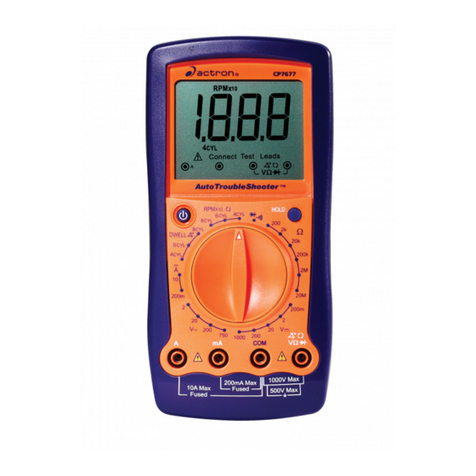

Actron SunPro CP7678 User manual

Index

Safety Precautions ....................................... 2

Vehicle Service Information ......................... 3

Visual Inspection ..........................................3

Warranty .....................................................72

1. Multimeter Basic Functions

Functions and Display Definitions............ 4

Setting the Range..................................... 6

Battery and Fuse Replacement ...............7

Measuring DC Voltage .............................8

Measuring Resistance.............................. 8

Measuring DC Current .............................9

Testing for Continuity .............................10

Testing Diodes........................................10

Measuring Engine RPM (TACH)............ 11

Measuring Dwell ..................................... 12

Measuring Duty Cycle ............................12

2. Automotive Testing with the CP7678

General Testing ......................................13

- Testing Fuses ......................................13

- Testing Switches..................................13

- Testing Solenoids and Relays.............14 1

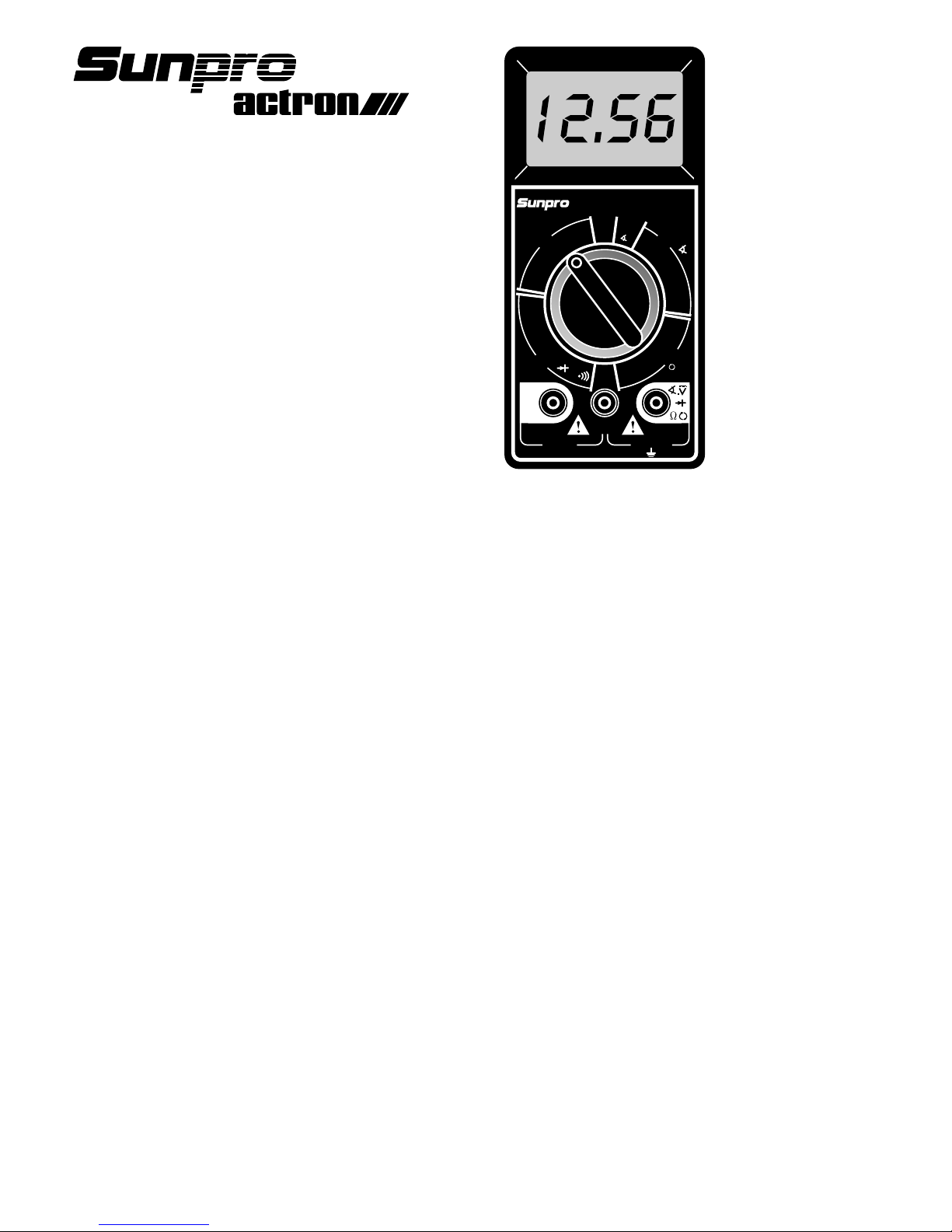

CP7678

®

by

®

Digital Multimeter

OPERATING

INSTRUCTIONS

Starting / Charging System Testing ...........15

- No Load Battery Test...........................15

- Engine Off Battery Current Draw ........ 16

- Cranking Voltage/Battery Load Test ... 17

- Voltage Drops ......................................18

- Charging System Voltage Test............ 19

Ignition System Testing.............................. 20

- Ignition Coil Testing .............................20

- Ignition System Wires..........................22

- Hall Effect Sensors/Switches ..............23

- Magnetic Pick-Up Coils .......................24

- Reluctance Sensors .............................24

- Ignition Coil Switching Action ..............25

Fuel System Testing...................................26

- Testing GM C-3 Mixture Control

Solenoid Dwell ....................................26

- Measuring Fuel Injector Resistance....27

Testing Engine Sensors .............................28

- Oxygen (O2) Type Sensors..................28

- Temperature Type Sensors................. 30

- Position Type Sensors –

Throttle and EGR Valve Position,

Vane Air Flow ......................................31

- Manifold Absolute Pressure

(MAP)

and

Barometric Pressure

(BARO)

Sensors ..... 32

- Mass Air Flow (MAF) Sensors ..............34

250V MAX

15A MAX

FUSED

COM

DC

15A

AUTO POWER OFF

CP7678

®

OFF

200

20

2

DC V

200

m

20M

200

K

20K

2K 200 8CYL6CYL TACH

X10

5CYL

4CYL

8CYL

6CYL

5CYL

4CYL

DWELL

DUTY

CYCLE

%

OHMS

°

20

15

A

20V

SAFETY GUIDELINES

TO PREVENT ACCIDENTS THAT COULD RESULT IN SERIOUS INJURY

AND/OR DAMAGE TO YOUR VEHICLE OR TEST EQUIPMENT, CAREFULLY

FOLLOW THESE SAFETY RULES AND TEST PROCEDURES

2

• Always wear approved eye protection.

• Always operate the vehicle in a well ventilated area. Do not inhale exhaust gases – they are

very poisonous!

• Always keep yourself, tools and test equipment away from all moving or hot engine parts.

• Always make sure the vehicle is in park (Automatic transmission) or neutral (manual

transmission) and that the parking brake is firmly set. Block the drive wheels.

• Never lay tools on vehicle battery. You may short the terminals together causing harm to

yourself, the tools or the battery.

• Never smoke or have open flames near vehicle. Vapors from gasoline and charging battery

are highly flammable and explosive.

• Never leave vehicle unattended while running tests.

• Always keep a fire extinguisher suitable for gasoline/electrical/chemical fires handy.

• Always use extreme caution when working around the ignition coil, distributor cap, ignition

wires, and spark plugs. These components contain High Voltage when the engine is

running.

• Always turn ignition key OFF when connecting or disconnecting electrical components,

unless otherwise instructed.

• Always follow vehicle manufacturer’s warnings, cautions and service procedures.

CAUTION:

Somevehiclesareequippedwithsafetyairbags.You

must

followvehicleservicemanualcautions

whenworkingaroundtheairbagcomponentsorwiring.Ifthecautionsarenotfollowed,theairbag

may open up unexpectedly, resulting in personal injury. Note that the air bag can still open up

severalminutesafterthe ignition key isoff(oreven if the vehiclebatteryisdisconnected) because

of a special energy reserve module.

All information, illustrations and specifications contained in this manual are based on the latest

information available from industry sources at the time of publication. No warranty (expressed

orimplied) canbe made for its accuracy or completeness, nor isany responsibilityassumed by

Actron Manufacturing Co. or anyone connected with it for loss or damages suffered through

relianceonanyinformationcontainedinthismanualormisuseofaccompanyingproduct.Actron

Manufacturing Co. reserves the right to make changes at any time to this manual or accompa-

nying product without obligation to notify any person or organization of such changes.

3

Vehicle Service Manual – Sources For Service Information

The following is a list of sources to obtain vehicle service information for your specific vehicle.

• Contact your local Automotive Dealership Parts Department.

• Contact local retail auto parts stores for aftermarket vehicle service information.

• Contact your local library. Libraries often allow you to check-out automotive service manuals.

Do a Thorough Visual Inspection

Do a thorough visual and “hands-on” underhood inspection before starting any diagnostic

procedure! You can find the cause of many problems by just looking, thereby saving yourself a

lot of time.

• Has the vehicle been serviced recently?

Sometimes things get reconnected in the

wrong place, or not at all.

• Don’t take shortcuts. Inspect hoses and

wiring which may be difficult to see due

to location.

• Inspect the air cleaner and ductwork for

defects.

• Check sensors and actuators for

damage.

• Inspect ignition wires for:

- Damaged terminals.

- Split or cracked spark plug boots

- Splits, cuts or breaks in the ignition

wires and insulation.

• Inspect all vacuum hoses for:

- Correct routing. Refer to vehicle service

manual, or Vehicle Emission Control

Information(VECI) decal located in the

engine compartment.

- Pinches and kinks.

- Splits, cuts or breaks.

• Inspect wiring for:

- Contact with sharp edges.

- Contact with hot surfaces, such as

exhaust manifolds.

- Pinched, burned or chafed insulation.

- Proper routing and connections.

• Check electrical connectors for:

- Corrosion on pins.

- Bent or damaged pins.

- Contacts not properly seated in housing.

- Bad wire crimps to terminals.

250V MAX

15A MAX

FUSED

COM

DC

15A

AUTO POWER OFF

CP7678

®

OFF

200

20

2

DC V

200

m

20M

200

K

20K

2K 200 8CYL6CYL

TACH

X10

5CYL

4CYL

8CYL

6CYL

5CYL

4CYL

DWELL

DUTY

CYCLE

%

OHMS

°

20

15

A

20V

4

2

Alligator Clip Adapters

Some multimeter tests and measurements are more easily done

using alligator clips instead of test prods. For these tests, push

the crimp end of the alligator clip onto the test prod. If the crimp

onthealligatorclip becomes loose, thenremovethealligator clip

from the test prod and re-crimp using a pair of pliers.

Section 1. Multimeter Basic Functions

DigitalmultimetersorDMMshavemanyspecialfeaturesandfunctions.Thissectiondefinesthese

features and functions, and explains how to use these functions to make various measurements.

1

11

3

5

4

6

7

8

9

10

Functions and Display Definitions

1. ROTARY SWITCH

Switch is rotated to turn multimeter ON/

OFF and select a function.

2. DC VOLTS

This function is used for measuring DC

(Direct Current) Voltages in the range of 0

to 200V.

3. OHMS

This function is used for measuring the

resistance of a component in an electrical

circuit in the range of 0.1Ωto 20MΩ. (Ωis

the electrical symbol for Ohms)

4. DIODE CHECK

This function is used to check whether a

diode is good or bad.

5. CONTINUITY TESTS

It is also used for fast continuity checks of

wires and terminals. An audible tone will

sound if a wire and terminal are good.

6. DC AMPS

This function is used for measuring DC

(Direct Current) Amps in the range of 0 to

15A.

7. TEST LEAD JACKS

BLACK Test Lead is always

inserted in the COM jack.

RED Test Lead is inserted in

the jack corresponding to the

multimeter rotary switch set-

ting.

8. TACH

Thisfunctionisusedformeasuringengine

speed (RPM).

9. DWELL

ThisfunctionisusedformeasuringDWELL

on distributor ignition systems, and sole-

noids.

10.DUTY CYCLE

This function is used for measuring DUTY

CYCLE on relays, solenoids, and other

ON/OFF types of devices.

11.DISPLAY

Used to display all measurements and

multimeter information.

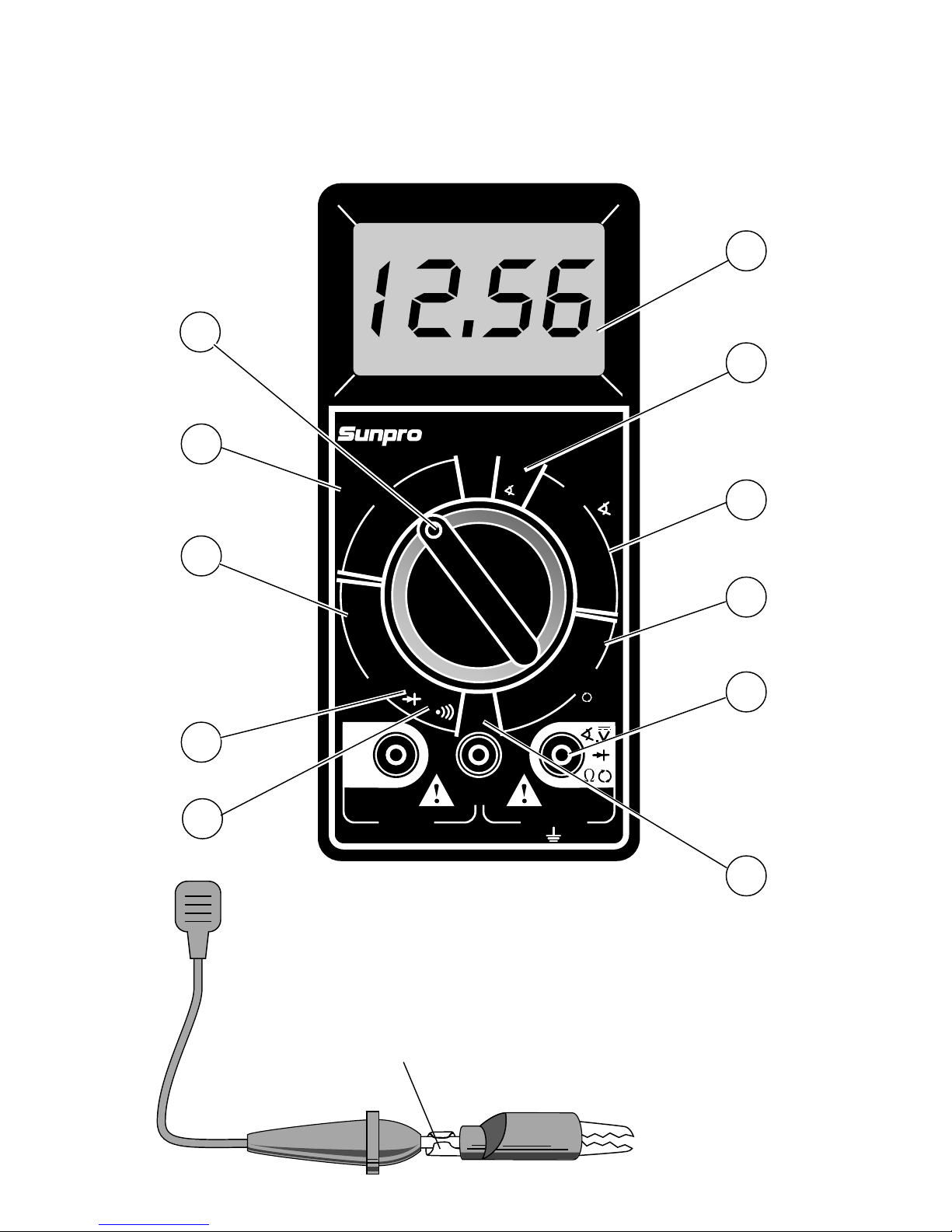

Low Battery – If this symbol

appears in the lower left corner

of the display, then replace the

internal 9V battery. (See Fuse

and Battery replacement on

page 7.)

Overrange Indication – If “1”

or “-1” appears on the left side

of the display, then the multim-

eter is set to a range that is too

small for the present measure-

ment being taken. Increase the

range until this disappears. If it

does not disappear after all the

ranges for a particular function have been

tried,thenthevaluebeingmeasuredistoo

large for the multimeter to measure. (See

Setting the Range on page 6.)

Automatic Power Off

Themultimeterwillautomaticallyturnitselfoff

after approximately thirty (30) minutes if the

rotary switch has not been rotated. Momen-

tarily change the rotary switch position to

restore normal operation.

Zero Adjustment

The multimeter will automatically zero on the

Volts, Amps and RPM functions.

Automatic Polarity Sensing

The multimeter display will show a minus (-)

sign on the DC Volts and DC Amps functions

when test lead hook-up is reversed.

5

Always connect TEST LEADS to the multi-

meter before connecting them to the cir-

cuit under test!!

COM

DC VOLTS

OHMS

DIODES

CONTINUITY

15

A

TACH

DWELL

DUTY CYCLE

DC AMPS

250V MAX

15A MAX

FUSED

COM

DC

15A

AUTO POWER OFF

CP7678

®

OFF

200

20

2

DC V

200

m

20M

200

K

20K

2K 200 8CYL6CYL

TACH

X10

5CYL

4CYL

8CYL

6CYL

5CYL

4CYL

DWELL

DUTY

CYCLE

%

OHMS

°

20 M

15

A

250V MAX

15A MAX

FUSED

COM

DC

15A

AUTO POWER OFF

CP7678

®

OFF

200

20

2

DC V

200

m

20M

200

K

20K

2K 200 8CYL6CYL TACH

X10

5CYL

4CYL

8CYL

6CYL

5CYL

4CYL

DWELL

DUTY

CYCLE

%

OHMS

°

2

15

A

250V MAX

15A MAX

FUSED

COM

DC

15A

AUTO POWER OFF

CP7678

®

OFF

200

20

2

DC V

200

m

20M

200

K

20K

2K 200 8CYL6CYL

TACH

X10

5CYL

4CYL

8CYL

6CYL

5CYL

4CYL

DWELL

DUTY

CYCLE

%

OHMS

°

20

15

A

Setting the Range

Two of the most commonly asked questions

aboutdigitalmultimetersareWhatdoesRange

mean? and How do I know what Range the

multimeter should be set to?

What Does Range mean?

Range refers to the largest value the multim-

etercanmeasurewiththerotaryswitchinthat

position.Ifthemultimeteris settothe20VDC

range, then the highest voltage the multim-

eter can measure is 20V in that range.

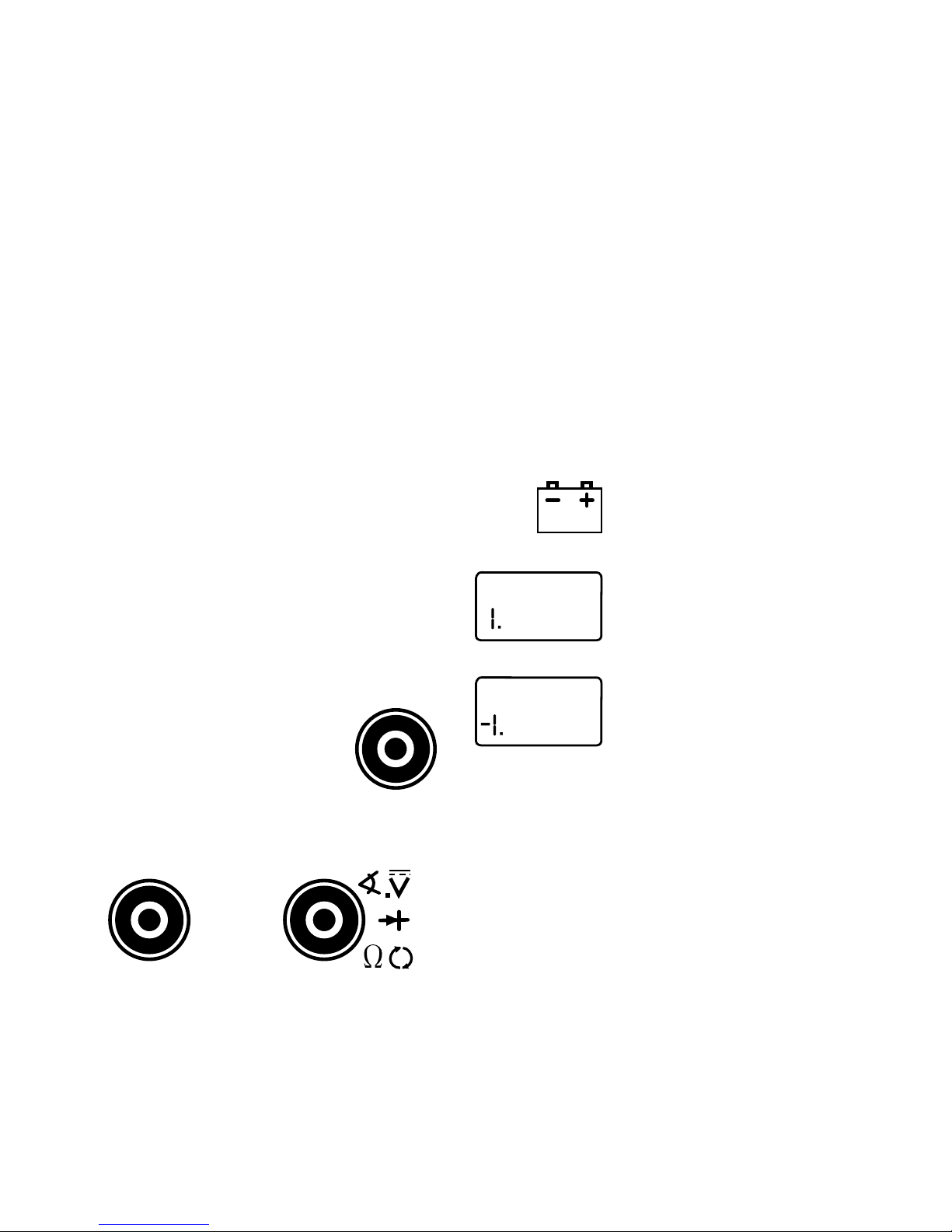

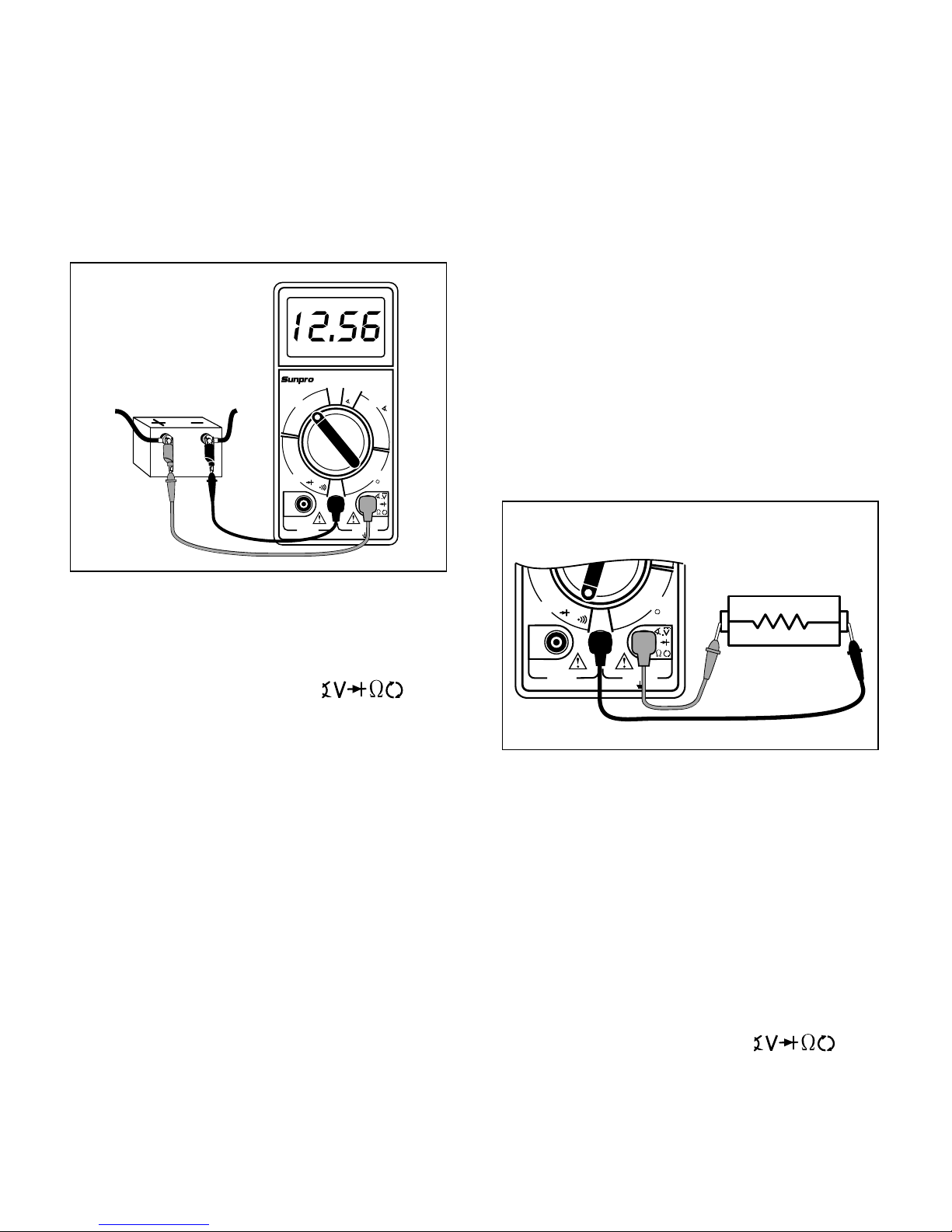

EXAMPLE: Measuring Vehicle Battery Volt-

age (See Fig. 1)

6

Now assume we set the multimeter to the 2V

range. (See Fig. 2)

The multimeter display now shows a “1” and

nothing else. This means the multimeter is

beingoverranged or in other wordsthevalue

being measured is larger than the current

range. The range should be increased until a

valueisshownonthedisplay. If you areinthe

highestrangeandthemultimeterisstillshow-

ingthat itis overranging,then thevalue being

measured is too large for the multimeter to

measure.

How do I know what Range the multimeter

should be set to?

The multimeter should be set in the lowest

possible range without overranging.

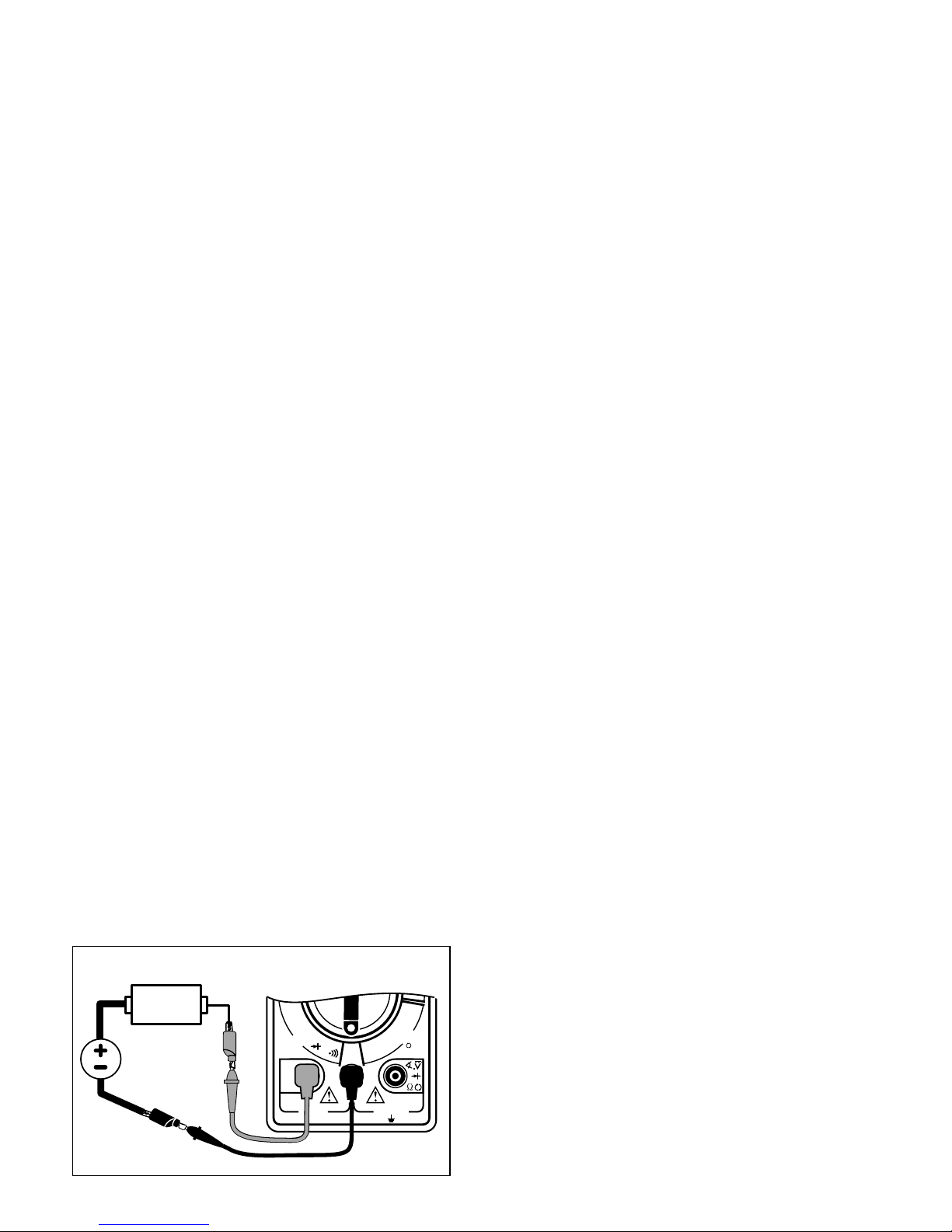

EXAMPLE: Measuring an unknown resis-

tance

Let’s assume the multimeter is connected to

anenginecoolantsensorwithunknownresis-

tance. (See Fig. 3)

Fig. 2

Fig. 1

Let’s assume the multimeter is connected to

the battery and set to the 20V range.

The display reads 12.56. This means there is

12.56V across the battery terminals.

Fig. 3

Start by setting the multimeter to the largest

OHMrange.Thedisplayreads0.0Ωorashort

circuit.

This sensor can’t be shorted so reduce the

range setting until you get a value of resis-

tance.

Atthe 200KΩrange themultimeter measured

a value of 4.0. This means there is 4KΩof

resistance across the engine coolant sensor

terminals. (See Fig. 4)

Red

Black

Red

Black

Black

Red

250V MAX

15A MAX

FUSED

COM

DC

15A

AUTO POWER OFF

CP7678

®

OFF

200

20

2

DC V

200

m

20M

200

K

20K

2K 200 8CYL6CYL

TACH

X10

5CYL

4CYL

8CYL

6CYL

5CYL

4CYL

DWELL

DUTY

CYCLE

%

OHMS

°

20K

15

A

250V MAX

15A MAX

FUSED

COM

DC

15A

AUTO POWER OFF

CP7678

®

OFF

200

20

2

DC V

200

m

20M

200

K

20K

2K 200 8CYL6CYL

TACH

X10

5CYL

4CYL

8CYL

6CYL

5CYL

4CYL

DWELL

DUTY

CYCLE

%

OHMS

°

200K

15

A

250V MAX

15A MAX

FUSED

COM

DC

15A

AUTO POWER OFF

CP7678

®

OFF

200

20

2

DC V

200

m

20M

200

K

20K

2K 200 8CYL6CYL TACH

X10

5CYL

4CYL

8CYL

6CYL

5CYL

4CYL

DWELL

DUTY

CYCLE

%

OHMS

°

2K

15

A

7

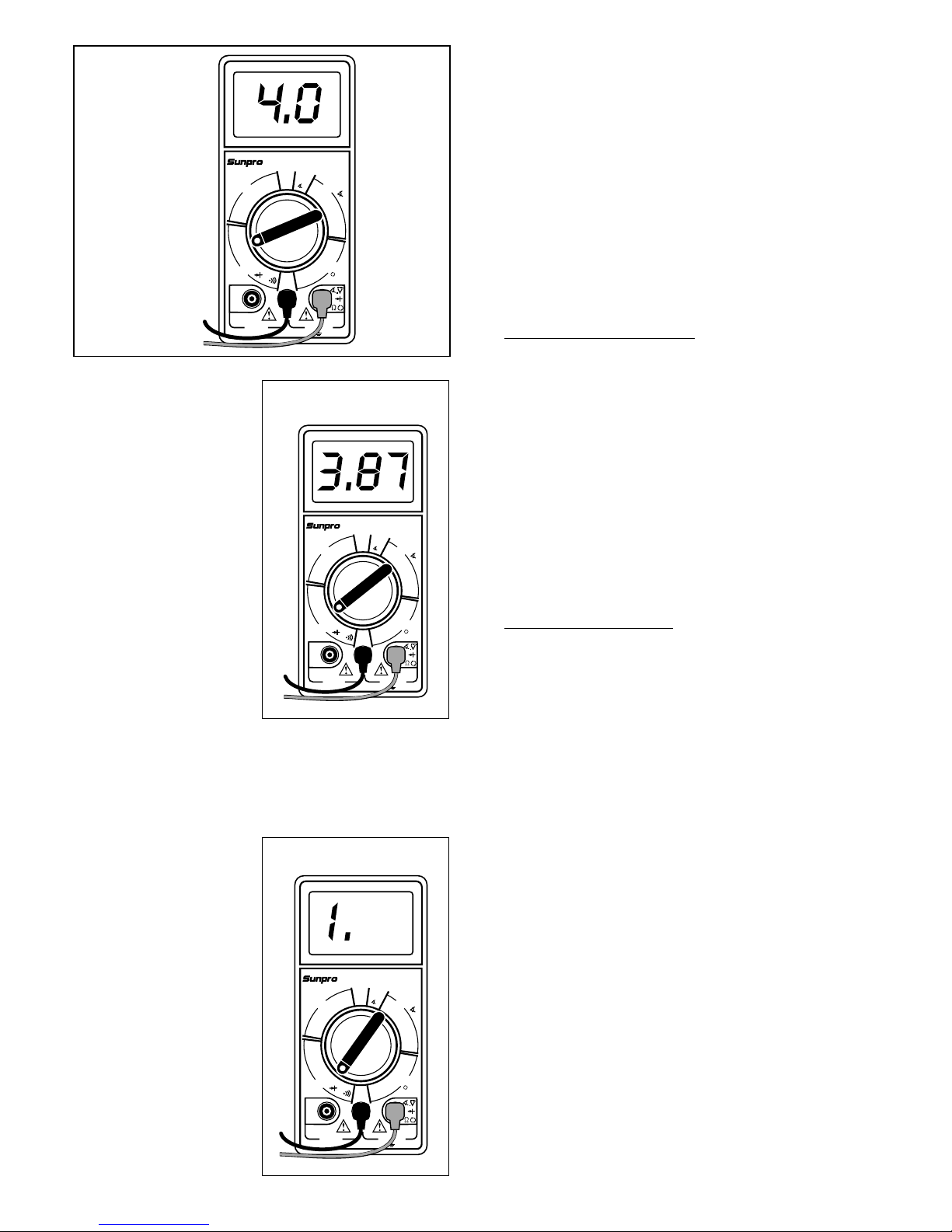

Fig. 4

Fig. 5

Ifwechangethemul-

timeter to the 20KΩ

range (See Fig. 5)

the display shows a

valueof3.87KΩ.The

actual value of resis-

tance is 3.87KΩand

not 4KΩthat was

measured in the

200KΩrange.Thisis

very important be-

causeifthemanufac-

turer specifications

say that the sensor

should read 3.8-

3.9KΩat 70°F then

on the 200KΩrange

the sensor would be defective, but at the

20KΩrange it would test good.

Now set the multimeter to the 2KΩrange.

(SeeFig. 6)The dis-

play will indicate an

overrange condition

because 3.87KΩis

larger than 2KΩ.

This example shows

that by decreasing

the range you in-

crease the accuracy

of your measure-

ment. When you

change the range,

you change the loca-

tion of the decimal

point. This changes

the accuracy of the

Fig. 6

measurement by either increasing or decreas-

ing the number of digits after the decimal point.

Battery and Fuse

Replacement

Important: A 9 Volt battery must be installed

before using the digital multimeter. (see pro-

cedure below for installation)

Battery Replacement

1. Turn multimeter rotary switch to OFF

position.

2. Remove test leads from multimeter.

3. Remove three screws from back of

multimeter.

4. Remove back cover.

5. Install a new 9 Volt battery.

6. Re-assemble multimeter.

Fuse Replacement

1. Turn multimeter rotary switch to OFF

position.

2. Remove test leads from multimeter.

3. Remove three screws from back of

multimeter.

4. Remove back cover.

5. Remove battery.

6. Remove fuse located on top of

battery clip.

7. Replace fuse with same size and type

as originally installed.

Use a 5mm X 20mm, 15A, 250V, fast blow

fuse.

8. Re-assemble multimeter.

250V MAX

15A MAX

FUSED

COM

DC

15A

200

K

20K

2K 200 8CYL6CYL TACH

X10

5CYL

4CYL

OHMS

15

A

250V MAX

15A MAX

FUSED

COM

DC

15A

AUTO POWER OFF

CP7678

®

OFF

200

20

2

DC V

200

m

20M

200

K

20K

2K 200 8CYL6CYL

TACH

X10

5CYL

4CYL

8CYL

6CYL

5CYL

4CYL

DWELL

DUTY

CYCLE

%

OHMS

°

20V

15

A

8

Measuring DC Voltage

This multimeter can be used to measure DC

voltagesin therange from 0 to 200V. You can

use this multimeter to do any DC voltage

measurementcalledoutinthevehicleservice

manual. The most common applications are

measuring voltage drops, and checking if the

correct voltage arrived at a sensor or a par-

ticular circuit.

crease to the appropriate range as re-

quired.(See Setting theRange on page6)

6. View reading on display - Note range

setting for correct units.

NOTE: 200mV = 0.2V

Measuring Resistance

Resistance is measured in electrical units

called ohms (Ω). The digital multimeter can

measure resistance from 0.1Ωto 20MΩor

(20,000,000 ohms). Infinite resistance is

shown with a “1” on the left side of display

(See Setting the Range on page 6). You can

usethis multimeter to do anyresistance mea-

surement called out in the vehicle service

manual.Testingignitioncoils,sparkplugwires,

and some engine sensors are common uses

for the OHMS (Ω) function.

Fig. 7

To measure DC Voltages (see Fig. 7):

1. Insert BLACK test lead into COM test

lead jack.

2. Insert RED test lead into test

lead jack.

3. Connect RED test lead to positive (+)

side of voltage source.

4. Connect BLACK test lead to negative (-)

side of voltage source.

NOTE: If you don’t know which side is

positive (+) and which side is negative (-),

then arbitrarily connect the RED test lead

to one side and the BLACK to the other.

The multimeter automatically senses po-

larityandwilldisplayaminus(-)signwhen

negativepolarityismeasured.Ifyouswitch

the RED and BLACK test leads, positive

polarity will now be indicated on the dis-

play.Measuringnegativevoltages causes

no harm to the multimeter.

5. Turn multimeter rotary switch to de-

sired voltage range.

If the approximate voltage is unknown,

start at the largest voltage range and de-

Fig. 8

To measure Resistance (see Fig. 8):

1. Turn circuit power OFF.

To get an accurate resistance measure-

ment and avoid possible damage to the

digital multimeter and electrical circuit un-

der test, turn off all electrical power in the

circuitwhere the resistance measurement

is being taken.

2. Insert BLACK test lead into COM test

lead jack.

3. Insert RED test lead into test

lead jack.

4. Turn multimeter rotary switch to 200Ω

range.

Touch RED and BLACK multimeter leads

together and view reading on display.

Red

Black

Red Black

Unknown

Resistance

250V MAX

15A MAX

FUSED

COM

DC

15A

20M

200

K

20K

2K 200 8CYL6CYL TACH

X10

5CYL

4CYL

8CYL

OHMS

15

A

9

Displayshouldreadtypically0.2Ωto1.5Ω.

If display reading was greater than 1.5Ω,

check both ends of test leads for bad

connections.Ifbadconnectionsarefound,

replace test leads.

5. Connect RED and BLACK test leads

across component where you want to

measure resistance.

When making resistance measurements,

polarity is not important. The test leads

justhavetobeconnectedacrossthecom-

ponent.

6. Turn multimeter rotary switch to de-

sired OHM range.

If the approximate resistance is unknown,

start at the largest OHM range and de-

crease to the appropriate range as re-

quired.(SeeSettingtheRangeonpage6)

7. View reading on display - Note range

setting for correct units.

NOTE: 2KΩ=2,000Ω;2MΩ=2,000,000Ω

If you want to make precise resistance

measurements,thensubtractthetestlead

resistance found in Step 4 above from the

display reading in Step 7. It is a good idea

to do this for resistance measurements

less than 10Ω.

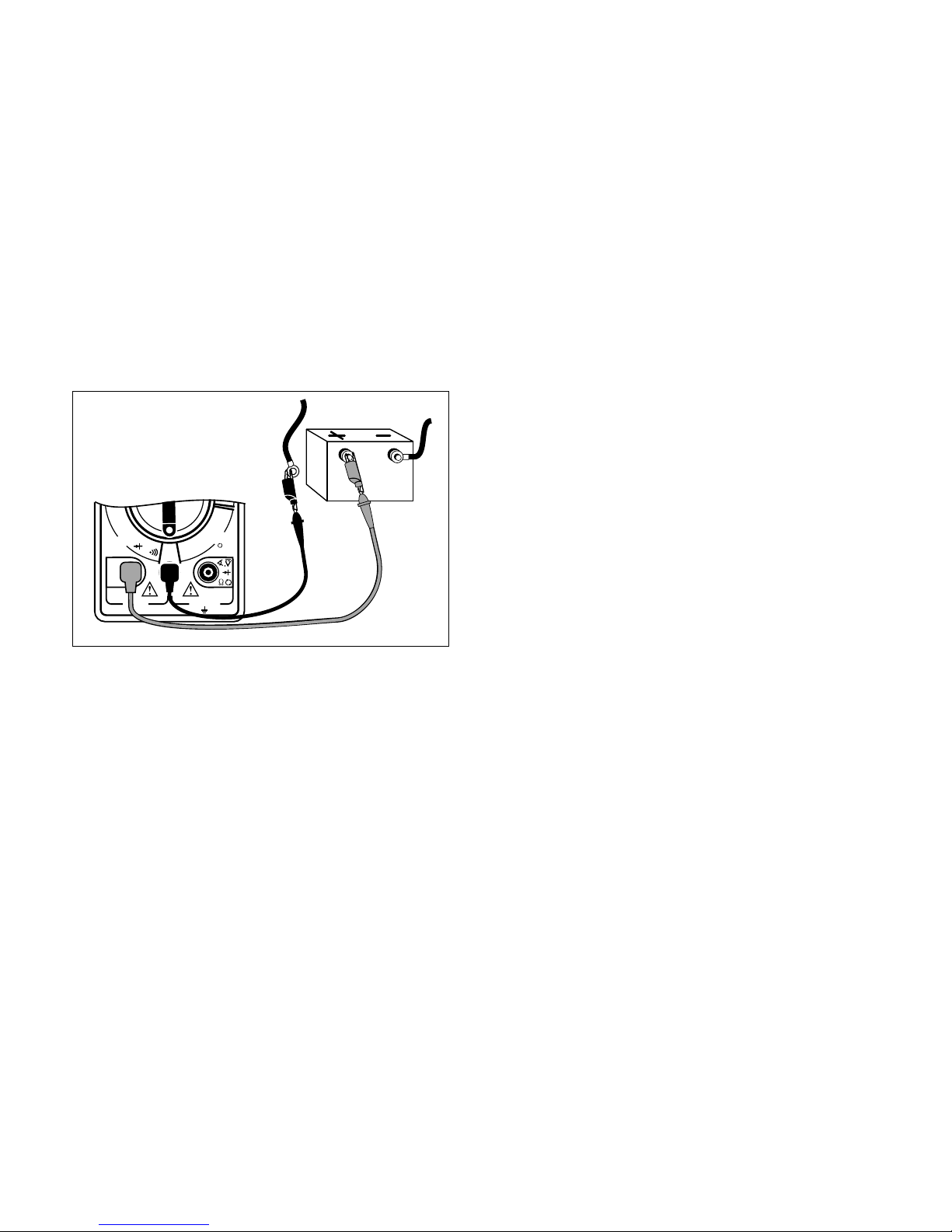

Measuring DC Current

This multimeter can be used to measure DC

current in the range from 0 to 15A. If the

current you are measuring exceeds 15A, the

internal fuse will blow (see Fuse Replace-

ment on page 7). Unlike voltage and resis-

tance measurements where the multimeter is

connected across the component you are

Fig. 9

testing,current measurements must be made

with the multimeter in series with the compo-

nent. Isolating current drains and short cir-

cuits are some DC Current applications.

To measure DC Current (see Fig. 9):

1. Insert BLACK test lead into COM test

lead jack.

2. InsertREDtest lead into "15A"testlead

jack.

3. Disconnect or electrically open circuit

where you want to measure current.

This is done by:

• Disconnecting wiring harness.

• Disconnecting wire from screw-on type

terminal.

• Unsolder lead from component if work-

ing on printed circuit boards.

• Cut wire if there is no other possible way

to open electrical circuit.

4. Connect RED test lead to one side of

disconnected circuit.

5. Connect BLACK test lead to remaining

side of disconnected circuit.

6. Turn multimeter rotary switch to 15A

DC position.

7. View reading on display.

If minus (-) sign appears on display, then

reverse RED and BLACK test leads.

Black

Red

Electrical

Device

DC

Voltage

Source

15A MAX

FUSED

COM

DC

15A

20M

200

K

20K

2K 200 8CYL6CYL

TACH

X10

5CYL

4CYL

8CYL

OHMS

15

A

250V MAX

250V MAX

15A MAX

FUSED

COM

DC

15A

20M

200

K

20K

2K 200 8CYL6CYL

TACH

X10

5CYL

4CYL

8CYL

OHMS

15

A

10

Testing for Continuity

Continuity is a quick way to do a resistance

test to determine if a circuit is open or closed.

The multimeter will beep when the circuit is

closedorshorted,soyoudon’thavetolookat

the display. Continuity checks are usually

done when checking for blown fuses, switch

operation, and open or shorted wires.

Testing Diodes

Adiodeisanelectricalcomponentthat allows

current to only flow in one direction. When a

positive voltage, generally greater than 0.7V,

is applied to the anode of a diode, the diode

will turn on and allow current to flow. If this

same voltage is applied to the cathode, the

diode would remain off and no current would

flow. Therefore, in order to test a diode, you

mustcheckitinbothdirections(i.e. anode-to-

cathode, and cathode-to-anode). Diodes are

typically found in alternators on automobiles.

Performing Diode Test (see Fig. 11):

1. Insert BLACK test lead into COM test

lead jack.

2. Insert RED test lead into test

lead jack.

3. Turn multimeter rotary switch to 2K

diodefunction.Nobeeperondiodetest.

4. Touch RED and BLACK test leads to-

gether to test continuity.

Check display – should reset to 0.00.

5. Disconnect one end of diode from cir-

cuit.

Diode must be totally isolated from circuit

in order to test its functionality.

6. Connect RED and BLACK test leads

across diode and view display.

Display will show one of three things:

• A typical voltage drop of around 0.7V.

• A voltage drop of 0 volts.

• A “1” will appear indicating the multim-

eter is overranged.

Fig. 11

Fig. 10

To measure Continuity (see Fig. 10):

1. Insert BLACK test lead into COM test

lead jack.

2. Insert RED test lead into test

lead jack.

3. Turn multimeter rotary switch to

200 function.

4. Touch RED and BLACK test leads to-

gether to test continuity.

Listen for tone to verify proper operation.

5. Connect RED and BLACK test leads

across component where you want to

check for continuity.

Listen for tone:

• If you hear tone – Circuit is closed or

shorted.

• If you don’t hear tone – Circuit is open.

Black

Red

Anode Cathode

BlackRed

250V MAX

15A MAX

FUSED

COM

DC

15A

20M

200

K

20K

2K 200 8CYL6CYL

TACH

X10

5CYL

4CYL

8CYL

OHMS

15

A

11

To measure Engine RPM (TACH) (see Fig.

12):

1. Insert BLACK test lead into COM test

lead jack.

2. Insert RED test lead into test

lead jack.

3. Connect RED test lead to TACH signal

wire.

• If vehicle is DIS (Distributorless Ignition

System), then connect RED test lead to

the TACH signal wire going from the DIS

module to the vehicle engine computer.

(refer to vehicle service manual for loca-

tion of this wire)

• Forallvehicleswithdistributors,connect

REDtestleadtonegativesideof primary

ignition coil. (refer to vehicle service

manual for location of ignition coil)

4. Connect BLACK test lead to a good

vehicle ground.

5. Turn multimeter rotary switch to cor-

rect CYLINDER selection.

6. Measure engine RPM (TACH) while en-

gine is cranking or running.

7. View reading on display.

• If using LO TACH, display reading is

actual RPM.

• Remembertomultiplydisplayreadingby

10 to get actual RPM.

If display reads 200, then actual engine

RPM is 10 times 200 or 2000 RPM.

7. Switch RED and BLACK test leads and

repeat Step 6.

8. Test Results

If the display showed:

• A voltage drop of 0 volts in both direc-

tions with the continuity beeper sound-

ing off, then the diode is shorted and

needs to be replaced.

• A“1”appearsinbothdirections,thenthe

diode is an open circuit and needs to be

replaced.

• The diode is good if the display reads

around0.5V–0.7V inone direction and a

“1”appearsintheotherdirectionindicat-

ing the multimeter is overranged.

Measuring Engine RPM

(TACH)

RPM refers to revolutions per minute. When

using TACH you must multiply the display

reading by 10 to get actual RPM. If display

reads 200 and the multimeter is set to 6

cylinder TACH, the actual engine RPM is 10

times 200 or 2000 RPM.

Typical

Ignition

Coil

Ground

Black

Red

Fig. 12

250V MAX

15A MAX

FUSED

COM

DC

15A

AUTO POWER OFF

CP7678

®

OFF

200

20

2

DC V

200

m

20M

200

K

20K

2K 200 8CYL6CYL TACH

X10

5CYL

4CYL

8CYL

6CYL

5CYL

4CYL

DWELL

DUTY

CYCLE

%

OHMS

°

15

A

250V MAX

15A MAX

FUSED

COM

DC

15A

AUTO POWER OFF

CP7678

®

OFF

200

20

2

DC V

200

m

20M

200

K

20K

2K 200 8CYL6CYL TACH

X10

5CYL

4CYL

8CYL

6CYL

5CYL

4CYL

DWELL

DUTY

CYCLE

%

OHMS

°

15

A

12

Measuring Dwell

Dwell measuring was extremely important on

breaker point ignition systems of the past. It

referred to the length of time, in degrees, that

thebreakerpointsremainedclosed,whilethe

camshaft was rotating. Today’s vehicles use

electronic ignition and dwell is no longer ad-

justable. Another application for dwell is in

testing the mixture control solenoid on GM

feedback carburetors.

5. Turn multimeter rotary switch to cor-

rect DWELL CYLINDER position.

6. View reading on display.

Measuring Duty Cycle

Duty Cycle refers to the percentage of time a

signal is “ON” verses “OFF”. A signal that is

“ON”halfthetimehasa50%DutyCycle.Duty

Cycleisusefulforcheckingsolenoids,relays,

switches, fuel injectors and any other compo-

nent that is switched “ON” and “OFF”.

To measure Dwell (see Fig. 13):

1. Insert BLACK test lead into COM test

lead jack.

2. Insert RED test lead into test

lead jack.

3. ConnectREDtestleadtoDWELLsignal

wire.

• If measuring DWELL on breaker point

ignition systems, connect RED test lead

to negative side of primary ignition coil.

(refer to vehicle service manual for loca-

tion of ignition coil)

• IfmeasuringDWELLonGMmixturecon-

trol solenoids, connect RED test lead to

ground side or computer driven side of

solenoid.(refertovehicleservicemanual

for solenoid location)

• If measuring DWELL on any arbitrary

ON/OFF device, connect RED test lead

to side of device that is being switched

ON/OFF.

4. Connect BLACK test lead to a good

vehicle ground.

Fig. 13

Fig. 14

To measure Duty Cycle (see Fig. 14):

1. Insert BLACK test lead into COM test

lead jack.

2. Insert RED test lead into test

lead jack.

3. Connect RED test lead to ON/OFF

switching side of device.

4. Connect BLACK test lead to a good

vehicle ground.

5. Turn multimeter rotary switch to DUTY

CYCLE position.

6. View reading on display.

Ground

Black

Red

Typical

Ignition

Coil

Black

Ground

Red

On/Off

Switching

Side

Power

Side

Solenoid

250V MAX

15A MAX

FUSED

COM

DC

15A

20M

200

K

20K

2K 200 8CYL6CYL TACH

X10

5CYL

4CYL

8CYL

OHMS

15

A

250V MAX

15A MAX

FUSED

DC

15A

20M

200

K

20K

2K 200 8CYL6CYL TACH

X10

5CYL

4CYL

8CYL

OHMS

15

A

COM

13

Section 2. AutomotiveTesting

The digital multimeter is a very useful tool for

trouble-shooting automotive electrical sys-

tems. This section describes how to use the

digitalmultimetertotestthestartingandcharg-

ing system, ignition system, fuel system, and

engine sensors. The digital multimeter can

also be used for general testing of fuses,

switches, solenoids, and relays.

General Testing

The digital multimeter can be used to test

fuses, switches, solenoids, and relays.

Testing Fuses

This test checks to see if a fuse is blown. You

can use this test to check the internal 15A

fuse inside the digital multimeter.

• If you hear tone - Fuse is good.

• If you don’t hear tone - Fuse is blown

and needs to be replaced.

NOTE: Always replace blown fuses with

same type and rating.

Testing Switches

Thistestcheckstoseeifaswitch“Opens”and

“Closes” properly.

Fig. 16

Red Black

Typical "Push"

Button Switch

To test Switches (see Fig. 16):

1. Insert BLACK test lead into COM test

lead jack.

2. Insert RED test lead into test

lead jack.

3. Turn multimeter rotary switch to

200 function.

4. Touch RED and BLACK test leads to-

gether to test continuity.

Listen for tone to verify proper operation.

5. Connect BLACK test lead to one side of

switch.

6. Connect RED test lead to other side of

switch.

Listen for tone:

• If you hear tone - The switch is closed.

• If you don’t hear tone - The switch is

open.

7. Operate switch.

Listen for tone:

To test Fuses (see Fig. 15):

1. Insert BLACK test lead into COM test

lead jack.

2. Insert RED test lead into test

lead jack.

3. Turn multimeter rotary switch to

200 function.

4. Touch RED and BLACK test leads to-

gether to test continuity.

Listen for tone to verify proper operation.

5. Connect RED and BLACK test leads to

opposite ends of fuse.

Listen for tone:

Fig. 15

Red Black

Fuse

250V MAX

15A MAX

FUSED

DC

15A

20M

200

K

20K

2K 200 8CYL6CYL TACH

X10

5CYL

4CYL

8CYL

OHMS

15

A

COM

•If you hear tone - The switch is closed.

• If you don’t hear tone - The switch is

open.

8. RepeatStep7toverifyswitchoperation.

Good Switch:

Tone turns ON and OFF as

you operate switch.

Bad Switch:

Tone always ON or tone al-

ways OFF as you operate switch.

14

4. Touch RED and BLACK test leads to-

gether and listen for tone.

5. ConnectBLACKtestleadtoonesideof

coil.

6. Connect RED test lead to other side of

coil.

7. View reading on display.

• Typical solenoid / relay coil resistances

are 200Ωor less.

• Refer to vehicle service manual for your

vehicles resistance range.

8. Test Results

Good Solenoid / Relay Coil:

Display in

Step 7 is within manufacturers specifica-

tion.

Bad Solenoid / Relay Coil:

• Display in Step 7 is not within manufac-

turers specifications.

• Displayreads overrangeon everyohms

range indicating an open circuit.

NOTE: Some relays and solenoids have

adiodeplacedacrossthecoil.Totestthis

diode see Testing Diodes on page 10.

To test Solenoids and Relays (see Fig. 17):

1. Insert BLACK test lead into COM test

lead jack.

2. Insert RED test lead into test

lead jack.

3. Turn multimeter rotary switch to

200 range.

Most solenoids and relay coil resistances

are less than 200Ω. If meter overranges,

turnmultimeterrotaryswitchtonexthigher

range. (see Setting the Range on page 6)

Testing Solenoids and Relays

This test checks to see if a solenoid or relay

have a broken coil. If the coil tests good, it is

still possible that the relay or solenoid are

defective. The relay can have contacts that

are welded or worn down, and the solenoid

maystickwhenthecoilisenergized.This test

does not check for those potential problems.

Fig. 17 Relay or

Solenoid

Red Black

250V MAX

15A MAX

FUSED

COM

DC

15A

AUTO POWER OFF

CP7678

®

OFF

200

20

2

DC V

200

m

20M

200

K

20K

2K 200 8CYL6CYL

TACH

X10

5CYL

4CYL

8CYL

6CYL

5CYL

4CYL

DWELL

DUTY

CYCLE

%

OHMS

°

15

A

15

Starting/Charging SystemTesting

The starting system “turns over” the engine. It consists of the battery, starter motor, starter

solenoid and/or relay, and associated wiring and connections. The charging system keeps the

battery charged when the engine is running. This system consists of the alternator, voltage

regulator, battery, and associated wiring and connections. The digital multimeter is a useful tool

for checking the operation of these systems.

No Load Battery Test

Before you do any starting/charging system

checks,youmustfirsttestthebatterytomake

sure it is fully charged.

Fig. 18

BlackRed

Test Procedure (see Fig. 18):

1. Turn Ignition Key OFF.

2. Turn ON headlights for 10 seconds to

dissipate battery surface charge.

3. Insert BLACK test lead into COM test

lead jack.

4. Insert RED test lead into test

lead jack.

5. Disconnect positive (+) battery cable.

6. Connect RED test lead to positive (+)

terminal of battery.

7. Connect BLACK test lead to negative (-)

terminal of battery.

8. Turn multimeter rotary switch to 20V

DC range.

9. View reading on display.

10.Test Results.

Compare display reading in Step 9 with

chart below.

Voltage Percent Battery is Charged

12.60V

or greater 100%

12.45V 75%

12.30V 50%

12.15V 25%

If battery is not 100% charged, then charge it

before doing anymore starting/charging sys-

tem tests.

250V MAX

15A MAX

FUSED

COM

DC

15A

200

K

20K

2K 200 8CYL6CYL TACH

X10

5CYL

4CYL

OHMS

15

A

Engine Off Battery Current Draw

16

Fig. 19

Black Red

2. Insert BLACK test lead into COM test

lead jack.

3. InsertREDtestleadinto"15A"testlead

jack.

4. Disconnect positive (+) battery cable.

5. Connect RED test lead to positive (+)

battery terminal.

This test measures the amount of current

being drawn from the battery when the igni-

tion key and engine are both off. This test

helps to identify possible sources of exces-

sive battery current drain, which could even-

tually lead to a “dead” battery.

1. Turn Ignition Key and all accessories

OFF.

Make sure trunk, hood, and dome lights

are all OFF.

(See Fig. 19)

6. ConnectBLACKtestleadtopositive(+)

battery cable.

NOTE: Do not start vehicle during this test,

because multimeter damage may result.

7. Turn multimeter rotary switch to 15A

DC position.

8. View reading on display.

• Typical current draw is 100mA. (1mA =

0.001A)

• Refertovehicleservicemanualformanu-

facturersspecificEngineOffBatteryCur-

rent Draw.

NOTE: Radio station presets and clocks

are accounted for in the 100mA typical

current draw.

9. Test Results.

Normal Current Draw:

Display reading in

Step 8 is within manufacturers specifica-

tions.

Excessive Current Draw:

- Display reading in Step 8 is well outside

manufacturers specifications.

- Remove Fuses from fuse box one at a

time until source of excessive current

draw is located.

- Non-Fused circuits such as headlights,

relays, and solenoids should also be

checked as possible current drains on

battery.

- When source of excessive current drain

is found, service as necessary.

250V MAX

15A MAX

FUSED

COM

DC

15A

AUTO POWER OFF

CP7678

®

OFF

200

20

2

DC V

200

m

20M

200

K

20K

2K 200 8CYL6CYL TACH

X10

5CYL

4CYL

8CYL

6CYL

5CYL

4CYL

DWELL

DUTY

CYCLE

%

OHMS

°

15

A

17

Cranking Voltage - Battery Load Test

This test checks the battery to see if it is

deliveringenoughvoltagetothestartermotor

under cranking conditions.

5. Connect BLACK test lead to negative (-)

terminal of battery.

6. Turn multimeter rotary switch to 20V

DC range.

7. Crank engine for 15 seconds continu-

ously while observing display.

8. Test Results.

Compare display reading in Step 7 with

chart below.

Fig. 20

Red Black

Test Procedure (see Fig. 20):

1. Disableignitionsystemsovehiclewon’t

start.

Disconnect the primary of the ignition coil

or the distributor pick-up coil or the cam/

crank sensor to disable the ignition sys-

tem. Refer to vehicle service manual for

disabling procedure.

2. Insert BLACK test lead into COM test

lead jack.

3. Insert RED test lead into test

lead jack.

4. Connect RED test lead to positive (+)

terminal of battery.

Voltage Temperature

9.6V or greater 70 °F and Above

9.5V 60 °F

9.4V 50 °F

9.3V 40 °F

9.1V 30 °F

8.9V 20 °F

8.7V 10 °F

8.5V 0 °F

If voltage on display corresponds to above

voltage vs. temperature chart, then cranking

system is normal.

If voltage on display does not correspond to

chart, then it is possible that the battery,

batterycables,startingsystemcables,starter

solenoid, or starter motor are defective.

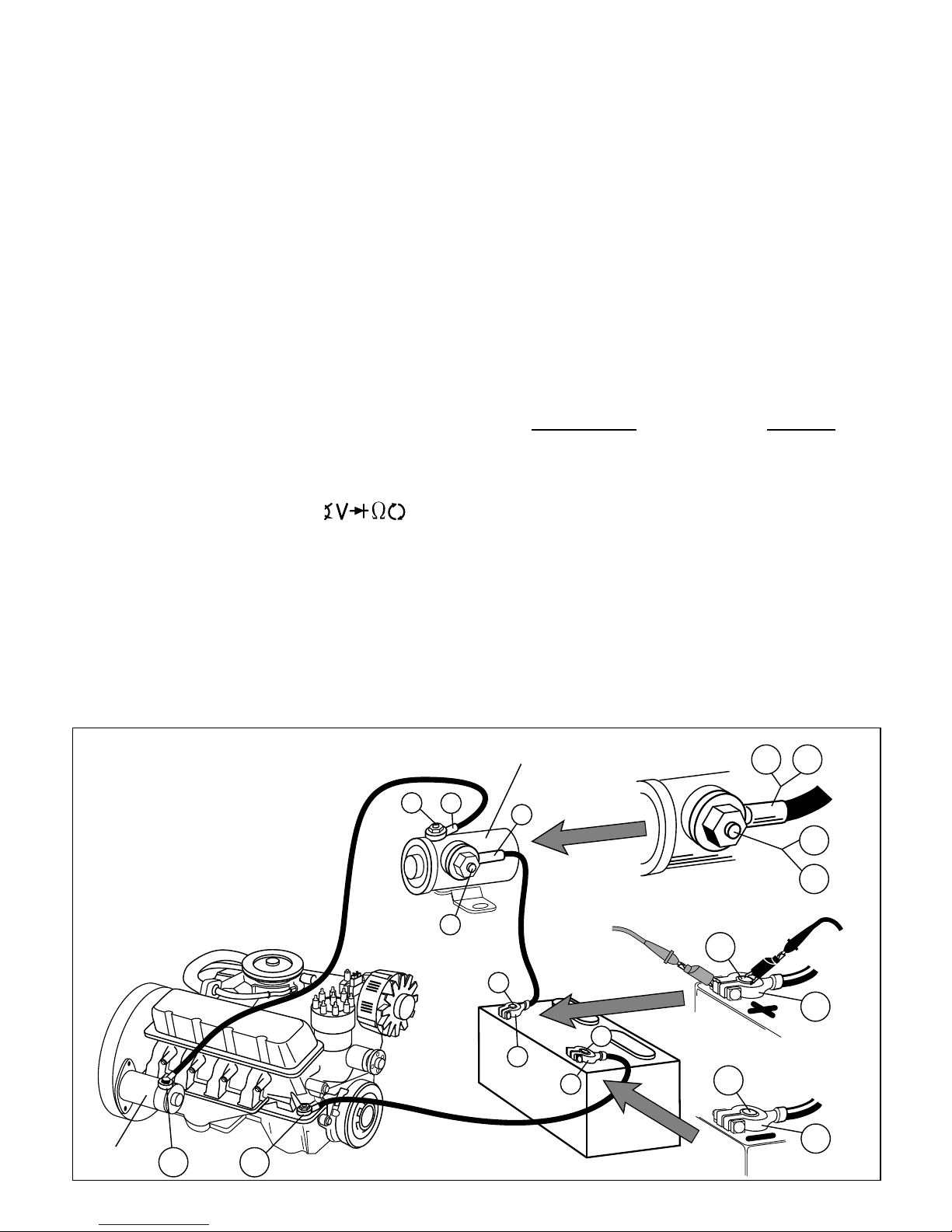

1

10

2

4

5

6 8

7

7

9

8

96

2

4

5

3

3

18

Voltage Drops 5. Turnmultimeterrotaryswitchto200mV

DC range.

If multimeter overranges, turn multimeter

rotary switch to the 2V DC range. (See

Setting the Range on page 6)

6. Crank engine until steady reading is on

display.

• Recordresultsateachpointasdisplayed

on multimeter.

• Repeat Step 4 & 5 until all points are

checked.

7. Test Results –

Estimated Voltage Drop of Starter Cir-

cuit Components

Component Voltage

Switches 300mV

Wire or Cable 200mV

Ground 100mV

Battery Cable Connectors 50mV

Connections 0.0V

• Comparevoltagereadingsin Step 6with

above chart.

• If any voltages read high, inspect com-

ponent and connection for defects.

• Ifdefectsarefound,serviceasnecessary.

This test measures the voltage drop across

wires, switches, cables, solenoids, and con-

nections. With this test you can find excessive

resistance in the starter system. This resis-

tancerestrictstheamountofcurrentthatreaches

the starter motor resulting in low battery load

voltage and a slow cranking engine at starting.

Test Procedure (see Fig. 21):

1. Disableignitionsystemsovehiclewon’t

start.

Disconnect the primary of the ignition coil

or the distributor pick-up coil or the cam/

crank sensor to disable the ignition sys-

tem. Refer to vehicle service manual for

disabling procedure.

2. Insert BLACK test lead into COM test

lead jack.

3. Insert RED test lead into test

lead jack.

4. Connect test leads.

Refer to Typical Cranking Voltage Loss

Circuit (Fig. 21).

• Connect RED and BLACK test leads al-

ternately between 1 & 2, 2 & 3, 4 & 5, 5

& 6, 6 & 7, 7 & 8, 8 & 9, and 8 & 10.

Red Black

Fig. 21 Typical Cranking Voltage

Loss Circuit Solenoid

This is a representative sample of one

type of cranking circuit. Your vehicle

may use a different circuit with

different components or locations.

Consult your vehicle service manual.

Starter

250V MAX

15A MAX

FUSED

COM

DC

15A

AUTO POWER OFF

CP7678

®

OFF

200

20

2

DC V

200

m

20M

200

K

20K

2K 200 8CYL6CYL TACH

X10

5CYL

4CYL

8CYL

6CYL

5CYL

4CYL

DWELL

DUTY

CYCLE

%

OHMS

°

15

A

19

Charging System Voltage Test

Thistest checksthe charging system to see if

it charges the battery and provides power to

the rest of the vehicles electrical systems

(lights, fan, radio etc).

Fig. 22

Red Black

Test Procedure (see Fig. 22):

1. Insert BLACK test lead into COM test

lead jack.

2. Insert RED test lead into test

lead jack.

3. Connect RED test lead to positive (+)

terminal of battery.

4. Connect BLACK test lead to negative (-)

terminal of battery.

5. Turn multimeter rotary switch to 20V

DC range.

6. Start engine - Let idle.

7. Turn off all accessories and view read-

ing on display.

• Chargingsystemisnormalifdisplayreads

13.2 to 15.2 volts.

• If display voltage is not between 13.2 to

15.2 volts, then proceed to Step 13.

8. Open throttle and Hold engine speed

(RPM) between 1800 and 2800 RPM.

Holdthis speed through Step 11 - Have an

assistance help hold speed.

9. View reading on display.

Voltage reading should not change from

Step 7 by more than 0.5V.

10.Load the electrical system by turning

on the lights, windshield wipers, and

setting the blower fan on high.

11.View reading on display.

Voltageshouldnotdropdownbelowabout

13.0V.

12.Shut off all accessories, return engine

to curb idle and shut off.

13.Test Results.

• If voltage readings in Steps 7, 9, and 11

were as expected, then charging system

is normal.

• Ifany voltage readings in Steps 7, 9, and

11 were different then shown here or in

vehicle service manual, then check for a

loose alternator belt, defective regulator

or alternator, poor connections, or open

alternator field current.

• Refer to vehicle service manual for fur-

ther diagnosis.

250V MAX

15A MAX

FUSED

COM

DC

15A

20M

200

K

20K

2K 200 8CYL6CYL

TACH

X10

5CYL

4CYL

8CYL

OHMS

15

A

250V MAX

15A MAX

FUSED

COM

DC

15A

20M

200

K

20K

2K 200 8CYL6CYL TACH

X10

5CYL

4CYL

8CYL

OHMS

15

A

20

Ignition SystemTesting

The ignition system is responsible for providing the spark that ignites the fuel in the cylinder.

Ignition system components that the digital multimeter can test are the primary and secondary

ignitioncoilresistance,sparkplugwireresistance,halleffectswitches/sensors, reluctancepick-

up coil sensors, and the switching action of the primary ignition coil.

Ignition Coil Testing

This test measures the resistance of the pri-

mary and secondary of an ignition coil. This

test can be used for distributorless ignition

systems (DIS) provided the primary and sec-

ondary ignition coil terminals are easily ac-

cessible.

Test Procedure:

1. If engine is HOT let it COOL down be-

fore proceeding.

2. Disconnect ignition coil from ignition

system.

6. Connect test leads.

• Connect RED test lead to primary igni-

tion coil positive (+) terminal.

• Connect BLACK test lead to primary ig-

nition coil negative (-) terminal.

• Refer to vehicle service manual for loca-

tion of primary ignition coil terminals.

7. View reading on display.

SubtracttestleadresistancefoundinStep

5 from above reading.

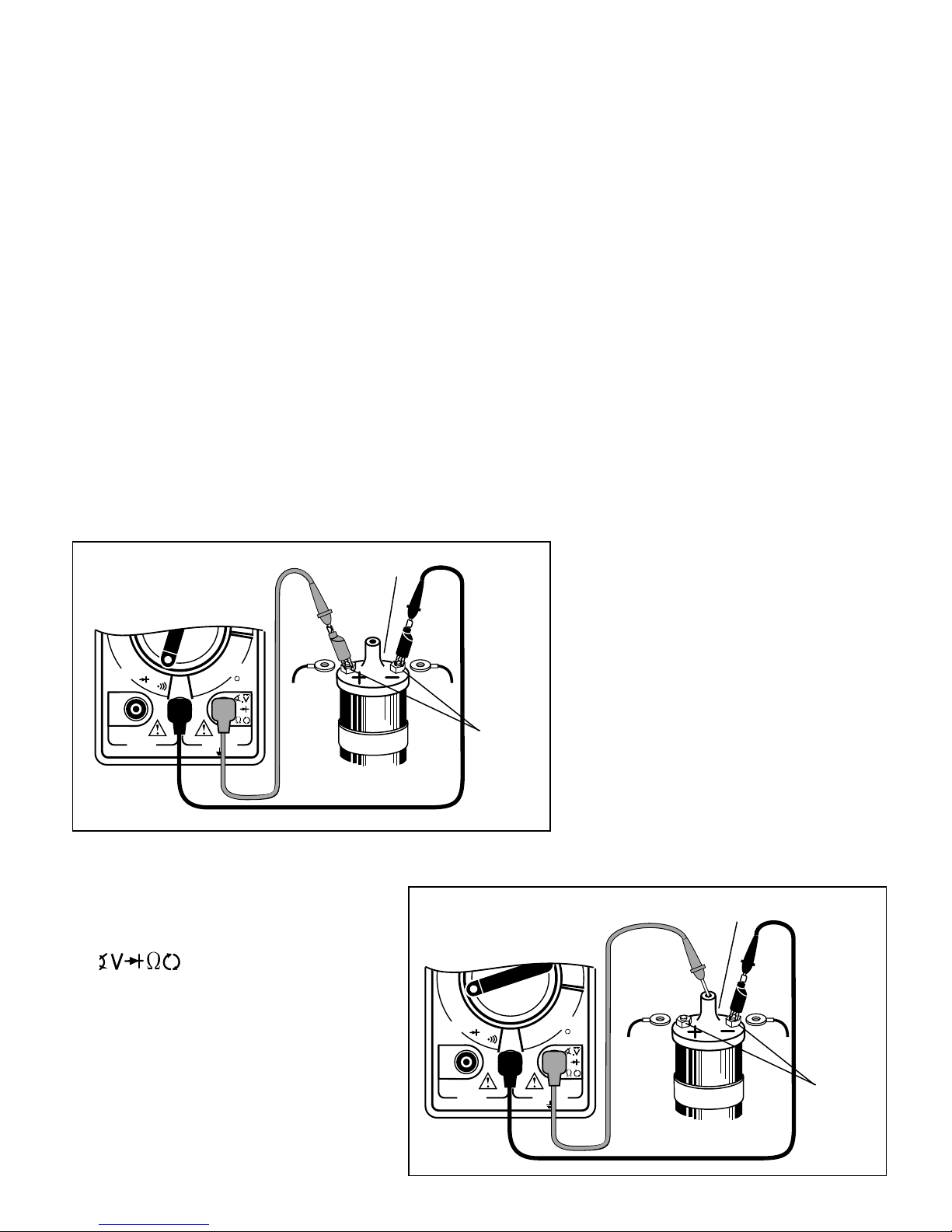

Fig. 23

Typical Cylindrical

Ignition Coil

BlackRed

Primary

Coil

Secondary

Coil

Fig. 24

Typical Cylindrical

Ignition Coil

Black

Secondary

Coil

Primary

Coil

Red

3. Insert BLACK test lead into

COM test lead jack (see Fig.

23).

4. Insert RED test lead into

test lead jack.

5. Turn multimeter rotary switch

to 200Ωrange.

8. If vehicle is DIS, repeat Steps 6

and 7 for remaining ignition

coils.

9. Test Results - Primary Coil

• Typical resistance range of pri-

mary ignition coils is 0.3 - 2.0Ω.

• Refer to vehicle service manual

for your vehicles resistance

range.

Other manuals for SunPro CP7678

1

Table of contents

Other Actron Multimeter manuals

Actron

Actron Digital Multimeter CP7676 User manual

Actron

Actron CP7847 User manual

Actron

Actron Digital Multimeter CP7676 User manual

Actron

Actron CP7849 User manual

Actron

Actron CP7677 User manual

Actron

Actron SunPro CP7678 User manual

Actron

Actron Digital Multitester CP7674 User manual

Actron

Actron Sunpro CP7605 User manual

Actron

Actron CP7849 User manual