Acson international ADB75B User manual

Ducted Blower

Split Systems

ADB-B_(i)

ADB 75-750 B

ADB 75-500 D

Models:

ADB 75/100 D

ADB 125/150 D

ADB 600 B4

TABLE OF CONTENTS

1. NOMENCLATURE ..................................................................................................... 1

- PRODUCT LINE UP ........................................................................................ 3

2. FEATURES ................................................................................................................ 9

3. APPLICATION INFORMATION

- OPERATING RANGE ..................................................................................... 10

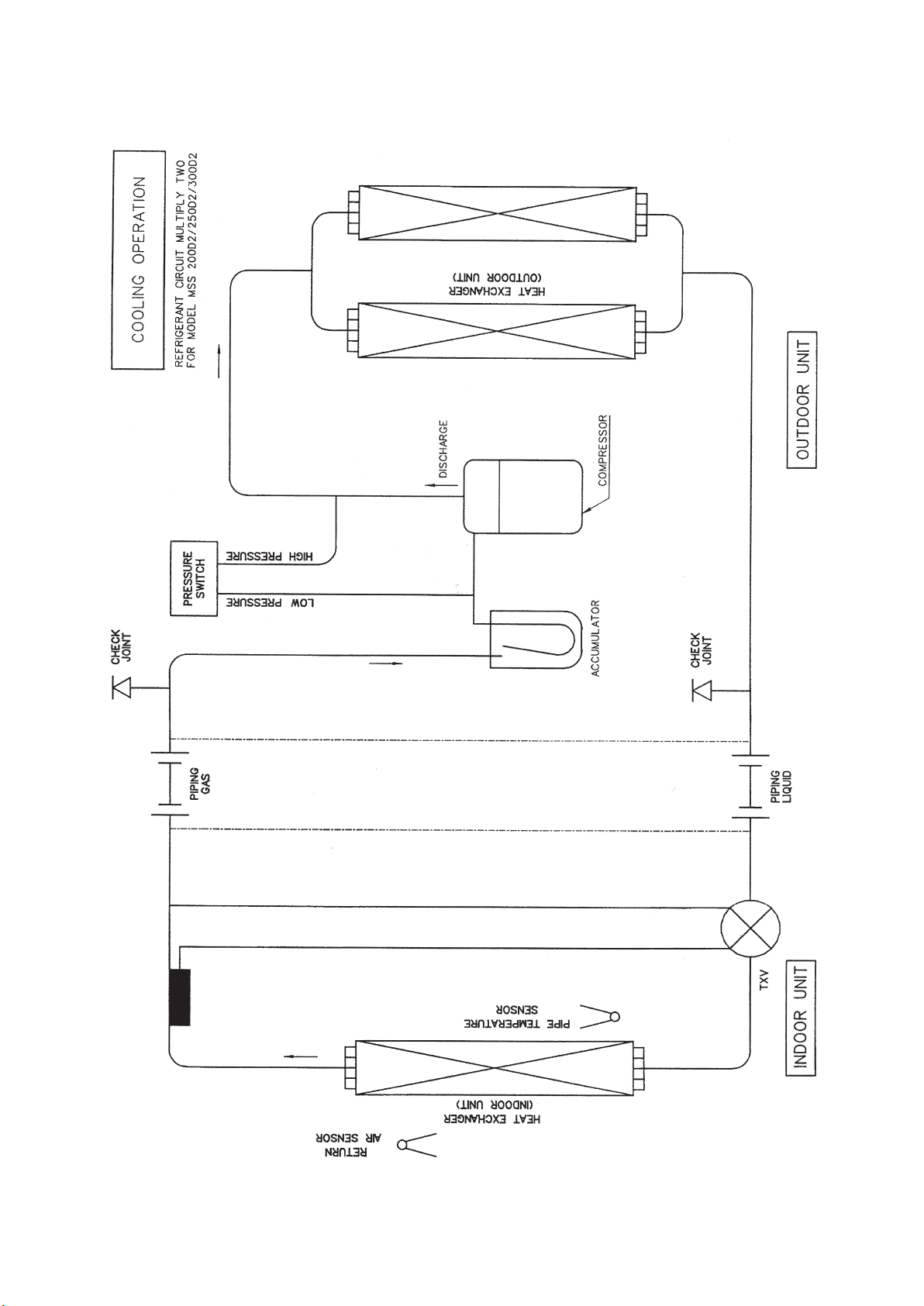

- REFRIGERANT CIRCUIT DIAGRAM ............................................................ 11

- CONTROLLER ............................................................................................... 13

- INSTALLATION .............................................................................................. 17

4. SOUND DATA ........................................................................................................... 27

- NC CURVES .................................................................................................. 29

5. SELECTION PROCESS

- FAN PERFORMANCE CHART ...................................................................... 44

6. ENGINEERING AND PHYSICAL DATA

- GENERAL DATA ............................................................................................ 70

- COMPONENTS DATA................................................................................... 100

- SAFETY DEVICES ........................................................................................ 142

7. PERFORMANCE DATA ........................................................................................... 152

- PERFORMANCE TABLES ............................................................................ 158

8. OUTLINE AND DIMENSION .................................................................................... 181

9. ELECTRICAL DATA ................................................................................................. 199

10. WIRING DIAGRAMS.............................................................................................. 216

11. SERVICING AND MAINTENANCE ........................................................................ 238

12. TROUBLESHOOTING ........................................................................................... 240

13. EXPLODED VIEW AND PART LIST ...................................................................... 245

THIS MANUAL SUPERCEDES ADB-2009

1

1. NOMENCLATURE

ADB 200 BR

Brand

A : ACSON

Capacity

200 : 200,000 Btu/h

Series

B : B series

D : D series

Model Type

R : Heatpump

Omitted if Cooling Only

A A

AB

-

Refrigerant

Blank : R22

4 : R407C

Model Name

DB : Ducted Blower

DSB : Double Skin Ducted Blower

Electrical

A : 50Hz/1Ph/220 ~ 240V

F : 50Hz/3Ph/380 ~ 415V

Others

AA : Revision

Type of Connection

B : For Brazed

F : For Flare

Indoor

2

AMC 75 BR

Brand

A : ACSON

Capacity

75 : 75,000 Btu/h

Series

B : B series

D : D series

Model Type

R : Heatpump

Omitted if Cooling Only

A A

AB

-

Refrigerant

Blank : R22

4 : R407C

Model Name

MC : Modular Condensing Unit

LC : Single Split Condensing Unit

Electrical

A : 50Hz/1Ph/220 ~ 240V

F : 50Hz/3Ph/380 ~ 415V

Others

AA : Revision

Type of Connection

B : For Brazed

F : For Flare

Outdoor

3

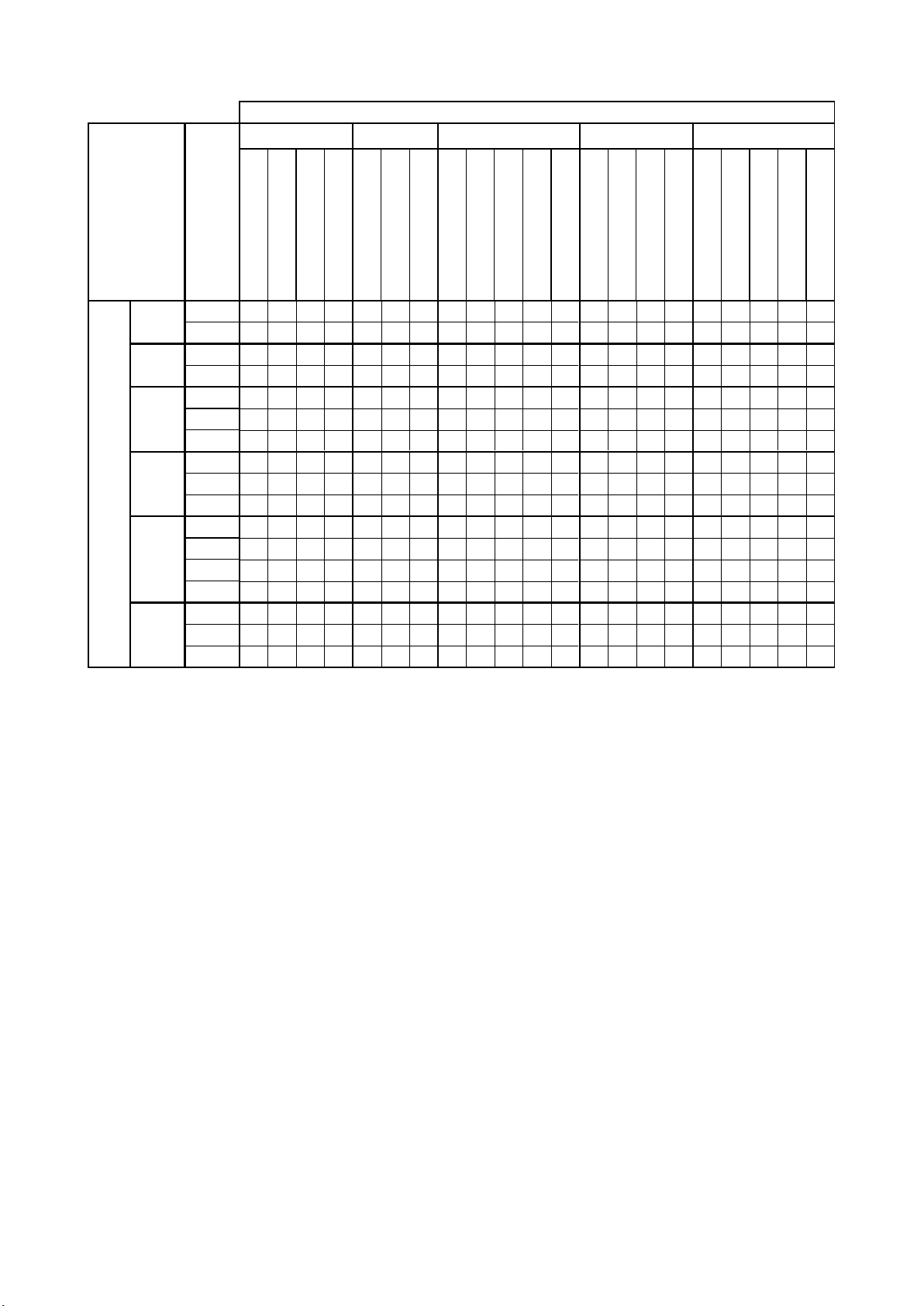

W/out Control

With Contactor

W/out Contactor

L208A

U1_SB125

Sequential

SLM3

Sequential Controller

CE Mark

Without Marking

TXV

Capillary Tube

Without Expansion Device

With air filter

W/out Air Filter

Horizontal & Changeable

Horizontal & Not Changeable

Vertical & Not changeable

Vertical & Changeable

Rivet "Made In Malaysia"

Very High Static

75B ABAF X X X X X X

100B ABAH X X X X X X

125B FBAH X X X X X X X

150B FBAG X X X X X X X

FBAH X X X X X

FBAI X X X X X X X

FBAG X X X X X

FBAI X X X X X X X

FBAC X X X X X

FBAE X X X X X X X

FBAC X X X X X

FBAE X X X X X X X

FBAG W X X X X

FBAI X X X X X X X

FBAC X X X X X

FBAE X X X X X X X

FBAC X X X X X

FBAE X X X X X X X

FBAG X X X X X

FBAI X X X X X X X

FBAC X X X X X

FBAD X X X X X X X

750B5 FBAC X X X X X

Classification

300B2

350B3

300B3

Marking Air Discharge

200B2

250B2

Others

A. Filter

COOLING MODEL

Control

400B4

450B3

Nomenclature

Refrigerant

Control

Handset

500B4

600B4

ADB

Product Line Up

4

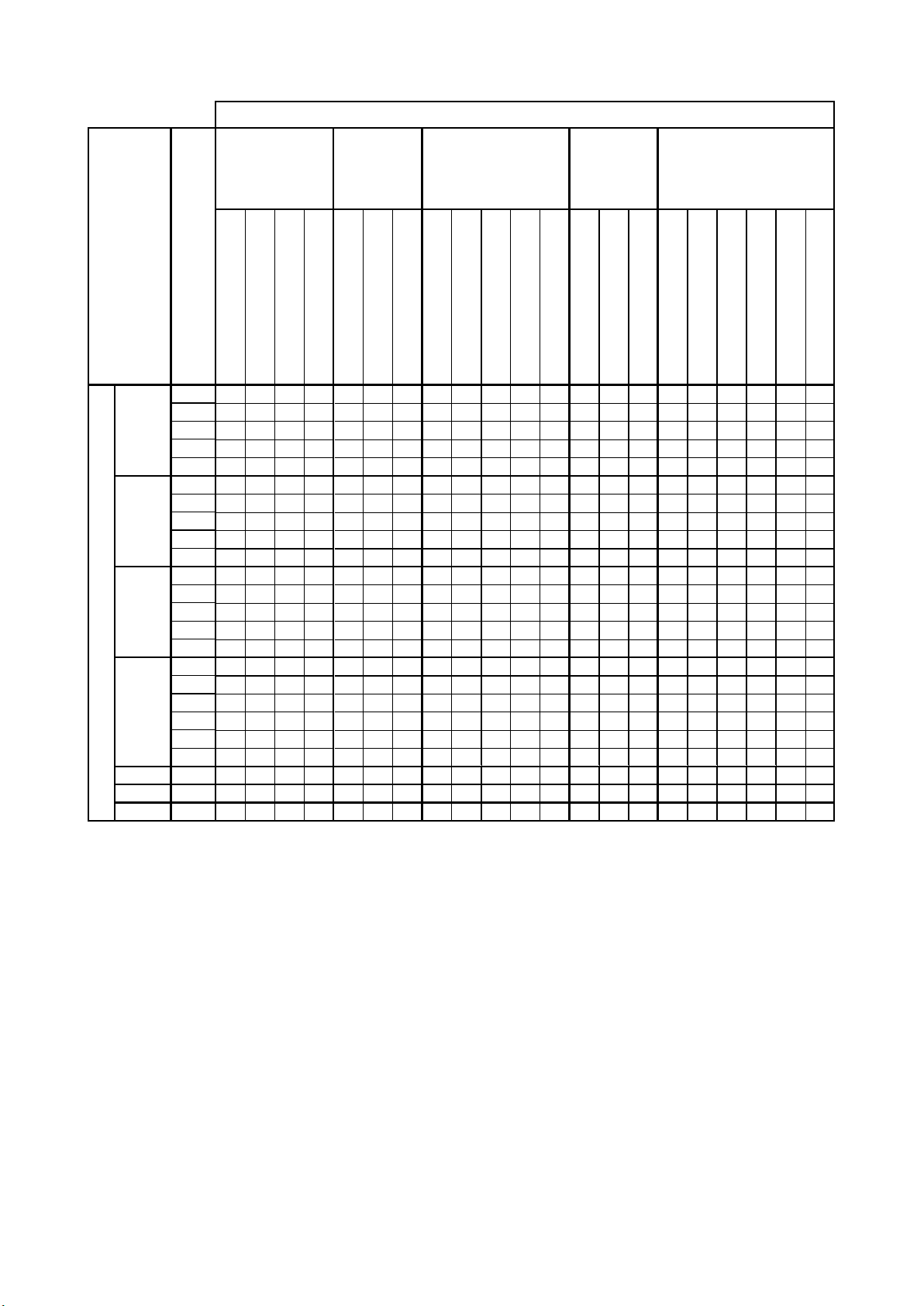

W/out Control

With Contactor

W/out Contactor

L208A

U1_SB125

Sequential Controller

SLM3

Sequential Controller

CE Mark

Without Marking

TXV

Cap. Tube & Check Valve

Withour Expansion Device

With air filter

W/out Air Filter

Horizontal & Changeable

Horizontal & Not Changeable

Vertical & Not changeable

Vertical & Changeable

Rivet "Made In Malaysia"

Very High Static

ABAE XXXXXX

ABAG X X X X X X X

ABAE XXXXXX

ABAG X X X X X X X

FBAE X X X X X X X

FBAF X X X X X X X X

FBHB X X X X X X X X

FBAA X X X X X X X

FBHA X X X X X X X X

FBAE X X X X X X X

FBHB X X X X X X X X

FBAC X X X X X X X

FBHA X X X X X X X X

200D2 FBAF X X X X X X X

250D2 FBAF X X X X X X X

300D2 FBAF X X X X X X X

400D4 FBAF X X X X X X

500D4 FBAF X X X X X X

Classification

Nomenclature

Controller Handset Marking Refrigerant

Control Filter Air Discharge Others

COOLING MODEL

75D

100D

125D

125D2

150D1

150D2

ADB

5

AMC

With Togami Contactor

With Chint Contactor

Without Contactor

With HP/LP

CE Mark

ETL

Without Marking

Scroll-Copeland

Scroll Maneurop

Reciprocating-Maneurop

Reciprocating Bristol

Reciproacating-Copeland

TXV

Capillary Tube

Bi-Flow TXV

Without Expansion Device

Centrifugal Fan

Rivet "Made In Malaysia"

With Accumulator

Phase Sequencer

Gold Fin (NA549)

FBAOXXXX X X

FBASXXXX X X

FBAMXXXX X X

FBASXXXX X X

FBAPXXXX X X

FBARXXXX XX

FBASXXXX XX

FBAHXXXX X X

FBAIXXXX XX

FBAJXXXX XX

FBARXXXX X X

FBAWXXXX XX

FBATXXXX XX

FBAYXXXX XX

FBAKXXXX X X

FBAMXXXX XX

FBAPXXXX XX

COOLING MODEL

Classification

OthersMarking

Nomenclature

XVCompressorControl

75B

150C

75C

100B

100C

125B

6

AMC

With Contactor

Without Contactor

With 24Vac Control Circuit

With HP/LP

CE Mark

ETL

Without Marking

Scroll-Copeland

Scroll Maneurop

Reciprocating-Maneurop

Reciprocating Bristol

Reciproacating-Copeland

TXV

Capillary Tube

Without Expansion Device

Centrifugal Fan

Rivet "Made In Malaysia"

With Accumulator

With Type Brazed Ball Valve

Phase Protector

Gold Fin (NA549)

FBAFXXXX X X

FBAGXXXX XX

FBAHXXXX XX

FCAAXXXX X X

FCABXXXX XXX

FBAFXXXX X X

FBAGXXXX XX

FBAHXXXX XX

FCAAXXXX X X

FCABXXXX XXX

FBAFXXXX X X

FBAGXXXX XX

FBAHXXXX XX

FCAAXXXX X X

FCABXXXX XXX

FBAGXXXX X X

FBAH X X X X X X X

FBAIXXX X XXX

FCAAXXXX X XX

FCABXXXX XXX

FCACXXX X XXXX

200D2 FBAA X X X X X X

250D2 FBAA X X X X X X

300D2 FBAA X X X X X X

Expansion

Device

Compressor OthersControl

COOLING MODEL

75D

100D

125D

150D

Nomenclature

Classification

Marking

7

A4MC

With Contactor

W/out Contactor with Auto HP/LP

W/out Contactor With Manual HP/LP

With HP/LP

Local (w/out DOL)

CE Mark

ETL

Without Marking

Scroll-Copeland

Scroll Maneurop

Reciprocating-Maneurop

Reciprocating Bristol

Reciproacating-Copeland

TXV

Capillary Tube

Without Expansion Device

Centrifugal Fan

For Sequential Controller

With Accumulator

With Type Brazed Ball Valve

Gold Fin (NA549)

FBAAXXXX XX

FBACXXXX XXX

FCAAXXXX XXX

FCABXXXX XXXXX

FBAAXXXX XX

FBACXXXX XXX

FCAAXXXX XXX

FCABXXXX XXXXX

FBAAXXXX XX

FBACXXXX XXX

FCAAXXXX XXX

FCABXXXX XXXXX

FBAAXXXX XX

FBACXXXX XXX

FCAAXXXX XXX

FCABXXXX XXXXX

Classification

Nomenclature

Control Marking Compressor Expansion

Device Others

COOLING MODEL

75D

125D

100D

150D

8

With Contactor

Without Contactor

With Auto HP/LP

With Manual HP/LP

CE Mark

ETL

Without Marking

Scroll-Daikin

Scroll-Copeland

Scroll Maneurop

Reciprocating-Maneurop

Reciprocating Bristol

Reciproacating-Copeland

TXV

Capillary Tube

Without Expansion Device

Centrifugal Fan

Phase Sequencer c/w Disc Ther

Gold Fin (NA549)

Rivet "Made In Malaysia"

With Brazed Type Ball Valve

Check valve

With Accumulator

FBCA X X X X X X X

FBEAXXX X XXX

FBCA X X X X X X X

FBEAXXX X XXX

FBCA X X X X X X X

FBEAXXX X XXX

COOLING

MODEL

75F

100F

125F

Classification

AMC

Nomenclature

Controller Marking Compressor XV Others

9

2. FEATURES

EASY MAINTENANCE

The simple design concept has provided the ease of maintenance and servicing. Access to the internal

part of the unit can be from the service panel or other side of the unit by loosening a few screws.

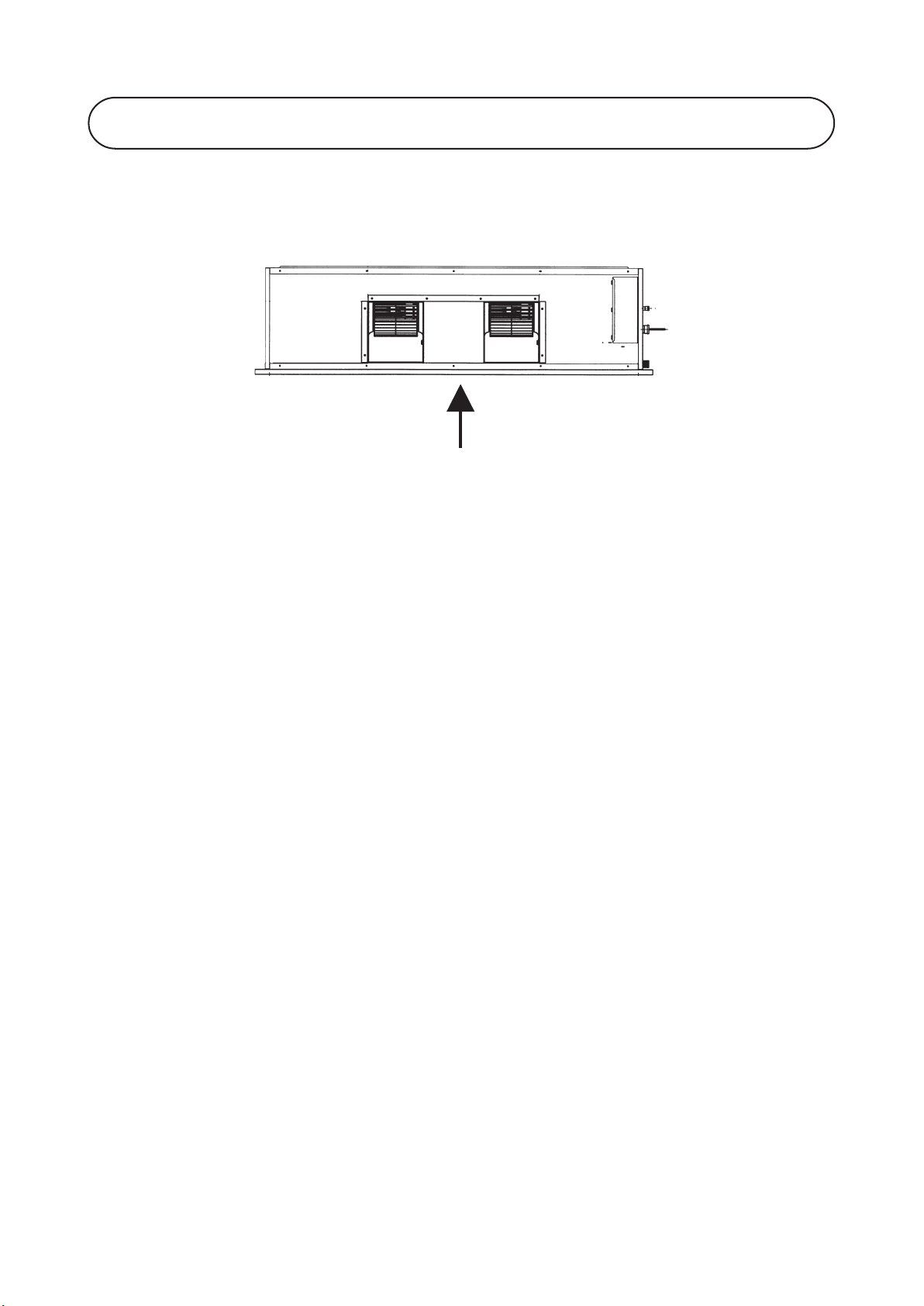

Only for model ADB75/100D with additional service panel from bottom

AIR DISCHARGE ORIENTATION

ADB200B and ADB75-150D models come with standard horizontal air discharge.

ADB250-500B and ADB200-500D models only come with standard vertical air discharge and they can be

converted to horizontal air discharge at the site. ADB250-500B and ADB200-500D models with horizontal air

discharge are not offered from factory. ADB600-750B models are offered in vertical and horizontal air discharge

as standard by differentiate of nomenclature.

COMPACT INDOOR UNIT

Indoor models are designed with compact size with twin coil structure. This design is able to provide some

saving in space for installation.

VERSATILITY

Multiple rooms can be cooled together at the same time by using just one unit of fan coil unit.

FRESH AIR INTAKE FOR HEALTHY LIVING

Fresh air can be introduced into the building through the design of fresh air intakes. This will help to improve the

indoor air quality.

SUPERIOR AIR DISTRIBUTION FOR COMFORTABLE LIVING

The conditioned air can be effectively distributed to every corner of the room through the ducting and this

ensure a more pleasant environment for comfort living.

FLEXIBILITY OF AIR SUPPLY

ADB200-750B and ADB125-500D models using belt driven blower such as that the air volume and static

required can be adjusted according to the requirement. This flexibility allows for wider application.

SCROLL COMPRESSOR

All outdoor units are using Scroll compressor which has better energy efficiency and quiet in operation.

SEQUENTIAL CONTROLLER AS STANDARD

This controller is supplied as the standard specification for cooling model where the systems are matching with

two outdoor units and more. The benefit of this controller is capable of part-loading of the system capacity.

10

3. APPLICATION INFORMATION

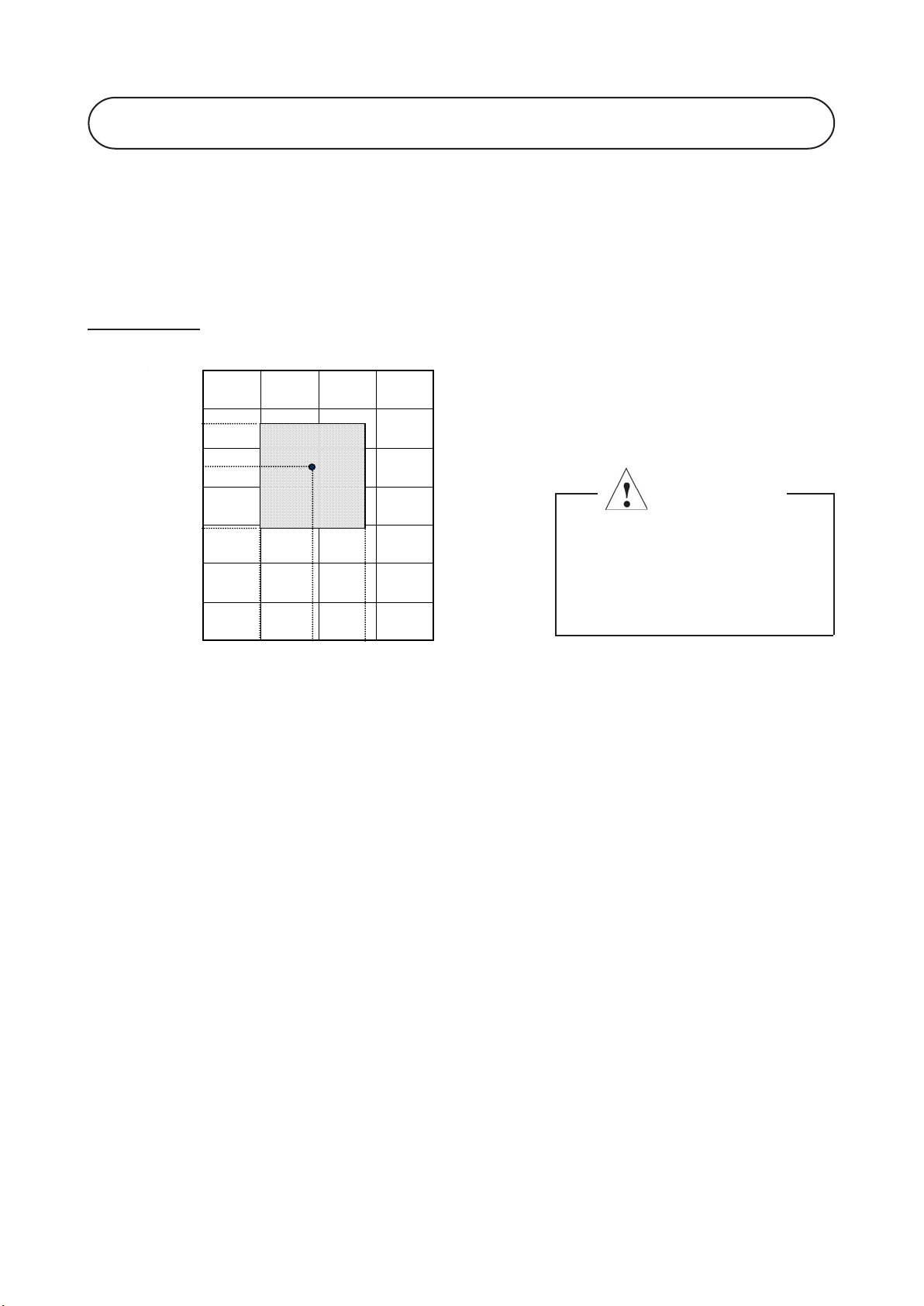

Operating Range

Ensure the operating temperature is in allowable range.

Cooling only

Caution :

The use of your air conditioner

outside the range of working

temperature and humidity can

result in serious failure.

Outdoor temp. (°CDB)

Indoor temp. (°CWB)

19

35

15

46

24

STD

11

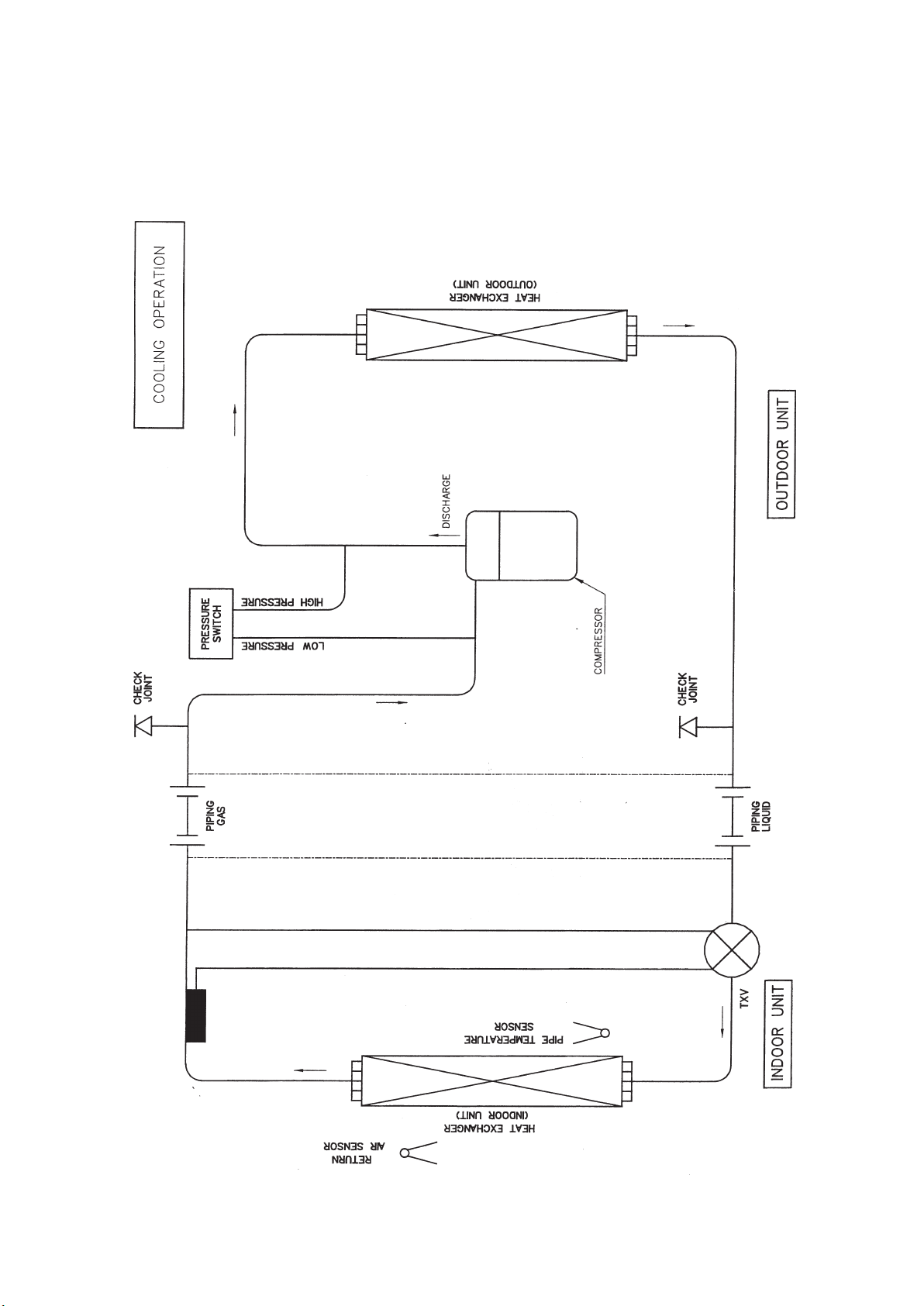

Standard Models

Refrigerant Circuit Diagram

12

MODEL : AMC200D2 / 250D2 / 300D2 (WITH ACCUMULATOR)

13

ELECTRICAL CONNECTION

Wiring regulations about wire diameter differs from country to country. Please refer to your LOCAL

ELECTRICAL CODES for field wiring rules. Be sure that installation comply with such rules and regulations.

GENERAL PRECAUTION

Ensure that the rated voltage of the unit correspond to the name plate before carrying out proper wiring

according to the wiring diagram.

Provide a power outlet to be used exclusively for each unit. A power supply disconnect and a circuit breaker

for over current protection should be provided in the exclusive line.

The unit must be GROUNDED to prevent possible hazard due to insulation failures

Every wiring must be firmly connected.

Every wiring should not touch the refrigerant piping, compressor and any moving parts of fan motor.

OPERATIONAL CHECK

After all wiring is completed and the system is charged with refrigerant, make sure the unit is operating

properly. Check that :

Condenser fans are running with warm air blowing off the condensing unit.

Evaporator blowers are running and discharging cool air from ducts.

Suction line and liquid line pressures are in the region of 75 psig and 275 psig respectively.

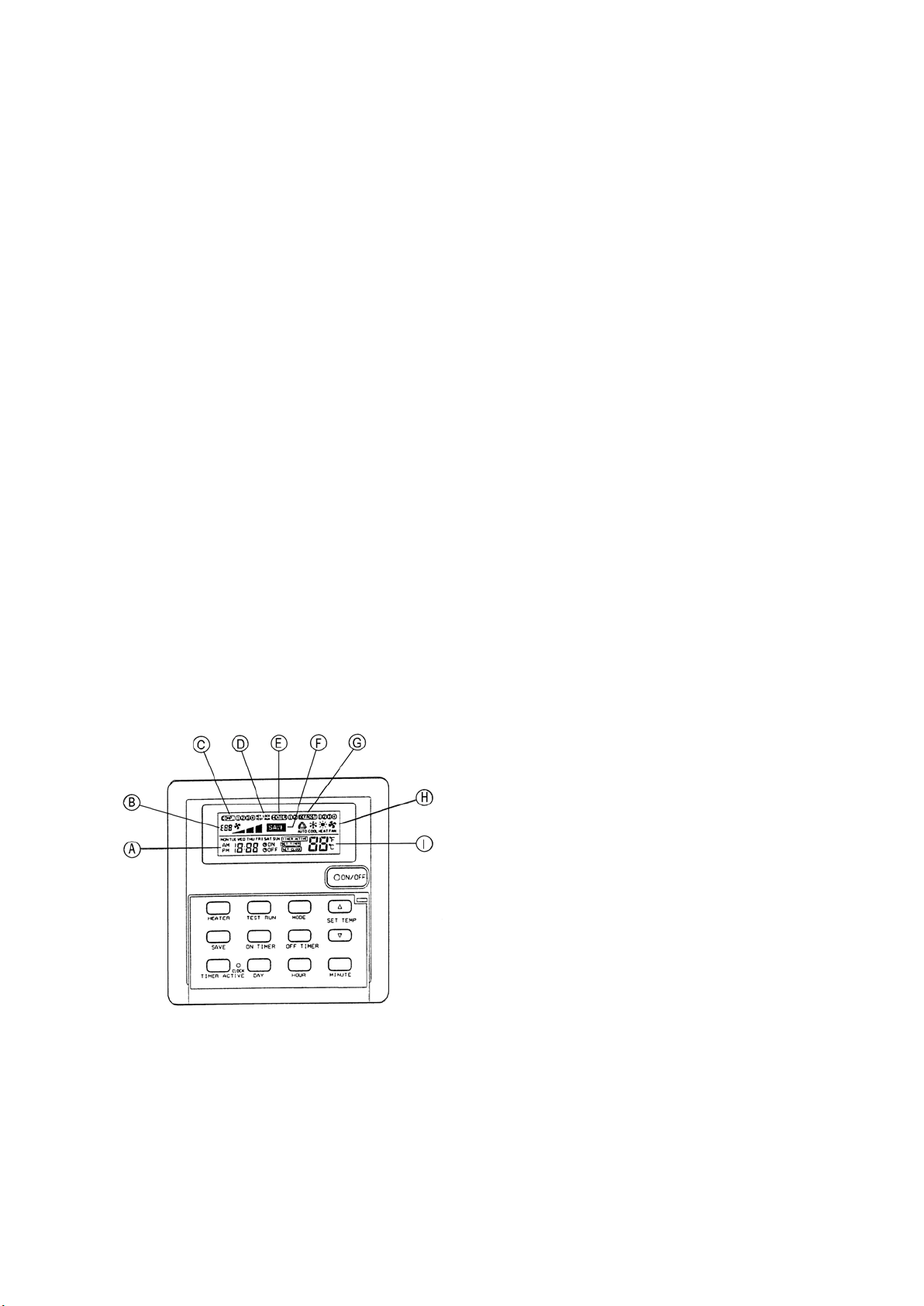

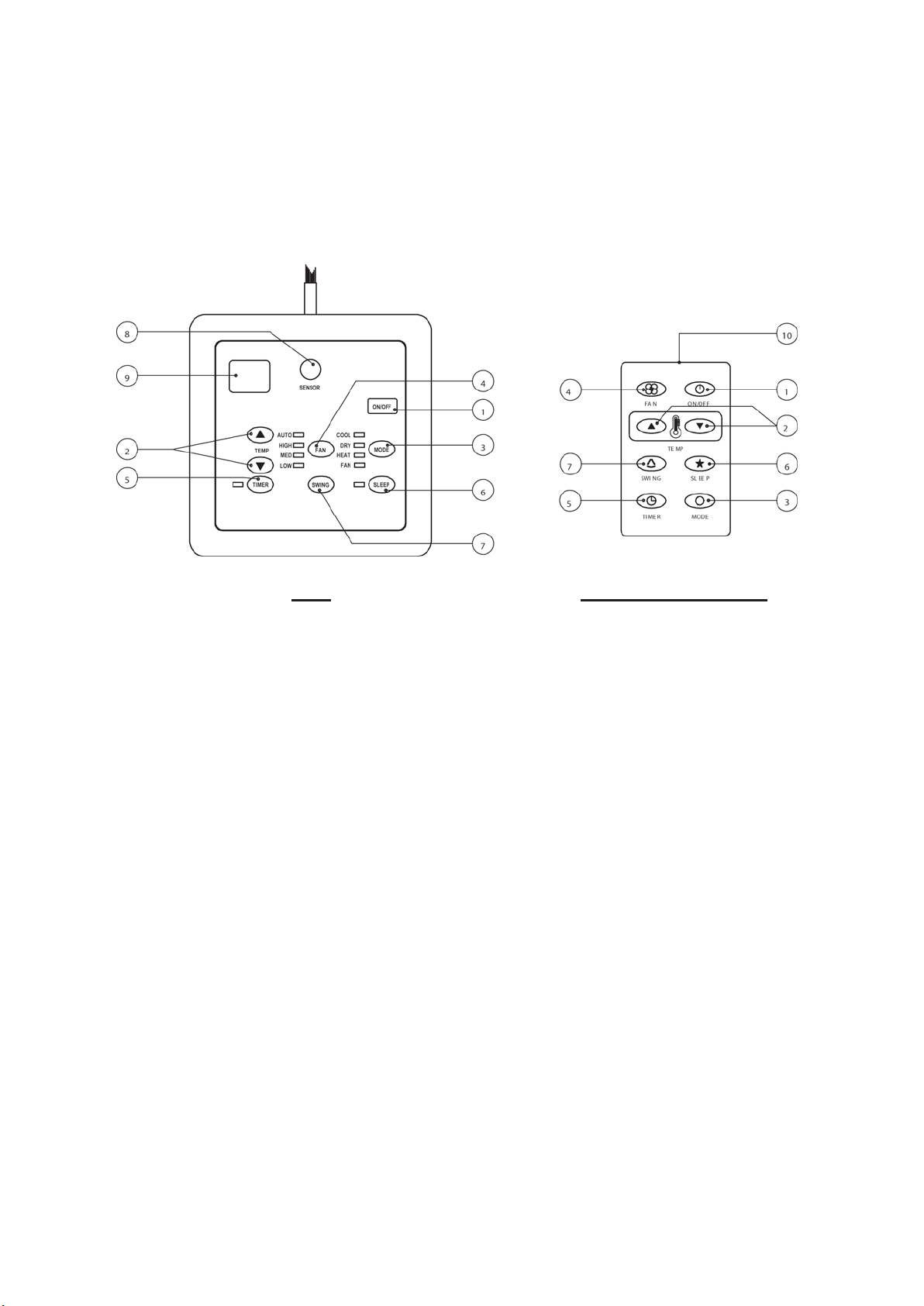

SEQUENTIAL CONTROLLER LCD OPERATING INSTRUCTIONS

(Standard for cooling and heatpump units)

Sequential controller LCD display

A : Time display

B : Error indication

C : Compressor running display (up to 4

compressors)

D : Key lock display

E : Heater display (up to 2 heaters)

F : Energy saving mode display

G : Compressor defrost cycle display (up to 4

compressors)

H : Operation mode display

I : Temperature set display

2. OPERATING GUIDE

2.1 ON/OFF key

Press once to start the air conditioning unit.

Press again to stop the unit.

The operation lamp next to the key lights up and goes off respectively when the unit is running

or not running.

Caution : In the case when the ON/OFF key is pressed immediately after the operation is

stopped, the unit will not restart until 3 minutes later to protect the compressor.

Controllers

14

2.2 Selecting Operation Mode

Press the MODE key to select the type of operating mode. Consecutive press of the key switches the

operation over “COOL”, “HEAT”, “AUTO” and “FAN”

2.3 SAVE Mode

Press the SAVE key to select the energy saving function. This option is only available for “COOL”,

“HEAT” and “AUTO” modes.

2.4 Auxiliary Electric Heater

If the “HEAT” mode provides insufficient heating to a room even at the highest temperature setting

(30°C), press the HEATER key to activate the auxiliary electric heater. For models with two heaters,

consecutive press of the key allows the selection of one or both heaters active.

2.5 Temperature Setting

To set the desired room temperature, press or to increase or decrease the set

temperature in the range of 16°C to 30°C.

Press both and simultaneously to toggle between °C and °F setting.

2.6 Time Setting

Real time Clock

Press the CLOCK key once to activate set clock mode.

Press again to disable set clock mode.

Under set clock mode, the time of the present day can be set by pressing the respective MINUTE, HOUR

and DAY key.

7 days timer

Press the ON TIMER key to activate auto ON timer mode. Under this mode, press the respective MINUTE,

HOUR and DAY key to select the time of the week when the air-conditioning unit is to automatically start

running. Press the ON TIMER key again to save the setting.

Press the OFF TIMER key to activate auto OFF timer mode. Under this mode, press the respective

MINUTE, HOUR and DAY key to select the time of the week when the air-conditioning unit is to automatically

stop running. Press the ON TIMER key again to save the setting.

Then to activate the 7 days timer, press and hold the TIMER ACTIVE key until the word “TIMER ACTIVE”

appears on the LCD screen. Repeat the same step to disable the 7 days timer.

2.7 Other Function

Key Lock

Press the MINUTE key 3 times consecutively to activate the key lock. A “KEY LOCK” symbol will appear

on the LCD screen. At this point, only the ON/OFF key is valid.

To disable the key lock, again press the MINUTE key 3 times consecutively.

Test run

Press the TEST key 2 times consecutively to test run the unit.

15

3. ERROR CODE

When the system is on and an error occurs, the ON/OFF LED on the LCD panel will blink and an error

code is shown. When the system is off and there is a thermistor error, the ON/OFF LED is off but the

error code is still displayed. Each error code represents different message as below

Error code Possible fault Error code Possible fault

E01 Require manual reset (possible causes) E19 Indoor coil sensor 4 short

E02 Compressor 1 high temperature (overload) E20 Indoor coil sensor 1 open

E03 Compressor 2 high temperature(overload) E21 Indoor coil sensor 2 open

E04 Compressor 3 high temperature(overload) E22 Indoor coil sensor 3 open

E05 Compressor 4 high temperature(overload) E23 Indoor coil sensor 4 open

E06 Compressor 1 high pressure trip / contact open E24 Outdoor coil sensor 1 short

E07 Compressor 2 high pressure trip / contact open E25 Outdoor coil sensor 2 short

E08 Compressor 3 high pressure trip / contact open E26 Outdoor coil sensor 3 short

E09 Compressor 4 high pressure trip / contact open E27 Outdoor coil sensor 4 short

E10 Compressor 1 trip / low R-22 / outdoor abnormal E28 Outdoor coil sensor 1 open

E11 Compressor 2 trip / low R-22 / outdoor abnormal E29 Outdoor coil sensor 2 open

E12 Compressor 3 trip / low R-22 / outdoor abnormal E30 Outdoor coil sensor 3 open

E13 Compressor 4 trip / low R-22 / outdoor abnormal E31 Outdoor coil sensor 4 open

E14 Room sensor short E32 Compressor 1 de-ice

E15 Room sensor open E33 Compressor 2 de-ice

E16 Indoor coil sensor 1 short E34 Compressor 3 de-ice

E17 Indoor coil sensor 2 short E35 Compressor 4 de-ice

E18 Indoor coil sensor 3 short

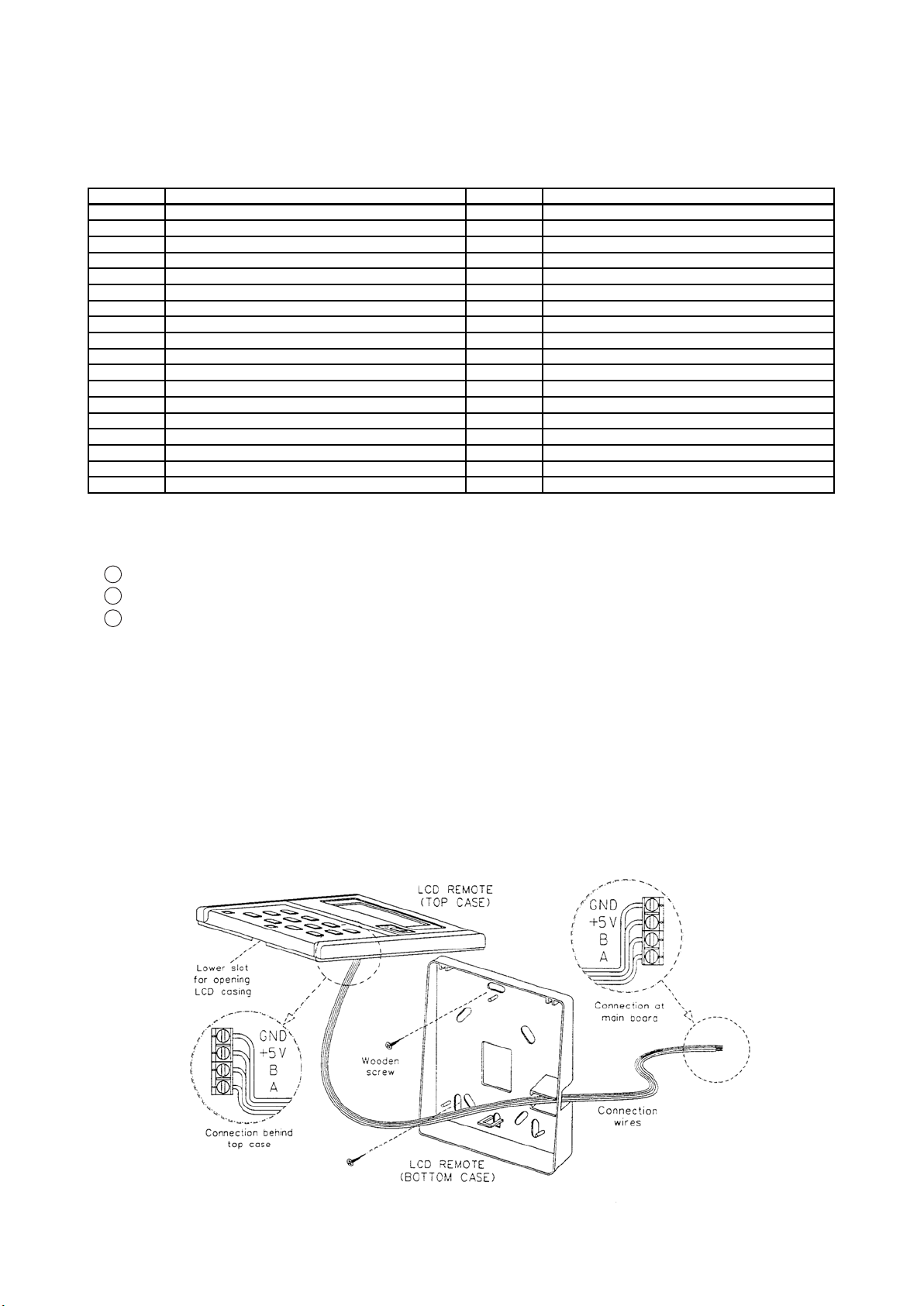

4. INSTALLATION OF LCD REMOTE CONTROLLER

4.1 Accessories

The following accessories are included. If any part is missing, contact your dealer immediately.

1Remote controller

2Wooden screw 4.1 x 16 (2 pieces)

3Instruction manual

4.2 Step by step guide

i) First, open up the casing of the LCD remote controller into its top and bottom case using a

screwdriver. To do this, insert the screwdriver into the lower slot and slide it in the outward direction.

ii) Fix the bottom case onto the wall with the 2 wooden screws provided. Then, insert the 4 connecting

wires (from the main board) through the slot on the lower right.

iii) Connect one end in each of the 4 wires to the terminal block behind the top case as shown below.

The wire that goes into the “GND” terminal at the top case must be connected at the other end to

the “GND” terminal at the main board. The same goes for the “+5V”, “B” and “A” connection.

iv) Fasten back the top and bottom case into place. Hook the two upper claws into their respective slots

and snap the lower part shut.

16

5. AUTO RANDOM RESTART

When power resumed, the unit will automatically restart and operate at the previous setting as before power

failure occurred. (Remove jumper at JH/JP1 will cancel the auto random restart function. Please refer to

wiring diagram for the location of the JH/JP1).

1. “ON/OFF” switch

•Press to start the air conditioner unit.

•Press again to stop the unit.

2. Temperature setting

•Set the desired room temperature.

•Press button to increase or decrease the set

temperature. Setting range are between 16°C

to 30°C (60°F to 80°F).

3. Operation Modes

•Press the “mode” button for select the type of

operating mode.

- Cooling Only :

COOL, DRY, FAN

- Heat Pump :

AUTO, COOL, DRY, HEAT, FAN

(AUTO mode is represented by bothCOOL and

HEAT LED light on)

4. Fan Speed selection

•Press the button until the desired fan speed is

achieved.

5. Timer

•Press the set button to select the switch timer

of the air conditioner unit (the setting range is

between 1 to 10 hours).

6. “Sleep” mode

•Press button to activate the sleep function can

only be activated under “cool” or heating mode

operation. When it is activated under “cool”

mode operation, the set temperature will

increase 0.5°C after 30 minutes, 1°C after 1 hour

and 2°C after 2 hours. If it is actiaved under

“HEAT” mode operation, the set temperature

will be descreased 0.5°C after 30 minutes, 1°C

after 1 hour and 2°C after 2 hours.

7. Air Swing

•Press button to activate the automatic air swing

function.

8. Sensor

•Infra red sensor to receive signals from wireless

controller.

9. LED Display

•To display the set temperature (in °C) and timer

delay setting (in hours).

10. Transmission source

•To transmit signals to the air conditioner.

SLM AC-5300 (OPTIONAL)

SLM CONTROLLER OPERATING INSTRUCTIONS

17

SPECIAL PRECAUTIONS WHEN DEALING WITH REFRIGERANT R407C UNIT

1) WHAT IS NEW REFRIGERANT R407C?

R407C is a zeotropic refrigerant mixture which has Zero Ozone Depletion Potential (ODP = 0) and thus

conformed to the Montreal Protocol regulation. It requires Polyol-ester oil (POE) oil for its compressor’s

lubricant. Its refrigerant capacity and performance are about the same as the refrigerant R22.

2) COMPONENTS

Mixture weight compositionR32(23%), R125(25%), R134a(52%)

3) CHARACTERISTIC

•R407C liquid and vapor components have different compositions when the fluid evaporates or condenses.

Hence, when leak occurs and only vapor leaks out, the composition of the refrigerant mixture left in the

system will change and subsequently affect the system performance. DO NOT add new refrigerant to

leaked system. It is recommended that the system should be evacuated thoroughly before recharging with

R407C.

•When refrigerant R407C is used, the composition will differ depending on whether it is in gaseous or liquid

phase. Hence when charging R407C, ensure that only liquid is being withdrawn from the cylinder or can.

This is to make certain that only original composition of R407C is being charged into the system.

•POE oil is used as lubricant for R407C compressor, which is different from the mineral oil used for R22

compressor. Extra precaution must be taken not to expose the R407C system too long to moist air.

4) CHECK LIST BEFORE INSTALLATION/SERVICING

•Tubing

Refrigerant R407C is more easily affected by dust of moisture compared with R22, make sure to temporarily

cover the ends of the tubing prior to installation

•Compressor oil

No additional charge of compressor oil is permitted.

•Refrigerant

No other refrigerant other that R407C

•Tools

Tools specifically for R407C only (must not be used for R22 or other refrigerant)

i) Manifold gauge and charging hose

ii) Gas leak detector

iii) Refrigerant cylinder/charging cylinder

iv) Vacuum pump c/w adapter

v) Flare tools

vi) Refrigerant recovery machine

5) HANDLING AND INSTALLATION GUIDELINES

Like R22 system, the handling and installation of R407C system are closely similar. All precautionary measures;

such as ensuring no moisture, no dirt or chips in the system, clean brazing using nitrogen, and thorough leak

check and vacuuming are equally important requirements. However, due to zeotropic nature of R407C and its

hydroscopic POE oil, additional precautions must be taken to ensure optimum and trouble free system operation.

a) Filter dryer must be installed along the liquid line for all R407C air conditioners. This is to minimise the

contamination of moisture and dirt in the refrigerant system. Filter dryer must be of molecular sieve type.

For a heat pump system, install a two--way flow filter dryer along the liquid line.

b) During installation or servicing, avoid prolong exposure of the internal part of the refrigerant system to

moist air. Residual POE oil in the piping and components can absorb moisture from the air.

Installation

18

c) Ensure that the compressor is not expose to open air for more than the recommended time specified by

its manufacturer (typically less than 10 minutes). Removed the seal plugs only when the compressor is

about to be brazed.

d) The system should be thoroughly vacuumed to 1.0 Pa ( 700mmHg) or lower. This vacuuming level is

more stringent than R22 system so as to ensure no incompressible gas and moisture in the system.

e) When charging R407C, ensure that only liquid is being withdrawn from the cylinder or can. This is to

ensure that only the original composition of R407C is being delivered into the system. The liquid composition

can be different from the vapor composition.

f) Normally, the R407C cylinder or can is being equipped with a dip pipe for liquid withdrawal. However, if

the dip pipe is not available, invert the cylinder or can so as to withdraw liquid from the valve at the

bottom.

g) When servicing leak, the top up method, commonly practiced for R22 system, is not recommended for

R407C system. Unlike R22 where the refrigerant is of a single component, the composition of R407C,

which made up of three different components, may have changed during the leak. Consequently, a top up

may not ensure that the R407C in the system is of original composition. This composition shift may

adversely affect the system performance. It is recommended that the system should be evacuated thor-

oughly before recharging with R407C.

R32/R125/R134

33% / 33% / 34%

23% / 25% / 52%

Composition of R407C in vapour phase

is different from liquid phase.

D

ip-pipe

I

nvert cylinde

r

without dip-pipe

L

iquid

withdrawal

This manual suits for next models

39

Table of contents

Popular Blower manuals by other brands

Grizzly

Grizzly ELS 2801 Prof Translation of the original instructions for use

Mazzoni

Mazzoni FLASH 650M Use and maintenance manual

MTD

MTD BV3100 Operator's manual

Craftsman

Craftsman 125B Operator's manual

Showa Denki

Showa Denki U2S Series Instruction Manual & Directions

Minuteman

Minuteman C44000-01 Operation, service and parts manual