AddSecure Asset Series User manual

Version 2.3 2017-01-26 / PEP & FB

Asset Light

&

Asset Pro

AddSecure

Asset

Installation Guide

Installation guide Asset

Content:

1Mounting the unit ....................................................................................................................................................................................1

2Wiring for Asset Light ............................................................................................................................................................................2

3Wiring for Asset PRO with one-wire temperature sensor...............................................................................................3

3.1 Cable for one-wire sensor................................................................................................................................................................................................................4

3.2 Temperature sensor –PRO version only.................................................................................................................................................................................4

4Wireless Sensors .......................................................................................................................................................................................5

4.1.1 Wireless temperature sensor ...........................................................................................................................................................................................6

4.1.2 Wireless Door sensor ............................................................................................................................................................................................................6

5Unit on/off and LED................................................................................................................................................................................7

6Final test........................................................................................................................................................................................................7

7Carrier Transicold....................................................................................................................................................................................8

7.1 Datalogger, Datacold 500, 600 and EuroScan X2 ..............................................................................................................................................................8

7.1.1 Mounting......................................................................................................................................................................................................................................8

7.1.2 Connection..................................................................................................................................................................................................................................8

7.1.3 Ignition Connection ...............................................................................................................................................................................................................9

7.1.4 Configuration of datacold 500, 600 and EuroScanX2........................................................................................................................................9

7.1.5 System configuration............................................................................................................................................................................................................9

8ThermoKing ..............................................................................................................................................................................................10

8.1 Datalogger DAS / SR2 / CargoWatch......................................................................................................................................................................................10

8.1.1 Serial RS 232 connection to CargoWatch..............................................................................................................................................................10

8.1.2 Ignition Connection ............................................................................................................................................................................................................10

8.1.3 Configuration of datalogger..........................................................................................................................................................................................10

8.1.4 System configuration.........................................................................................................................................................................................................10

8.2 i-Box ...........................................................................................................................................................................................................................................................11

9Hultstein.....................................................................................................................................................................................................12

9.1 HUK Datalogger..................................................................................................................................................................................................................................12

10 System configuration..........................................................................................................................................................................12

1

1Mounting the unit

The Asset Light and Asset Light Pro units can be mounted on various places on the vehicle, but to

ensure best possible GPS and GSM signals, it must not be placed under metal. Plastic, fibreglass and

fabric will not affect the signals. The antenna is located at the end opposite the connector. Use the

supplied splash-proof mounting box.

Protect from sunlight and do not expose to temperatures under -20oC and above +45oC Celsius.

Important: Mount the supplied 1A splash-resistant auto fuse on the white wire to permanent supply.

Place the fuse as close to the power source as possible to protect the vehicle.

To obtain a water-proof installation, mount the supplied four locking devices.

Mount the unit on a suitable place where it is protected from water. Never clean the unit with a high-

pressure cleaner.

The wire output must face downwards.

When attaching the power-/multi connector to the unit, you have to hear a click sound to ensure, that

the connector is attached properly. Possibly you have to press it gently further into the connector with

a tool, until you can hear the click.

Up to 5 minutes may pass from power on till the unit is charged and ready for use.

2

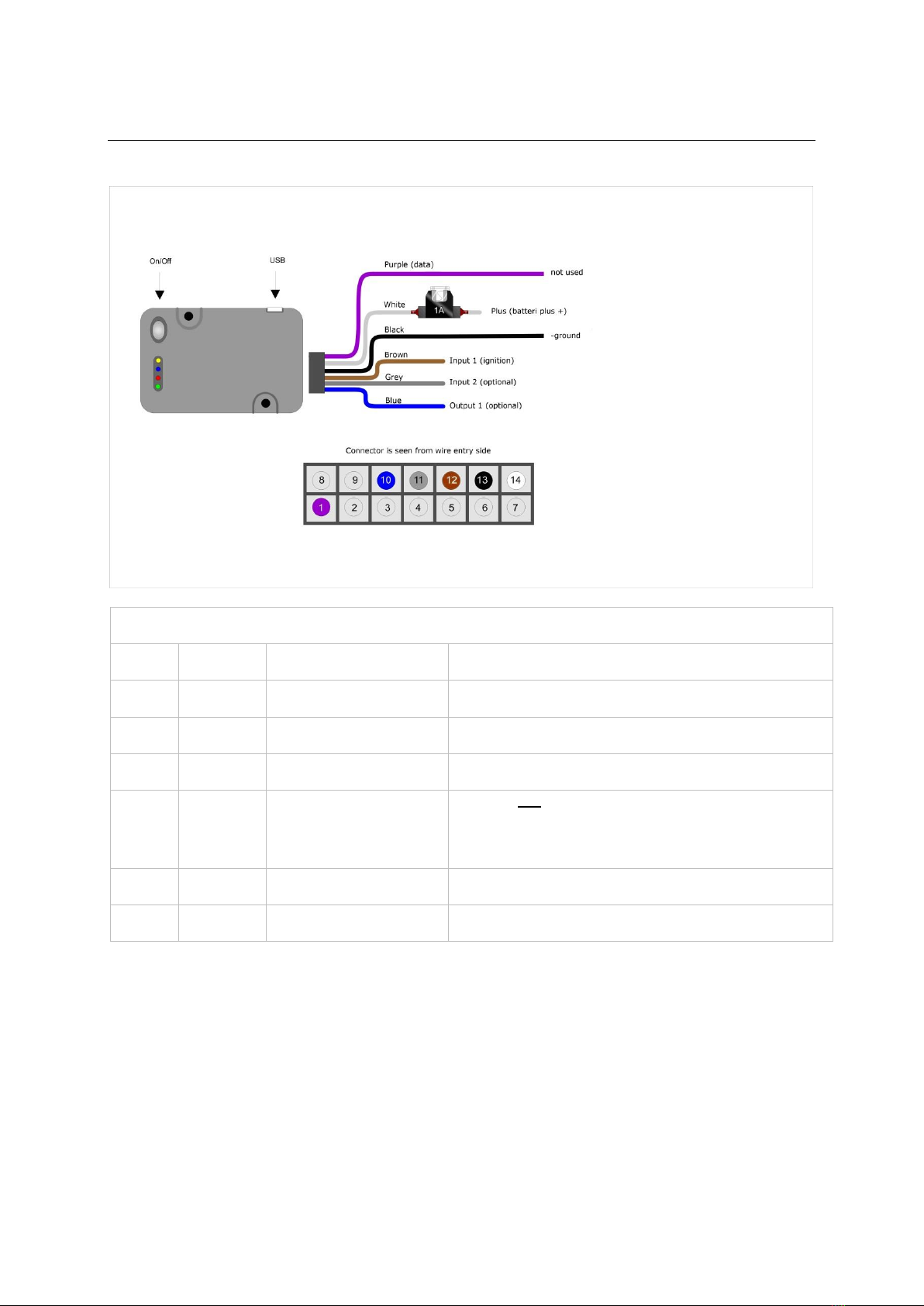

2Wiring for Asset Light

Asset Light is supplied with the following wires:

Wire chart

Pin

Colour

Function

Note

1

Purple

Not used

Dallas 1-wire –for temperature sensor

10

Blue

Not used

Digital Output

11

Grey

Not used

Digital Input

12

Brown

Terminal 15 ignition

Ignition (has to be connected –if there is no ignition

signal in the vehicle connect the cable to terminal 30

+24 Volt)

13

Black

Terminal 31 ground

Battery minus terminal

14

White

Terminal 30 +24 Volt

Constant supply between +10 Volt to +60 Volt

3

3Wiring for Asset PRO with one-wire temperature sensor

Asset Pro with temperature sensor(s) is supplied with the following wires:

Wire chart

Pin

Colour

Function

Note

1

Purple

Temperature

Dallas 1-wire –for temperature sensor

2

Orange

TX (RS 232)

Used for ThermoKing / Carrier

3

Green

RX (RS 232)

Used for ThermoKing / Carrier

4

Black/Whit

e

CAN

Not used

5

Red/White

CAN

Not used

10

Blue

Outout

Not used

11

Grey

Input 2

Not used

12

Brown

Terminal 15

ignition

Ignition (has to be connected –if there is no ignition signal in

the vehicle connect the cable to terminal 30 +24 Volt)

13

Black

Terminal 31

ground

Battery minus terminal

14

White

Terminal 30

+24 Volt

Constant supply between +10 Volt for +60 Volt

4

To test that the temperature sensors are detected and what temperatures are being measured, send a

SMS with the text OWTEMP-SHOW to the data number of the SIM-card mounted in the unit. The unit

will return a SMS with a list of the detected temperature sensors and the measured temperature. If the

returned value is “No sensors defined”, the sensor is not responding – check the installation! The

answer can be divided into several SMS if the content of the response contains too many characters.

The responds SMS can look as follows:

283326B30100007C = 27.3

2974E541564B1575 = 7.3

(Serial number) (measured temperature)

3.1 Cable for one-wire sensor

It is very important to use a twisted pair cable when an extension is needed. The cable should

preferably be the same type as the original sensor cable. The cable is with silicone outer jacket and

Teflon inner jackets so it is durable in high and low temperatures. The capacity between wires must

not be higher than 10 –15 pF per meter. Total length (added) for all sensors is maximum 20 meters.

3.2 Temperature sensor –PRO version only

Where to mount the temperature sensor

Possible places to mount the temperature sensor:

•At the air intake of the cooling system

•At the air out of the cooling system

•On a central place in the compartment

AddSecure recommends that you agree on a mounting place with the customer.

Mounting/fixing the temperature sensor

Take care not to damage the temperature sensor when mounting/fixing it and make sure it is placed

well protected.

The sensor head must be free, i.e. it must not be covered by a bracket, glue, etc.

Sensor ID

Each sensor is labelled with a unique ID No. Enter this ID number and state the mounting place on the

data sheet.

The data sheet must be given to the AddSecure support.

More temperature sensors

5

Up to 8 external temperature sensors can be connected to an Asset Pro. If more temperature sensors

are connected they must be parallel mounted. White core to white core, and brown core to brown

core. Wires may be extended. All soldering must be isolated.

4Wireless Sensors

When mounting wireless sensors the Asset unit is not allowed to be placed in the trucks cabin.

The Asset unit should be mounted on the trailer or cargo unit.

6

4.1.1 Wireless temperature sensor

4.1.2 Wireless Door sensor

.

Awireless door sensor consists

of two parts, the Sensor (the

larger of the two) and a Magnet

(the smaller one).

It’s important that the sensor is

fitted to the door and that the

magnet is mounted to the

ceiling.

Depending on materials

between and around the sensor

and Asset unit, the range will

vary. e.g. the Asset unit cannot

be mounted in the trucks cabin

and communicate with the

sensor.

Note!

Write down the serial number of

the sensor located on the back

of the sensor.

Awireless temperature sensor consists of only one part,

the Sensor. Depending on materials between and

around the sensor and Asset unit, the range will vary.

e.g. the Asset unit cannot be mounted in the trucks

cabin and communicate with the sensor.

Note!

Write down the serial number of the sensor located on

the back of the sensor.

7

5Unit on/off and LED

6Final test

Send a SMS with the text: STAT to the GSM number of the unit. The following reply must be received

Reply

Meaning

Version=Blackbird 0.11

Software version

OPT2

Firmware Version in OPT2 board (PRO version only)

FW=0.35

Firmware program version

NodeID=3090818019

The serial number (S/N) of the unit

BattV=3987

Current battery voltage in mV –typically between 3650mV and 4200mV

Runtime= 3239

Number of seconds that the unit has been on

MCC=23802

Provider network code

Signal= 81

GSM signal strength –must be between 100 and 50. Low is best

Sat=11

No of satellites

HDOP=10

GPS HDOP value GPS quality

Ichg=127.6

Charging power

Bt=35.60

Battery temperature

Odo

Current Odometer value

Vt

0/1 valid time or not on unit

All values stated after = are examples.

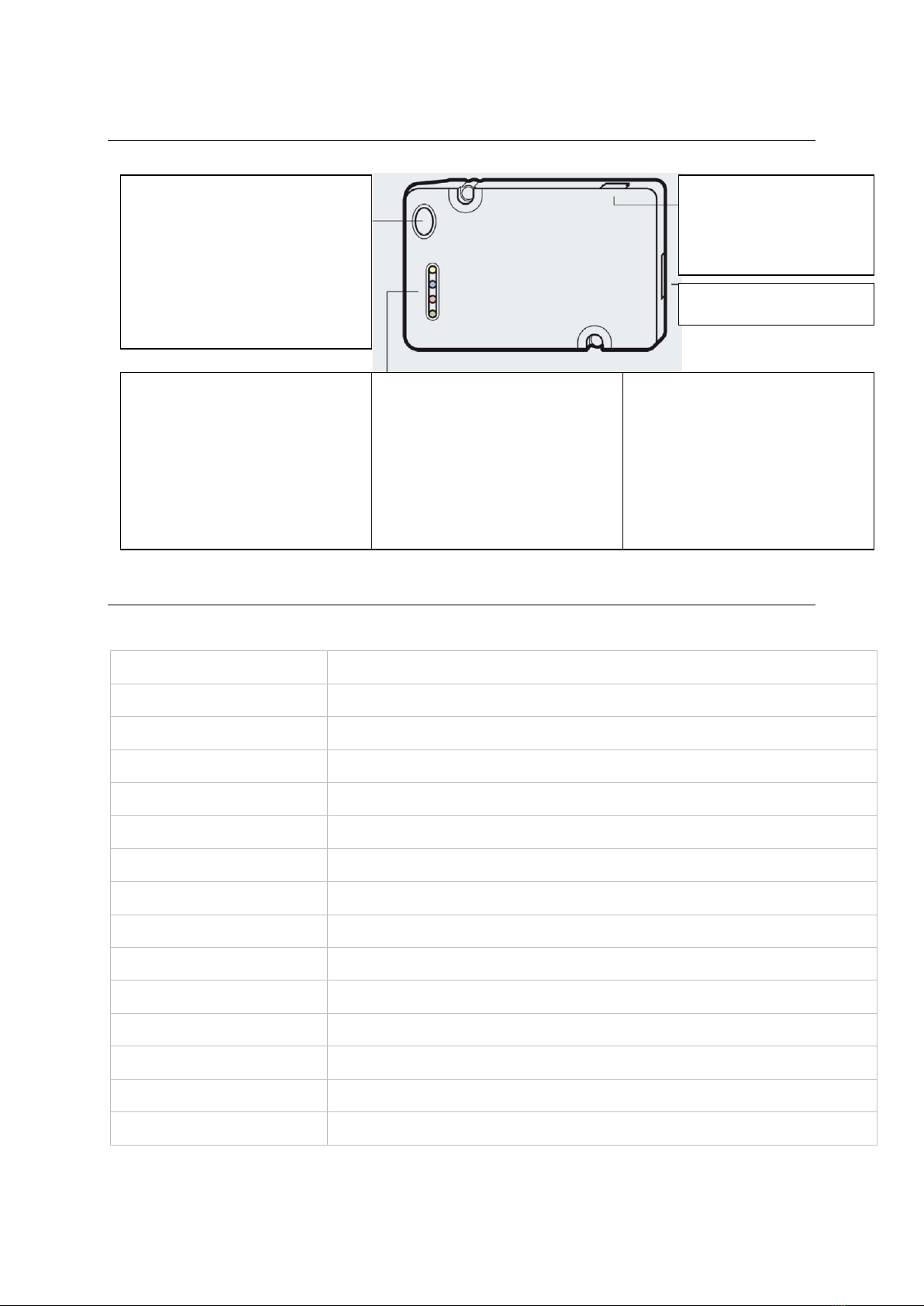

ON/OFF button

When the unit is off it must not be

connected to a power source.

•Press button for 5 seconds till yellow lamp

starts to flash differently.

•Release the button and press it briefly

again. Turn off the unit.

Yellow. System service

•Constant light: System starts.

•1 flash: System is on, but not connected

to GSM data.

•2 fast flashes: System is on server.

Blue. GPS receiver

•1 quick flash: No GPS satellites received

•1 long flash followed by a number of quick

flashes: Receiving GPS. The number of

short flashes states the number of

satellites being received.

Red. Power/Charging status Constant light:

Fully uploaded

•1 flash: battery low level

•2 flashes: Charging

Green. GSM service

•Flashing sporadic: OK

•Flashing constant: SIM card error

USB-input for charger

230 V charger and

12/24 V cigarette charger

available as option.

Installation inputs

Yellow

Blue

Red

Green

8

7Carrier Transicold

7.1 Datalogger, Datacold 500, 600 and EuroScan X2

7.1.1 Mounting

The Asset Pro can be mounted on the rear of the datalogger

7.1.2 Connection

It mush flush with the edges

Make sure that there is room for the

printer cable

9

7.1.3 Ignition Connection

The ignition input (Brown –pin 12) can be connected to the trailer 24 volt (Light). It will then show if

the trailer is connected to a truck with ignition on (Light turned on). Trailer and datalogger has

separated ground. Remember to mount the 1 kohm resistor R2. On trucks the ground is normally

common and the resistor is not needed.

Can also be connected to the ignition of the refrigeration unit and used to indicate is the cooler is

running.

If this option is not used, the brown wire must be connected to the white wire (Datacold 12 volt).

7.1.4 Configuration of datacold 500, 600 and EuroScanX2

The configuration of the datacold must be done before the Lommy works.

•Hold the green button for 2 seconds.

•The display shows "Enter PIN“

•Factory code is 1111 (press 4 times the blue)

•Select menu 11 with the arrow keys

•Datacold 500 - Com 1 should be “Thirdparty”

•Datacold 600 –Com 1 should be “Partner Protocol”

•EuroScan –Com 1 should be “Old ES Protocol”

•Com 2 should be Vector, TM or R / T depending on the unit which is mounted.

7.1.5 System configuration

Note the placement and names of the different temperature sensors and set-points. Needed for system

configuration.

10

8ThermoKing

8.1 Datalogger DAS / SR2 / CargoWatch

8.1.1 Serial RS 232 connection to CargoWatch.

Solder the TX and RX connections on the connector on the controller board or use a connector.

The 1 kohm resistor R1 secures that the CargoWatch Port is not blocked when connection in parallel

with the connector. When a connector is used R1 is not necessary.

8.1.2 Ignition Connection

The ignition input (Brown –pin 12) can be connected to the trailer 24 volt (Light). It will then show if

the trailer is connected to a truck with ignition on (Light turned on). Trailer and datalogger has

separated ground. Remember to mount the 1 kohm resistor R2. On trucks the ground is normally

common and the resistor is not needed.

Can also be connected to the ignition of the refrigeration unit and used to indicate is the cooler is

running.

If this option is not used, the brown wire must be connected to the white wire (CargoWatch 12 volt).

8.1.3 Configuration of datalogger

(Will be described later)

8.1.4 System configuration

Note the placement and names of the different temperature sensors and set-points. Needed for system

configuration.

11

8.2 i-Box

12

9Hultstein

9.1 HUK Datalogger

To connect to a HUK, you will need a

male

DB9 connector.

Power is connected as usual.

PINOUT

Asset

DB9

Green

2

Orange

3

Black

5

Jumper between 7 & 8

10 System configuration

See the document: Asset configuration AddSecure.

This manual suits for next models

2

Table of contents

Popular Automobile Accessories manuals by other brands

Thule

Thule Rapid System 1362 Fitting instructions

Bestop

Bestop HighRock 4x4 Element 51814 installation instructions

Sony

Sony DCC-E34CP - Car Battery Cord operating instructions

Loughbless

Loughbless BC28 user manual

Airxcel

Airxcel Aqua-Hot GEN1 Series installation manual

LSD-Doors

LSD-Doors 50075004 installation instructions