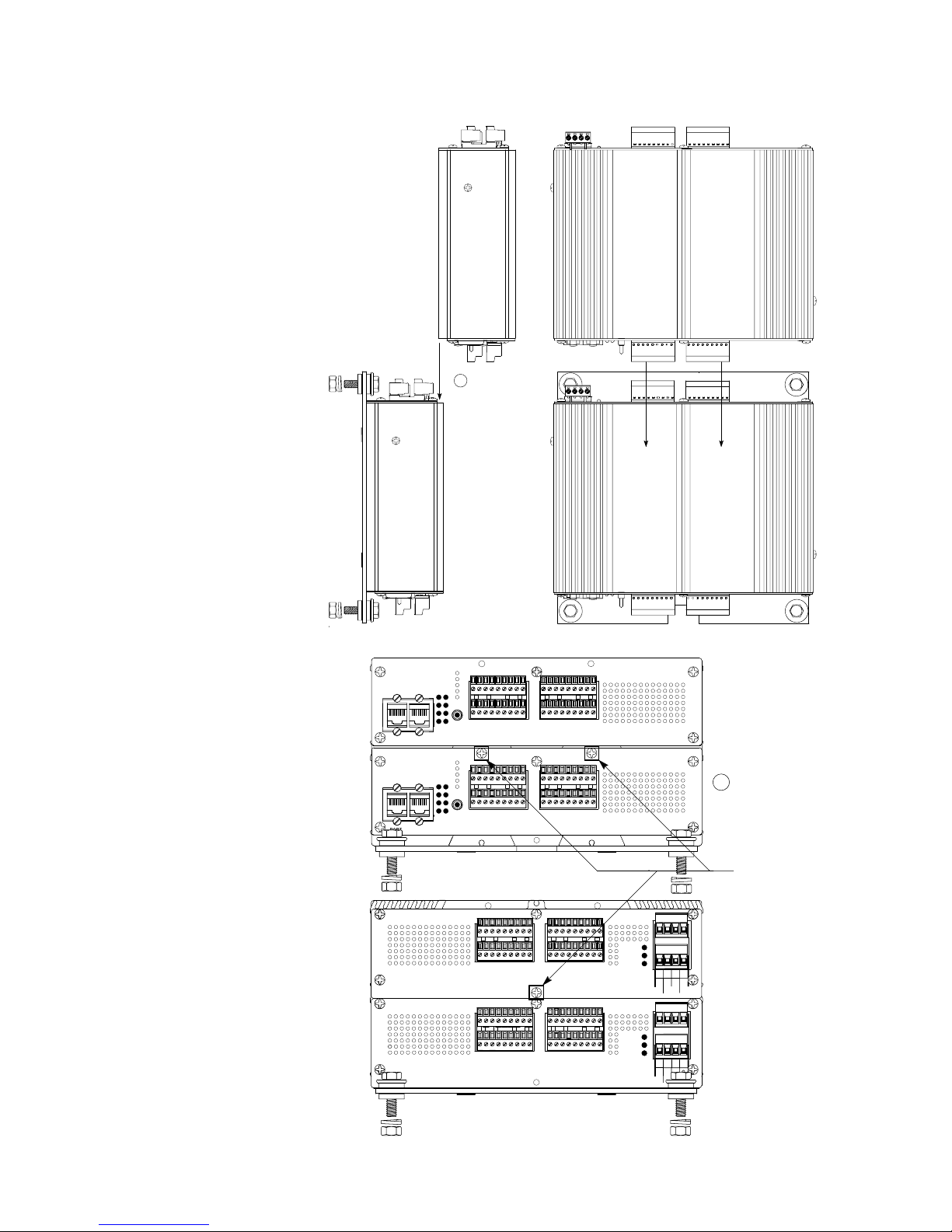

Units are designed to interlock and stack together up to three units high. A

stack of units can be bolted to a wall or flat surface, or mounted on deep-

channel, “T” type, 35mm x15mm DIN rails (per DIN EN60715 TH35),

depending on the optional mounting kit selected. Available mounting kits are

shown below.

DIN Rail Vertical Mount Kit ESA-DIN-VMK (One or Two Units):This kit

includes two plastic DIN clips (Rose Bopla #77003500) that slide into the

dove-tail channel of the bottom of the housing. You can use one clip to

mount a single unit, or both for added stability when stacking two units. If

stacking more than two units on a DIN rail, see ESA-DIN-HMK.

08 10 12

TS1

14 C 24 26 28 30 C

1 2

00 02 04 06 C 16 18 20 22 C

PORT 1

PORT 2

RST 09 11 13 15 25 27 29

TS2

31

DFT

01

TOP

03 05 07 17 19 21 23

STATUS

ETHERNET 10/100M

TOP should coincide with

the upper lip of the DIN rail

This side of clip should

align with top of rail

COM

UPWARD

Position clip such that TOP is aligned

with end of unit you want upright.

Acromag

DIN MTG CLIP

OF ESA-DIN-VMK

TO REMOVE: Push unit upward and tilt TOP of

unit back towards you to disengage it from rail.

TO HANG: Tilt unit and place TOP of clip over upper lip

of DIN rail. Press bottom towards rail to snap in place.

MOUNTING AND

DIMENSIONS

These Models are open-type

devices and intended for

installation into a suitable

enclosure by the end-user.

It is recommended that

enclosed units be panel-

mounted with the vented

endplates positioned at top

and bottom for improved

cooling. Review the Operating

Ambient Temperature

specification for more

information.

A single unit stands 2.444

inches tall. Each additional

unit adds 2.229 inches.

A two-unit stack would be

4.673 inches tall. A three unit

stack is 6.902 inches tall. Add

any additional height as

necessary to account for the

mounting plate, DIN clip, and

DIN rail, if required.

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

__________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

6

USE A DIN RAIL STOP TO

PREVENT MOVEMENT

(Example: IDEC BNL-5)

NOT INCLUDED

Note: Position of stop not

exactly as shown.

UNIT IS SHOWN

MOUNTED USING

BOTH CLIPS OF

ESA-DIN-VMK KIT.

35mm x15mm DIN RAIL

(Example: IBOCO OMEGA 3AF)

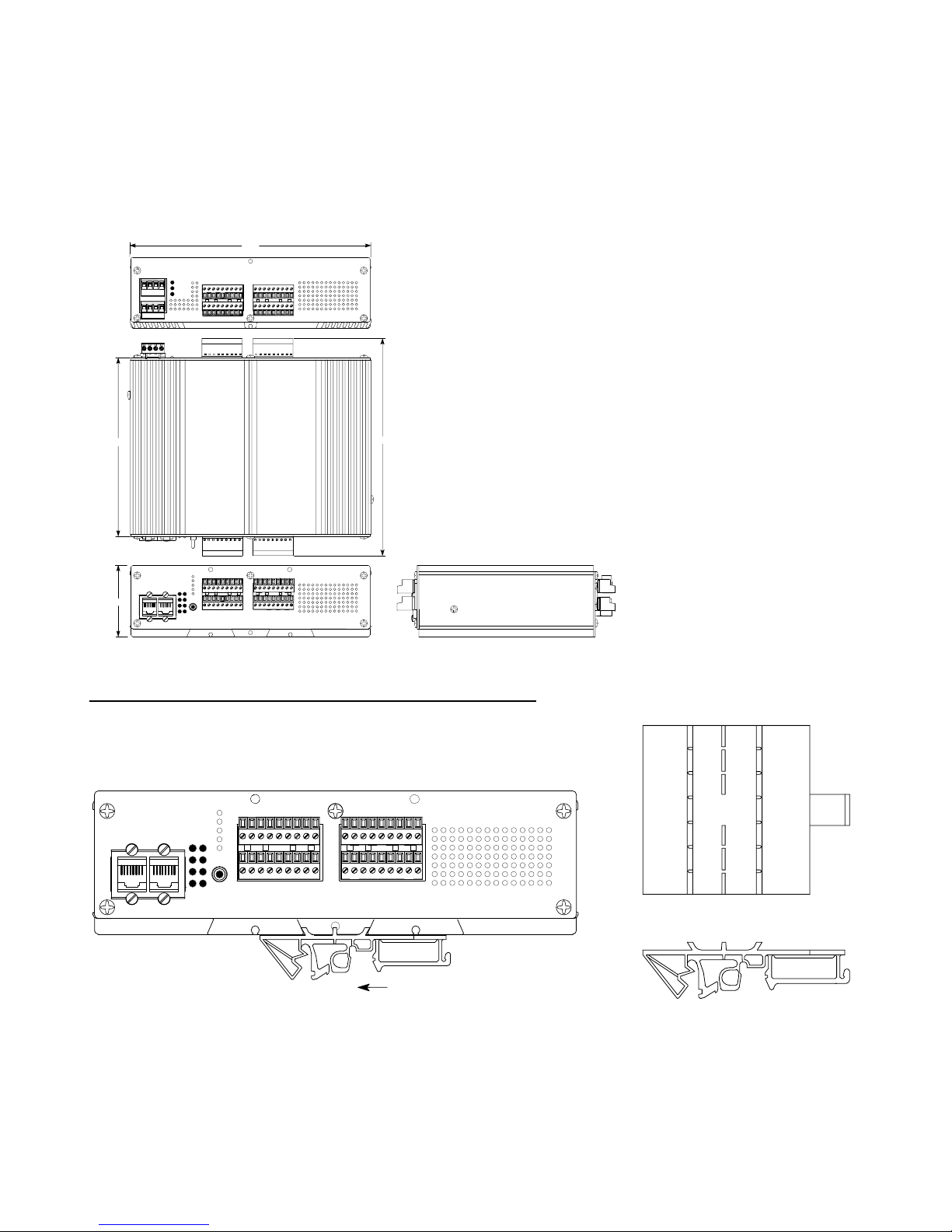

VERTICAL DIN-RAIL MOUNT

USING ESA-DIN-VMK

Simply slide the clips of this kit into the dovetail channel at the bottom of the

enclosure. You can use one clip, or both (recommended) DIN clips of this

kit to mount a single unit. For a stack of two units, both clips must be used.

To remove a unit from the DIN rail, you have to lift the assembly upward and

tilt the top of the unit back to disengage it from the rail. If you choose to

install both DIN clips for added security (recommended), then more pressure

will be required to disengage the unit from the rail. To mount a stack of 3

units to a DIN rail, use the heavy-duty DIN kit model ESA-DIN-HMK instead.

TOP

35mm x15mm

DIN RAIL

IMPORTANT: Stack no more than 2 units with ESA-DIN-VMK.

Use both clips of this kit with two units stacked together.

ETHERSTAX MOUNTING WITH ESA-DIN-VMK

MOUNTING AND

DIMENSIONS

The drawing at right shows

how to mount a unit with the

ESA-DIN-VMK kit.

This kit includes two DIN clips

for added stability, or for

mounting a stack of two units.

Note the orientation of the DIN

clips relative to the rail.

To remove a unit from the rail,

grip unit on each side and

pull/push upward, while tilting

the top back to release the unit

from the upper lip of the DIN

rail.

You can use the ESA-DIN-

VMK to mount a unit

horizontally, or vertically as

shown at right. Be sure to use

a DIN rail stop to prevent the

unit from moving along the rail

with vertically mounted DIN

rail.

Note that enclosed units

oriented as shown at right will

have improved cooling ability

(see Operating Ambient

Temperature).

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

___________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

7

5.368

2.986

6.675

0.375

1.923

0.400"

TYP

2.250

0.625

4.250

0.25

TYP

0.400"

TYP

OPEN BOARD

MTG HOLES

0.160 DIA

(4 PLACES)

4.709

1.875

1.980

0.125

4.00

RUBBER

GROMMET

COUNTER-SINK THIS

SIDE (4 PLACES)

5.750

ESA-SMK SIDE VIEW

3.500

3.291

1.000

ESA-SMK TOP VIEW

8.000

RUBBER

GROMMET

2.000

8.000

ENCL MOUNT

0.250 DIA HOLE w/

0.500 DIA x 100 DEG

COUNTER-SINK ON

BOTTOM SIDE

(4 PLACES)

NOTCH FOR

DIN LATCH

0.266 I.D. x 0.625 O.D. GROMMET

IN 0.406 HOLE (4 PLACES)

NOTE VERTICAL OFFSET

OF THIS HOLE COMPARED

TO HOLE AT RIGHT SIDE

DIN MOUNT

0.089 DIA FOR 4-40

TAP (7 PLACES)

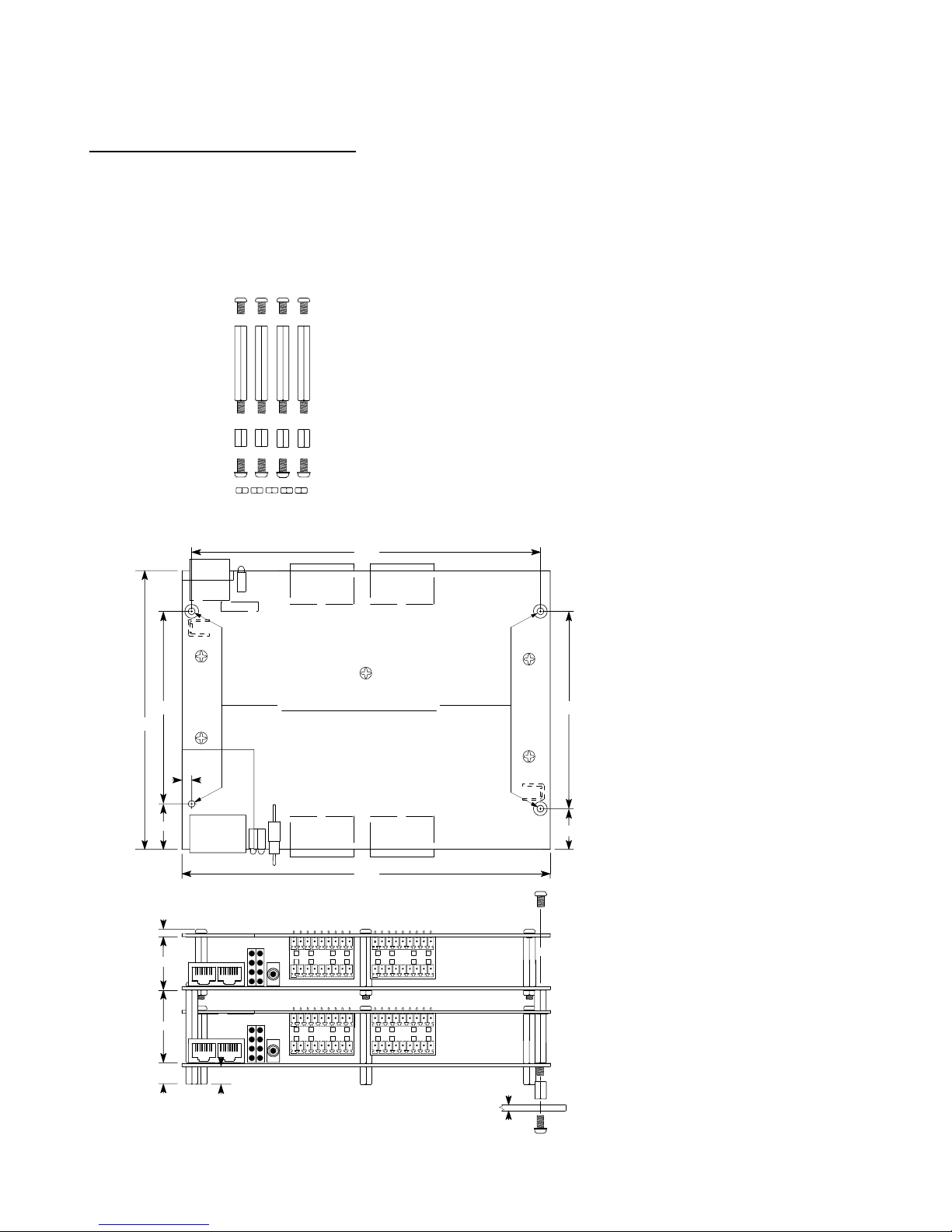

Surface-Mount Kit ESA-SMK (One to Three units):This kit includes a

shock-mounted aluminum base-plate and bolts that attach to the bottom of

the housing. Mounting holes with rubber grommets at each corner support

¼-inch bolts for mounting to flat surfaces. Up to three units may be stacked

on this plate.

This plate also includes the four holes necessary for mounting an open-

frame circuit board to it (i.e. no enclosure with hardware of ESA-OMK).

ESA-SMK Kit Contents:

1 Pre-Drilled Aluminum Base-Plate, 8 x 8 x 0.125.

4 ¼-20 x 0.375 Flat-Head, 100° Counter-Sink, Phillips

4 Rubber Grommet, 0.625 O.D. x 0.266 I.D.

The ¼-inch bolts and washers recommended to attach this assembly to

a flat surface or panel are not provided.

For DIN rail mounting of this plate, see ESA-DIN-HMK

MOUNTING AND

DIMENSIONS

Insert the four rubber

grommets into the holes at

each corner of the base-plate.

Then use the four ¼-20x0.375,

flat head, counter-sink bolts

provided to bolt this plate to

the bottom of the enclosure.

Be sure to insert the bolts from

the counter-sink side of the

plate.

Add any additional units to

your stack–you can safely

stack up to three units on this

plate.

Use ¼-inch bolts (not

provided) to bolt this assembly

to a wall or flat surface. It is

further recommended that flat

washers (not provided) be

used to protect the rubber

grommet.

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

__________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

8

1

2

3

Bolt to wall or flat surface using

1/4 bolts (not provided) at each

corner. Use a flat washer at the

grommet interface as shown.

You will have to temporarily

unplug terminal blocks to

insert bolts through grommet.

Insert rubber grommet

provided into holes at

each corner of baseplate. FLAT WASHER REQUIRED, 4 PLACES (NOT INCLUDED)

ETHERSTAX SURFACE MOUNTING WITH ESA-SMK

Attach baseplate to

enclosure using four

1/4-20 flat-head bolts

provided. Insert bolts

through counter-sink

side of baseplate.

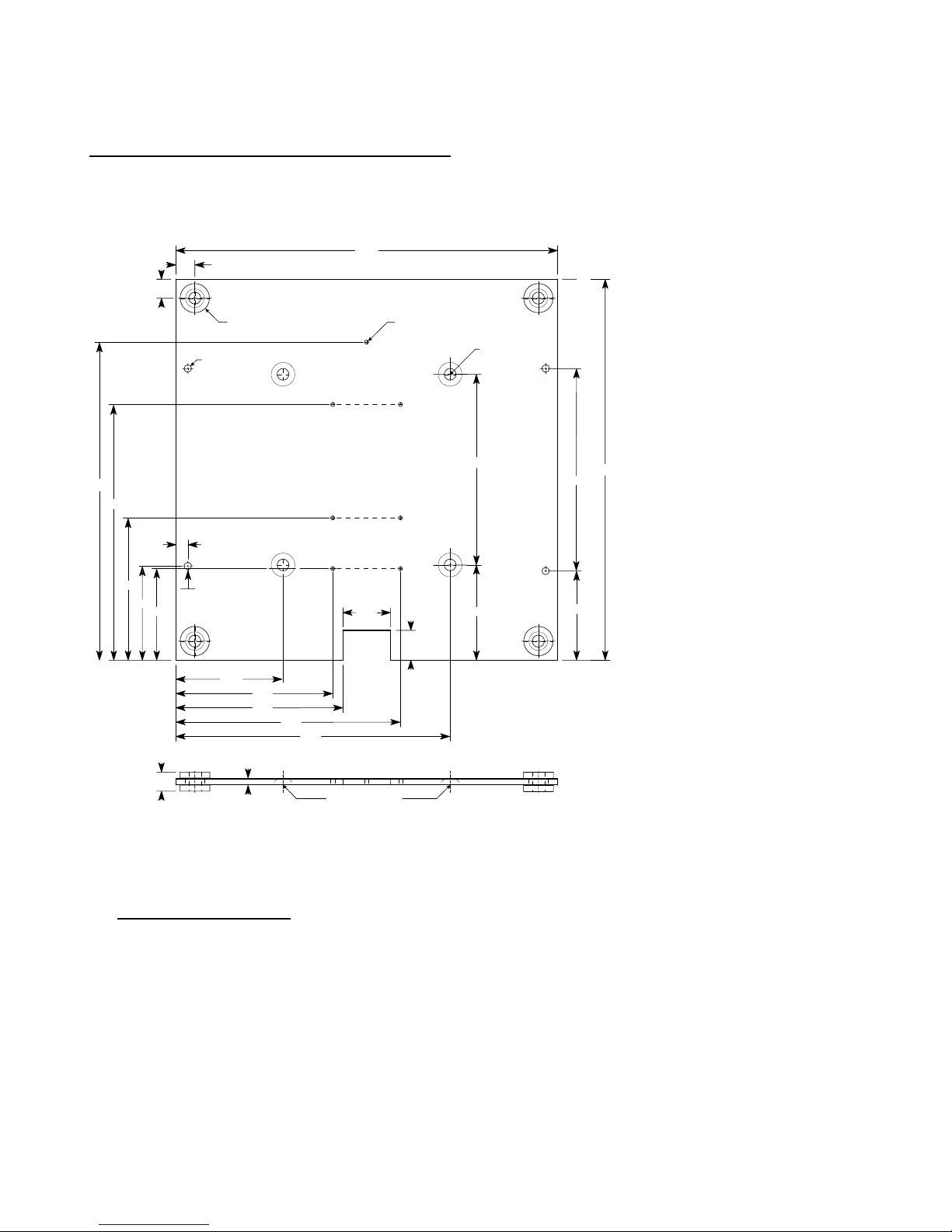

DIN Rail Horizontal Mount Kit ESA-DIN-HMK (one to three units):This

kit has the same base-plate as ESA-SMK above, but adds a heavy-duty DIN

adapter (Phoenix UTA-159), and screws for mounting to 35x15mm T-type

DIN rails. Up to three units may be stacked on this plate and mounted to a

DIN rail.

0.10"

35mm x15mm

DIN RAIL

NOTCH FOR ACCESS TO

DIN CLIP RELEASE TAB

(Insert screwdriver here to

pry back spring clamp and

release unit from rail)

ETHERSTAX MOUNTING WITH ESA-DIN-HMK

ESA-DIN-HMK Kit Contents:

1 Pre-Drilled Aluminum Base-Plate, 8 x 8 x 0.125.

4 ¼-20 x 0.375 Flat-Head, 100° Counter-Sink

4 Rubber Grommet, 0.625 O.D. x 0.266 I.D.

1 Heavy-Duty DIN Adaptor (Phoenix UTA-159)

7 4-40 x 0.25 screw with lock-washer

MOUNTING AND

DIMENSIONS

This is the recommended

mounting orientation for

reducing internal heat

generation (see Ambient

Operating Temperature at the

back of this manual).

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

___________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

9

0.84" 2.44" 2.29"

7.74"

2.29"

3.28"

5.51"

0.25"

35mm x15mm

DIN RAIL

SUBTRACT 0.59" FROM DIMENSIONS SHOWN IF USING

ESA-SMK BASE-PLATE (NO DIN RAIL MOUNT).

UP TO 3 UNITS MAY BE STACKED ON A DIN RAIL USING ESA-DIN-HMK AS SHOWN.

ETHERSTAX ESA-DIN-HMK STACKING

To attach or remove the ESA-DIN-HMK to/from the DIN Rail, use a

screwdriver tip inserted into the slot at the end of the DIN clip, in the area of

the notch of the base-plate as shown below. Pry back to compress the DIN

clip spring, then release it from the rail. You may have to temporarily unplug

the terminal blocks in the area of this notch to gain access to the DIN clip.

09 11 13 15 25 27 29 31

21

01 03 0 076 C 17 19 21 23

PORT 2

DFT

08 10 12 14

TS1

24 26 C28 30

TS2

RST

COM

STATUS

00 02 04 16 18 C20 22

PORT 1

ETHERNET 10/100M

LOCATE DIN LATCH IN AREA OF NOTCH IN BASE-PLATE

35mm x15mm

DIN RAIL

ETHERSTAX ESA-DIN-HMK

REMOVAL FROM DIN RAIL

Acromag

USE A SCREWDRIVER AS SHOWN TO PRY BACK

ON DIN RAIL LATCH AND RELEASE UNIT FROM RAIL.

IT MAY BE NECESSARY TO TEMPORARILY UNPLUG

TERMINAL BLOCKS TO GAIN ACCESS TO DIN LATCH.

MOUNTING AND

DIMENSIONS

IMPORTANT: Be sure to

remove power before

attempting to disengage unit

from the DIN rail.

Be sure to grip unit firmly

before disengaging unit from

rail and avoid dropping it.

Note that you can stack up to

3 units on the ESA-DIN-HMK

or ESA-SMK as shown at left.

Subtract 0.59 inches from

dimensions shown if using

ESA-SMK (i.e. no DIN rail

mount).

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

__________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

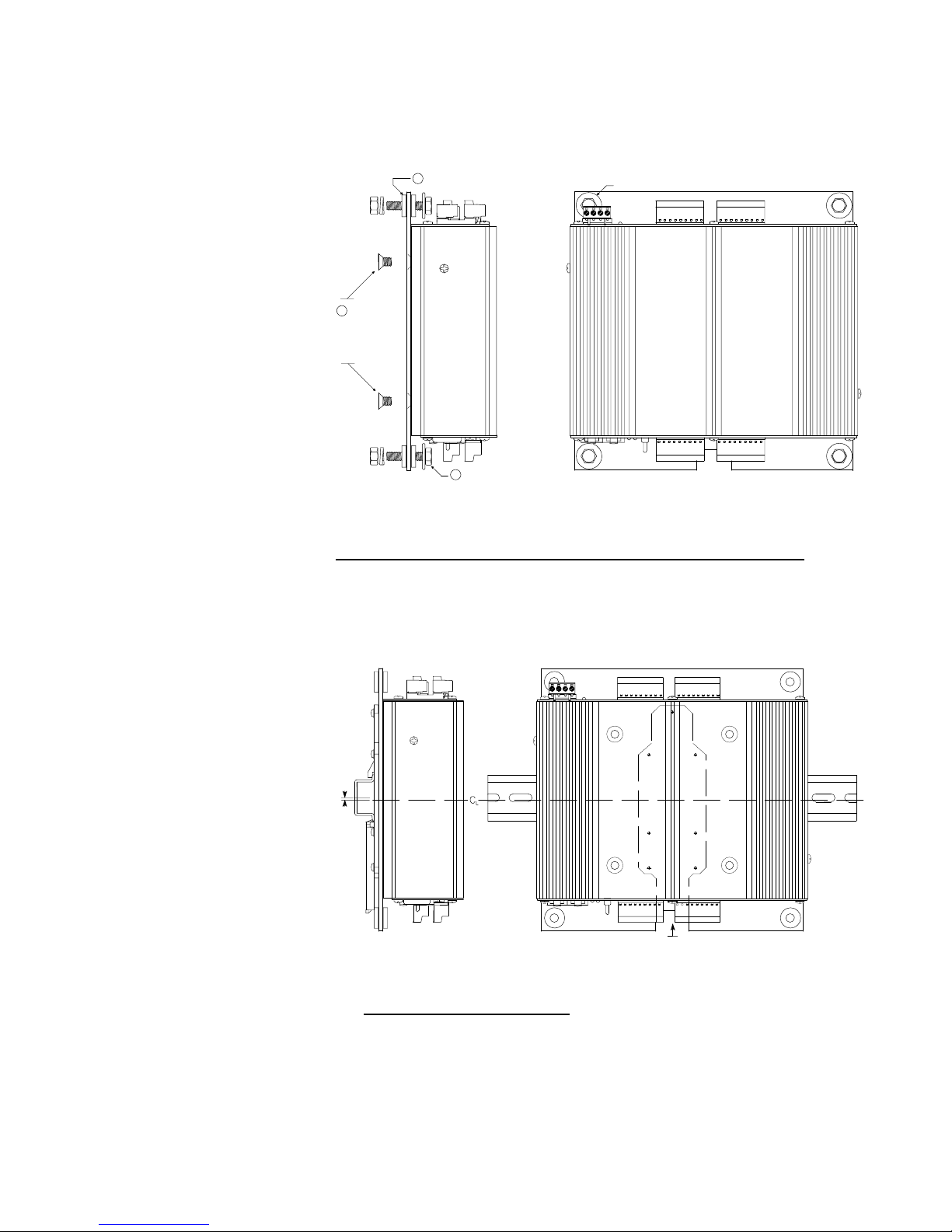

10

1

UPPER UNIT

RESTS ON FRONT

PLATE OF LOWER

UNIT

SLIDE UNITS

TOGETHER

SLIDE UPPER UNIT INTO

DOVETAIL CHANNEL OF

LOWER UNIT UNTIL IT

RESTS UPON FRONT

ENDPLATE.

SECURE UNITS

TOGETHER VIA TWO

6-32 SCREWS AT

FRONT, AND ONE

6-32 SCREW AT

CENTER OF REAR

ENDPLATE.

BUILDING A STACK

2

21

40

32

09

01

42

42

34

11

03

44

36

13

05

45

37 38

15

07

C47

C

39 C

C

C

56

48

25

17

58

50

27

19

60

TS4

52

29

21

62

54

31

23

C

C

RLY

B

A

+-

+-G

21

32

40

09

01

34

11

03

36

44

13

05

37 38

45 46

15

07

C39

47

C

C

O

U

T

P

U

T

S

O

U

T

P

U

T

S

56

48

25

17

58

50

27

19

TS4

60

52

29

21

62

54

31

23

C

C

A

B

RLY

+-

+-

G

G

PORT 1

COM

STATUS

41 43

43

33 35

10 1208

00 02 04

46

14 24

06 16

57 59 61 63

55535149

C26 28 30

C18 20 22

TS2

STATUS

RELAY

RUN

COM

STATUS

PORT 1

33 35

41

08 10 12

02 0400

14 24

06 16

57 59 61 63

55535149

C26 28 30

TS2

C18 20 22

RUN

STATUS

RELAY

PWR GND

2

RSTRST

ETHERNET 10/100M

TS3

TS1

ETHERNET 10/100M

DFT

PORT 2

RST

Acromag

RST

DFT

TS3

REAR VIEW

TS1

Acromag

SECURE UNITS

TOGETHER VIA TWO

6-32 SCREWS AT

FRONT AS SHOWN,

AND ONE 6-32 SCREW

AT CENTER OF REAR

ENDPLATE.

FASTEN UNITS

TOGETHER w/

3 SCREWS AS

SHOWN

MOUNTING AND

DIMENSIONS

The drawing at right shows

how to stack units together.

You can stack up to three units

together in this manner.

WARNING: Be sure to grip

the edges of unit firmly when

stacking units and avoid

dropping it.

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

___________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

11

6-32 NUT

(NYLON)

BOTTOM

STANDOFF

MTG PLATE

SCREW

TOP BOARD

SCREW

BD-TO-BD

STANDOFF

#5 6-32 NYLON NUT, REPLACES

STANDOFF OF UPPER BOARD

ESA-OMK kit items are also included with every open board assembly.

#4 1/4-HEX FEMALE STANDOFF

3/8 LONG w/6-32 THREADS

#4 6-32x0.25 PAN HEAD SCREWS

ESA-OMK KIT CONTENTS

#4 6-32 x0.25 SEMS SCREW

WITH INTEGRATED WASHER

#4 1/4-HEX MALE-FEMALE STANDOFF

1-9/16 LONG WITH

6-32 x0.375 FEMALE THREAD &

6-32 x0.250 MALE THREAD

0.440

1.139

0.980

4.145

0.25

TYP

0.125

1.563

0.375

0.150

6.000

MTG PLATE

(ESA-SMK)

7.920

STANDOFF MOUNTING - 4 PLACES

7.500

0.875

4.250

DIMENSIONS ARE IN INCHES

(FOUR 0.150 DIA MOUNTING HOLES

WITH 0.280 DIAMETER SHOULDER

AND 0.108 ISOLATION CLEARANCE)

OPEN STACK ASSEMBLY (TWO DUO UNITS)

ETHERSTAX DUAL BOARD

OPEN FRAME DIMENSIONS

Open-Board Mounting Kit ESA-OMK:EtherStax units can be ordered and

mounted without their enclosure. This kit includes the jack-screws, and

fasteners necessary to stack two open circuit boards together (or two dual

board assemblies), plus the standoffs and screws for mounting this

assembly to a flat surface. Note that this is also a replacement kit, as open-

frame units already include these items (except for 6-32 nuts). Use

additional kits as required for stacking more than two boards in this manner.

MOUNTING AND

DIMENSIONS

IMPORTANT: Units ordered

without their enclosure do not

retain safety agency listing, but

are recognized components

(see Specifications – Agency

Approvals). Open-frame units

are also vulnerable with

respect to ESD. While the

open unit retains all of its built-

in transient suppression and

filtering, the sensitive

electronic circuits are left

exposed to ESD damage

without the protection of an

enclosure.

You should take adequate

measures to protect open-

frame mounted units from

dust, debris, and ESD.

Thus, it is recommended that

open units be mounted in a

protective enclosure or

cabinet.

Note: Open-frame units may

also mount to the optional

surface-mounted base plate

ESA-SMK to facilitate surface

or DIN-rail mounting. This

plate has mounting holes

located as shown to mate with

those of the circuit board.

Be very careful when handling

open-frame circuits to avoid

ESD damage to sensitive

circuit components.

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

__________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

12

DFT

08

I

09 10 11 13 15 24 26 28 30 C

Rx

Tx 2RST

00 02 04 05 07 16 18 20 22 C

10/100 T/TX

ETHERNET

STATUS

V

12 14

TS1

C25 27

I

V

29 31

100 FX

PORT 2

1

01 03 06 C171921 23

NETWORK PORTS

100 FX

TS2

10/100 T/TX

PORT 1

Acromag

ES2163-1XXX FRONT-PANEL

(w/ SC-TYPE FIBER PORT 1)

ES2164-1XXX IS IDENTICAL

INPUT PORT 2

(CH16-CH31)

COMMUNICATION STATUS INDICATORS

DEFAULT/RESET TOGGLE SWITCH

INPUT PORT 1

(CH00-CH15)

09

01

11

03

13

05

15

07

24

16

26

18

28

20

30

22

C31

C23

2

DFT

RST

08 10 12 14

00 02 04 06

TS 1

C25 27

C1719

29

21

PORT2

1

COM

STATUS

TS 2

PORT1

NETWORK PORTS

ETHE RNE T 10/100M

Acromag

(10/100MEthernet)

ES2163-0XXX FRONT-PANEL

(ES2164-0XXX IS IDENTICAL)

INPUT PORT 2

(CH16-CH31)

COMMUNICAT ION STAT US INDICAT ORS

DEFAULT / RE SE T T OGGLE SWI T CH

INPUT PORT 1

(CH00-CH15)

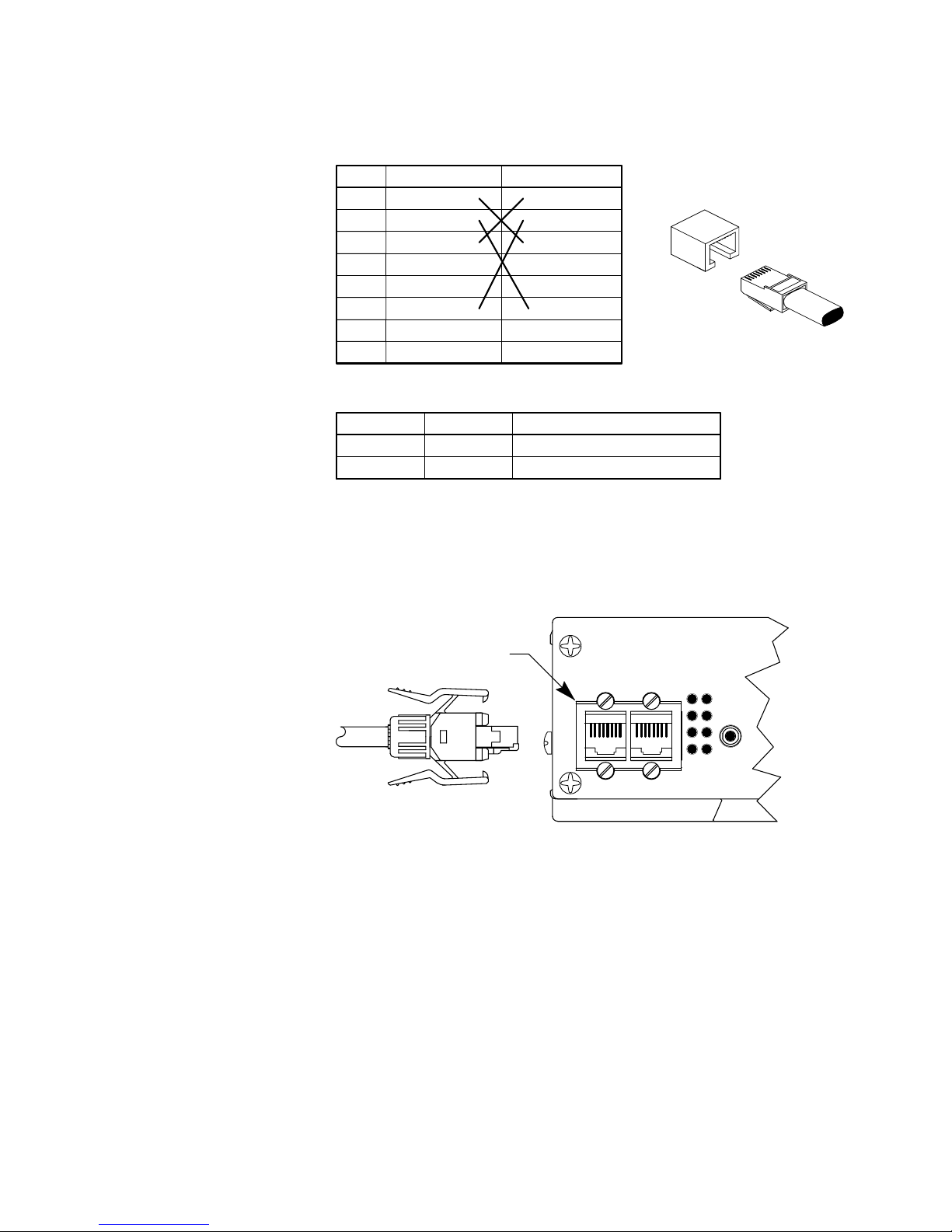

Cable Termination Kit ESA-CTK: The EtherStax enclosure includes a

panel mounted frame around the RJ45 network port that accommodates

special IP20 clip-type plug connectors that help to secure network

connections from shock and vibration. You can still utilize standard RJ45

modular plug connectors, but if you want the added security of this clip

frame, then you have to use the compatible cable plug connectors provided

by this kit. This kit provides the male plug and sleeve housing for one end of

Category 5 Ethernet cable that will mate to this frame. Category 5 cable is

not included. You will also require a modular crimping tool for attaching the

plug to your cable (most standard RJ45 crimping tools will work).

Units ordered without their enclosure cannot utilize this clip.

MOUNTING AND

DIMENSIONS

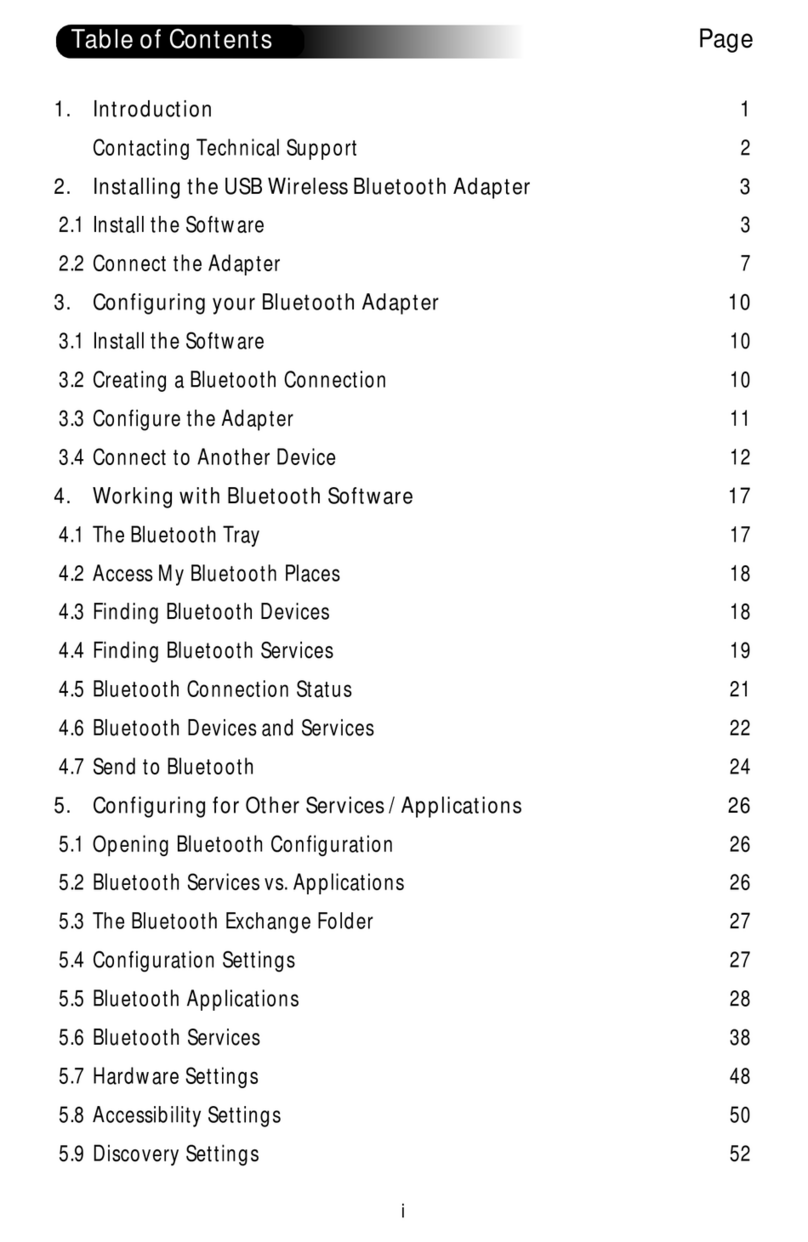

CONTROLS &

INDICATORS

Front Panel

Two columns of status

indicators for the network ports

are used to indicate different

things according to whether

the unit is in switch mode, or

hub/repeater mode. Refer to

Specifications – Controls &

Indicators for these definitions.

The toggle switch is used to

toggle the unit into or out of

Default Mode (toggle up & hold

4 seconds), or to reset the unit

(toggle down).

In Default Communication

Mode, the yellow STATUS

LED on the back of the unit will

flash slowly and the unit will

assume a fixed static IP

address of “128.1.1.100”, a

default subnet mask of

“255.255.255.0”, a default

username of “User”, and a

default password of

“password”.

RJ45 PLUG

IP20 SLEEVE

HOUSING

CAT5 CABLE

(NOT INCLUDED)

CLAMPS TO FRAME

OF ETHERSTAX

HOUSING

ESA-CTK IP20 CAT5

CABLE TERMINATION KIT

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

___________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

13

40 42 44 46 C 57 59 60 61 62 C

GND

32 34 36 38 C 49 51 53 54 55 C

B

A

-

-

G

G

41 43 45 47 56 58 63 RUN

STATUS

PWR

TS3

33 35 37 39 48 50

TS4

52

RELAY

+

+

RLY

ES2163-0XXX BACK-PANEL

(ES2164-0XXX IS IDENTICAL)

INPUT PORT 4

(CH48-CH63)

The Earth Ground (G) terminals are common

to the enclosure and isolated from I/O, power,

and relay connections.

ES2163 INPUTS ARE CURRENT, ES2164 INPUTS ARE VOLTAGE UNIT INDICATORS -

Alarm (Red), Status

(Yellow), and Run

(Green).

POWER/

EARTH GROUND/

RELAY CONNECTIONS

INPUT PORT 3

(CH32-CH47)

RELAY

Port 1

GROUND

POWER

NETWORK

Port 2

GROUND

SCREW

GROUND

SCREW

INPUT CIRCUITRY INPUT PORTS SHARE ANALOG COMMON.

CONNECT PORT COMMON (C) TO EARTH GROUND.

MODEL ES216x ISOLATION DIAGRAM

(Dashed Lines Denote Isolation Barriers)

INPUT CIRCUITRY INPUT PORTS SHARE ANALOG COMMON.

CONNECT PORT COMMON (C) TO EARTH GROUND.

NOTE: The Ground (G) terminals are

common to the enclosure and isolated

from the power, relay, inputs, and network

circuits for safety and noise immunity.

CONTROLS &

INDICATORS

Back Panel

The Green RUN LED (bottom)

is ON if power is on and will

blink in “wink” ID mode.

The Yellow STATUS LED

(middle) blinks ON/OFF slowly

in default communication

mode and blinks rapidly if a

watchdog timeout has

occurred.

The Red RELAY LED (top) is

ON if relay is energized (relay

terminals A & B are closed).

ISOLATION BARRIERS

Dashed Lines denote isolation

barriers. Additionally, the

enclosure is also isolated.

The input circuitry, network

ports (each), power circuit,

relay, and enclosure (earth

ground) are isolated from each

other for safety and noise

immunity.

Note that the network ports are

individually isolated from the

rest of the circuit and from

each other.

IMPORTANT: Transient

suppression devices are

internally shunted to earth

ground, please connect the

ground terminal to a suitable

earth ground to complete this

path and protect the unit.

Ground may alternately

connect to the ground screw

on either side of the unit

instead of the ground terminal.

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

__________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

14

1 2 RST

PORT 2

DFT

COM

STATUS

PORT 1

ETHERNET 10/100M

FRONT OF UNIT

Acromag

The RJ45 clip frame mates with the compatible

connectors of the ESA-CTK for increased

immunity to shock & vibration.

RJ45 Clip Frame

for secure media

connections.

For Compatible

Connectors, see

ESA-CTK Cable

Termination Kit

8

8

CLIP

8

5

6

2

3

PIN

CABLE

1

1

7

4

1

100M

SPEED DISTANCE

10Base-T

Not Used

Not Used

Receive -

Transmit -

Receive +

MDI WIRING

100M100Base-TX

RECOMMENDED CABLE

Not Used

Not Used

Transmit + ETHERNET PORT

CAT 3, CAT 4, or CAT 5 UTP

Not Used RJ-45 CONNECTOR

Not Used

Transmit -

Receive -

Transmit +

MDI-X WIRING

CAT 5/5e UTP/STP

Not Used

Not Used

Receive +

Note Crossover Connections

RJ45 MDI AND MDI-X CONNECTIONS

The Ethernet port of this unit is wired MDI-X by default, but includes

automatic crossover (the Ethernet port of your PC is typically wired MDI).

Thus, you can use either a straight-through or crossover cable to connect

this device directly to a PC, Ethernet switch, or another unit.

For increased immunity to shock and vibration, the RJ45 network

connections include special clip frames that can be used with compatible

plug connectors to help secure your network connection from breaking free

under shock or vibration. You can still utilize industry standard RJ45

modular plugs, but if you want the extra security provided by this clip frame,

then you can order compatible connectors via the Acromag ESA-CTK Cable

Termination Kit. This kit includes the male plug and sleeve housing that

mate to the RJ45 frame of the enclosure for one end of CAT5 cable (cable

not included). You will also need a modular plug crimping tool for attaching

the plug provided to your cable.

CONNECTIONS

Network

For 100Base-TX systems, at a

minimum, use data grade

Unshielded Twisted-Pair

(UTP) wiring that has a 100

characteristic impedance and

meets the EIA/TIA Category 5

wire specifications.

It is recommended that you

use a CAT-5 cable to connect

this device to your PC.

For 10Base-T systems, you

may use Category 3, Category

4, or Category 5/5E UTP/STP

cable.

In either case, you are limited

to 100 meters between any

two devices.

For compatible male plug

connectors, order the Cable

Termination Kit, Acromag

ESA-CTK.

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

___________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

15

Rx

100 FX

Tx

09

01

11

03

13

05

15

07

25

17

27

19

29

21

31

23

2RST

DFT

08

00

10 12 14 C

02 04 06 C

TS1

24 26 28

16 18 20

TS2

30 C

C22

PORT 2 PORT 1

ETHERNET 10/100M

1

COM

STATUS

Acromag

(Use Regular or

Crossover Cable)

Connect to

Network

Port 1 or 2

CAT-5 UTP CABLE

UP TO 100 METERS

HOST PC

Host PC w/ Network Interface Card (NIC)

Note: This MDI to MDI-X connection does not require a crossover cable.

HOST PC CONNECTED DIRECTLY TO UNIT

If your unit is a Model ES2163/2164-1xxx, it includes both a 100FX fiber port

and a 10BT/100BTX copper port. To connect directly to the fiber port from

your PC, you will need a compatible NIC card installed in your PC, or a

media converter. Note that the auto-crossing feature does not apply to fiber

connections and the Tx and Rx fiber channels must be mechanically

crossed.

Optionally, you may use an external Ethernet switch to connect to your

EtherStax unit (recommended). The recommended approach for switched

Ethernet is to connect one unit or Ethernet device per switch port. This is

the most efficient and deterministic method of communication as it increases

network throughput and eliminates data collisions.

The next section reviews the operation of Ethernet hubs and switches as it

relates to the built-in Ethernet switch of this device, which may optionally

operate as an Ethernet hub/repeater. You can skip the next two pages if you

are already familiar with these terms.

1

COM

STATUS

LED Column 1 - Port 1

LED Column 2 - Port 2

1=LED of Column 1

2=LED of Column 2

2

SWITCH MODE

YELLOW

YELLOW

GREEN No Function in Switch Mode.

1=Port 1 Link/Activity, 2=Error at Port 1.

1=Port 2 Link/Activity, 2=Error at Port 2.

1=Hub Activity, 2=Hub Collision.

YELLOW 1=MII/CPU Link/Activity, 2=MII/CPU Error.

HUB/REPEATER MODE

Speed - ON for 100Mbps, OFF for 10Mbps.

Full-Duplex/Collision - ON for Full-Duplex, Blinks for Half-

Duplex Collisions, OFF for Half-Duplex and No Collisions.

Refer to Specifications - Controls & Indicators Section for more detail.

Link/Activity - ON if Linked/Blinks if Activity.

CONNECTIONS

Network – Basic

Connections

Your host PC will require that

a 10/100M network interface

card (NIC) for Ethernet be

installed to connect to the

EtherStax unit. You may

connect to port 1 or port 2 of

the EtherStax. The EtherStax

unit is auto-crossing, allowing

you to use a regular or

crossover cable to make

connections.

IMPORTANT (Fiber Models):

Some models will substitute an

SC-type fiber port connector

for port 1. The auto-crossing

feature of these units does not

apply to the fiber connection

and transmit must be manually

crossed over to receive, and

visa-versa. Facing the front

end-plate of the unit, the

Transmit (Tx) channel is the

bottom half of the SC style

connector, while the top half is

Receive (Rx).

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

__________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

16

This device has a built-in Ethernet switch that can alternately operate as an

Ethernet hub. To understand which mode to use and how to network

connect Ethernet devices, you need to review switch operation and the

differences between a switch and a hub. If you are already familiar with

these terms, skip over this information and review the various network

connections examples outlined in the following pages.

An Ethernet hub (or repeater) is a device that simply connects Ethernet

nodes. Any message at one hub port is repeated on all ports. That is, hubs

forward data packets they receive from a single station to all hub ports. As a

result, all port devices connected to a single hub will share the same

bandwidth. Then as nodes are added to the network hub, they compete for

this finite amount of bandwidth (at 10Mbps or 100Mbps). This can cause

data collisions to occur and makes network determinism impossible,

particularly on busy networks. Determinism is a term that is used to

describe the ability to guarantee that a packet is sent or received in a finite

and predictable amount of time. In the past, lack of determinism is the main

reason that Ethernet has had problems being accepted for use in critical

control applications, as most control systems have a defined time

requirement for packet transmission, typically less than 100ms.

An Ethernet switch (or switching hub) is an intelligent device that is used to

more efficiently connect distributed Ethernet nodes than a hub. Unlike a

simple hub, a switch provides targeted data transfer, as it will forward a data

packet to a specific port or network segment, rather than all ports, thus

freeing up bandwidth. The ability to target a packet to a specific port

increases network throughput and helps to eliminate the collisions that

historically make Ethernet non-deterministic.

•Switches act as intelligent repeaters to increase network distance.

•Switches split networks into separate collision domains at each port.

•Switches provide determinism by reducing collisions.

•Switches increase network bandwidth/throughput.

•Switches can provide supplemental error checking.

With Ethernet, any device can try to send a data frame at any time. The

arbitration protocol for carrier transmission access of the Ethernet network is

called Carrier Sense Multiple Access with Collision Detect (CSMA/CD). If

two devices happen to send a data frame at the same time, then a collision

may occur. With CSMA/CD, each device will first sense whether the line is

idle and available for use. If it is, the device will begin to transmit its first

frame. If another device also tries to send a frame at the same time, then a

collision occurs and both frames are discarded. Each device then waits a

random amount of time and retries its transmission until it is successfully

sent.

Unlike other Ethernet devices, such as an Ethernet host adapter or Network

Interface Card (NIC), the port of a switch does not require its own MAC

address. During retransmission of a received packet, the switch port will

instead look like the originating device by having assumed its source

address. This is why the Ethernet collision domain is said to terminate at the

switch port. That is, a two-port switch will effectively break a network into

two distinct data links or segments (also called collision domains). Since all

Ethernet nodes are able to recognize the occurrence of a collision, and since

the detection of a collision is principal to the way Ethernet arbitrates media

access, large domains containing many nodes can become cumbersome.

CONNECTIONS

Network – Background

Hubs & Switches

To properly network connect

this device, you need to know

a little bit about network hubs

and switches. Please take a

moment to review this material

before installing your unit.

Switched Ethernet involves

connecting one Ethernet

device per switch port. This

suppresses CSMA/CD and

allows the segment to operate

full speed in full duplex. A

throughput of 100M at half-

duplex effectively doubles with

full-duplex. This provides a

more reliable and deterministic

communication link, as no data

collisions are possible.

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

___________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

17

Thus, using an Ethernet switch to subdivide a large network into separate

collision domains will certainly help to increase throughput. Each port of a

switch forwards data to another port based on the MAC address contained in

the received data packet/frame. In order to know which port to forward a

data packet to, the switch will learn and store the MAC addresses of every

device it is connected to, along with the associated port number (up to 1024

MAC addresses are stored in high speed SRAM). However, until the switch

actually learns the switch port a particular MAC address resides at (after the

first packet), it forwards this initial packet traffic to all ports. The switch will

use the internal look-up table to quickly determine the location (port) of a

node, establish a temporary connection between itself and the node, then

terminate the connection once a packet is transferred. In this way, it

increases network bandwidth and provides the network determinism

required for critical control applications.

Most switches use a store and forward algorithm to process Ethernet

frames. That is, it first stores the Ethernet frame and examines it for errors

before forwarding it to its destination. Although in some case this method

may seem to increase the forwarding time (latency) and possibly cause

fragmentation, it can also effectively reduce the occurrence of error frames

and improve overall throughput for most applications. This is particularly

useful where there is heavy network traffic and or greater potential for noise

and interference.

The optional hub/repeater mode of this switch provides low-latency network

packet transmission that effectively reduces jitter on the network. Ethernet

switches have higher inherent latency that varies with packet size due to

their store-and-forward behavior. Thus, operation in switch mode adds

latency and results in possible latency deviations up to 167us (jitter). In hub-

mode, there is a maximum port-to-port latency of only 310ns with a total

deviation of only 40ns. This is because hubs immediately repeat the bits

arriving on one port at their other ports, rather than storing the entire

message first before forwarding it as switches do. This sometimes makes

them more useful for transmission of time-critical data, or for reducing

latency where there is concentrated link traffic (like the main trunk of

cascaded units).

We can also use the hub mode of this switch to implement media

redundancy to this device. That is, if you connect the EtherStax to an

external switch that happens to support media redundancy via a proprietary

ring method, or the Spanning Tree Protocol (STP), or Rapid Spanning Tree

Protocol (RSTP), then the EtherStax unit can be placed in “hub mode” and

you can connect a cable to both ports. The external redundant switch will

sense the redundant path and disable it temporarily. If the primary path

should later fail, then the external switch can reactivate the other path,

effectively providing media failover protection right to the unit.

Note that Acromag offers several industrial managed and unmanaged

Ethernet switch models that can be used to interface to this product (please

consult the factory or visit www.acromag.com).

Some examples of various types of network connections using Ethernet

switches are included in the following pages.

CONNECTIONS

Network – Background

Hubs & Switches

The current tendency in critical

industrial control applications

is to connect one Ethernet

device per switch port. This

will produce the most

deterministic mode of

operation as the switch can

operate full-duplex, with no

chance of collisions. This

ensures determinism, helping

critical control applications to

remain predictable and on-

time.

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

__________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

18

2

2

0

8

0

0

1

9

1

1

3

11

TS1

3

TS1

3

TS1

4

12

4

4

6

14

6

6

7

15

7

7

16

24

16

16

17

25

17

17

19

27

19

TS2

19

TS2

20

28

20

20

22

30

22

22

23

31

23

23

32

32

33

41

33

33

35

35

36

44

36

36

38

38

39

47

39

39

2

8

8

9

9

11

11

14

14

24

24

25

25

27

27

28

28

30

30

31

31

40

40

41

41

43

43

44

44

46

46

47

47

PORT 2

PORT 2

PORT 2

PORT 1

1

PORT 1

1

PORT 1

R 2

E1 10

R 2

R 2

5R

13 E2

5 R

5 R

18 21

26 29

TS2

18 21

18 21

R 32 34

40E3 42

R 34

R 34

35 3837

43 4645

37

37

COM

STATUS

COM

STATUS

1

COM

STATUS

E1 10

E1 10

13 E212 15

13 E212 15

26 29

26 29

E3 42

E3 42

45

45

RST

RST

DFT

ETHERNET 10/100M

DFT

ETHERNET 10/100M

TS3

TS3

TS3

ETHERNET 10/100M

Acromag

DFT

Acromag

RST

Acromag

You may use straight-through or

crossover cables.

Limit cascaded connections to 4 segments.

CASCADING UNITS

You can connect directly to a Host PC with

a NIC installed, or via an Ethernet switch.

HOST PC

Units have automatic crossover

and may utilize straight-through

or crossover cables when making

connections.

CAT-5 UTP Cable, up to

100 meters per segment Connections may use Port 1 or Port 2.

Limit cable segments to 100M in length.

Connection may be made to Port 1 or 2

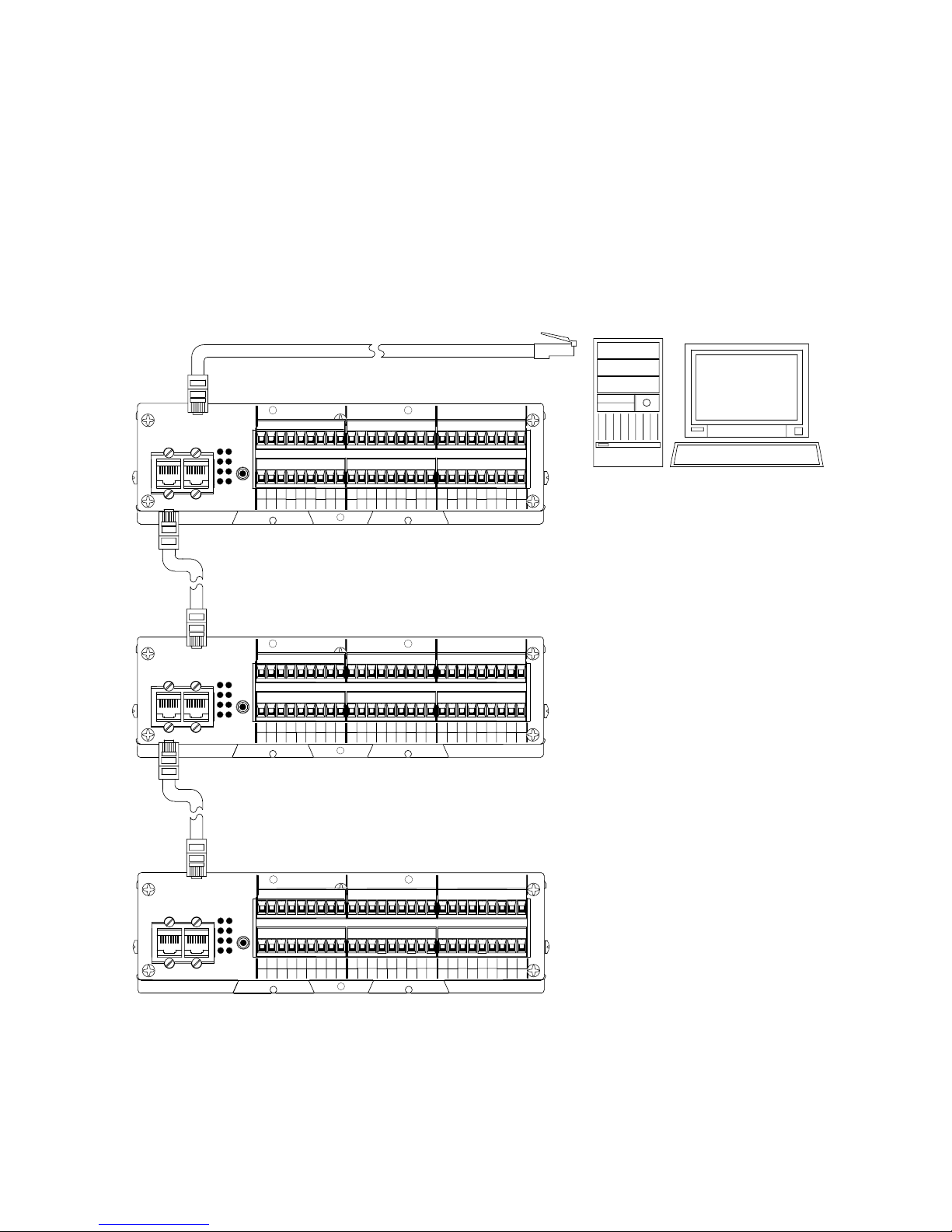

The unit includes two Ethernet ports for convenient cascaded network

connections as shown here. This is also useful for extending the network as

each segment may extend up to 100 meters.

Note that data collisions are still possible in the first two network segments

shown below, as these connections carry the data of more than one unit.

You can isolate each segment and prevent collisions using an external

Ethernet switch connected as shown in the diagram of the following page

(our recommended approach).

TIP: You can significantly enhance the EMI/RFI performance of your

network connections by using Category 5E STP cable (Shielded Twisted

Pair) cable. The use of shielded cable is strongly recommended for

installations in harsh industrial environments and/or in the presence of

strong electrical fields. For more information on cable, refer to the Cables &

Connectors section at the back of this manual.

CONNECTIONS

Network

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

___________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

19

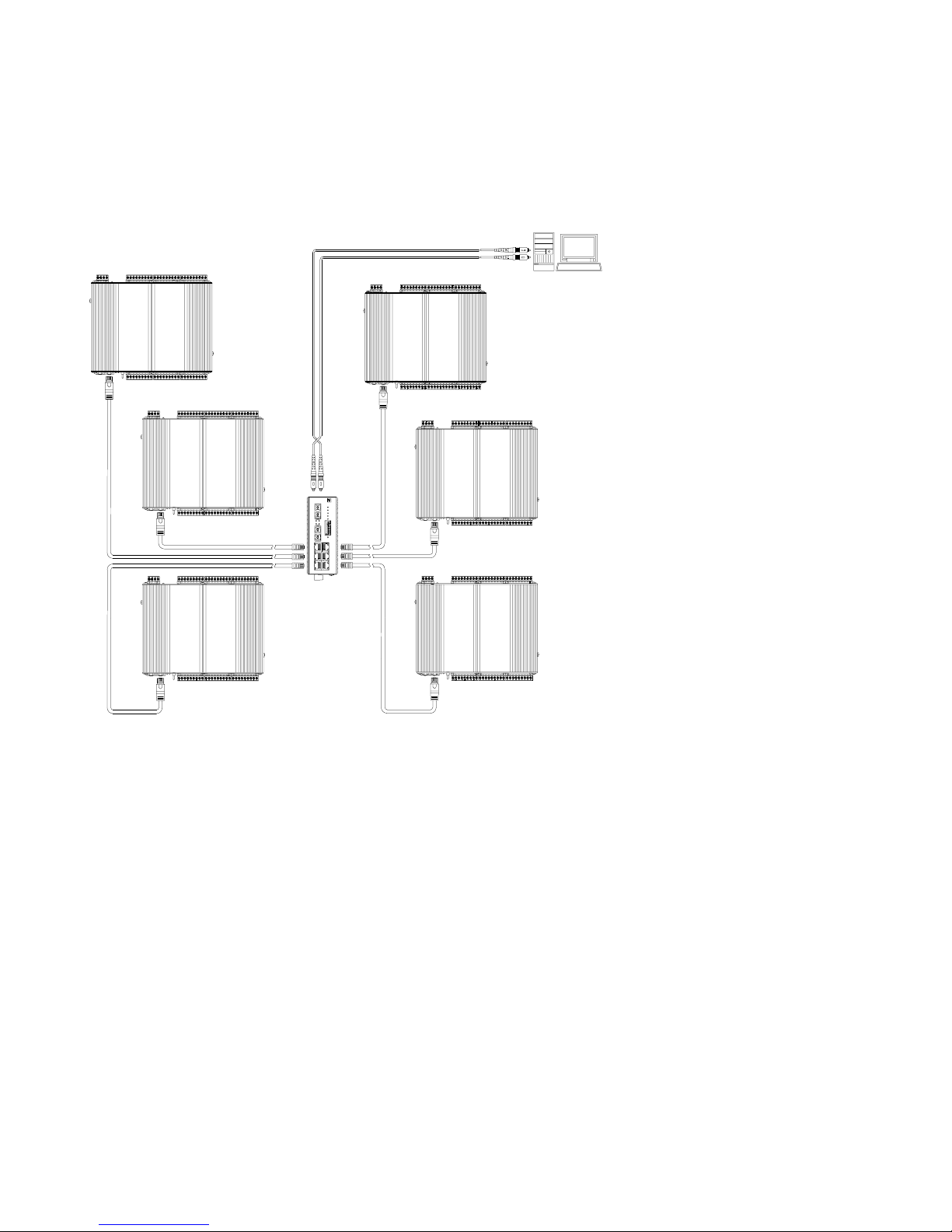

You can use an Ethernet switch or switching hub to build a network of

EtherStax units, similar to that shown below. The drawing depicts our

recommended approach to distributing I/O via switched Ethernet—that is,

one EtherStax unit is connected per switch port.

P1

P2

P4

P5

P7

P8

P3

P6

R.M.

P5

P7

P8

P6

RX RESET

FAULT

PWR2

RX

R.M.

TX PWR

P1

P3

FDX/

COL

P2

P4

TX

PWR1

LNK/

ACT

SC

EIS-408FX-M

Acromag

SC

I/O 1

I/O 6

I/O 2

I/O 4

I/O 5

I/O 3

ETHERNET

SWITCH

CROSSOVER

HOST PC

(OR PLC/DCS CONTROLLER)

LOCAL AREA NETWORK

NODES WIRED FOR SWITCHED

ETHERNET (ONE UNIT PER

SWITCH PORT) VIA COPPER

RJ45 CONNECTIONS.

UP TO 100M PER SEGMENT.

ACROMAG

EIS-408FX-M

REMOTE HOST

(NIC W/FIBER INSTALLED)

OR

NIC TO SC-TYPE FIBER

MEDIA CONVERTER

FIBER TO REMOTE HOST (UP TO 2KM)

RECOMMENDED CONNECTIONS

(SWITCHED ETHERNET)

The drawing above shows how to network-connect EtherStax units to an 8-

port Ethernet switch (such as Acromag Model EIS-408FX-M). Note that the

I/O LAN is distributed locally using copper/RJ45 cable connections (up to

100M per segment), and then connected to a remote (distant) host using

fiber cable. The copper connections may use standard or crossover cables,

as both the EtherStax unit and the Ethernet switch include automatic

crossover, but it is generally not considered good practice to use crossover

cables when connecting to an auto-crossing switch.

The switch shown above could be eliminated, if you were connecting to an

EtherStax Model ES2163/2164-1000, which includes one fiber port and one

standard RJ45 port. For example, you could use the fiber port built into the

EtherStax to connect to the distant host using fiber, then add an additional

EtherStax locally via its RJ45 port, similar to that shown on the next page.

However, the traffic of both units would still be concentrated in the main

trunk from the host, and this does not follow the key principle of switched

Ethernet, which seeks to suppress CSMA/CD and prevent data collisions by

connecting only one device per switch port.

CONNECTIONS

Network

The drawing at left gives our

recommended approach to

making network connections to

the EtherStax via switched

Ethernet.

Here we show one EtherStax

unit connected per switch port.

Thus, each segment is limited

to the traffic of only one device

and no collisions are possible.

This provides the most

deterministic method of

network communication. Only

the segment between the host

and the switch carries the

traffic of multiple units and

collisions are still possible in

this segment.

Note that fiber connections

must be crossed over, as the

auto-crossing feature only

applies to copper connections.

OBSERVATION: The extra

copper port of any of these

units can optionally connect to

other network devices, but the

resulting concentrated traffic in

the upstream network segment

would violate the goal of

switched Ethernet which is to

limit the traffic on each

segment to the traffic of one

device, suppressing

CSMA/CD. This is generally

not a problem for a small

number of cascaded units.

For many cascaded nodes, it

is good practice for the

upstream network segment to

use a data rate that is 10x the

data rate of the downstream

nodes, otherwise careful

attention must be paid to

limiting the number of Ethernet

devices that traffic on this

segment.

EtherStax™ ES2163/2164 User’s Manual Modbus TCP/UDP/IP Analog Input

__________________________________________________________________

_______________________________________________________________________________________

Acromag, Inc. Tel:248-295-0880 Fax:248-624-9234 Email:sales@acromag.com http://www.acromag.com

20

Unfortunately, you cannot avoid concentrated traffic in the main host

segment, even with a switch. As such, this aggregate path is usually chosen

to operate at a higher data rate than the downstream segments. With the

traffic of many Ethernet devices, this would mean that if the main trunk runs

at 100MB, then the downstream nodes should operate at 10MB (or 100MB if

the main trunk was 1Gbps, which the switch of the EtherStax units does not

support). If you cannot easily increase the bandwidth of this segment, then

you should be careful to limit the traffic in this shared segment by limiting the

total number of Ethernet devices connected downstream.

SC

CROSSOVER

SC

HOST PC

ETHERSTAX HAS

AN ETHERNET

SWITCH BUILT-IN

MODEL ES2113-1000

(One Copper Port and one Fiber Port)

CASCADED

COPPER

CONNECTION

I/O 2

I/O 1

ALTERNATE CONNECTIONS

(SWITCHED ETHERNET WITH

TWO NODES)

REMOTE HOST

(NIC W/FIBER INSTALLED)

OR

NIC TO SC-TYPE FIBER

MEDIA CONVERTER

CAUTION: YOU SHOULD LIMIT THE NUMBER

OF CASCADED CONNECTIONS, AS THIS WILL

INCREASE THE CONCENTRATION OF TRAFFIC

IN THE CUT-THROUGH PATH WITH THIS

CONNECTION.

FIBER TO REMOTE HOST (UP TO 2KM)

LOCAL AREA NETWORK

NODES WIRED FOR SWITCHED

ETHERNET (ONE UNIT PER

SWITCH PORT) VIA COPPER

RJ45 CONNECTIONS.

UP TO 100M PER SEGMENT.

NOTE:

I/O 1 IS THE ES2113-1000,

WHICH HAS ONE PORT OF

FIBER, AND ONE PORT OF

COPPER.

ALL ETHERSTAX UNITS HAVE

A BUILT-IN ETHERNET SWITCH.

THUS, THIS CONNECTION RETAINS

THE BENEFITS OF SWITCHED

ETHERNET FOR TWO UNITS.

For optimum performance, the ideal recommended approach is to utilize an

external Ethernet switch and connect no more than one Ethernet device per

switch port—this is what is referred to as switched Ethernet. Connection in

this manner avoids the negative effects of concentrated traffic and

suppresses the need for collision detection. This effectively allows a

segment to operate in full-duplex at the fastest possible speed. Thus, the

throughput of 100M at half-duplex, can effectively approach 200MB when

operating at full-duplex for switched Ethernet.

Although the connection shown above still retains the benefit of switched

Ethernet without utilizing an external switch, it really only applies to the first

two nodes. If you wanted to connect more than two nodes, but still retain the

benefits of switched Ethernet, you would have to utilize an external Ethernet

switch and connect one EtherStax unit per switch port.

CONNECTIONS

Network

The drawing at right gives an

alternate method for

connecting to a remote host,

while still retaining the benefit

of switched Ethernet between

two nodes.

This still adheres to the

principles of switched Ethernet

because the network ports of

the EtherStax are provided by

an internal 3-port Ethernet

switch.

However, note that the fiber

connection carries the traffic of

both units and this segment is

subject to data collisions.

Likewise, if you add a third

unit, I/O3, cascaded from I/O

2, then the first copper

segment carries the burden of

the traffic of I/O 2 and I/O 3.

This would not promote the

benefit of switched Ethernet in

this segment where we

attempt to limit the traffic on a

switched segment to a single

device and suppress the need

for CSMA/CD.

WARNING: Never use the

EtherStax as a bridge device

connected in series within your

enterprise LAN, as the effect

of concentrated traffic in the

shared segment could inhibit

communication to/from your

EtherStax unit.

Ideally, the shared segment

link that carries the

concentrated 100Mbps traffic

should operate at a higher

data rate, like 1Gbps, which

this switch does not support

.

This manual suits for next models

1

Table of contents

Other Acromag Adapter manuals

Popular Adapter manuals by other brands

Toa

Toa NF-CS1 Read me first

D-Link

D-Link XTREME N DUAL BAND USB ADAPTER DWA-160 Quick installation guide

Olympus

Olympus xD-Picture Card MAUSB-300 Start guide

BeachTek

BeachTek DXA-5D operating instructions

TRENDnet

TRENDnet TEW-604UB Quick installation guide

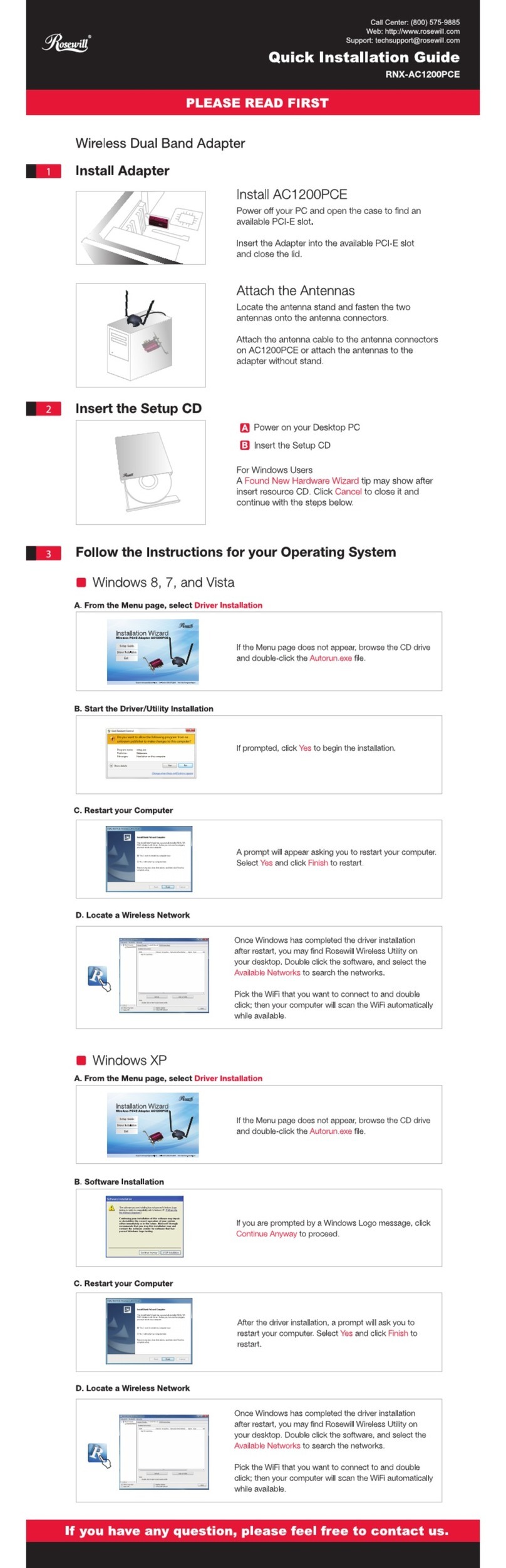

Rosewill

Rosewill RNX-AC1200PCE Quick installation guide