ADADVANCED Motion Controls DigiFlex Performance Assembly instructions

Everything’s possible.

www.a-m-c.com

Hardware Installation Manual

DigiFlex® Performance™ DPP Drives

POWERLINK / Modbus TCP / Ethernet Communication

MNDGDPIN-06

ORIGINAL INSTRUCTIONS

MNDGDPIN-06 ii

Preface

ADVANCED Motion Controls constantly strives to improve all of its products. We review the information in

this document regularly and we welcome any suggestions for improvement. We reserve the right to modify

equipment and documentation without prior notice.

For the most recent software, the latest revisions of this manual, and copies of compliance and

declarations of conformity, visit the company’s website at www.a-m-c.com. Otherwise, contact the

company directly at:

ADVANCED Motion Controls •3805 Calle Tecate Camarillo, CA •93012-5068 USA

Agency Compliances

The company holds original documents for the following:

•UL 508c, file number E140173

•Electromagnetic Compatibility, EMC Directive - 2014/30/EU

EN61000-6-2:2005

EN61000-6-4:2007/A1:2011

•Electrical Safety, Low Voltage Directive - 2014/35/EU

EN 60204-1:2006/A1:2009

•Reduction of Hazardous Substances (RoHS II), 2011/65/EU

•Functional Safety Type Approved, TUV Rheinland

Trademarks

ADVANCED Motion Controls®, the combined isosceles trapezoid/right triangle logo, DIGIFLEX®,

DIGIFLEX® Performance™ and DriveWare® are either registered trademarks or trademarks of ADVANCED

Motion Controls in the United States and/or other countries. All other trademarks are the property of their

respective owners.

Related Documentation

•Product datasheet specific for your drive, available for download at www.a-m-c.com

•DriveWare Software Guide, available for download at www.a-m-c.com

•POWERLINK Communication Manual, available for download at www.a-m-c.com

•Modbus Communication Manual, available for download at www.a-m-c.com

•Ethernet Communication Manual, available for download at www.a-m-c.com

/

iii MNDGDPIN-06

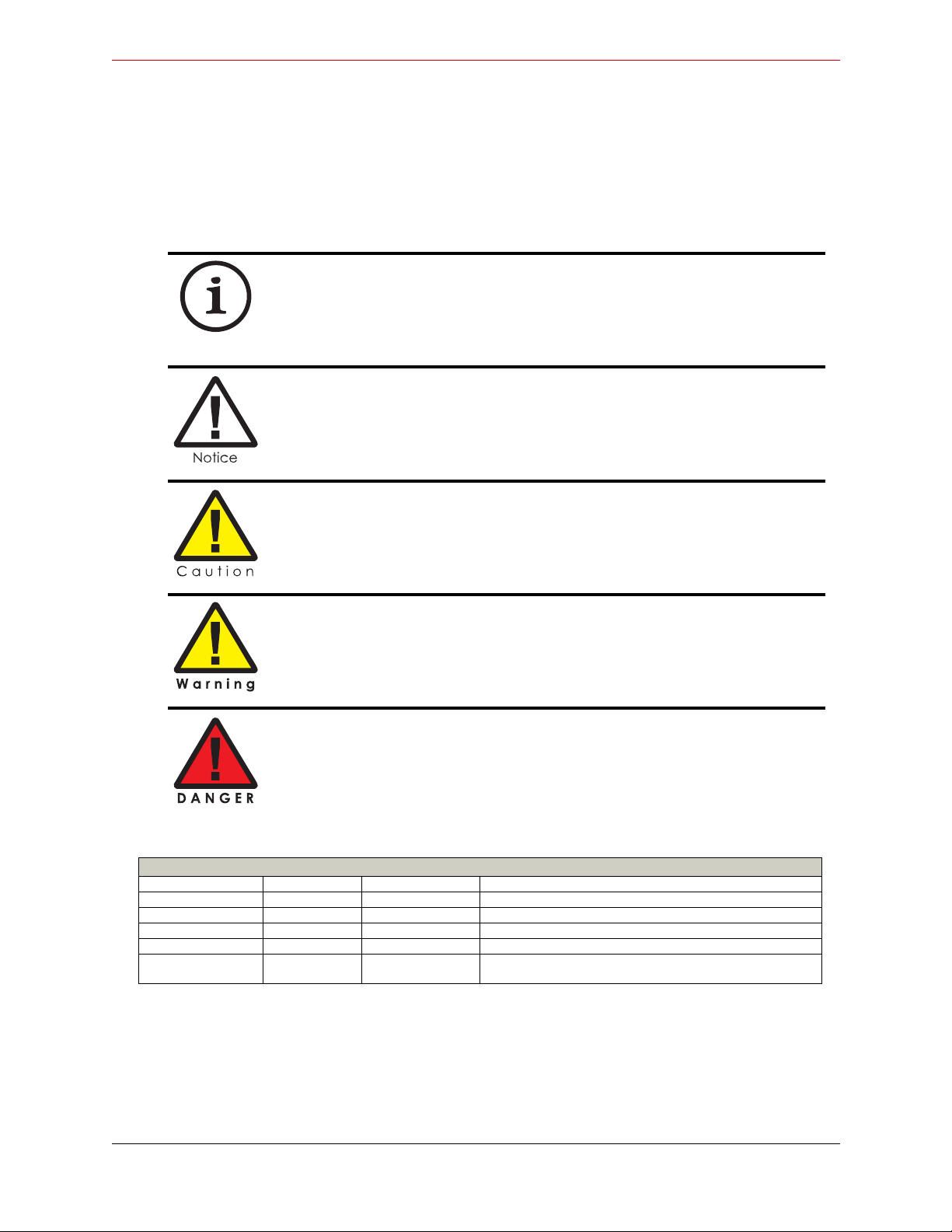

Attention Symbols

The following symbols are used throughout this document to draw attention to important operating

information, special instructions, and cautionary warnings. The section below outlines the overall directive

of each symbol and what type of information the accompanying text is relaying.

Revision History

Document ID Revision # Date Changes

MNDGDPIN-01 13/2015 DPP Install Manual First Release

MNDGDPIN-02 210/2015 Added Ethernet POWERLINK as a supported network communication type

MNDGDPIN-03 33/2016 Added -040A400 power module information

MNDGDPIN-04 44/2017 Added -030A800 and -060A800 power module information

MNDGDPIN-05 511/2017 Added -100B080 power module information

MNDGDPIN-06 65/2018 - Added 2-Phase Stepper motor information

- Added PDO power-up delay information

© 2018 ADVANCED Motion Controls. All rights reserved.

Note - Pertinent information that clarifies a process, operation, or ease-

of-use preparations regarding the product.

Notice - Required instruction necessary to ensure successful completion

of a task or procedure.

Caution - Instructs and directs you to avoid damaging equipment.

Warning - Instructs and directs you to avoid harming yourself.

Danger - Presents information you must heed to avoid serious injury or

death.

Note

MNDGDPIN-06 iv

Contents

1 Safety 1

1.1 General Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Products and System Requirements 4

2.1 DPP Drive Family Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1.1 Drive Datasheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Products Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2.1 Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Communication Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Control Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.1 Profile Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Profile Current (Torque) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Profile Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Profile Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.2 Cyclic Synchronous Modes . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cyclic Synchronous Current . . . . . . . . . . . . . . . . . . . . . . . . 10

Cyclic Synchronous Velocity . . . . . . . . . . . . . . . . . . . . . . . . 10

Cyclic Synchronous Position . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4.3 Current (Torque) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4.4 Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4.5 Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5 Feedback Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Feedback Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5.1 Incremental Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5.2 Absolute Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5.3 1Vp-p Sin/Cos Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MNDGDPIN-06 v

/

2.5.4 Hall Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5.5 Auxiliary Incremental Encoder . . . . . . . . . . . . . . . . . . . . . . 13

2.5.6 Tachometer (±10 VDC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5.7 ±10 VDC Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6 Command Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.6.1 ±10V Analog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.6.2 Encoder Following . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.6.3 Indexing and Sequencing . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.6.4 Jogging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.6.5 Over the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.7 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.7.1 Specifications Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.7.2 Motor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.7.3 Power Supply Specifications . . . . . . . . . . . . . . . . . . . . . . . 16

2.7.4 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Shock/Vibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ambient Temperature Range and Thermal Data . . . . . . 17

3 Integration in the Servo System 19

3.1 LVD Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 CE-EMC Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Analog Input Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

PWM Input Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

MOSFET Switching Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

IGBT Switching Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Fitting of AC Power Filters . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.1 Ferrite Suppression Core Set-up . . . . . . . . . . . . . . . . . . . . . 21

3.2.2 Inductive Filter Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4.1 Wire Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4.2 Motor Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4.3 Power Supply Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4.4 Feedback Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4.5 I/O and Signal Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.5 Connector Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.5.1 Power Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

MNDGDPIN-06 vi

/

3.5.2 Feedback Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.5.3 I/O Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.5.4 Communication Connectors . . . . . . . . . . . . . . . . . . . . . . . 29

3.5.5 STO Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.6 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4 Operation and Features 31

4.1 Features and Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1.1 Initial Setup and Configuration . . . . . . . . . . . . . . . . . . . . . 31

4.1.2 Input/Output Pin Functions . . . . . . . . . . . . . . . . . . . . . . . . . 33

Programmable Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Programmable Limit Switch (PLS) Outputs . . . . . . . . . . . . 35

Auxiliary Encoder Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Programmable Analog I/O . . . . . . . . . . . . . . . . . . . . . . . . . 36

Motor Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.1.3 Feedback Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Absolute Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1 Vp-p Sin/Cos Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Incremental Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Hall Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Tachometer (±10 VDC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.1.4 Logic Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.1.5 Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . 40

AC or DC Power Modules . . . . . . . . . . . . . . . . . . . . . . . . . . 40

DC Only Power Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.1.6 Power LEDs Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Power LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.1.7 Motor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.1.8 External Shunt Resistor Connections . . . . . . . . . . . . . . . . . 43

4.1.9 STO (Safe Torque Off) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

STO Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

STO Operation Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.1.10 Communication and Commissioning . . . . . . . . . . . . . . . 46

Ethernet Node ID/Address . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Network Communication LEDs Functionality . . . . . . . . . . 46

4.1.11 Commutation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Sinusoidal Commutation . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

MNDGDPIN-06 vii

/

Trapezoidal Commutation . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.1.12 Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.1.13 Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

A Specifications 50

A.1 Specifications Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

B Troubleshooting 52

B.1 Fault Conditions and Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Over-Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Over-Voltage Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Under-Voltage Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Short Circuit Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Invalid Hall Sensor State . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

B.1.1 Software Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

B.1.2 Connection Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

B.1.3 Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

B.1.4 Current Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

B.1.5 Motor Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

B.1.6 Causes of Erratic Operation . . . . . . . . . . . . . . . . . . . . . . . . 54

B.2 Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

B.2.1 Drive Model Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

B.2.2 Product Label Description . . . . . . . . . . . . . . . . . . . . . . . . . 55

B.2.3 Warranty Returns and Factory Help . . . . . . . . . . . . . . . . . 56

Index I

MNDGDPIN-06 1

1 Safety

This section discusses characteristics of your DPP digital drive to raise your awareness of potential risks and

hazards. The severity of consequences ranges from frustration of performance, through damage to equipment,

injury or death. These consequences, of course, can be avoided by good design and proper installation into your

mechanism.

1.1 General Safety Overview

In order to install a DPP drive into a servo system, you must have a thorough knowledge and

understanding of basic electronics, computers and mechanics as well as safety precautions

and practices required when dealing with the possibility of high voltages or heavy, strong

equipment.

You must install and operate motion control equipment so that you meet

all applicable safety requirements. Ensure that you identify the relevant

standards and comply with them. Failure to do so may result in damage

to equipment and personal injury.

Read this entire manual prior to attempting to install or operate the drive.

Become familiar with practices and procedures that allow you to

operate these drives safely and effectively. You are responsible for

determining the suitability of this product for the intended application.

The manufacturer is neither responsible nor liable for indirect or

consequential damages resulting from the inappropriate use of this

product.

Over current protective devices recognized by an international safety

agency must be installed in line before the servo drive. These devices

shall be installed and rated in accordance with the device installation

instructions and the specifications of the servo drive (taking into

consideration inrush currents, etc.). Servo drives that incorporate their

own primary fuses do not need to incorporate over current protection in

the end user’s equipment.

Observe your facility’s lock-out/tag-out procedures so that work can proceed without residual

power stored in the system or unexpected movements by the machine.

High-performance motion control equipment can move rapidly with

very high forces. Unexpected motion may occur especially during

product commissioning. Keep clear of any operational machinery and

never touch them while they are working.

Keep clear of all exposed power terminals (motor, DC Bus, shunt, DC

power, transformer) when power is applied to the equipment. Follow

these safety guidelines:

•When using a separate logic supply, turn on the logic power supply

first before turning on the main power supply.

•Always turn off the main power and allow sufficient time for

complete discharge before making any connections to the drive.

•Do not rotate the motor shaft without power. The motor acts as a

generator and will charge up the power supply capacitors through

the drive. Excessive speeds may cause over-voltage breakdown in

the power output stage. Note that a drive having an internal power

converter that operates from the high voltage supply will become

operative.

•Do not short the motor leads at high motor speeds. When the motor is

shorted, its own generated voltage may produce a current flow as

high as 10 times the drive current. The short itself may not damage

the drive but may damage the motor. If the connection arcs or

opens while the motor is spinning rapidly, this high voltage pulse flows

back into the drive (due to stored energy in the motor inductance)

and may damage the drive.

•Do not make any connections to any internal circuitry. Only

connections to designated connectors are allowed.

•Do not make any connections to the drive while power is applied.

•Do not reverse the power supply leads! Severe damage will result!

•If using relays or other means to disconnect the motor leads, be sure

the drive is disabled before reconnecting the motor leads to the

drive. Connecting the motor leads to the drive while it is enabled can

generate extremely high voltage spikes which will damage the drive.

Use sufficient capacitance!

Pulse Width Modulation (PWM) drives require a capacitor on the high

voltage supply to store energy during the PWM switching process.

Insufficient power supply capacitance causes problems particularly with

high inductance motors. During braking much of the stored mechanical

energy is fed back into the power supply and charges its output

capacitor to a higher voltage. If the charge reaches the drive’s over-

voltage shutdown point, output current and braking will cease. At that

time energy stored in the motor inductance continues to flow through

diodes in the drive to further charge the power supply capacitance. The

voltage rise depends upon the power supply capacitance, motor

speed, and inductance.

MNDGDPIN-06 2

Safety / General Safety Overview

MNDGDPIN-06 3

Safety / General Safety Overview

Make sure minimum inductance requirements are met!

Pulse Width Modulation (PWM) servo drives deliver a pulsed output that

requires a minimum amount of load inductance to ensure that the DC

motor current is properly filtered. The minimum inductance values for

different drive types are shown in the individual data sheet

specifications. If the drive is operated below its maximum rated voltage,

the minimum load inductance requirement may be reduced. Most

servo-motors have enough winding inductance. Some types of motors

(e.g. "basket-wound", "pancake", etc.) do not have a conventional iron

core rotor, so the winding inductance is usually less than 50 μH.

If the motor inductance value is less than the minimum required for the

selected drive, use an external filter card.

MNDGDPIN-06 4

2 Products and System Requirements

This document is intended as a guide and general overview in selecting, installing, and operating ADVANCED

Motion Controls® DigiFlex® Performance™ digital servo drives that use POWERLINK / Modbus TCP / Ethernet

for networking. These specific drives are referred to herein and within the product literature as DPP drives.

Other drives in the DigiFlex Performance product family that utilize other methods of network communication

such as CANopen, EtherCAT®, or RS-485 / Modbus RTU are discussed in separate manuals that are available at

www.a-m-c.com. Contained within each DigiFlex Performance product family manual are instructions on

system integration, wiring, drive-setup, and standard operating methods.

2.1 DPP Drive Family Overview

The DPP drive family can power three phase or single phase brushless or brushed

servomotors, two phase or three phase closed loop stepper motors, and closed loop vector AC

induction motors. The command source can be generated externally or can be supplied

internally. A digital controller can be used to command and interact with DPP drives, and a

number of dedicated and programmable digital and analog input/output pins are available for

parameter observation and drive configuration. DPP drives are capable of operating in current

(torque), velocity, or position modes, and utilize Space Vector Modulation, which results in

higher bus voltage utilization and reduced heat dissipation compared to traditional PWM. DPP

drives also offer a variety of firmware-dependent feedback options.

DPP drives offer POWERLINK, Modbus TCP or Ethernet communication for multiple drive

networking, and feature a USB interface for drive configuration and setup. Drive

commissioning is accomplished using DriveWare, the setup software from ADVANCED Motion

Controls, available for download at www.a-m-c.com.

2.1.1 Drive Datasheet

Each DPP digital drive has a separate datasheet that contains important information on the

options and product-specific features available with that particular drive. The datasheet is to be

used in conjunction with this manual for system design and installation.

In order to avoid damage to equipment, only after a thorough reading

and understanding of this manual and the specific datasheet of the DPP

drive being used should you attempt to install and operate the drive.

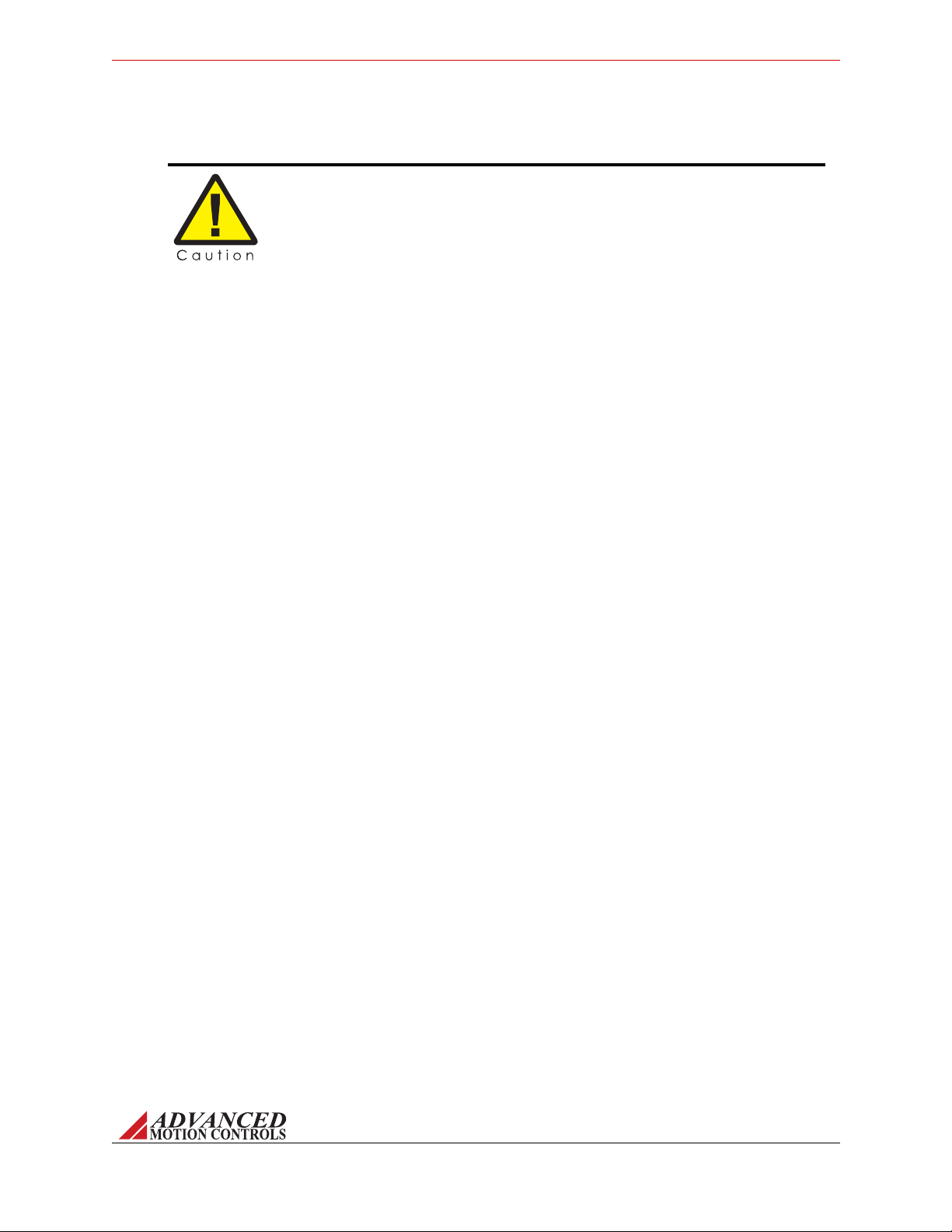

FIGURE 2.1 DPP Part Numbering Structure

C-

Drive Series

DigiFlex Performance

Communication

Command Inputs

PPD INA U 060 A 004Example:

DP

POWERLINK / Modbus TCP / EthernetP

Analog (±10V)

No Step & Direction

AN

Digital I/O

Isolated (24V)I

Motor Feedback

Max DC Bus Voltage (VDC)

400400

AC Input

+24VDC User Logic Supply Required

A

15015

-

Code used to identify customer

specials

Universal (Halls, Inc. Enc, Abs. Enc,

1Vp-p Sin/Cos Enc.)

U030 (800V models only)030

60 (800V models only)060

AC Input Single Phase Only

+24VDC User Logic Supply Required

S

Power and Logic Supply

Peak Current (A0 to Peak)

Customer Special

80080

DC Input

Both Logic Supply Options (Internal or User)

B

20020

40040

100100

60C060

800800

100C100

MNDGDPIN-06 5

Products and System Requirements / Products Covered

2.2 Products Covered

The products covered in this manual adhere to the following part numbering structure.

However, additional features and/or options are readily available for OEM’s with sufficient

ordering volume. Feel free to contact ADVANCED Motion Controls for further information.

TABLE 2.1 Power Specifications - AC Power Modules

Power Specifications

Description Units 015S400 040A400 C060A400 C100A400 030A800 060A800

Rated Voltage VAC(VDC) 240 (339) 240 (339) 240 (339) 240 (339) 480 (678) 480 (678)

AC Supply Voltage Range VAC 100-240 100-240 200-240 200-240 200-480 200-480

AC Supply Minimum VAC 90 90 180 180 180 180

AC Supply Maximum VAC 264 264 264 264 528 528

AC Input Phases -133333

AC Supply Frequency Hz 50-60 50-60 50-60 50-60 50-60 50-60

DC Supply Voltage Range VDC 127-373 127-373 255-373 255-373 255-747 255-747

DC Bus Over Voltage Limit VDC 394 394 420 420 850 850

DC Bus Under Voltage Limit VDC 55 55 205 205 230 230

Maximum Peak Output Current A (Arms) 15 (10.6) 40 (28.3) 60 (42.4) 100 (70.7) 30 (21.2) 60 (42.4)

Maximum Continuous Output Current A (Arms) 7.5 (7.5) 20 (20) 30 (30) 50 (50) 15 (10.6) 30 (21.2)

Max. Continuous Output Power @ Rated Voltage1W2415 6441 9662 16103 6830 13650

Max. Continuous Power Dissipation @ Rated Voltage W127 339 509 848 360 720

Internal Bus Capacitance μF540 660 1120 1120 330 330

PWM Switching Frequency kHz 20 20 14 10 10 10

External Shunt Resistor Minimum Resistance Ω25 25 20 20 note 2 40

Minimum Load Inductance (Line-To-Line) μH600 600 600 600 3000 3000

1. P = (DC Rated Voltage) * (Cont. RMS Current) * 0.95

2. Contact factory before using an external shunt resistor with this power module

TABLE 2.2 Power Specifications - DC Power Modules

Power Specifications

Description Units 020B080 100B080

DC Supply Voltage Range VDC 20-80 20-80

DC Bus Over Voltage Limit VDC 88 88

DC Bus Under Voltage Limit VDC 17 17

Maximum Peak Output Current A (Arms) 20 (14.1) 100 (70.73)

Maximum Continuous Output Current A (Arms) 10 (10) 60 (60)

Max. Continuous Output Power @ Rated Voltage1W760 4560

Max. Continuous Power Dissipation @ Rated Voltage W40 240

Internal Bus Capacitance μF33 500

PWM Switching Frequency kHz 20 20

Minimum Load Inductance (Line-To-Line) μH600 250

MNDGDPIN-06 6

Products and System Requirements / Products Covered

TABLE 2.3

Description DPPANIU

Network Communication POWERLINK / Modbus TCP / Ethernet (USB for Configuration)

Command Sources ± 10V Analog, Over the Network, Encoder Following, Sequencing, Indexing, Jogging

Commutation Methods Sinusoidal, Trapezoidal

Control Modes Profile Modes, Cyclic Synchronous Modes, Current, Velocity, Position

Motors Supported Three Phase (Brushless Servo), Single Phase (Brushed Servo, Voice Coil, Inductive Load), Stepper (2- or 3-Phase Closed Loop), AC

Induction (Closed Loop Vector)

Hardware Protection 40+ Configurable Functions, Over Current, Over Temperature (Drive & Motor), Over Voltage, Short Circuit (Phase-Phase & Phase-

Ground), Under Voltage

Programmable Digital I/O 11/7

Programmable Analog I/O 2/0

Primary I/O Logic Level 24 VDC

Control Specifications

TABLE 2.4

Description DPPANIU

Hall Sensors

Incremental Encoder

Auxiliary Incremental Encoder

Absolute Encoder (Hiperface®, EnDat®, BiSS C-Mode)

1Vp-p Sine/Cosine Encoder

Tachometer (10 ±VDC)

±10 VDC Position

Note: Drive will support either Incremental Encoder, Absolute Encoder, or 1Vp-p Sine/Cosine Encoder depending on drive firmware

Feedback Options

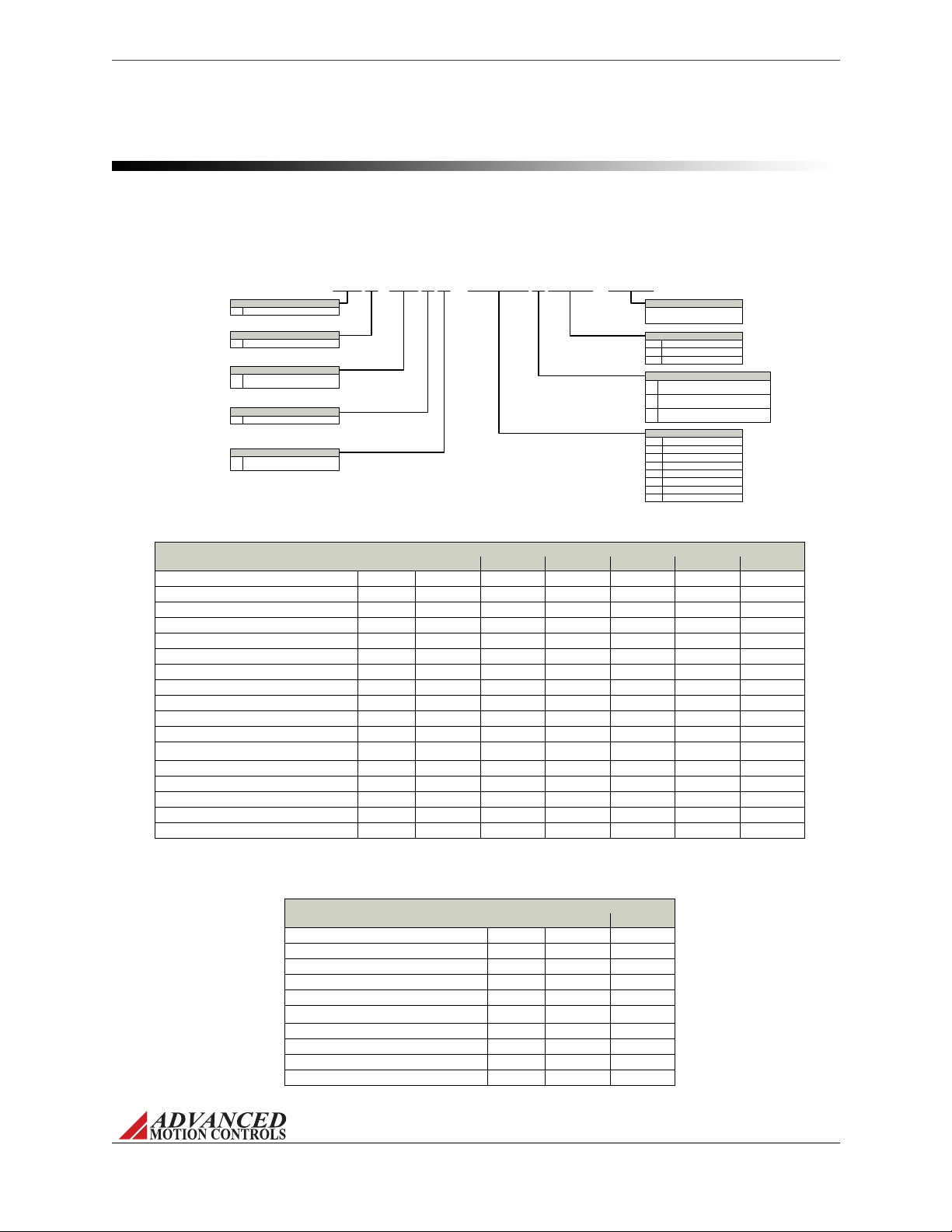

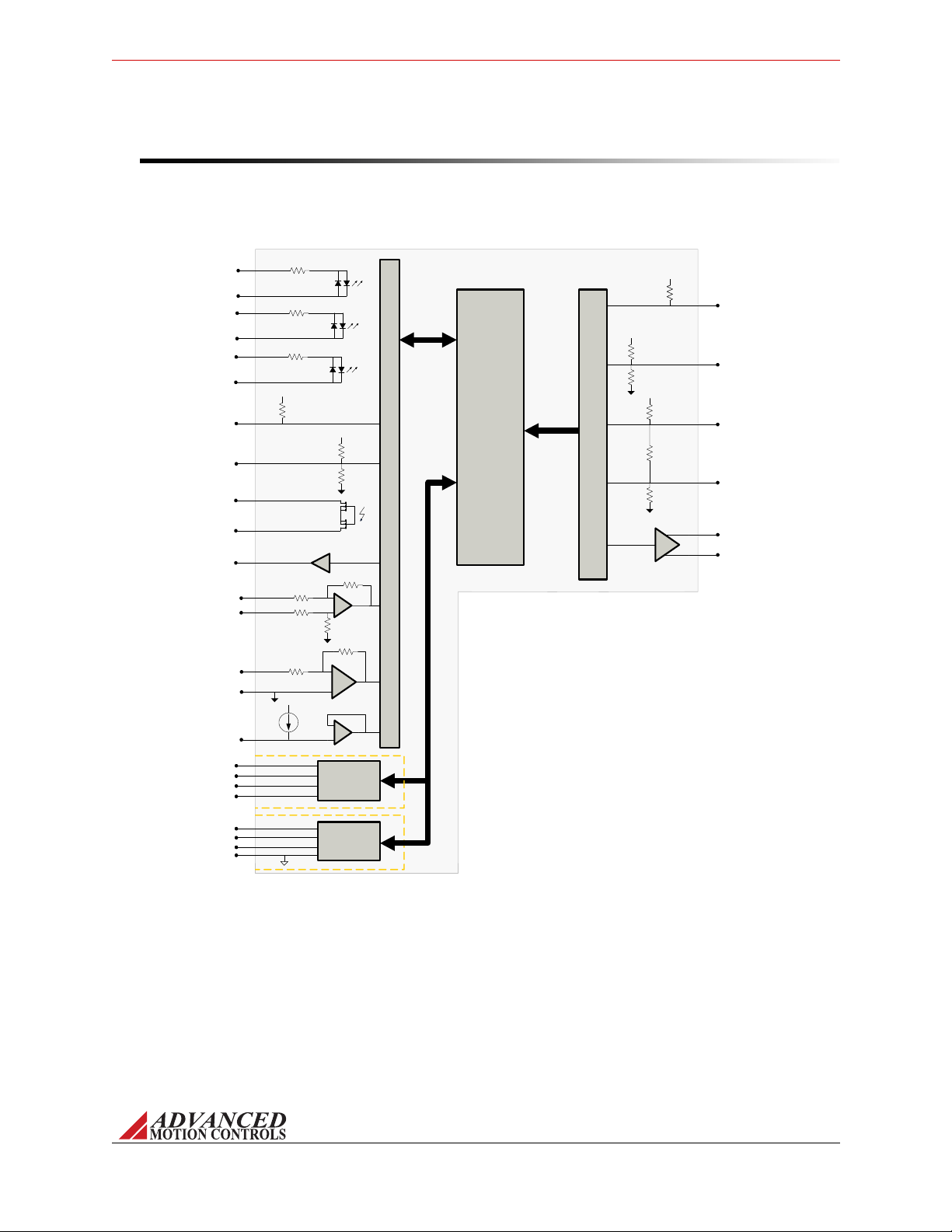

FIGURE 2.2

PAI-1 + (REF+)

PAI-1 – (REF–)

TD+

TD-

I/O Interface

I/O Interface

Drive

Logic

Ethernet

Interface

CONTROL MODULE

10k

+5V

10k

20k

20k 20k

MOTOR THERMISTOR/

SWITCH

DATA-

DATA+

GND

AUX ENC A,B,-)

USB Interface

RD+

RD-

VBUS

AUX ENC A,B,I+

10k

+5V

PDI-1,2,3,4

(GENERAL PURPOSE)

IN COMMON (1-4)

2.5K

PDO-1,2,3,4,5,6

OUT COMMON (1-6)

PDI-5,6,7

(GENERAL PURPOSE)

IN COMMON (5-7)

2.5K

PDI-8,9,10,11

(GENERAL PURPOSE)

IN COMMON (8-11)

2.5K

ENC A,B,I + /

SIN+ / COS+ /

REF MARK+

ENC A,B,I – /

SIN- / COS- /

REF MARK-

HALL A,B,C + /

DATA,CLOCK+

HALL A,B,C – /

DATA,CLOCK-

+5V

+5V

+5V

Motor Feedback

ENC A,B,I + OUT

ENC A,B,I – OUT

PAI-2

SGN GND

33k

HS PDO-7

DPPANIU Control Module

MNDGDPIN-06 7

Products and System Requirements / Products Covered

2.2.1 Control Module

The diagram below shows the general block diagram for the DPPANIU control module. For

complete pinouts, consult the drive’s datasheet.

MNDGDPIN-06 8

Products and System Requirements / Communication Protocol

2.3 Communication Protocol

DPP digital drives offer networking capability through POWERLINK, Modbus TCP or Ethernet

communication. An auxiliary USB port is featured for configuring the drive through

DriveWare.

Ethernet POWERLINK is an open-source real-time industrial Ethernet protocol created by

B&R Automation. POWERLINK expands upon Ethernet according to the IEE 802.3 standard

with a mixed polling and time slicing mechanism. The POWERLINK communication profile is

based on CANopen communication profiles DS301 and DS302. POWERLINK is developed and

maintained by the Ethernet POWERLINK Standardization Group (EPSG). For more detailed

information on POWERLINK communication with DPP drives and a complete list of register

definitions, consult the ADVANCED Motion Controls’ POWERLINK Communication Manual

available for download at www.a-m-c.com.

For more information on POWERLINK visit www.ethernet-powerlink.org.

Modbus is an open standard, master slave system developed for communication between

multiple devices using a single wire. The Modbus protocol uses a defined message structure,

regardless of the physical layer of the network used to communicate. A master device initiate a

"query", and slave devices return a "response", supplying the requested data or taking the

requested action. The query can be made to individual devices or broadcast to all connected

devices. For more detailed information on Modbus TCP communication with DPP drives and a

complete list of register definitions, consult the ADVANCED Motion Controls’ Modbus

Communication Manual available for download at www.a-m-c.com.

The Modbus TCP protocol for ADVANCED Motion Controls’ DPP drives follows the Modbus

Application Protocol Specification V1.1b. More information can be found at www.Modbus-

IDA.org.

MNDGDPIN-06 9

Products and System Requirements / Control Modes

2.4 Control Modes

DPP digital drives operate in a variety of operating modes. The setup and configuration

parameters for these modes are commissioned through DriveWare. See the DriveWare

Software Manual for mode configuration information.

2.4.1 Profile Modes

In Profile Modes, the trajectory is limited by the drive, using the Command Limiter values to

limit the maximum command rate. If the host sends a large command step, the drive spreads

the demand over some period of time to stay equal to or below the maximum defined rate.

Profile Current (Torque) In Current (Torque) Mode, the input command voltage controls the

output current. The drive will adjust the output duty cycle to maintain the commanded output

current. This mode is used to control torque for rotary motors (force for linear motors), but

the motor speed is not controlled. The output current and other parameters can be monitored

in DriveWare through the digital oscilloscope function. DriveWare also offers configuration of

maximum and continuous current limit values.

Profile Velocity In Velocity Mode, the input command voltage controls the motor velocity. This

mode requires the use of a feedback element to provide information to the drive about the

motor velocity. DPC drives allow velocity control with either Hall Sensors, an encoder, a

resolver, or a tachometer as the feedback element. The motor velocity and other parameters

can be monitored in DriveWare through the digital oscilloscope function. The feedback

element being used for velocity control must be specified in DriveWare, which also offers

configuration of velocity limits. See “Feedback Supported” on page 11 for more information on

feedback devices.

Profile Position In Position Mode, the input command voltage controls the actual motor position.

This mode requires the use of a feedback element to provide information to the drive about

the physical motor location. DPC drives allow position control with either an encoder, a

resolver, or ±10V Position feedback. The motor position and other parameters can be

monitored in DriveWare through the digital oscilloscope function. The feedback element being

used for position control must be specified in DriveWare, which also offers configuration of

position limits. See “Feedback Supported” on page 11 for more information on feedback

devices.

2.4.2 Cyclic Synchronous Modes

Cyclic Synchronous Modes give responsibility of trajectory control to the host. The drive

interpolates between command points, defining the rate by dividing the change in command

While in Current (Torque) Mode, the drive will maintain a commanded

torque output to the motor based on the input reference command.

Sudden changes in the motor load may cause the drive to output a high

torque command with little load resistance, causing the motor to spin

rapidly. Therefore, Current (Torque) Mode is recommended for

applications using a digital position controller to maintain system stability.

Note

MNDGDPIN-06 10

Products and System Requirements / Control Modes

by the interpolation time period. This allows the drive to respond smoothly to each step in

command.

Cyclic Synchronous Current In Cyclic Synchronous Current Mode, the drive closes the

current loop. The host is allowed more control by having the ability to instantly add current

feedforward values. This allows for gain compensation in applications with varying loads.

Cyclic Synchronous Velocity In Cyclic Synchronous Velocity Mode, the drive closes two

control loops: velocity and current. The host is allowed more control by having the ability to

instantly add velocity and current feedforward values. This allows for gain compensation in

applications with varying loads.

Cyclic Synchronous Position In Cyclic Synchronous Position Mode, the drive closes three

control loops: position, velocity, and current. The host can send target position, velocity

feedforward, and current feedforward values to the drive. This allows for gain compensation in

applications with varying loads.

2.4.3 Current (Torque)

In Current (Torque) Mode, the input command controls the output current. The drive will

adjust the output duty cycle to maintain the commanded output current. This mode is used to

control torque for rotary motors (force for linear motors), but the motor speed is not

controlled. The output current and other parameters can be monitored within the

configuration software, or externally through network commands.

While in Current (Torque) Mode, the drive will maintain a commanded

torque output to the motor based on the input reference command.

Sudden changes in the motor load may cause the drive to output a high

torque command with little load resistance, causing the motor to spin

rapidly. Therefore, Current (Torque) Mode is recommended for

applications using a digital position controller to maintain system stability.

2.4.4 Velocity

In Velocity Mode, the input command controls the motor velocity. This mode requires the use

of a feedback element to provide information to the drive about the motor velocity. The motor

velocity and other parameters can be monitored within the configuration software, or

externally through network commands. See “Feedback Supported” on page 11 for more

information on velocity feedback devices.

2.4.5 Position

In Position Mode, the input command controls the actual motor position. This mode requires

the use of a feedback element to provide information to the drive about the physical motor

location. The motor position and other parameters can be monitored within the configuration

software, or externally through network commands. See “Feedback Supported” on page 11 for

more information on position feedback devices.

Note

MNDGDPIN-06 11

Products and System Requirements / Feedback Supported

2.5 Feedback Supported

DPP drives feature the ability to support a variety of primary feedback devices by downloading

the appropriate firmware into the drive. Compatible firmware-dependent devices are

Incremental Encoders, Absolute Sin/Cos Encoders (Hiperface®, EnDat®, and BiSS C-Mode),

and 1Vp-p Sin/Cos Encoders. Consult the DriveWare Software Manual for instructions on how

to download firmware into a digital servo drive.

Other supported feedback types that do not require a firmware change are Hall Sensors,

Auxiliary Incremental Encoder, Tachometer, and ±10 VDC Position feedback.

Feedback Polarity The drive compares the feedback signal to the command signal to produce

the required output to the load by continually reducing the error signal to zero. The feedback

element must be connected for negative feedback. Connecting the feedback element for

positive feedback will lead to a motor "run-away" condition. In a case where the feedback

lines are connected to the drive with the wrong polarity, the drive will attempt to correct the

"error signal" by applying more command to the motor. With the wrong feedback polarity, this

will result in a positive feedback run-away condition. The correct feedback polarity will be

determined and configured during commissioning of the drive. Otherwise, to correct this,

either change the order that the feedback lines are connected to the drive, or use DriveWare to

reverse the internal velocity feedback polarity setting.

2.5.1 Incremental Encoder

DPP drive models can utilize incremental encoder feedback for velocity or position control,

with the option of also using the encoder to commutate the motor. The encoder provides

incremental position feedback that can be extrapolated into very precise velocity or position

information. With an encoder being used as the feedback element, the input command

controls the motor velocity or motor position, with the frequency of the encoder pulses closing

the velocity and/or position loop. The encoder signals are read as "pulses" that the drive uses

to essentially keep track of the motor’s speed, position and direction of rotation. Based on the

speed and order in which these pulses are received from the encoder, the drive can interpret

the motor velocity and physical location. The actual motor speed and physical location can be

monitored within the configuration software, or externally through network commands.

Figure 2.3 below represents differential encoder "pulse" signals, showing how dependent on

which signal is read first and at what frequency the "pulses" arrive, the speed and direction of

the motor shaft can be extrapolated. By keeping track of the number of encoder "pulses" with

respect to a known motor "home" position, DPP drives are able to ascertain the actual motor

location.

FIGURE 2.3 Encoder Feedback Signals

Encoder A+

Encoder B+

Encoder A+

Encoder B+

Example 1: Encoder-A precedes Encoder-B. The pulses

arrive at a certain frequency, providing speed and

directional information to the drive.

Example 2: Encoder-B precedes Encoder-A, meaning the

direction is opposite from Example 1. The signal frequency

is also higher, meaning the speed is greater than in

Example 1.

Encoder A-

Encoder B-

Encoder A-

Encoder B-

The high resolution of motor mounted encoders allows for excellent

velocity and position control and smooth motion at all speeds. Encoder

feedback should be used for applications requiring precise and

accurate velocity and position control, and is especially useful in

applications where low-speed smoothness is the objective.

FIGURE 2.4 Sin/Cos Encoder Interpolation

Electrical Degrees

090 180 270 360

1 Vp-p Sin/Cos

Encoder Interpolation

Cos

Sin

0

Volts

1 to 512 lines

per Sin/Cos

cycle

# of Counts per

Sin/Cos cycle = (Interpolation value) x 4

MNDGDPIN-06 12

Products and System Requirements / Feedback Supported

2.5.2 Absolute Encoder

DPP drives support Hiperface®, EnDat® (2.1/2.2 command set), or BiSS C-Mode absolute

encoders for velocity and absolute position feedback. The encoder resolution and other

options can be configured within the drive configuration software. The drive breaks down the

signals from the encoder into individual reference points (counts). For feedback devices that

accept 1 Vp-p signals, the interpolation is configurable in powers of 2 from 1 to 512 lines per

Sin/Cos cycle. The quadrature number of counts per cycle is the interpolation value multiplied

by 4, as shown in Figure 2.4. This allows for very high interpolated encoder resolution (4-2048

counts).

The absolute position feedback eliminates the need for a homing routine

when the drive is powered on.

Note

Note

MNDGDPIN-06 13

Products and System Requirements / Feedback Supported

2.5.3 1Vp-p Sin/Cos Encoder

DPP drives support 1Vp-p Sin/Cos encoders for position and velocity feedback. The drive

breaks down the 1 Vp-p sinusoidal signals from the encoder into individual reference points

(counts). The interpolation is configurable in powers of 2 from 1 to 512 lines per Sin/Cos cycle.

The quadrature number of counts per cycle is the interpolation value multiplied by 4, as shown

in Figure 2.4. This allows for very high interpolated encoder resolution (4-2048 counts per

Sin/Cos cycle).

2.5.4 Hall Sensors

DPP drives can use single-ended or differential Hall Sensors for commutation and/or velocity

control. The Hall Sensors (typically three) are built into the motor to detect the position of the

rotor magnetic field. With Hall Sensors being used as the feedback element, the input

command controls the motor velocity, with the Hall Sensor frequency closing the velocity loop.

Hall velocity mode is not optimized for relatively high or relatively low Hall

frequencies. To determine if Hall velocity mode is right for your

application, contact Applications Engineering.

For more information on using Hall Sensors for trapezoidal commutation, see “Trapezoidal

Commutation” on page 48.

2.5.5 Auxiliary Incremental Encoder

The auxiliary encoder input pins can be used as a command source for encoder following

mode, or as a secondary feedback device input for closing the position loop. The particular

function is configured in the configuration software.

2.5.6 Tachometer (±10 VDC)

DPP drives support the use of a tachometer for velocity feedback. The tachometer measures

the rotary speed of the motor shaft and returns an analog voltage signal to the drive for

velocity control. DPP drives provide a Programmable Analog Input on the motor Feedback

Connector that is available for use with a tachometer. The tachometer signal is limited to ±10

VDC.

2.5.7 ±10 VDC Position

DPP drives accept an analog ±10 VDC Position feedback, typically in the form of a load-

mounted potentiometer. The feedback signal must be conditioned so that the voltage does not

exceed ±10 V, and is connected to the drive through the Programmable Analog Input. In

DriveWare, the connection method that is used must be selected under the Position Loop

Feedback options. See the DriveWare Software Guide for more information.

Note

Table of contents

Popular DC Drive manuals by other brands

Moons'

Moons' MSSTAC6 user manual

Erreka

Erreka ERGOS Series Quick installation and programming guide

PrimoPal

PrimoPal PSR5042 user manual

FALK

FALK Ultramite UB Installation & maintenance instructions

Antal

Antal LD700/24 Installation and user guide

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 4M installation instructions

Trinamic

Trinamic PANdrive PD-1140 Hardware manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 755 installation instructions

Johnson Controls

Johnson Controls PENN VFD68 installation instructions

KLEE

KLEE Drive MS Series manual

Nidec

Nidec E300 Series Installation and System Design Guide

Siemens

Siemens SINAMICS S120 Function manual