ACS contsys DAL-311x9x0S User manual

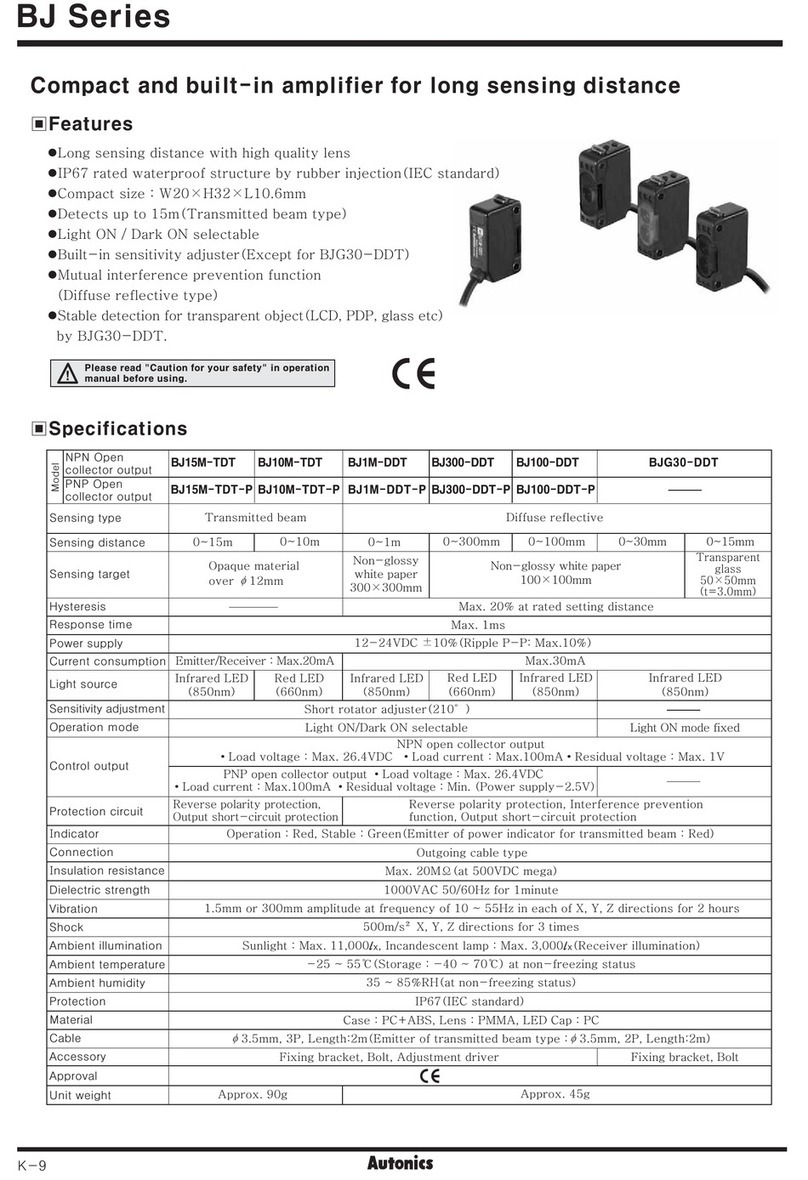

Technical features:

• red display of -19999…99999 digits (optional: green, orange or blue display)

• installation depth: 120 mm without plug-in terminal

• min/max memory

• 30 parameter driven setpoints

• optical threshold value indication at threshold value exceedance / undercut

•[O]-key for triggering of Hold, Tara or sensor alignment

• digital input for triggering of Hold, Tara or sensor alignment

• permanent min/max-value recording

• sensor alignment with integrated switching output

• mathematical functions like e.g. reciprocal value, square root, squaring or rounding

• sliding averaging

• brightness control

• programming interlock via access code

• protection class IP65 at the front

• plug-in terminal

• option: 1 or 2 analog outputs

• option: 2 or 4 relay outputs or 8 PhotoMos outputs

• option: interface RS232 or RS485

• accessories: PC-based configuration kit PM-TOOL incl. CD and USB-adapter for devices

without keypad and for a simple adjustment of standard devices

User manual M3

Strain gauge amplifier with a calibration for 350 Ohm melt pressure sensors

96x48

M3_1MGB.pdf update: 08.04.2015

Technical features:

• red display of -19999…99999 digits (optional: green, orange or blue display)

• installation depth: 120 mm without plug-in terminal

• min/max memory

• 30 parameter driven setpoints

• optical threshold value indication at threshold value exceedance / undercut

•[O]-key for triggering of Hold, Tara or sensor alignment

• digital input for triggering of Hold, Tara or sensor alignment

• permanent min/max-value recording

• sensor alignment with integrated switching output

• mathematical functions like e.g. reciprocal value, square root, squaring or rounding

• sliding averaging

• brightness control

• programming interlock via access code

• protection class IP65 at the front

• plug-in terminal

• option: 1 or 2 analog outputs

• option: 2 or 4 relay outputs or 8 PhotoMos outputs

• option: interface RS232 or RS485

• accessories: PC-based configuration kit PM-TOOL incl. CD and USB-adapter for devices

without keypad and for a simple adjustment of standard devices

User manual M3

Strain gauge amplifier with a calibration for 350 Ohm melt pressure sensors

96x48

M3_1MGB.pdf update: 08.04.2015

Operating Instructions

DAL-311x9x0S

Strain gauge amplier with a calibration for 350 Ohm melt pressure sensors

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

2

power supply

0 100-240V AC

2 10...40V DC galvanic seperated

3 100-240V AC with sensor supply 24V DC/50mA and digital input 1)

4 10...40V DC galvanic seperated with sensor supply 24V DC/50mA and digital input 1)

Y other voltages

function input

9 weighing technology

function output

A display + 2 relay outputs (changeover)

B display + 4 relay outputs

C display with analog output 0-10V/4-20mA, switchable

D display + 2 relay with analog output 0-10V/4-20mA, switchable

E display + 4 relay with analog output 0-10V/4-20mA, switchable

Y others outputs

0 standard conguration

S standard, protection IP65

DAL-311 S09

Order code

1) sensor supply

only at 0/4...20 mA,

0...10V DC input

Note

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 3

Contents

1

1. Brief description 2

2. Assembly 3

3. Electrical connection 4

4. Function description and operation 5

4.1. Programming software PM-TOOL 6

5. Setting up the device 7

5.1. Switching on 7

5.2. Standard parameterisation (flat operation level) 7

Value assignment for the triggering of the signal input

5.3. Programming interlock „RUN“ 10

Activation/Deactivation of the programming interlock or change into

professional

or flat operation level

5.4. Extended parametersation (professional operation level) 11

5.4.1. Signal input parameters „INP“ 11

Value assignment for the triggering of the signal input incl. linearisation

5.4.2. General device parameters „FCT“ 14

Superior device functions like Hold, Tara, min/max permanent, averaging, brightness control,

as well as the control of the digital input and keyboard layout

5.4.3. Safety parameters „COD“ 17

Assignment of user and master code to lock or to receive access to defined parameter such as

analog output and alarms, etc.

5.4.4. Serial parameters „ser“ 19

Parameter for interface definition

5.4.5. Analog output parameters „Out“ 20

Analog output functions

5.4.6. Relay functions „rel“ 23

Parameter for setpoint definition

5.4.7. Alarm parameters „AL1…AL4“ 25

Actuator and dependencies of the alarms

6. Reset to factory settings 27

Reset parameters onto the delivery state

7. Alarms / Relays 28

Functional principle of the switching outputs

8. Interfaces 29

Connection RS232 and RS485

9. Sensor aligment 30

Diagram of functional sequences for sensors with existing adjustable resistor

10. Technical data 31

11. Safety advices 33

12. Error elimination 34

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

4

1. Brief description

2

1. Brief description

The panel meter M3-1M is a 5-digit device for connection to a 4-wire-measuring bridge with calibration

contact (80% alignment) and a visual threshold value monitoring via the display. The configuration happens

via four front keys or via the optional PC software PM-TOOL. An integrated programming interlock prevents

unrequested changes of the parameters and can be unlocked again by an individual code. Optional the

following functions are available: a 10 V bridge feeding, a digital input for the triggering of Hold (Tara) or the

80%-alignment, two analog outputs, one interface, as well as two or four galvanic isolated setpoints, by

which free adjustable threshold values can be controlled and reported to a superior master display.

The electrical connection is carried out on the back side via plug-in terminals.

Selectable functions like e.g. the request of the min/max-value, an average determination of the measuring

signals, a direct change of threshold value in operation mode and additional measuring supporting points for

linearisation complete the modern device concept.

1. Brief description

2

1. Brief description

The panel meter M3-1M is a 5-digit device for connection to a 4-wire-measuring bridge with calibration

contact (80% alignment) and a visual threshold value monitoring via the display. The configuration happens

via four front keys or via the optional PC software PM-TOOL. An integrated programming interlock prevents

unrequested changes of the parameters and can be unlocked again by an individual code. Optional the

following functions are available: a 10 V bridge feeding, a digital input for the triggering of Hold (Tara) or the

80%-alignment, two analog outputs, one interface, as well as two or four galvanic isolated setpoints, by

which free adjustable threshold values can be controlled and reported to a superior master display.

The electrical connection is carried out on the back side via plug-in terminals.

Selectable functions like e.g. the request of the min/max-value, an average determination of the measuring

signals, a direct change of threshold value in operation mode and additional measuring supporting points for

linearisation complete the modern device concept.

The panel meter instrument DAL-311 is a 5-digit device for connection to a 4-wire-measuring bridge with calib-

ration contact (80% alignment) and a visual threshold value monitoring via the display. The conguration hap-

pens via 4 keys at the front or via the optional PC software PM-TOOL. The integrated programming interlock

prevents unrequested changes of parameters and can be unlocked again with an individual code. Optional the

following functions are available: a supply for the sensor, a digital input for triggering of Hold (Tara), two analog

outputs and interfaces for further evaluating in the unit.

With help of the galvanic isolated setpoints (optional), free adjustable limit values can be controlled and

reported to a superior master display.

The electrical connection is done via plug-in terminals on the back side.

Selectable functions like e.g. the recall of the min/max-value, an averaging of the measuring signals, a

nominal presetting or setpoint presetting, a direct threshold value regulation during operation mode and

further measuring setpoints for linearisation, complete the modern device concept.

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 5

2. Assembly

3

2. Assembly

Sealing

48,0

3,0

139,0

M3

Gap for physical unit

1. After removing the fixing elements, insert the device.

2. Check the seal to make sure it fits securely.

3. Click the fixing elements back into place and tighten the clamping screws by hand. Then use a

screwdriver to tighten them another half a turn.

CAUTION! The torque should not exceed 0.1 Nm!

The dimension symbols can be exchanged before installation via a channel on the side!

Please read the Safety advices on page 33 before installation and keep this user manual for future reference.

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

6

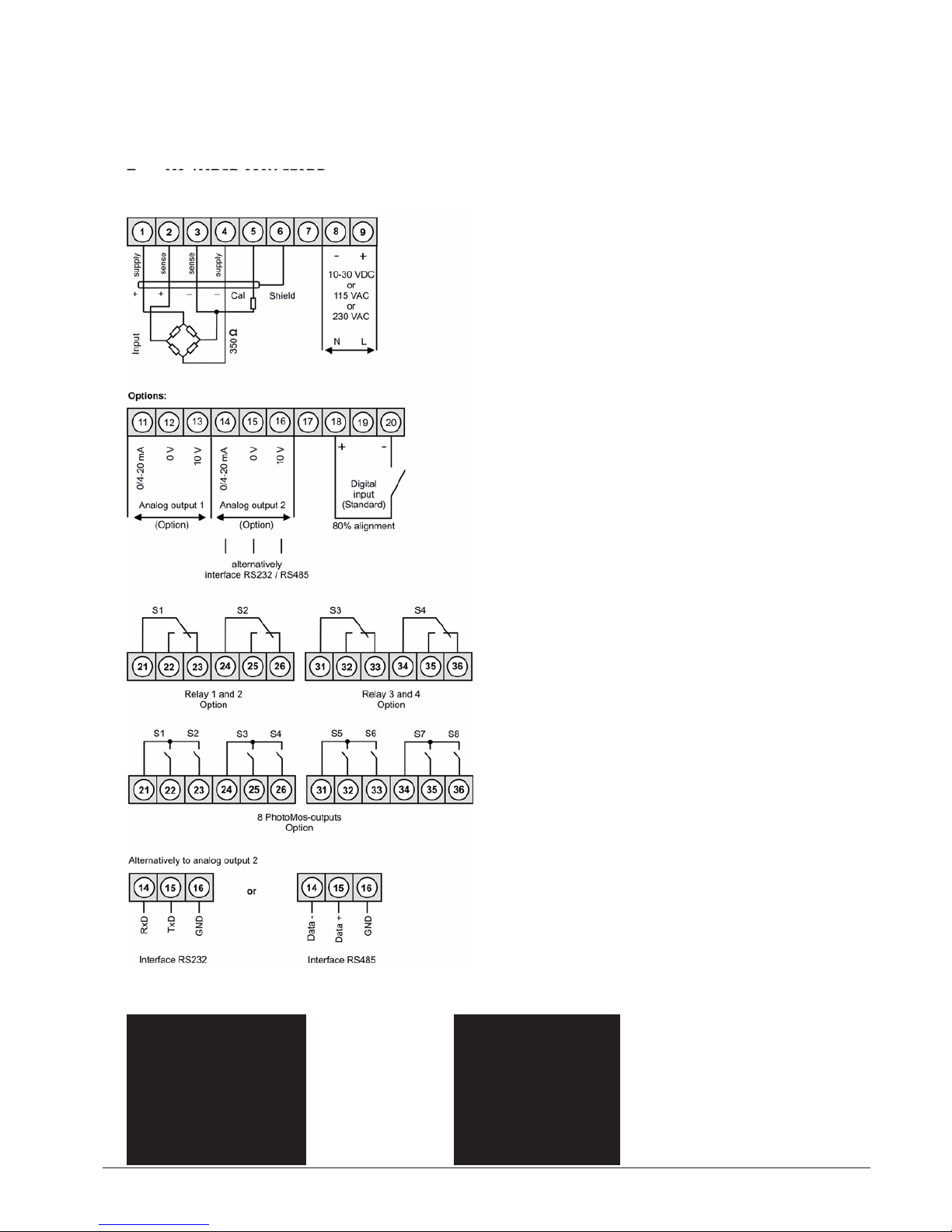

3. Electrical connection

4

3. Electrical connection

Type M3-1MR5B.020X.470BD supply of 115 VAC

Type M3-1MR5B.020X.570BD supply of 230 VAC

Type M3-1MR5B.020X.670BD supply of 10-30 VDC

DAL-311x9x0S with digital input and external

voltage source

DAL-311x9x0S with digital input in combination

with 24 VDC sensor supply

Type DAL-311x9x0S

Type DAL-311x9x0S

Type DAL-311x9x0S

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 7

5

4. Function and operation description

4. Function and operation description

Level Key Description

Menu-level

Change to parameterisation level and deposited values.

Keys for up and down navigation in the menu level.

Change into operation mode.

Parameterisation-

level

To confirm the changes made at the parameterization level.

Adjustment of the value / the setting.

Change into menu level or break-off in value input.

Menu-group-level

Change to menu level.

Keys for up and down navigation in the menu group level.

Change into operation mode or back into menu level.

Operation

The operation is divided into three different levels.

Menu level (delivery status)

This level was designed for the standard settings of the device. Only menu items which are sufficent to set

the device into operation are displayed. To get into the professional level, run through the menu level and

parameterise prof under menu item RUN.

Menu group level (complete function volume)

Suited for complex applications as e.g. linkage of alarms, setpoint treatment, totaliser function etc. In this

level function groups which allow an extended parameterisation of the standard settings are availabe. To

leave the menu group level, run through this level and parameterise uloc under menu item RUN.

Parameterisation level:

Parameter deposited in the menu item can here be parameterised. Functions, that can be changed or

adjusted, are always signalised by a flashing of the display. Settings that are made in the parameterisation

level are confirmed with [P] and thus saved. Pressing the [O]-key leads to a break-off of the value input and

to a change into the menu level. All adjustments are saved automatically by the device and changes into

operating mode, if no further key operation is done within the next 10 seconds.

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

8

6

4. Function and operation description

Function chart:

4.1 Parameterisation software PM-TOOL:

Part of the PM-TOOL are the software on CD and an USB-cable with device adapter. The connection

happens via a 4-pole micromatch-plug on the back side of the device, to the PC-side the connection

happens via an USB plug.

System requirements: PC incl. USB interface

Software: Windows XP, Windows VISTA

With this tool the device configuration can be generated, omitted and saved on the PC. The parameters can

be changed via the easy to handle program surface, whereat the operating mode and the possible selection

options can be preset by the program.

CAUTION!

During parameterisation with connected measuring signal, make sure that the measuring signal has no

mass supply to the programming plug. The programming adapter is galvanic not isolated and directly

connected with the PC. Via polarity of the input signal, a current can discharge via the adapter and destroy

the device as well as other connected components!

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 9

7

5.1. Switching on

Once the installation is complete, start the device by applying the voltage supply. Before, check once again

that all electrical connections are correct.

Starting sequence

For 1 second during the switching-on process, the segment test (8 8 8 8 8) is displayed followed by an

indication of the software type and, after that, also for 1 second the software version. After the starting

sequence, the device switches to operation/display mode.

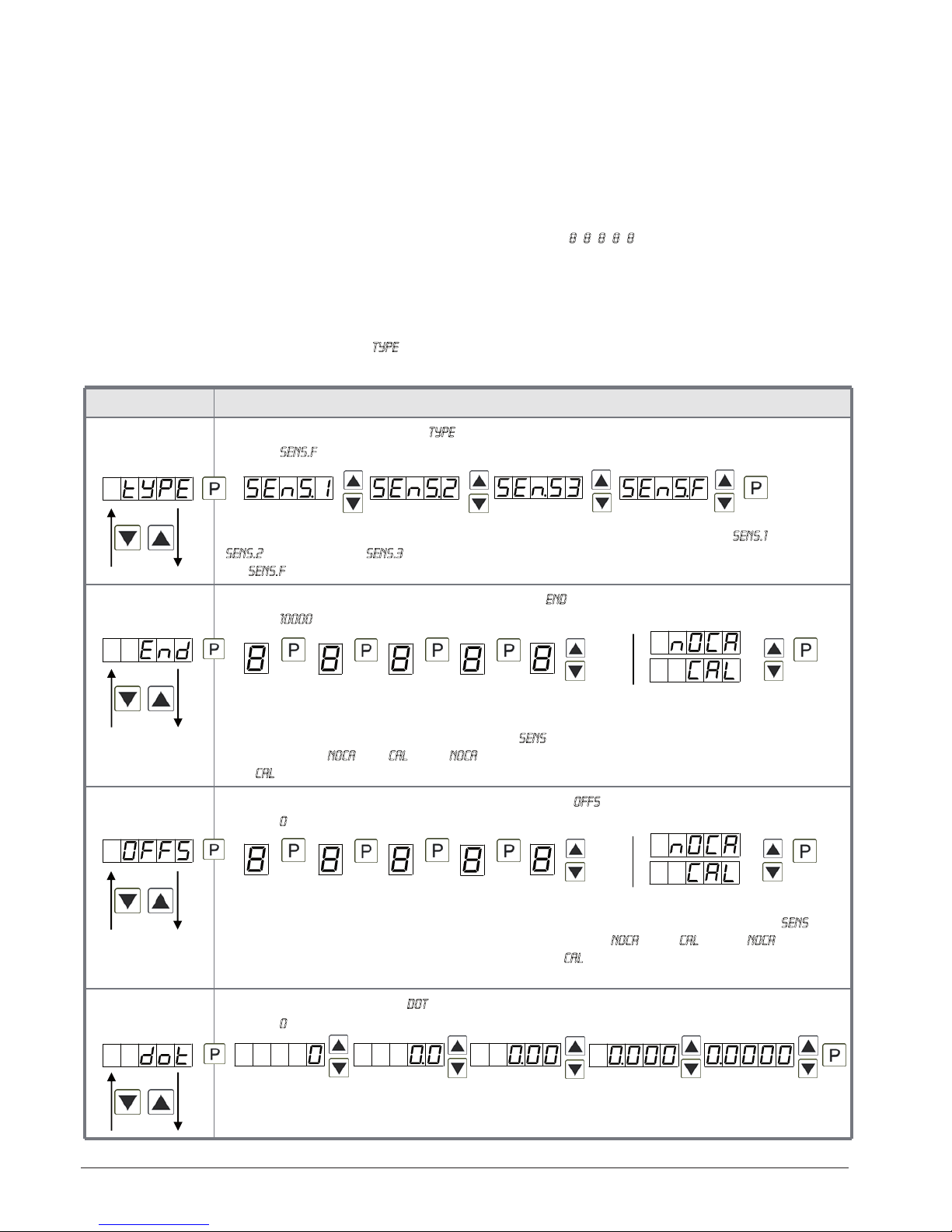

5.2. Standard parameterisation: (Flat operation level)

To parameterise the display, press the [P]-key in operating mode for 1 second. The display then changes to

the menu level with the first menu item TYPE.

5. Setting up the device

Menu level Parameterisation level

Selection of the input signal, tYPE:

Default: sens.f

There are 3 measuring input options available for known sensor sensibilities: SENS.1 for 1mV/V,

SENS.2 for 2mV/V and SENS.3 for 3.3mV/V. Each sensor is measured and calibrated up to 4mV/V

via SEnS.F. Confirm the selection with [P] and the display switches back to menu level.

Setting the end value of the measuring range, END:

Default: 10000

Set the end value from the smallest to the highest digit with [▲] [▼]and confirm each digit with

[P]. A minus sign can only be parameterized on the highest value digit. After the last digit, the

display switches back to the menu level. If Sens was selected as input option, you can only

select between noca and cal. With noca, only the previously set display value is taken over, and

with cal, the device takes over both the display value and the analogue input value.

Setting up the measuring range start/offset value, offs:

Default: 0

Enter the start/offset value from the smallest to the highest digit with [▲] [▼]and confirm each

digit with [P]. After the last digit the display switches back to the menu level. If Sens was

selected as input option, you can only select between noca and cal. With noca, only the

previously set display value is taken over, and with cal, the device takes over both the display

value and the analogue input value.

Setting the decimal point, dot:

Default: 0

The decimal point on the display can be moved with [▲] [▼]and confirmed with [P]. The

display then switches back to the menu level again.

5. Setting up the device

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

10

8

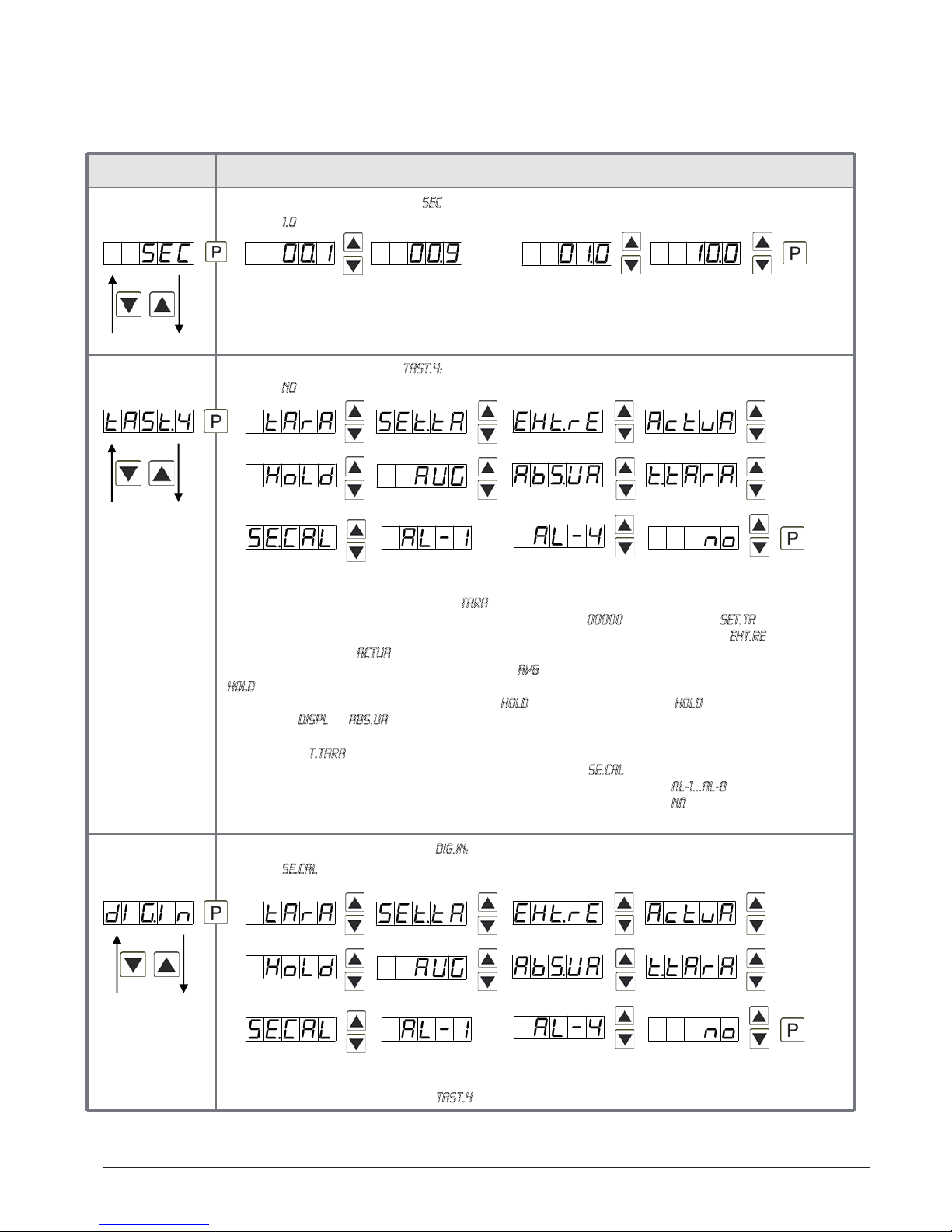

5. Setting up the device

Menu level Parameterisation level

Setting up the display time, SEC:

Default: 1.0

The display time is set with [▲] [▼]. The display moves up in increments of 0.1 up to 1 second

and in increments of 1.0 up to 10.0 seconds. Confirm the selection by pressing the [P] button.

The display then switches back to the menu level again.

Special function [O]-key, tASt.4:

Default: no

For the operation mode, special functions can be deposited on the [O]-key. This function is

activated by pressing the key. With tArA the display is tared to zero und saved permanently as

offset. The device acknowledges the correct taring with oo0oo in the display. Set.tA switches into

the offset value and can thus be changed via the navigation keys [▲] [▼].EHt.rE deletes the

min/max memory. ActuA shows the measurand, then the display changes onto the para-

meterised display value. The same goes for AVG, here the sliding average value is displayed. If

HOLD has been selected, the moment can be hold constant by pressing the [O]-key, and is

updated by releasing the key. Advice: Hold is activated only, if HOLD was selected under

parameter DISPL. If AbS.UA (absolute value) was selected, the display shows the values that have

been measured since the voltage has been connected, without consideration of a previous

taring. With t.tAra (temporarily Tara) the offset is determined by rising shoulder of the digital

input and kept only for the period of the signal. Via SE.CAL a sensor calibration is done by

pushing the zero-key, the flow diagram is shown in chapter 4.4. At AL-1…AL-8 an output can be

set and therewith e.g. a switch of the metering point can be done. If nois selected, the [O]-key

is without any function in the operation mode.

Special function digital input, dIG.In:

Default: se.cal

The above given parameters can be set for the operation mode onto the optional digital input

aswell. See function description tASt.4.

then

…

…

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 11

9

5. Setting up the device

Menu level Parameterisation level

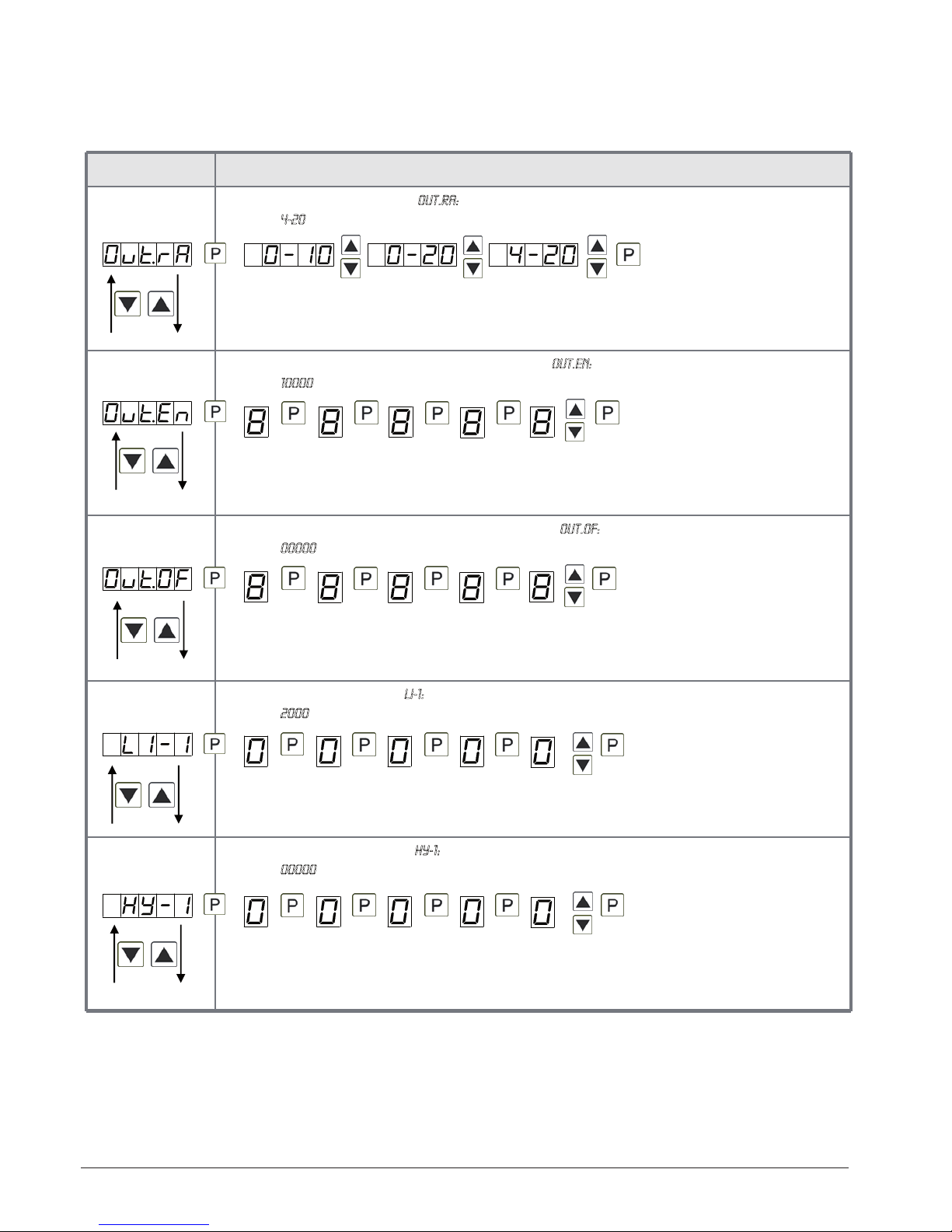

Selection of analog output, Out.rA:

Default: 4-20

Three output signals are available: 0-10 VDC, 0-20 mA and 4-20 mA, with this function, the

demanded signal is selected.

Setting up the final value of the analog output, Out.En:

Default: 10000

The final value is adjusted from the smallest digit to the highest digit with [▲] [▼]and digit by

digit confirmed with [P]. A minus sign can only be parameterised on the highest digit. After the

last digit, the device changes back into menu level.

Setting up the initial value of the analog output, Out.OF:

Default: 00000

The final value is adjusted from the smallest digit to the highest digit with [▲] [▼]and digit by

digit confirmed with [P]. A minus sign can only be parameterised on the highest digit. After the

last digit, the device changes back into menu level.

Threshold values / limits, LI-1:

Default: 2000

This value defines the threshold, that activates/deactivates an alarm.

Hysteresis for limit values, HY-1:

Default: 00000

The delayed reaction of the alarm is the difference to the threshold value, which is defined by

the hysteresis.

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

12

10

5. Setting up the device

Menu level Parameterisation level

Function for threshold value undercut / exceedance, Fu-1:

Default: high

A limit value undercut is selected with Louu (for LOW = lower limit value), a limit value

exceedance with High (for HIGH = higher limit value). If e.g. limit value 1 is on a threshold level

of 100 and allocated with function High, an alarm is activated by reaching of the threshold level.

If the threshold value was allocated to Low, an alarm will be activated by undercutting the

threshold value, as long as the hysteresis is zero.

The same applies to LI-2 !

User code (4-digit number-combination, free available), U.CodE:

Default: 0000

If this code was set (> 0000), all parameters are locked for the user, if LOC has been selected

before under menu item run. By pressing [P] for 3 seconds in operation mode, the display

shows COde. The U.Code needs to be entered to get to the reduced number of parameter sets.

The code has to be entered befor each parameterisation, until the A.Code (Master code) unlocks

all parameters again.

Master code (4-digit number-combination, free available), A.CodE:

Default: 1234

All parameters can be unlocked with this code, after LOC has been activated under menu item

run. By pressing [P] for 3 seconds in operation mode, the display shows COde and enables the

user to reach all parametes by entering the A.codE. Under run the parameterisation can be

activated permanently by selecting ULOC or ProF, thus at an anew pushing of [P] in operation

mode, the code needs not to be entered again.

5.3. Programming interlock „RUN“

Activation / deactivation of the programming lock or completion of the standard

parameterisation with change into menu group level (complete function range), run:

Default: uloc

Choose between the deactivated key lock Uloc (works setting) and the activated key lock Loc, or

the change into the menu group level ProF with the navigation keys [▲] [▼]. Confirm the

selection with [P]. After this, the display confirms the settings with "-- - - -", and automatically

switches to operating mode. If Loc was selected, the keyboard is locked. To get back into the

menu level, press [P] for 3 seconds in operating mode. Now enter the CODE (works setting 1 2 3

4) that appears using [▲] [▼] plus [P] to unlock the keyboard. FAIL appears if the input is

wrong. To parameterise further functions ProF needs to be set. The device confirms this setting

with „-- - - -„and changes automatically in operation mode. By pressing [P] for approx. 3

seconds in operation mode, the first menu group InP is shown in the display and thus confirms

the change into the extended parameterisation. It stays activated as long as ULOC or LOC is

entered in menu group RUN.

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 13

11

5. Setting up the device

5.4. Extended parametrisation (Professional operation level)

Menu group level

Menu level

5.4.1. Signal input parameters

Menu level Parameterisation level

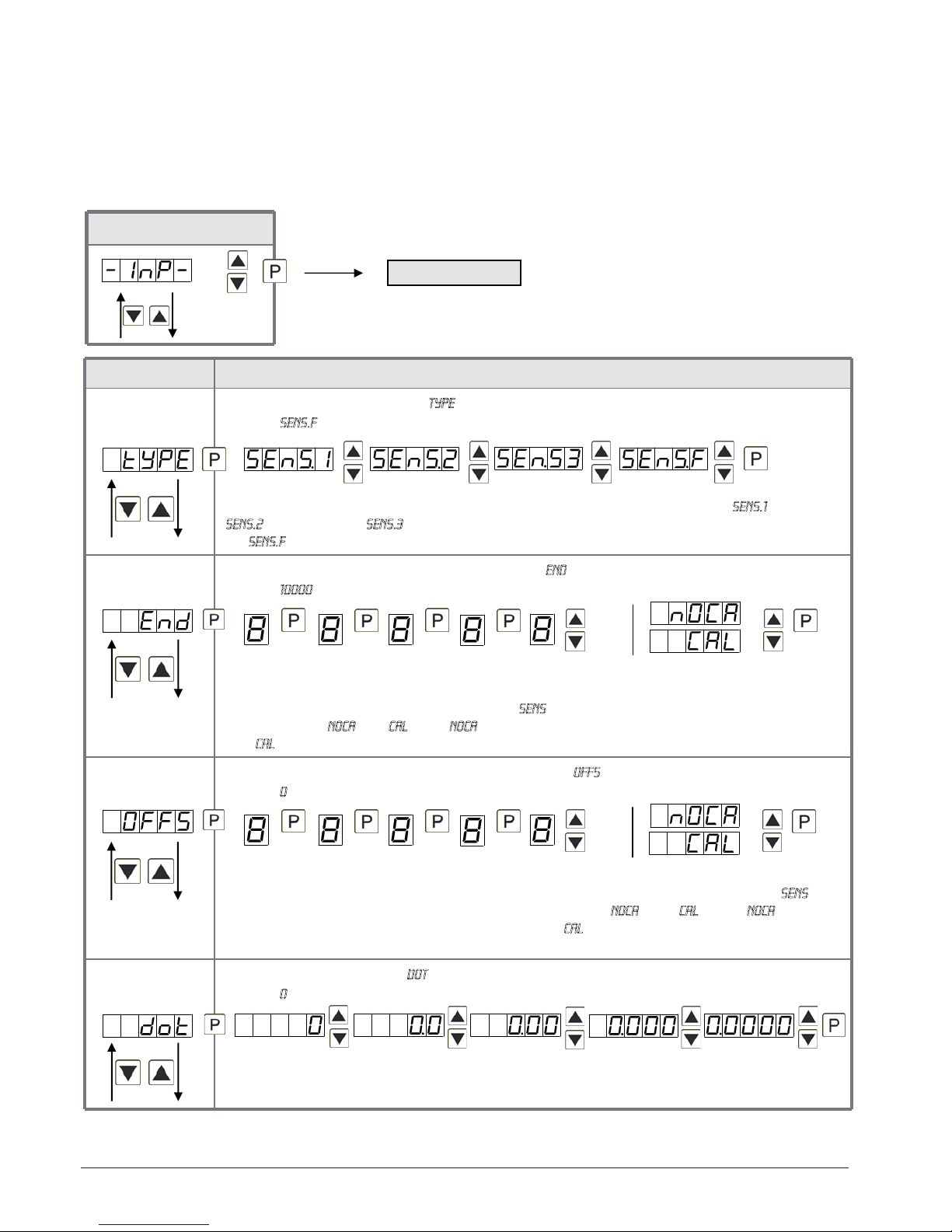

Selection of the input signal, tYPE:

Default: sens.f

There are 3 measuring input options available for known sensor sensibilities: SENS.1 for 1mV/V,

SENS.2 for 2mV/V and SENS.3 for 3.3mV/V. Each sensor is measured and calibrated up to 4mV/V

via SEnS.F. Confirm the selection with [P] and the display switches back to menu level.

Setting the end value of the measuring range, END:

Default: 10000

Set the end value from the smallest to the highest digit with [▲] [▼]and confirm each digit with

[P]. A minus sign can only be parameterized on the highest value digit. After the last digit, the

display switches back to the menu level. If Sens was selected as input option, you can only

select between noca and cal. With noca, only the previously set display value is taken over, and

with cal, the device takes over both the display value and the analogue input value.

Setting up the measuring range start/offset value, offs:

Default: 0

Enter the start/offset value from the smallest to the highest digit with [▲] [▼]and confirm each

digit with [P]. After the last digit the display switches back to the menu level. If Sens was

selected as input option, you can only select between noca and cal. With noca, only the

previously set display value is taken over, and with cal, the device takes over both the display

value and the analogue input value.

Setting the decimal point, dot:

Default: 0

The decimal point on the display can be moved with [▲] [▼]and confirmed with [P]. The

display then switches back to the menu level again.

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

14

5. Setting up the device

12

Menu level Parameterisation level

Setting up the display time, SEC:

Default: 1.0

The display time is set with [▲] [▼]. The display moves up in increments of 0.1 up to 1 second

and in increments of 1.0 up to 10.0 seconds. Confirm the selection by pressing the [P] button.

The display then switches back to the menu level again.

Rescaling the measuring input values, EndA:

Default: 10000

With this function, you can rescale the input value of e.g. 1.1 mV/V (works setting) without

applying a measuring signal. If sensor calibration has been selected, these parameters are not

available.

Rescaling the measuring input values, OFFA:

Default: 0

With this function, you can rescale the input value of e.g. 3.5 mA (works setting) without

applying a measuring signal. If sensor calibration has been selected, these parameters are not

available.

Setting up the tare/offset value, tArA:

Default: 0

The given value is added to the linearized value. In this way, the characteristic line can be

shifted by the selected amount.

Setting up the balance point, Adj.pt:

Default: 80.00

The balance point is preset to 80%. Assume an 80% detuning while switching the alignment

relay during an automatic sensor alignment. This value can be freely adjusted.

Setting up the physical unit, UnIt:

Default: no

One can choose between the above shown physical units. It will be displayed on the 5th digit of

the display.

then

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 15

13

5. Setting up the device

Menu level Parameterisation level

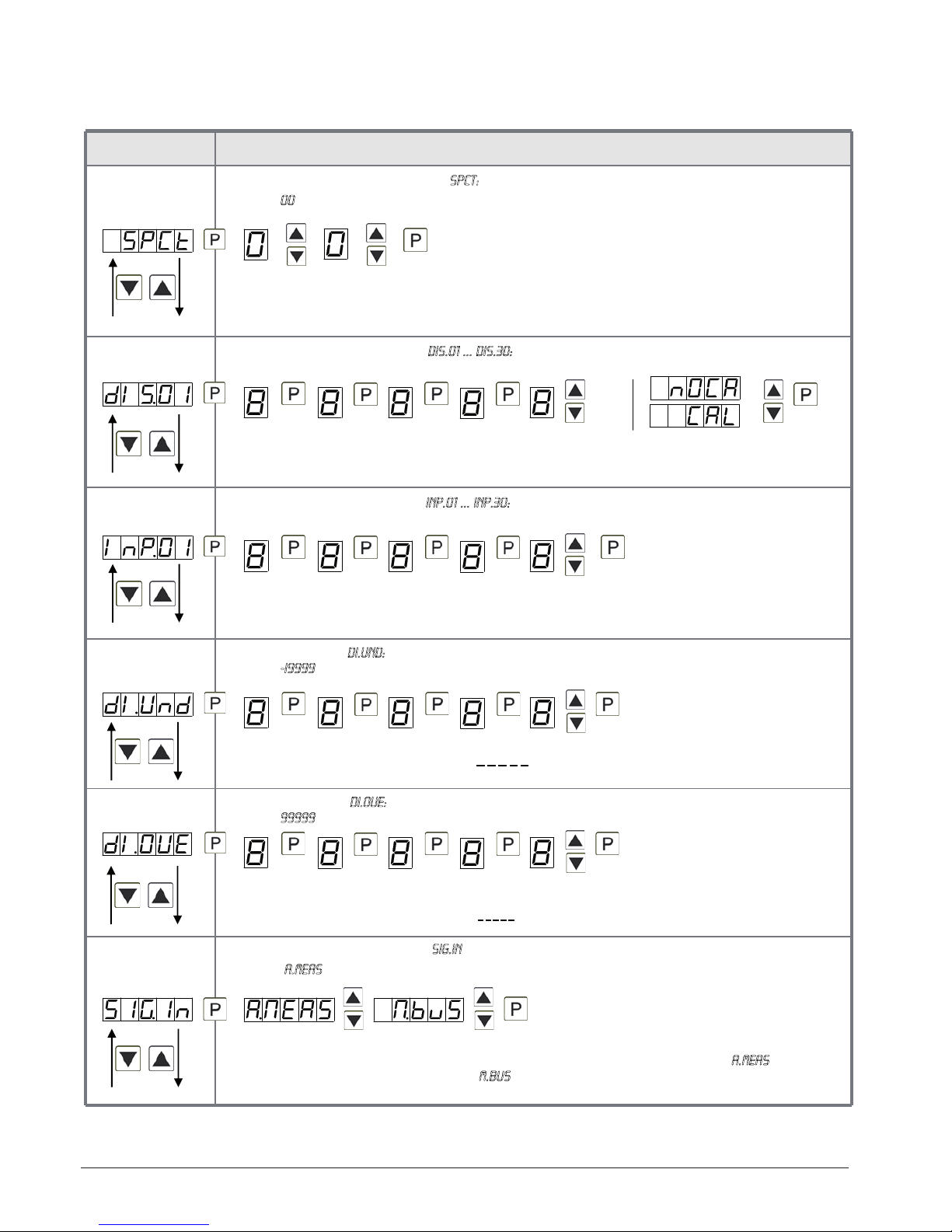

Number of additional setpoints, SPCt:

Default: 00

30 additional setpoints can be defined to the initial value and final value, so linear sensor

values are not linearised. Only activated setpoint parameters are displayed.

Display values for setpoints, dIS.01 … dIS.30:

Under this parameter setpoints are defined according to their value. At the sensor calibration,

like at final value / offset, one is asked at the end if a calibration shall be activated.

Analog values for setpoints, InP.01 … InP.30:

The setpoints are always set according to the selected input signal. The desired analog values

can be freely parameterised in ascending order.

Device undercut, dI.Und:

Default: -i9999

With this function the device undercut (_ _ _ _ _) can be defined on a definite value. Exception is

input type 4-20 mA, it already shows undercut at a signal <1 mA, so a sensor failure is marked.

Display overflow, dI.OUE:

Default: 99999

With this function the display overflow (_ _ _ _ _) can be defined on a definite value.

Input variable of process value, SIG.in:

Default: a.meas

With this parameter, the device can be controlled via the analog input signals a.meas = mV/V or

via the digital signals of the interface M.bus = RS232/RS485 (modbus protocol). With [P] the

selection is confirmed and the device changes into menu level.

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

16

14

5. Setting up the device

Menu level Parameterisation level

Back to menu group level, rEt:

With [P] the selection is confirmed and the device changes into menu group level „–INP–“.

5.4.2. General device parameters

Menu level Parameterisation level

Display time, DISEC:

Default: 01.0

The display is set up with [▲] [▼]. Thereby it switches up to 1 second in increments of 0.1

seconds and up to 10.0 seconds in increments of 1.0. With [P] the selection is confirmed and

the device changes into menu level.

Rounding of display values, round:

Default: 00001

This function is for instable display values, where the display value is changed in

increments of 1, 5, 10 or 50. This does not affect the resolution of the optional outputs. With [P]

the selection is confirmed and the device changes into menu level.

Arithmetic, ArItH:

Default: n0

With this function the calculated value, not the measuring value, is shown in the display. With

no, no calculation is deposited. With [P] the selection is confirmed and the device changes into

menu level.

Sliding average determination, AVG:

Default: 1.0

Here, the number of the meterings that need to be averaged is preset. The time of averaging

results of the product of measuring time SEC and the averaged metering AVG. With the selection

of AVG in the menu level DISPL, the result will be shown in the display and evaluated via the

alarms.

Menu group level

Menu level

then

Reciprocal Root

extraction

Square

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 17

5. Setting up the device

15

Menu level Parameterisation level

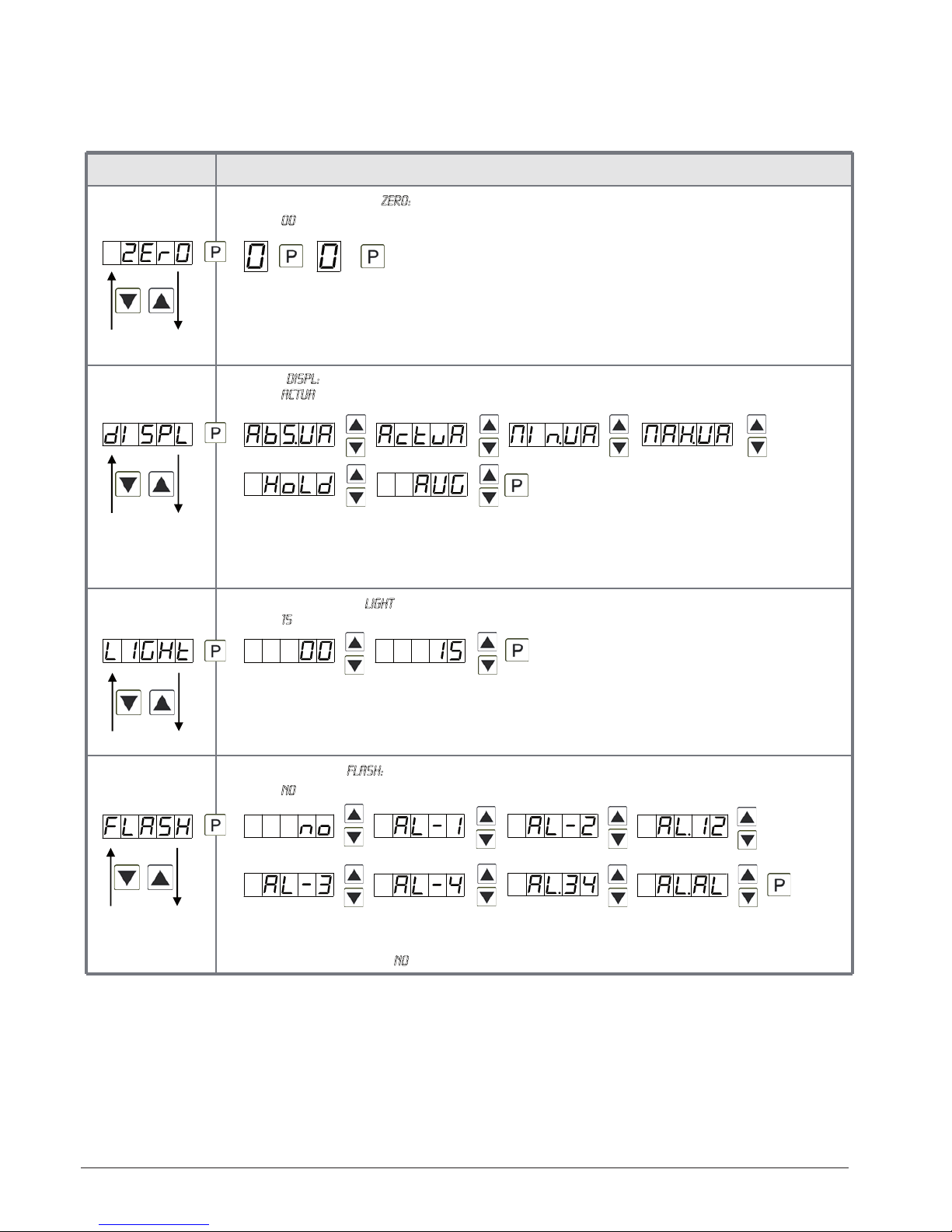

Zero point slowdown, ZErO:

Default: 00

At the zero point slowdown, a value range around the zero point can be preset, so the display

shows a zero. If e.g. a 10 is set, the display would show a zero in the value range from -10 to

+10; below continue with -11 and beyond with +11. The maximum adjustable range of value is

99.

Display, dISPL:

Default: actua

With this function the current measuring value, the min/max-value, the totaliser, the process-

controlled hold-value, the sliding average value, the constant value or the difference between

constant value and current value can be allocated to the display. With [P] the selection is

confirmed and the device changes into menu level.

Brightness control, Light:

Default: 15

The brightness of the display can be adjusted in 16 levels from 00 = very dark to 15 = very

bright via this parameter or alternatively via the navigation keys from the outside. During the

start of the device the level that is deposited under this parameter will always be used, even

though the brightness has been changed via the navigation keys in the meantime.

Display flashing, FLASH:

Default: no

A display flashing can be added as additional alarm function either to single or to a combination

of off-limit condition. With no, no flashing is allocated.

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

18

5. Setting up the device

16

Menu level Parameterisation level

Assignment (deposit) of key functions, tASt:

Default: no

For the operation mode, special functions can be deposited on the navigation keys [▲] [▼], in

particular this function is made for devices in housing size 48x24mm which do not have a 4th

key ([O]-key). If the min/max-memory is activated with EHtr, all measured min/max-values are

saved during operation and can be recalled via the navigation keys. The values get lost by

restart of the device. If the threshold value correction LI.12 or LI.34 was choosen, the values of the

threshold can be changed during operation without disturbing the operating procedure. With

tArA the device is tared to zero and saved permanently as offset. The device confirms the

correct taring by showing ooooo in the display. Set.tA switches into the offset value and can be

changed via the navigation keys [▲] [▼]. The configuration of EHt.rE deletes the min/max-

memory. Under ActuA the current measurand is shown (by pushing the button) and under Abs.ua

the absolute value is displayed. If AbS.UA (absolute value) was selected, the display shows the

value that has been measured since voltage connection, without consideration of a previous

taring. If nois selected, the navigation keys are without any function in the operation mode.

Special function [O]-key, tASt.4:

Default: no

For the operation mode, special functions can laid be on the [O]-key. This function is triggered

by pushing the key. With tArA the display is tared to zero and is saved permanently as offset.

The display confirms the correct taring by showing ooooo in the display. Set.tA switches into the

offset value and can be changed via the direction keys [▲] [▼].EHt.rE deletes the min/max-

memory. ActuA shows the measuring value. Then the display switches to the parameterised

display value. The same goes for AVG, here the sliding average value is displayed. At selected

HOLD the instant value is held by pushing the [O]-key and updated by releasing the key.

Advice: Hold can only be activated if HOLD was selected under parameter DISPL. If AbS.UA

(absolute value) was selected, the display shows the values that have been measured since

the voltage has been connected, without consideration of a previous taring. With t.tAra

(temporarily Tara) the offset is determined by rising shoulder of the digital input and kept only

for the period of the signal. Via SE.CAL a sensor calibration is done by pushing the zero-key, the

flow diagram is shown in chapter 4.4. At AL-1…AL-8 an output can be set and therewith e.g. a

switch of the metering point can be done. If nois selected, the [O]-key has no function in the

operation mode.

…

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 19

5. Setting up the device

17

Menu level Parameterisation level

Special function digital input, dIG.In:

Default: no

For the operation mode, the above shown parameters can be laid on the optional digital input,

too. Functions description see tASt.4.

Back to menu group level, rEt:

With [P] the selection is confirmed and the device changes into menu group level „–fct–“.

…

Menu level Parameterisation level

User code U.Code:

Default: 0000

Via this code reduced sets of parameters can be set free. A change of the U.CodE can be done

via the correct input of the A.CodE (master code).

Master code, A.Code:

Default: 1234

By entering A.CodE the device will be unlocked and all parameters are released.

Menu group level

5.4.3. Safety parameters

Menu level

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

20

5. Setting up the device

18

Menu level Parameterisation level

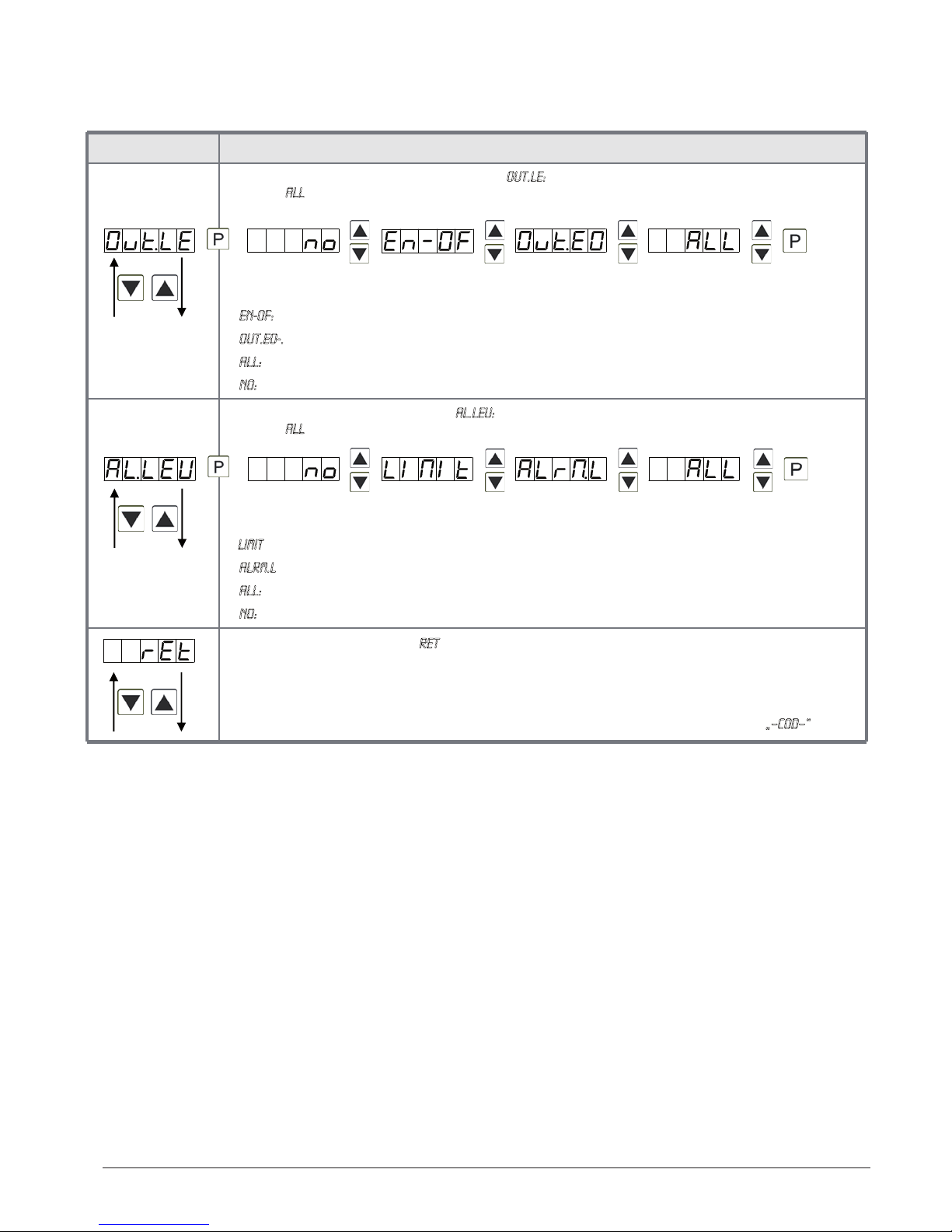

Release/lock analog output parameter, Out.LE:

Default: all

Analog output parameter can be locked or released for the user:

-En-oF: the initial or final value can be changed in operation mode

-Out.EO-. the output signal can be changed from e.g. 0-20 mA to 4-20 mA or 0-10 VDC

-ALL: analog output parameters are released

-no: all analog output parameters are locked

Release/lock alarm parameters, AL.LEU:

Default: all

This parameter describes the user release/user lock of the alarm.

- LIMIt: here only the range of value of the threshold values 1-4 can be changed

-ALrM.L: here the range of value and the alarm trigger can be changed

-ALL: all alarm parameters are released

-no: all alarm parameters are locked

Back to menu group level, rEt:

With [P] the selection is confirmed and the device changes into menu group level „–COD–“.

Table of contents

Popular Amplifier manuals by other brands

Rockville

Rockville RCS650-6 owner's manual

Televes

Televes 4509 Safety instructions

Marantz

Marantz PM10s1 owner's manual

Studiomaster Professional

Studiomaster Professional PA Series owner's manual

Phontech Communication

Phontech Communication Argo A-1 Handbook

Audio Note

Audio Note SORO Phono SE Signature Owner's Information