Actron PKY470T User manual

1

ActronAir is constantly seeking ways to improve the design of its products, therefore specifications are subject to change without notice.

Copyright © 2015 Actron Engineering Pty. Ltd.

Table of Contents

01. Information ..............................................................................................................2

02. R-410A Refrigerant Reclaim Procedure .....................................................................2

03. Installing The New Thermal Expansion Valve............................................................2

04. Recharging the System / Operation Preparation for Unit Start-Up............................ 5

TXV REPLACEMENT - PACKAGE UNIT

TXV REPLACEMENT - PACKAGE UNIT

2Tri-Capacity Package - TXV Replacement

Doc. 9590-2014-19B Ver. 3 211105

01. Information

To replace the Thermal Expansion Valve (TXV) of the unit, it is necessary to first reclaim the R-410A refrigerant from the

system before proceeding with the required task. To do this, it is important that refrigerant reclaim procedures to be

carried out in accordance with Australia and New Zealand refrigerant handling code of practice. Particularly observe

the notes and important information described below to safely replace the affected TXV:

NOTES

• The units covered in this manual have two independent circuits, i.e. Circuit # 1 (small comp) and Circuit # 2 (large

comp). Working on one of the circuits will not affect the other.

• When performing TXV replacement process, ensure to correctly identify and work only in the components of the

affected Circuit.

CAUTION

• Never allow R-410A refrigerant to vent into the atmosphere. It is an offence to do so here in Australia.

Always reclaim refrigerant using equipment and container dedicated for R-410A system use only.

• Only licensed trades personnel must perform any work related to addition or removal of refrigerant.

• R-410A refrigerant has POE oil that rapidly absorbs moisture.

The maximum time any system can be opened to atmosphere is 15 minutes.

02.R-410A Refrigerant Reclaim Procedure

1. Connect gauges as per procedure in fitting of refrigerant gauges.

2. Remove caps off from reclaim fittings.

3. Connect reclaim unit to gauge manifold charging port on inside of unit.

4. Connect container cylinder to reclaim unit outside.

5. Open gauge ports and hose ball valve.

6. Open refrigerant cylinder and start the unit.

7. Observe gauge readings until they hold at zero pressure or below.

NOTE

To keep R-410A bottle cool, place the bottle in a bin of water and replace water as necessary.

8. Switch off the unit and close off cylinder valve, unit valve hose ball valve and manifold valves.

9. Disconnect the manifold hoses.

10. Isolate the power to the unit.

03. Installing The New Thermal Expansion Valve

1. Always replace TXV with the same valve.

Below is the list of thermal expansion valve part number specific to corresponding unit model and circuit:

Model

Thermal Expansion Valve (TXV) Part Number

Circuit #1

(Small Compressor)

Circuit #2

(Large Compressor)

PKY470T 4570-122 4570-126

PKY500T 4570-123 4570-128

PKY540T 4570-123 4570-128

PKY620T 4570-123 4570-128

PKY700T 4570-126 4570-128

TXV REPLACEMENT - PACKAGE UNIT

3

ActronAir is constantly seeking ways to improve the design of its products, therefore specifications are subject to change without notice.

Copyright © 2015 Actron Engineering Pty. Ltd.

2. Ensure TXV is installed with its flow arrow to follow the direction of flow of the refrigeration system. As reference,

take note of the direction of flow of the old TXV and fit the new one with the same orientation as the old valve.

TXV FLOW ARROW

DIRECTION OF

REFRIGERANT FLOW

3. Always use wet rags when brazing the valves. They are heat sensitive and can be easily damaged when brazing.

NOTES

• Always face the flame away from TXV when braizing.

• Cool down the expansion valve immediately after braizing.

4. Braze the equalizer tube in the new TXV.

5. When installing the TXV bulb sensor, ensure to clean the surface of the suction line where the previous one was

installed.

6. Make sure that the location of new bulb sensor will be in the exact location as the old bulb sensor.

As a reference, location of sensor bulb will be as follows:

D

a

b

b

Item

Suction Pipe

Outside

Diameter (D)

Bulb Location

a 1/2” to 5/8” 1 o’clock

b 3/4” to 1-1/4” 2-3 o’clock

7. Form the strap to shape and radius of the valve.

8. Leaving the bulb in formed strap, wrap the remaining end of the strap around the suction line.

9. Insert the end of the strap through the fastening clip (make sure the fastening screw is almost fully backed off), pull

tight then bend over the clip.

TXV REPLACEMENT - PACKAGE UNIT

4Tri-Capacity Package - TXV Replacement

Doc. 9590-2014-19B Ver. 3 211105

10.Securely tighten bolt ensuring the correct positioning as the previous one installed or as per above table in item 6.

ACCUMULATOR

SMALL COMPRESSOR PIPING

ACCUMULATOR

BIG COMPRESSOR PIPING

SUCTION PIPE

TXV BULB

SENSOR

TXV BULB

STRAP

DETAIL A

NOTES

• Make sure that the total length of the bulb is in good contact with suction line pipe.

• Check that equal lengths of the bulb are protruding from each side of the strap.

• Securely fastened bulb unto suction line.

• Always install bulb on the horizontal part of the suction line where the previous one was installed.

TXV REPLACEMENT - PACKAGE UNIT

5

ActronAir is constantly seeking ways to improve the design of its products, therefore specifications are subject to change without notice.

Copyright © 2015 Actron Engineering Pty. Ltd.

11. Wrap the whole bulb sensor area with insulation tape. See figure below.

SUCTION PIPE

INSULATION

TAPE

12. Adjust TXV spindle to match ActronAir default settings.

Model TXV Location Adjustment Settings Direction

PKY470T

Large Compressor Open 2 turns. 2

Small Compressor none ---

PKY500T

Large Compressor Close 3 turns. 3

Small Compressor Close 3-1/2 turns. 31/2

PKY540T

Large Compressor Open 2 turns. 2

Small Compressor Open 2 turns. 2

PKY620T

Large Compressor Open 2 turns. 2

Small Compressor Open 2 turns. 2

PKY700T

Large Compressor Open 2-1/2 turns. 21/2

Small Compressor Open 2 turns. 2

04.Recharging the System / Operation Preparation for Unit Start-Up

1. Start evacuation process as per ActronAir evacuation procedure.

2. Re-connect gauges and the cylinder of reclaimed R410a refrigerant as per refrigerant reclaim procedures above.

3. Recharge the system as per Refrigerant Charging procedures in the Installation and Commissioning Guide.

NOTE

A fresh R-410A refrigerant may be required as a replacement, particularly where there is contamination in the old

reclaimed refrigerant.

4. Switch back on the power to the unit.

5. Operate the system and check for system subcooling and superheat. If necessary, add refrigerant charge as per

procedure detailed in the Refrigerant Charging section of the Installation and Commissioning Guide.

TXV REPLACEMENT - PACKAGE UNIT

6Tri-Capacity Package - TXV Replacement

Doc. 9590-2014-19B Ver. 3 211105

TXV Supplier Default Setting and Specifications

SH

TXV Supplier Default Superheat Setting (SS):

TGE 10 (2 Full Turns*): SS = 4K (-13.8°C)

TR 6 (3 1/3 Turns*): SS = 2K (-15.8°C)

*No. of Turns required from spring stop point

= 19mm (3/4”)

T = 10Nm (7 ft-lbf)

Superheat Adjustment Parameter

+-

Change in Superheat per 360° ≈ 2°C

Undo TXV

Protective Cap

TXV

Remove

Protective Cap

Superheat

Adjustment

Spindle

Stop

1. Remove Protective Cap from the TXV Valve Body. 2. Turn Superheat Adjustment Spindle until it reach the stop

point, as shown above.

Change in Superheat / Turn :

TGE 10: ∆SH / 360° ≈ 2°C

TR 6: ∆SH / 360° ≈ 0.6°C

Replace TXV

Protective Cap

TXV

Replace

Protective Cap

3. To get into TXV supplier default setting, turn Superheat

Adjustment Spindle in the direction as shown. Refer to

TXV specifications above for the number of turns required

for particular TXV model.

4. Replace TXV Protective Cap onto Valve Body.

NOTES

Using the above set point as reference, further adjust the TXV as per instructions in the TXV.

Replacement section of this manual in order to finally set the TXV into ActronAir default settings.

This manual suits for next models

8

Table of contents

Popular Air Conditioner manuals by other brands

Pioneer

Pioneer FAB Series installation manual

Haier

Haier HDU-42HT03/H Operating & installation manual

Kaden

Kaden KCS Series manual

Bryant

Bryant Evolution Extreme 186CNV installation instructions

Mitsubishi Electric

Mitsubishi Electric PUZ-ZM200YKA2-ET Service manual

Carrier

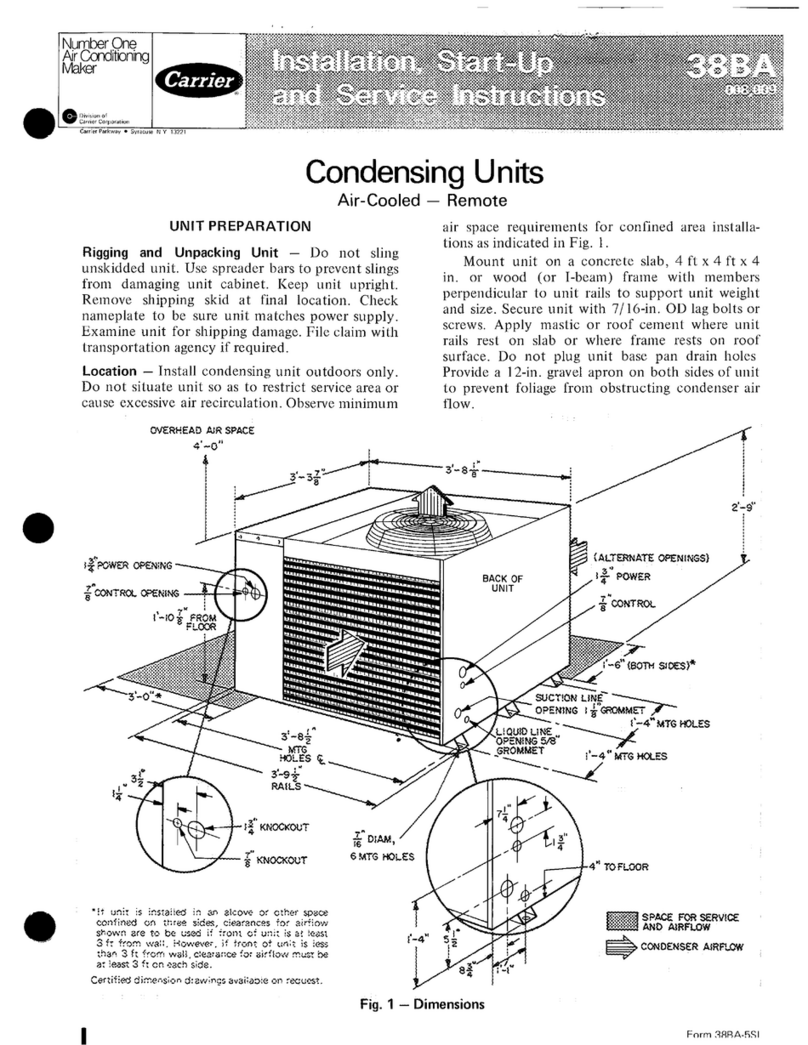

Carrier 38BA Installation, Start-Up and Service Instructions

Whynter

Whynter ARC-12SDH instruction manual

Hisense

Hisense 7K Use and Installation Instructions

Mitsubishi Electric

Mitsubishi Electric MSC-GE20VB operating instructions

Hokkaido

Hokkaido HKEI-HCNI 263 XR Service manual

Samsung

Samsung AS07P2GE/XCH Owner's instructions

Mitsubishi

Mitsubishi PQHY-P200YGM-A installation manual