FOREWORD

Congratulations, and thank you for buying an A.D.

Boivin design inc. Snow Hawk™ vehicle. We

appreciate the confidence in our product that you

have demonstrated by making this purchase.

Several years of design, tests and improvements

were necessary to produce this vehicle which

combines performance, driving pleasure and safety.

Proper maintenance on a regularly-scheduled basis is

essential in order to obtain the performance you have

the right to expect from your machine. In this manual,

you will find all the information needed for adjustments

to and the maintenance of this vehicle.

We sincerely hope that you will have many years of

enjoyment with your Snow Hawk™.

A D Boivin design inc.

All the information, illustrations, photographs and

specifications found in this manual are based on the

latest available data at the time of publication. Due to

improvements or other changes, it is possible that

you will note a few differences. A D Boivin design

reserves the right to make changes at any time.

WARNING /CAUTION / NOTICE

Please read this manual and follow the instructions

carefully. Pay particular attention to the boxes

entitled WARNING and CAUTION as well as to the

paragraphs preceded by the word NOTICE.

WARNING

This symbol is designed to call attention to

particular instructions and procedures, which,

if not followed to the letter, could cause injury

and even fatal accidents.

tt CAUTION

This symbol is designed to call attention to

particular instructions and procedures, which,

if not followed to the letter, could cause

damage to or even destruction of the vehicle.

lNOTICE:

The information in the NOTICES is designed to

explain maintenance procedures and to ensure the

best possible use of the vehicle.

IMPORTANT REMARKS

Using this vehicle can be a very pleasurable

experience and we wish you all the enjoyment that it

can bring you. However, if certain rules are not

respected, this sport can become a source of

environmental problems and of interpersonal

conflicts.

Adopting a responsible attitude and behaving in a

responsible manner at all times will help avoid such

problems and conflicts.

PROTECT THE FUTURE OF YOUR SPORT. BE

SURE TO RESPECT THE RULES AT ALL TIMES.

DEMONSTRATE AN AWARENESS OF THE

IMPORTANCE OF THE ENVIRONMENT AND

RESPECT THE RIGHTS OF OTHERS.

WARRANTY

1. All the parts of this vehicle are covered by the

warranty for a period of one winter season

against any problem related to its assembly

or construction.

2. The labour costs of repairs covered by the

warranty are the responsibility of the vehicle

owner.

3. The company reserves the right to require

that the dealer carrying out the repairs send

back any parts declared defective.

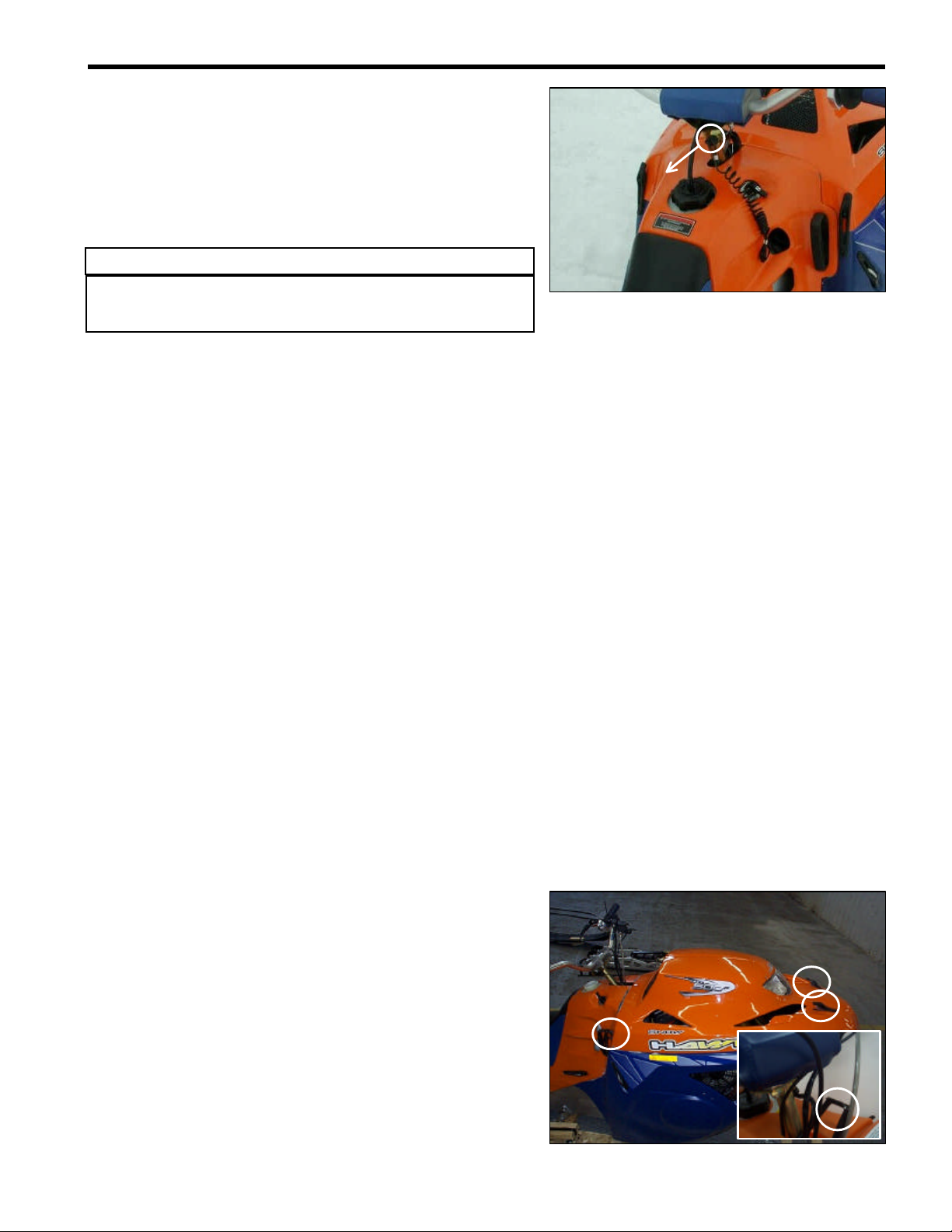

LOCATION OF THE V.I.N.