AD Boivin 2002 Snow Hawk User manual

2002-03

Set-up, service and repair

Manual

Snow Hawk™

HIGH ALTITUDE TECHNICAL DATA

1

700, rue Jean-Marchand

Lévis , QC Canada G6V 9G6

Tél.: (418) 838-3783 Fax.: (418) 838-3957

Web site: www.adboivin.com

2002 Snow Hawk Hi-Altitude Carburetor and Clutching Set-up:

GENERAL

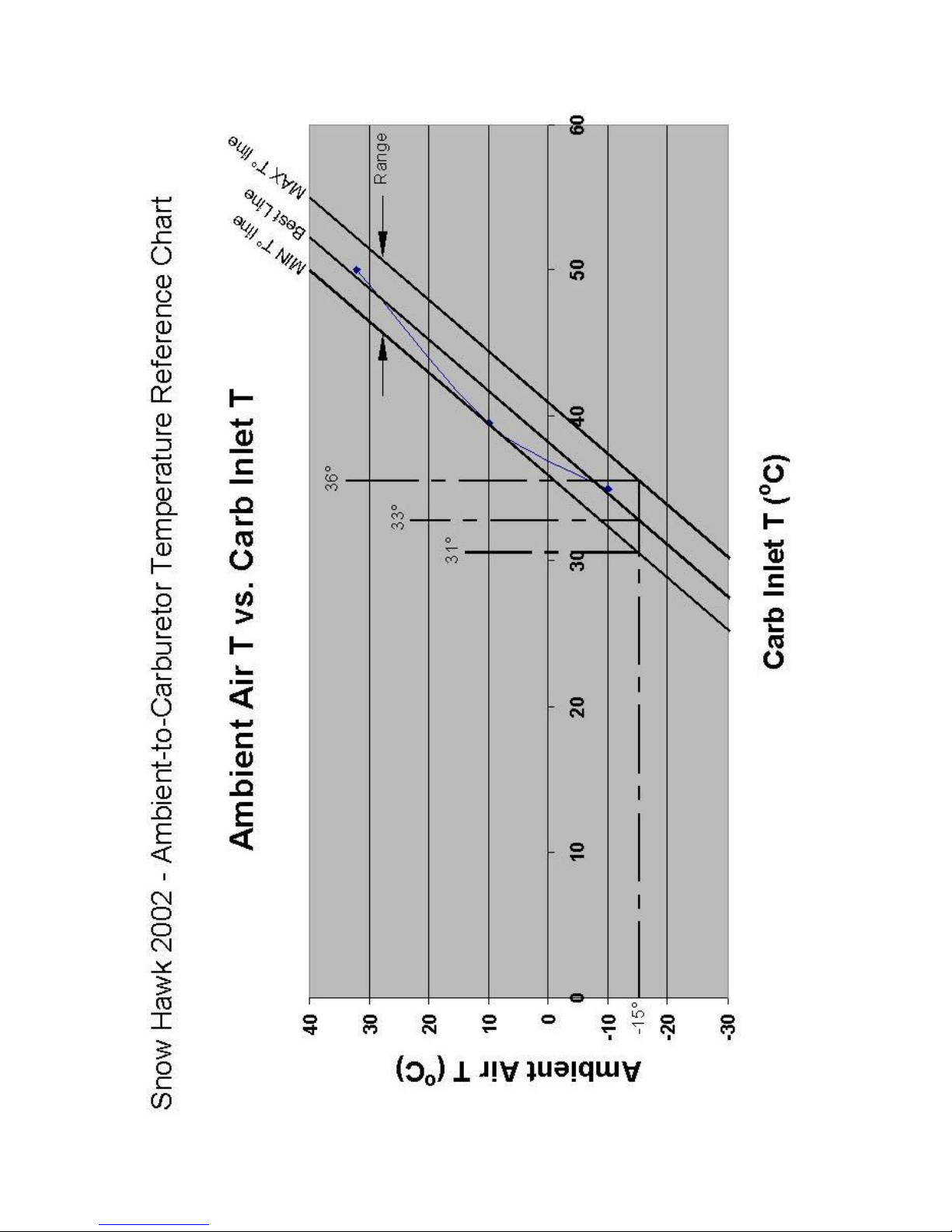

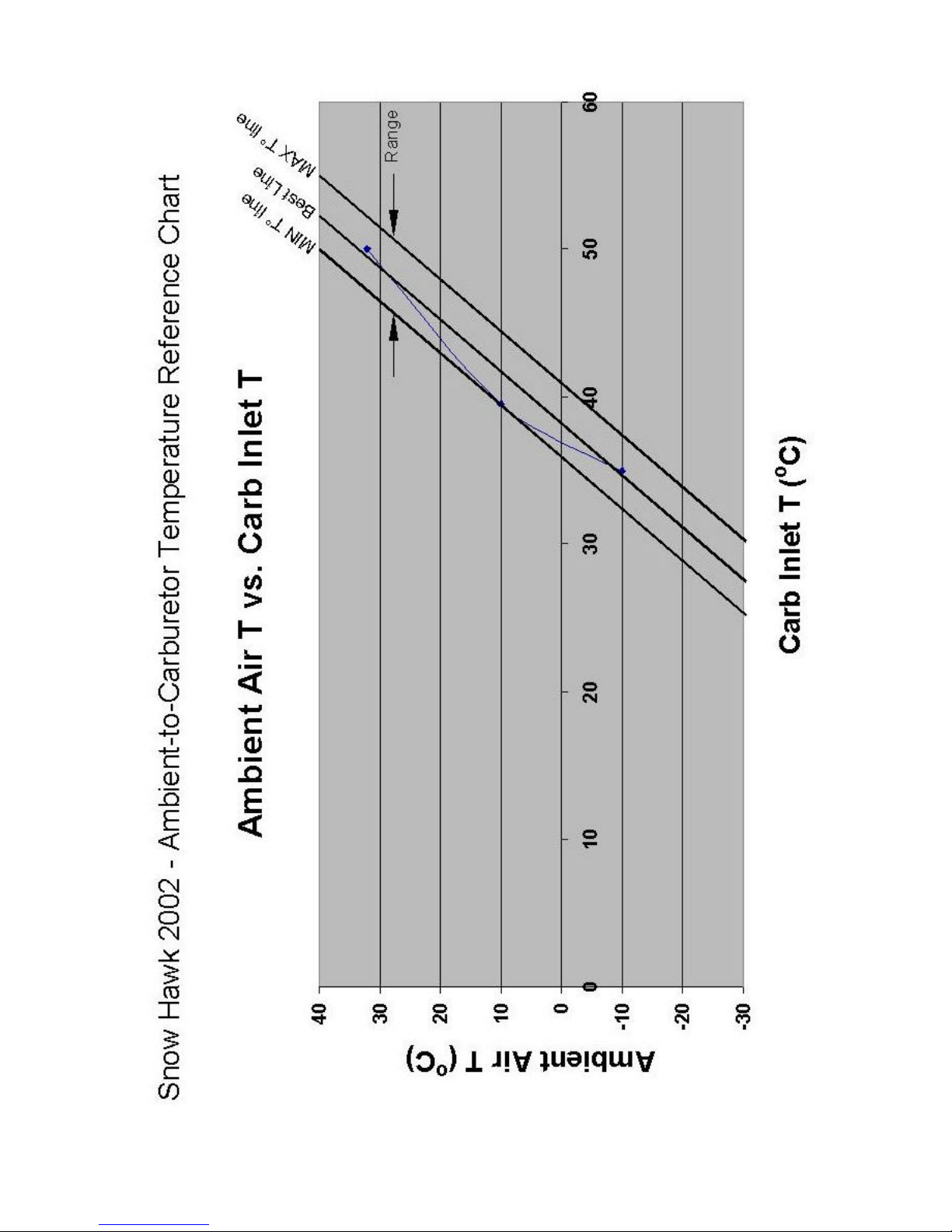

Since the 2002 Snow Hawk uses individual carburetor filters, carburetor inlet temperature is not

always the same as outside temperature, thus jetting is not. Influences from engine heat and

the exhaust system have a tendency to increase the engine bay temperature relative to outside

air temperature. We have plotted their approximate relationship in the graph shown on the

fourth page of this guide.

PROCEDURE -JETTING

How to use the Jetting chart:

1.Measure the outside (ambient) air temperature

2.Determine the altitude at your location

3.Using the chart on page four of this guide, determine the range of temperatures at the

carb inlet by first drawing a horizontal line to the right, away from the vertical ambient air

temperature axis.

4.Second, draw a vertical line upwards from each of the intersection points where the

horizontal line crosses over the Best Line, the MIN Toline and the MAX To line.

5.The temperature values where each of these vertical lines intersect the horizontal carb

inlet temperature axis are the approximate min, median and max temperatures that are

normally found at the carb inlet during normal operation at the specified outside air

temperature.

6.Adjust jetting set-up according to the carb inlet temperature given by the intersection of

the Best Lineand the ambient air temperature line.

7.After a short trial run, observe the plug color and performance feel of the vehicle closely.

If the mixture is too rich, try jetting according to the MAX Toline; If the mixture is too

lean, try jetting according to the MIN Toline.

8.The correct set-up will normally lie in this range.

9. An example is shown on page three of this guide where the outside air temperature

(ambient) is shown as –15oC. The resulting approximated carb inlet temperature ranges

from 31oC(minimum carb inlet temperature) to 36oC(maximum carb inlet temperature)

with the best approximation of the carb inlet temperature at 33oC.

NOTE: This set-up is a recommendation only. It is the responsibility of the owner to pay close

attention to spark plug color and engine performance when modifying the stock set-up to avoid

lean burn-down.

2

PROCEDURE –CLUTCHING

As a rule of thumb, it is recommended to remove one weight from each arm of the primary clutch

for each 2000ft increase in elevation. As a reference, the sea level (0 ft elevation) set-up has

nine weights at each of the three primary clutch arms.

3

4

5

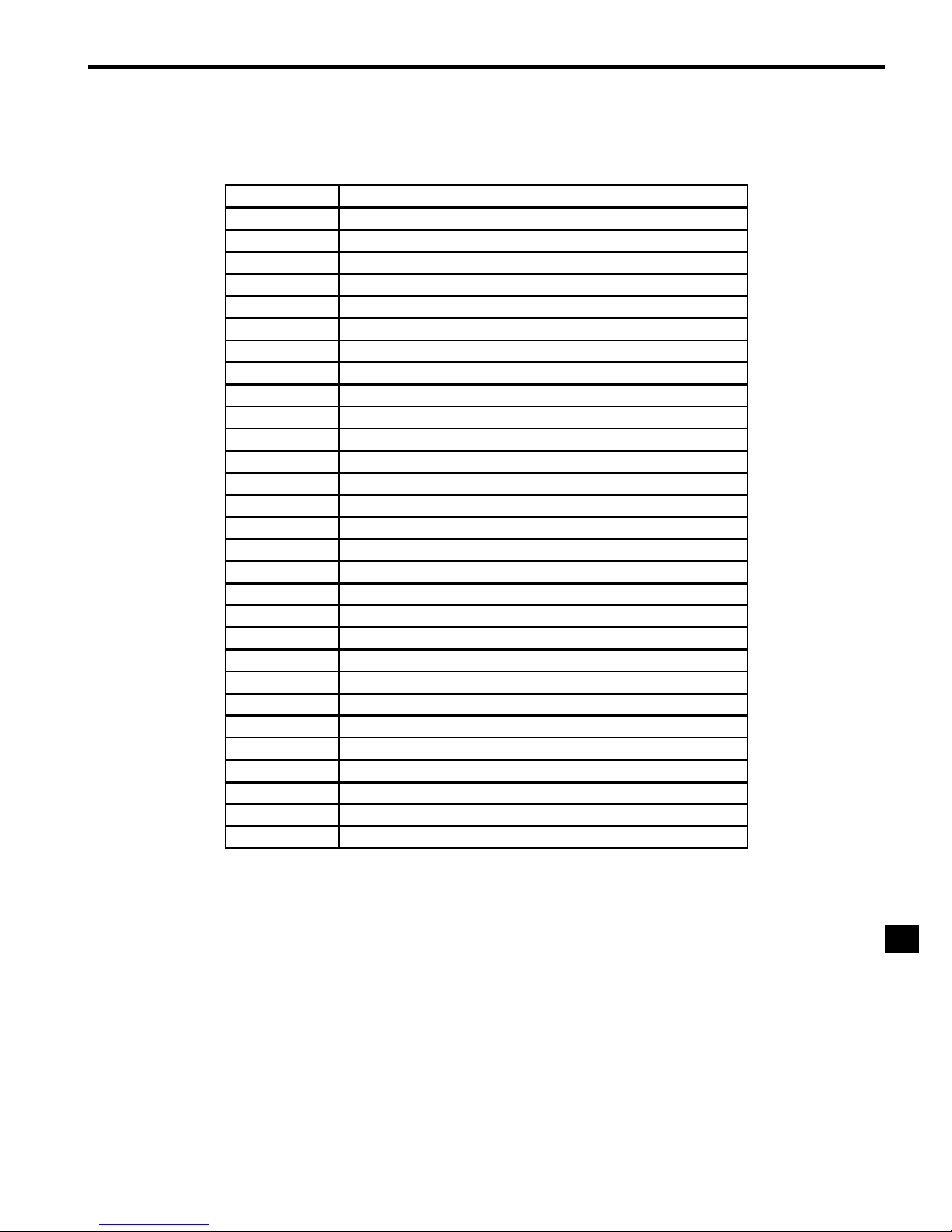

MAIN JET CHART

@CARB

°C 01000 2000 3000 4000 5000 6000 7000 8000 9000 10000 Feet

°F

0

305

610

914

1219

1524

1829

2134

2438

2743

3048

Meter

20 230 220 220 210 200 190 180 180 170 160 160 PTO

68

220

210

200

190

190

180

170

160

160

150

150

MAG

25 230 220 210 200 190 190 180 170 170 160 150 PTO

77

210

210

200

190

180

170

170

160

150

150

140

MAG

30 220 220 210 200 190 180 180 170 160 150 150 PTO

86

205

200

200

190

180

170

170

160

150

150

140

MAG

35 220 210 200 190 190 180 170 160 160 150 140 PTO

95

210 200 190 190 180 170 160 160 150 140 140

MAG

40 210 210 200 190 180 170 170 160 150 150 140 PTO

104

200 200 190 180 170 170 160 150 150 140 130

MAG

45 210 200 190 180 180 170 160 150 150 140 140 PTO

113

200

190

180

180

170

160

150

150

140

140

130

MAG

50 200 190 190 180 170 160 160 150 140 140 130 PTO

122

190

190

180

170

160

160

150

140

140

130

130

MAG

NOTE: These values are suggestions only, tuners are reminded to pay very close attention to plug color and performance

feel in order to avoid lean burndown.

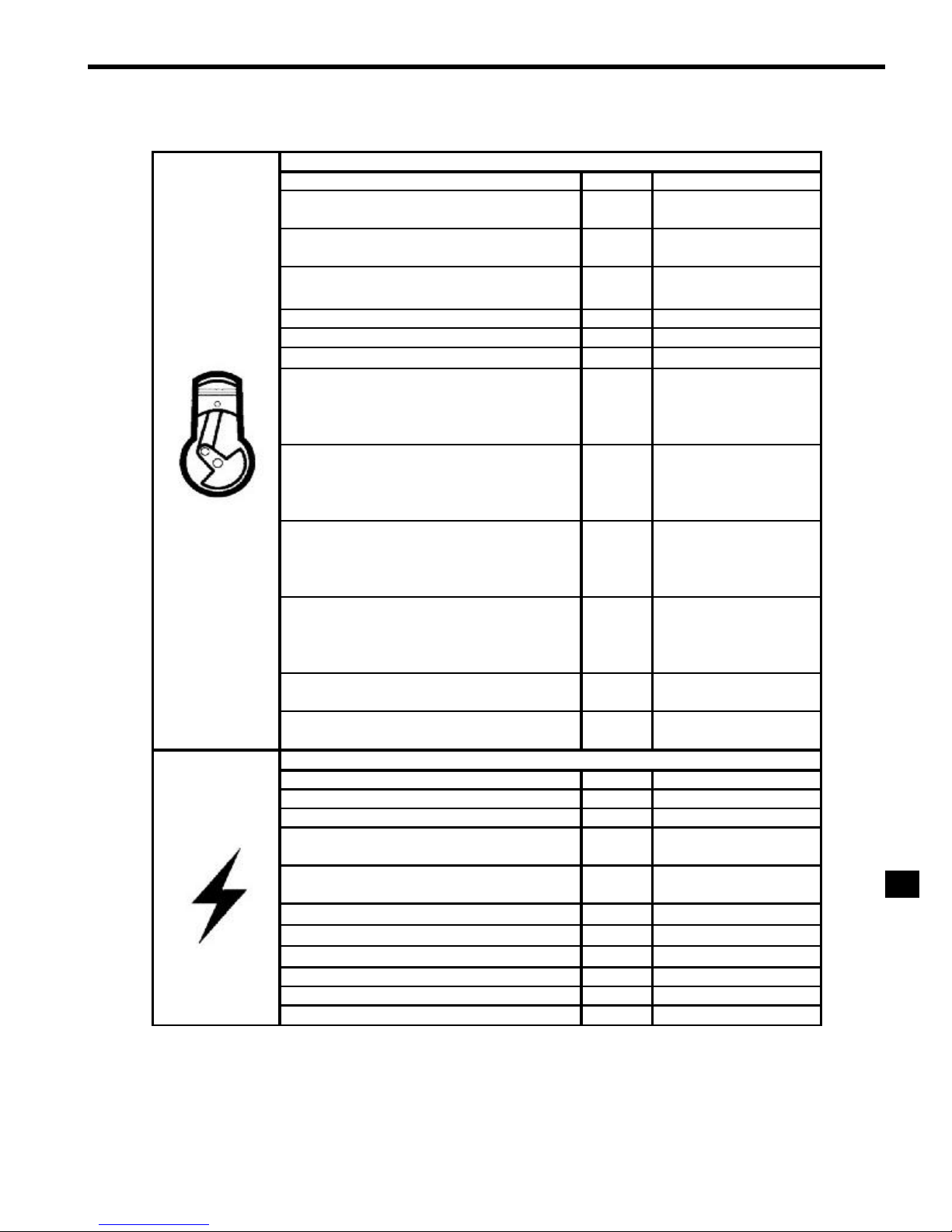

PILOT JET CHART

@CARB

°C 01000 2000 3000 4000 5000 6000 7000 8000 9000 10000 Feet

°F

0

305

610

914

1219

1524

1829

2134

2438

2743

3048

Meter

20 65 60 60 55 55 55 50 50 45 45 45 PTO

68

65

60

60

55

55

55

50

50

45

45

45

MAG

25 65 60 60 55 55 50 50 50 45 45 40 PTO

77

65

60

60

55

55

50

50

50

45

45

40

MAG

30 60 60 55 55 55 50 50 45 45 45 40 PTO

86

60

60

55

55

55

50

50

45

45

45

40

MAG

35 60 60 55 55 50 50 45 45 45 40 40 PTO

95

60

60

55

55

50

50

45

45

45

40

40

MAG

40 60 55 55 50 50 50 45 45 40 40 40 PTO

104

60

55

55

50

50

50

45

45

40

40

40

MAG

45 60 55 55 50 50 45 45 45 40 40 40 PTO

113

60

55

55

50

50

45

45

45

40

40

40

MAG

50 55 55 50 50 45 45 45 40 40 40 35 PTO

122

55

55

50

50

45

45

45

40

40

40

35

MAG

NOTE: * When the difference between suggested pilot jet size is less than 15, the correction can be made through airscrew adjustment.

*Shaded areas indicate stock set-up

TUNING: *The "zero setting" for a pilot jet is with the airscrew set to 1.5 turns out from full tight (I.e. zero position).

*To effectively reduce the size of a pilot jet, turn the airscrew further out; 1/4 turn outwards [CCW] is equal to reducing a pilot

jet one size, or equivalently reducing the jet number by 5.

*Airscrew range of adjustment varies from 1 to 3 turns outwards. 1 to 2 turns outwards is optimal.

SPECIFICATIONS 18 - 1

ENGINE

SNOW HAWK SPECIFICATIONS

Engine type

SUSPENSION

IBC Formula, cam on countershafti

7100 RPM

3450 RPM

304.8 (mm) / 11.9 (in)

28

56

No. of cylinders

Displacement

Bore

Stroke

Carburation

Exhaust Sytem

DRIVE SYSTEM

Primary clutch

Secondary clutch

Max RPM

Engagement

Clutch C-C distance

Upper sprocket - # teeth

Lower sprocket - # teeth

Drive sprocket diameter

Brake system

Secondary transmission

61 (mm) / 2.4 (in)

2 x Mikuni VM 34 ( choke )

Tuned pipe and silencer

IBC Power Bloc

Rotax 503, fan cooled, piston port

2

496.7 (cc) / 30.3 (in3)

72 (mm) / 2.8 (in)

High efficiency cog belt (8mm)

177 (mm) / 6.9 (in)

Brembo; floating 34 mm twin piston on 175 mm disc

308 (mm) / 12 (in)

385 (mm) / 15 (in)

PAIOLI 46mm inverted fork - adj. rebound and compression damping

A.D. Boivin EXPERT " X " c/w rebuildable Kayaba HPG shocks

Front suspension

Vertical Travel

Rear Suspension

Vertical Travel

SPECIFICATIONS

18

SPÉCIFICATIONS 18 - 2

UHMW polyethylene

Color Blue / Orange

Bellypan

Ski

87

Bombardier pre-mix oil

240W @ 6000 RPM

HMW Polyethylene

308 (mm) / 12 (in)

350 (lbs) / 160 (kg)

920 (mm) / 35.8 (in)

Pre-mix 40 : 1

860 (mm) / 33.5 (in)

283 (mm) / 11 (in)

257 (mm) / 10 (in)

Official dry weight

Ski length

Ski width

835 (mm) / 32.5 (in)

1233 (mm) / 48 (in)

2698 (mm) / 105 (in)

DIMENSIONS

Overall length

Headlight high/low beam

MATERIALS

Chassis

Hood

2 x 30 / 30 W

6061-T6 Aluminium

HMW Polyethylene

Recommended fuel

Recommended octane level

Recommended oil

Electrical output ( AC )

Nominal track length

Lug height

CAPACITIES

Fuel capacity

58 (mm) / 2.25 (in)

17.5 (liters) / 4.5 (US gal)

3074 (mm) *3495* (mm) / 121 (in) *136* (in)

Nominal track width

Seat height

Overall width

Overall height

Ground clearance

WIRE, CABLE AND HOSE ROUTING 17-1

1

1

2

3

4

1

2

3

WIRE, CABLE AND HOSE ROUTING

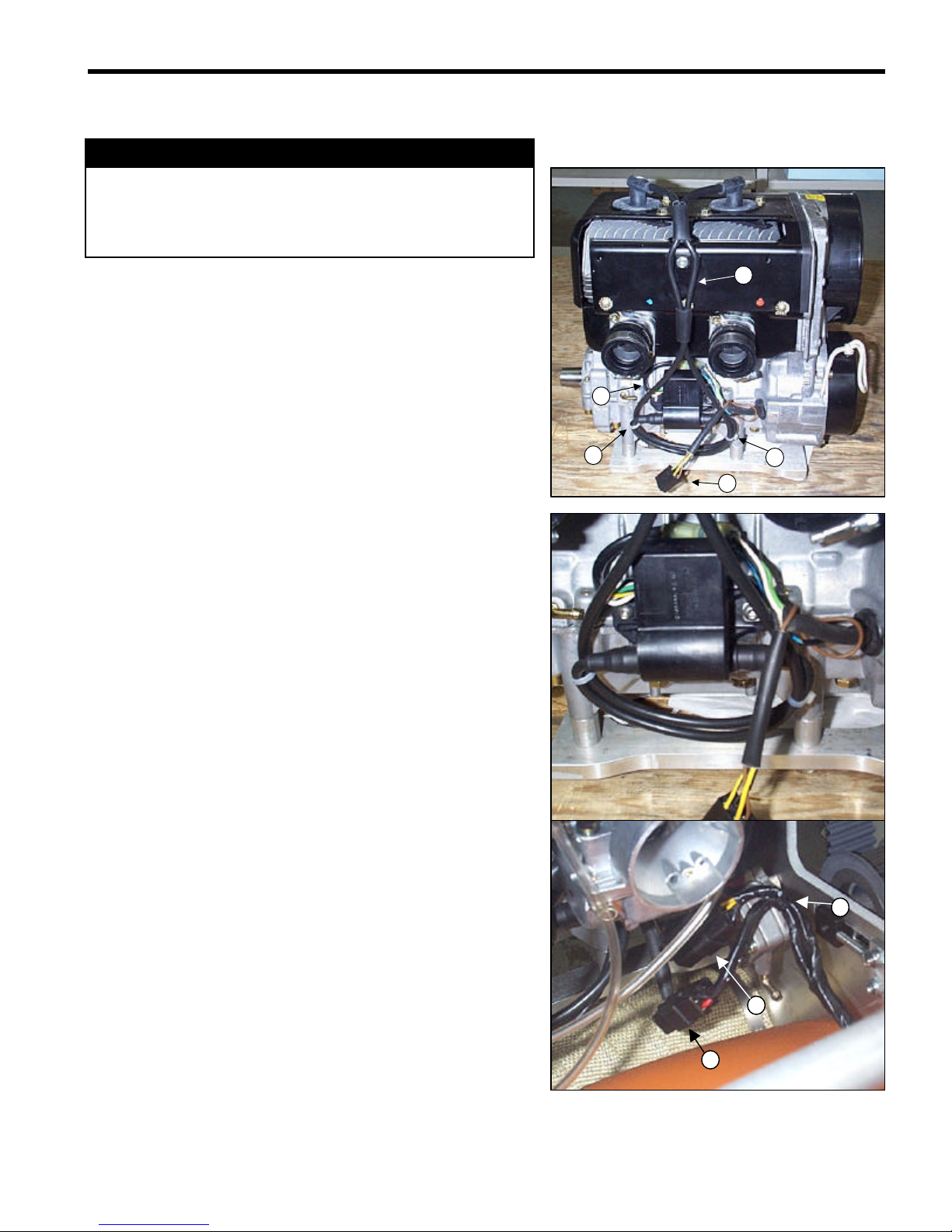

uu WARNING

Make sure that all the wires are well set in the terminals

and that the connector holders are well installed. Keep

the wires away from any rotating, moving, heating or

vibrating part. If necessary, use good retaining devices.

When reassembling, it is important to always re-install the wires

to the stock positions.

SPARK PLUG WIRES AND ELECTRONIC BOX

1-Nylon fasteners

2-Electronic box wires

3-Spark plug wires

4-Engine electrical power output

When replacing the electronic box or the spark plug wires, it is

important that the wires be put back in the stock arrangement.

The connecting wire for the electronic box (No. 2) and the two

spark plug wires (No. 3) must be installed in the way shown in

the photograph.

Use two tie wraps (No. 1) to keep the spark plug wires in place.

ROUTING THE WIRES

1-Connection to the voltage regulator

2-Connection to the engine power source

3-Tie wrap

Using a tie wrap, attach the two bundles of wires together to the

empty hole in the fuel pump.

WIRE, CABLE AND HOSE ROUTING 17-2

2

1

2

8

3

8

4

8

1

8

Under the transversal shaft (No. 1) of the chassis, the wiring

separates into two segments, one going toward the front of the

vehicle and the other going toward the back

Using a tie wrap, secure the wiring that goes toward the front of

the vehicle in the cable attachment (No. 2).

2-Nylon cable attachment

uu WARNING

It is important that the wires be installed exactly where

they are intended to avoid interference during operation.

(Refer to the photograph on the right)

The section of the wiring harness going toward the rear of the

vehicle must pass under the gas tank bracket.

1-Tie wrap

2-Adhesive nylon cable fastener

3-Safety fuse

4-Tail light connection

Using a tie wrap, secure the wiring in the adhesive nylon

fastener (No.2).

Position the fuse (No. 3) correctly in the connector holder.

Using a tie wrap, secure the wiring harness to the two holes.

(Refer to the photograph on the right -No. 1).

WIRE, CABLE AND HOSE ROUTING 17-3

1

B

A

E

C

D

1

2

c

1

C

D

E

The forward wiring section comes up inside the steering column

plate of the vehicle and is anchored with a tie wrap in the nylon

cable fastener (No. 1).

1. Nylon cable fastener

After the nylon cable fastener, the wiring divides into five

segments (A-E).

Secure the accessories wire to the wire for the headlight, using

a tie wrap (No. 1).

Join the wire for the headlight to the accelerator cable, using a

nylon fastener (No. 2).

A-Headlight wire

B-Accessories wire

C-Engine cutoff and emergency stop

D-Stop lamp microswitch

E-Dimmer switch

Bring together the wires of the switch for the lights (E), of the

switch for the stop light (D) of the engine cutoff and emergency

stop (C) and the accelerator cable, and join them using a nylon

fastener (No. 1).

The wires for the engine cutoff and the emergency stop

separate into two segments after the junction of wires in No. 1.

C-Emergency stop

c-Engine cutoff

Place the wires for the emergency stop, the switch for the stop

light, and the switch for the lights under the protective cushion

(see the photograph).

The cab

Nylon fasteners anchor the cab wiring in three places:

WIRE, CABLE AND HOSE ROUTING 17-4

3

1

2

1

2

1

1

1. On the retaining screw of the light (No. 1)

2. On the protective screen (grille) (No. 2)

3. On a nylon cable attachment secured to the back

protective screen (grille) of the cabin (No. 3).

CABLE ROUTING

Throttle cable

oThe throttle cable is secured in the accelerator (No. 1).

oPass the cable in front of the handlebars.

oUsing a cable collar, attach the accelerator cable to the

retaining screw of the steering column (No. 2).

uu WARNING

Before installing them, make sure the cables are in good

condition. Install the ends of the cables carefully and

secure them solidly in place. Make sure they are routed

where they should be and keep them away from any

rotating, moving, heating or vibrating part.

The accelerator cable divides into two cables, one for each

carburetor (No. 1).

(See section 3, Fuel System, for instructions on installing the

throttle cable on the carburetors.)

Choke cables

oInstall the choke cables in the part that holds the cables

up (No. 1).

WIRE, CABLE AND HOSE ROUTING 17-5

1

1

2

3

oRun the cables along the gas tank and pass them

through the hole in the plate of the steering column (see

the arrow on the photograph).

oPass the choke cables under the electric wires and over

the carburetor cables.

oThen install the choke cables on the carburetors.

lNOTICE:

One of the two choke cables is longer than the other. Install it

on the carburetor that is farther away.

Recoil starter cord

oPass the recoil starter cord over the pulley (No. 1).

oThen pass it under the pulley (No. 2).

oThen pass the cord through the guide ring (No. 3).

oInstall the starter handle.

WIRE, CABLE AND HOSE ROUTING 17-6

1

1

HOSE ROUTING

uu WARNING

Always make sure that the conduits are well secured to

the connectors, that they are neither perforated nor

mixed-up, and that they are well positioned, far from any

rotating, moving, heating or vibrating parts. In addition,

check to make sure there are no leaks. Replace them if

necessary.

Brake hose

oThe brake hose is secured to the brake master cylinder.

oPass the hose in front of the handlebars and steering

column.

oThe hose then goes down behind the steering column

plate.

oThe brake hose is attached along the plate of the

steering column with two tie wraps (No. 1).

oThe hose then goes outside the chassis through the

hole on the left side, near the brake system.

oThe hose is then secured to the calliper.

WIRE, CABLE AND HOSE ROUTING 17-7

4

2

3

1

3

2

5

Vacuum

Fuel feeder lines:

The fuel pump (No. 1) has two intakes and two outlets.

The two intakes are:

1. The gas tank feed (No. 4)

2. The vacuum (No. 2)

The two outlets are:

1. The carburetor feed on the MAG side (No. 3).

2. The carburetor feed on the PTO side (No. 5).

After leaving the pump, the vacuum hose goes along the base of

the engine under the two carburetor intake adapters.

The hose is installed onto in the vacuum fitting at the base of the

engine.

Make sure the spring clamp is well installed to ensure an airtight

seal.

WIRE, CABLE AND HOSE ROUTING 17-8

3

5

2

1

1

1

1

Hose (No. 3) passes under the choke cable and the throttle

cable, and connects to the MAG side carburetor.

Hose (No. 5) passes along the base of the engine housing and

over the two carburetor intake adapters. It goes around the

throttle cable and the choke cable, and connects to the PTO

side carburetor.

Carefully install all the spring clamps.

Overflow hose and carburetor vent hoses

The overflow hose is connected to the cap of the gas tank. It is

then routed down through the steering column tube.

The overflow hose (No. 2) comes out at the end of the steering

column and passes between the two carburetors.

The carburetor vent hoses (No. 1) and the overflow hose (No. 2)

are grouped together and pass outside the chassis through a

hole near the brake system.

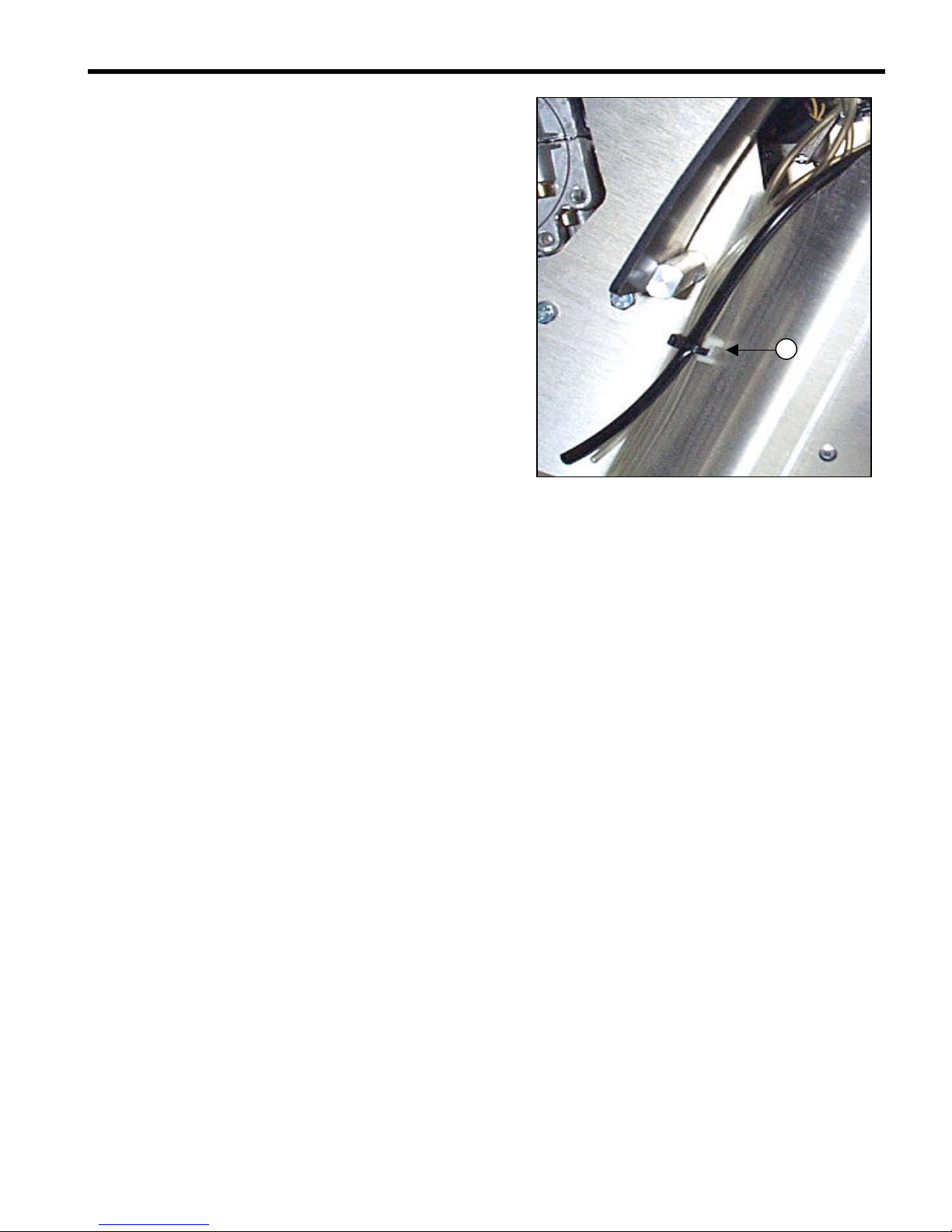

WIRE, CABLE AND HOSE ROUTING 17-9

3

The hoses go along the chassis and are attached to the nylon

cable fastener by a tie wrap.

SPECIAL TOOLS 16 -1

P/N Item Description

X-1756 Primary Clutch Puller

529 027 300 Spring Compressor

43990092 Belt Tensioning Tool

529 027 600 Primary Clutch Tool

529 031 103 Application Plate

529 031 102 Extractor

529 031 200 Secondary slider installation tool

529 031 300 Secondary slider installation tool

529 008 700 Secondary belt changing tool

404 112 000 Mikuni VM Toolkit

529 009 900 Hose Pinch Clamp

420 876 357 Cooling Fan Nut Removal Tool

529 021 000 Piston Wrist Pin Extractor

529 023 400 Rubber Cushion

529 016 900 Piston Circlip Installation Tool

420 876 970 Piston Ring Compressor

413 701 000 Anti-Seize Compound

420 876 620 Thickness Gauge

420 876 824 Positioning Gauge

413 708 100 Curing Spray

449.450.020 A.D Boivin Complete Fork Servicing Toolkit

949.000.046 Fork Top Cap Tool

949.000.045 Fork Cartridge Removal Tool

949.000.016 Fork Seal Drivers

08-0B75 Needle Adapter

413 709 400 Kayaba Shock Oil

420 876 080 Stator plate puller

529 022 500 Magneto puller

419 003 300 Ignition timing tester

SPECIAL TOOLS

16

DIMENSIONS AND TOLERANCES 15 -1

ENGINE

Engine type Rotax 503

Bore mm 72.00

(in) (2.835)

Stroke mm 61.00

(in) (2.402)

Displacement cm

3

496.70

(in

3

)

(30.31)

Compression Ratio 6.20

Max RPM Range 7000-7200

Piston ring type (1

st

, 2

nd

)

ST/R

Piston ring opening (new) mm 0.2

(in) (0.008)

(wear limit) mm 1.00

(in) (0.039)

Piston ring/groove play (new) mm 0.04

(in) (0.0016)

(wear limit) mm 0.2

(in) (0.008)

Piston/Cylinder play (new) mm 0.08

(in) (0.031)

(wear limit) mm 0.2

(in) (0.008)

Maximum connecting rod axial play (new) mm 0.2

(in) (0.008)

(wear limit) mm 1.00

(in) (0.039)

Maximum crankshaft axial play mm 0.3

(in) (0.018)

Maximum crankshaft curvature mm 0.08

(in) (0.031)

ELECTRICAL

Magneto output W240

Ignition type CDI

Spark plug type NGK BR9ES

Spark plug gap mm 0.45

(in) (0.018)

Ignition timing before TDC mm 1.66

(in) (0.065)

Primary lgnition coil

W

230 - 330

Lighting coil

W

0.23 - 0.28

Secondary Ignition coil

W

5.1 - 6.3

Head lamp bulb W30/30

Tail lamp bulb W18/23

Fuse A25

DIMENSIONS AND TOLERANCES

15

Table of contents

Other AD Boivin Offroad Vehicle manuals