Isotech IDM 205 RMS User manual

Other Isotech Multimeter manuals

Isotech

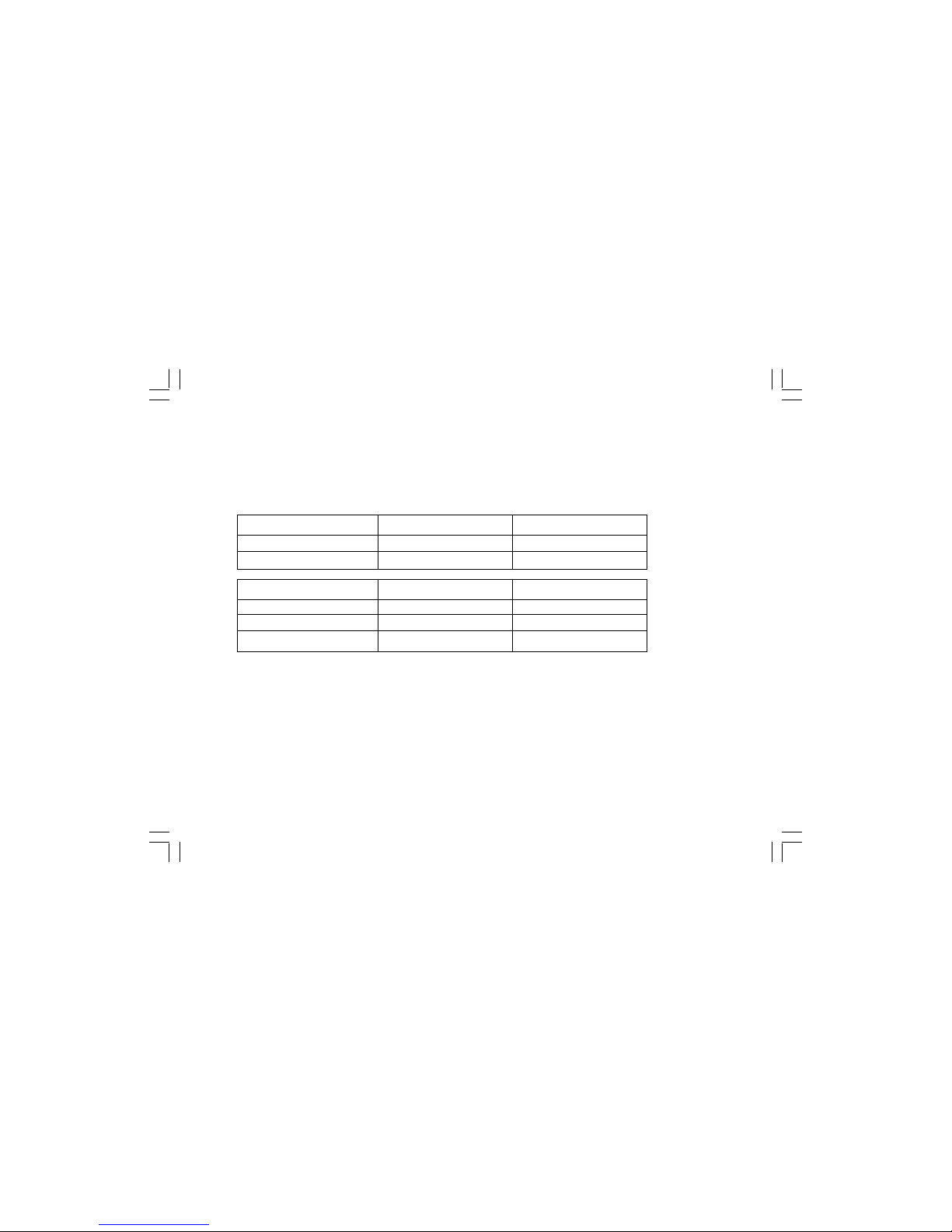

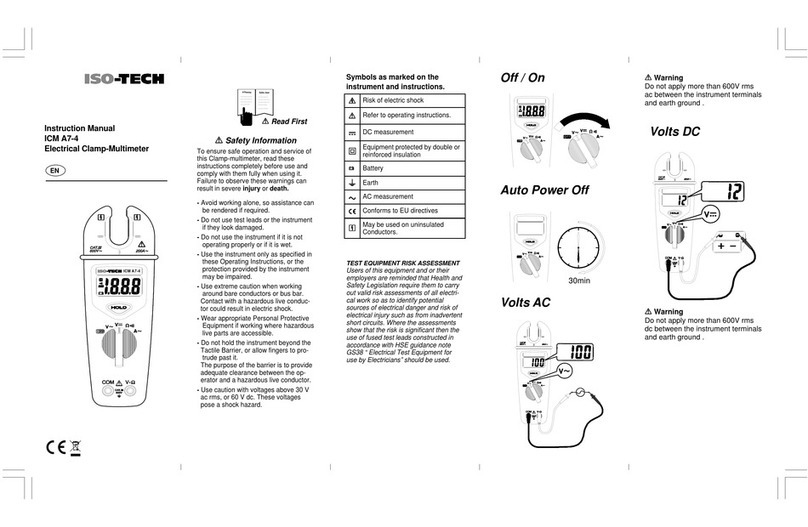

Isotech ICM A7-4 User manual

Isotech

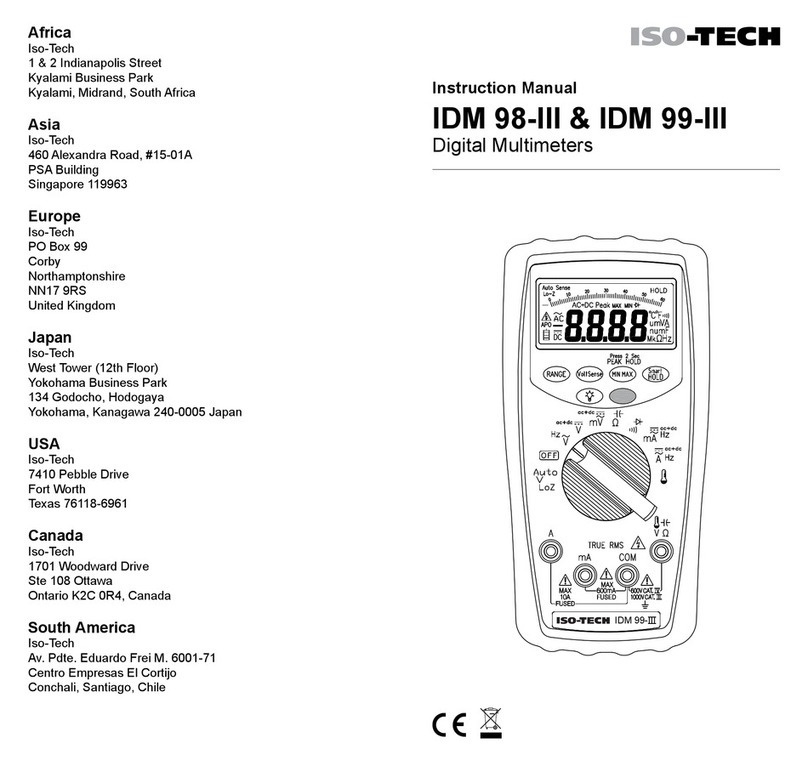

Isotech IDM 98-III User manual

Isotech

Isotech IDM 507 User manual

Isotech

Isotech IDM 97 User manual

Isotech

Isotech IDM93N User manual

Isotech

Isotech IDM101 User manual

Isotech

Isotech IDM97II User manual

Isotech

Isotech ICM33R II User manual

Isotech

Isotech ICM36R User manual

Isotech

Isotech IDM99II User manual

Isotech

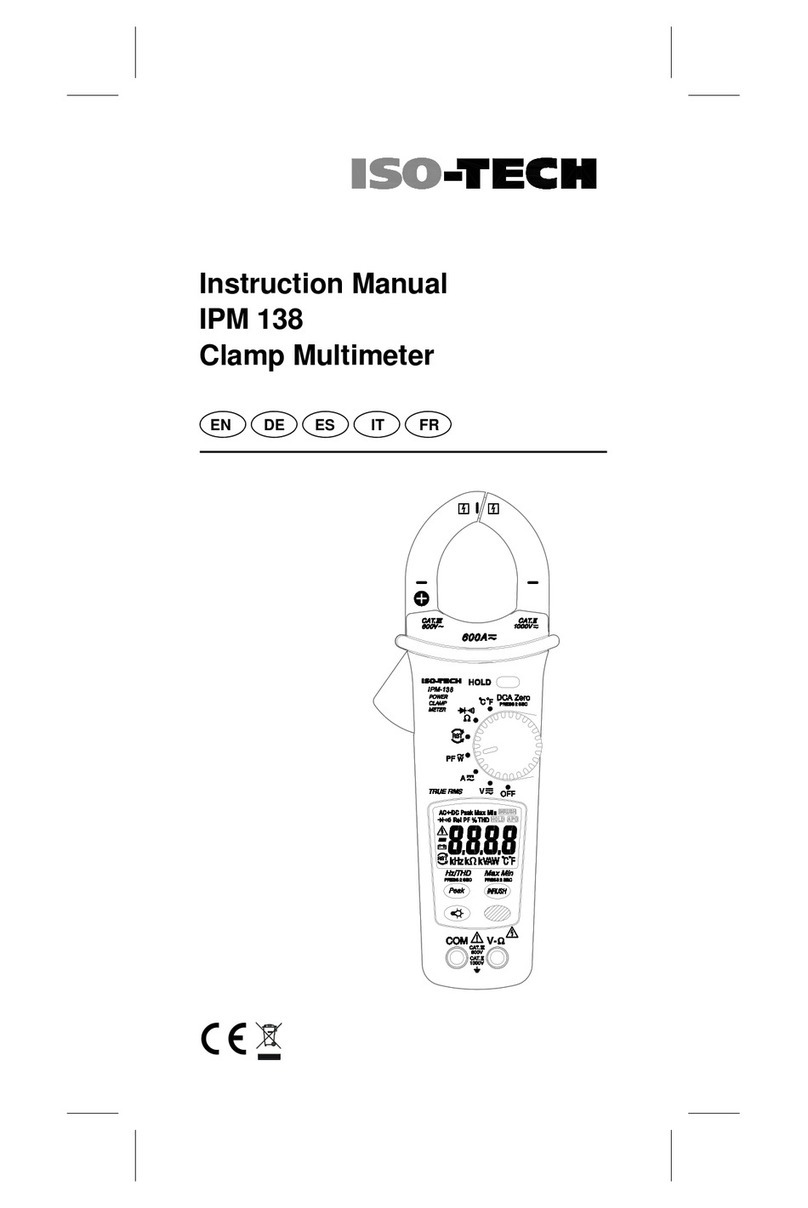

Isotech IPM 138 User manual

Isotech

Isotech IDM17 User manual

Isotech

Isotech IDM63N User manual

Isotech

Isotech IDM5 User manual

Isotech

Isotech IDM 91E User manual

Isotech

Isotech IDM61 User manual

Isotech

Isotech IDM201N User manual

Isotech

Isotech IDM 91E User manual

Isotech

Isotech IDM-8341 Series User manual

Isotech

Isotech IDM 103N User manual

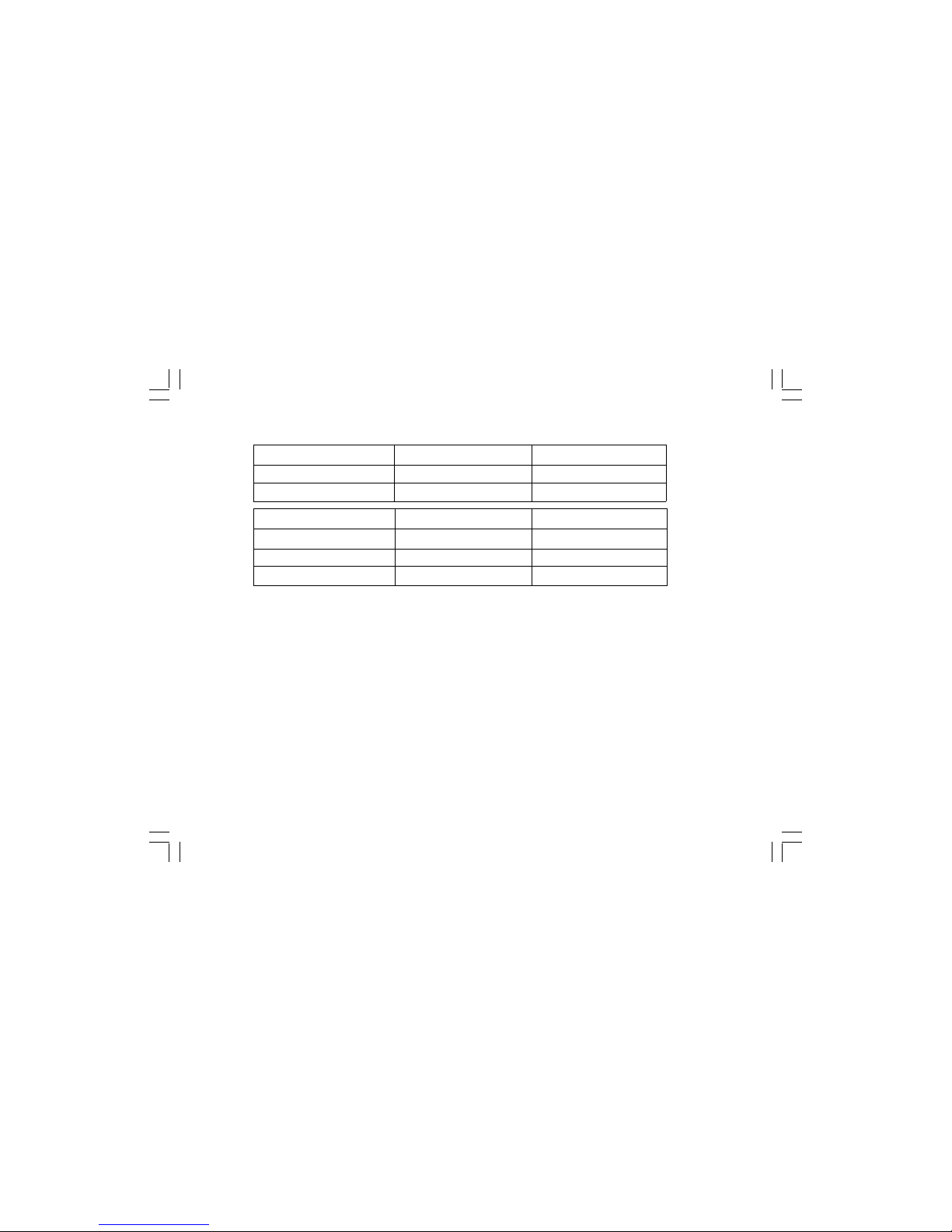

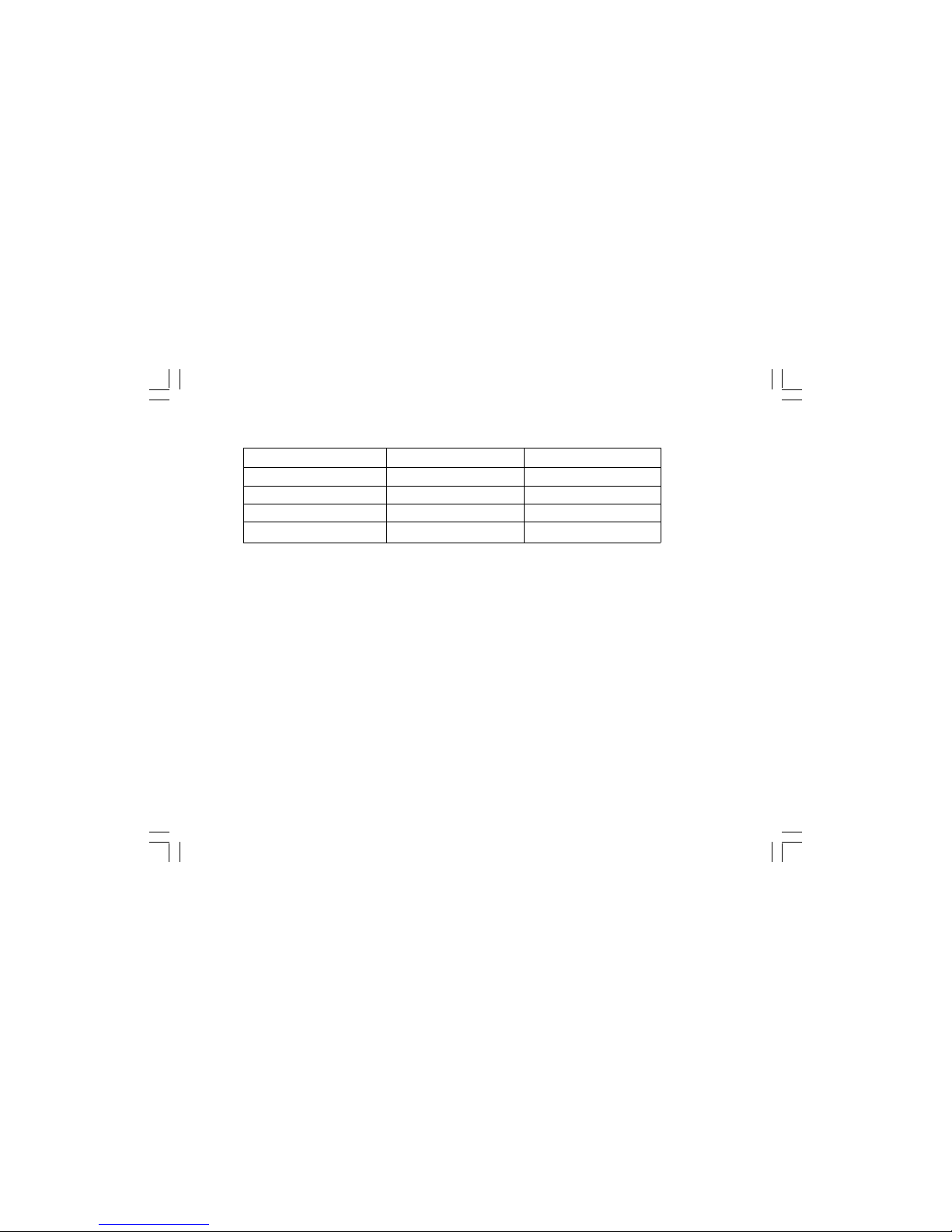

Popular Multimeter manuals by other brands

Gossen MetraWatt

Gossen MetraWatt METRAmax 6 operating instructions

PeakTech

PeakTech 4000 Procedure of calibration

YOKOGAWA

YOKOGAWA 90050B user manual

Gossen MetraWatt

Gossen MetraWatt METRALINE DMM16 operating instructions

Fluke

Fluke 8846A Programmer's manual

Tempo Communications

Tempo Communications MM200 instruction manual