Adel System MRF102 User manual

Via Luigi Barchi 9/B –Reggio Emilia 42124 –Italy

Tel. +39 0522 345518 –Fax +39 0522 345551 –www.adelsystem.com

Instruction Manual MRF102_7.docx

Page 1

MRF102

2- Channels Electronic Circuit Breaker

Instruction Manual

Thank you for having chosen one of our products for your work.

We are certain that it will give the utmost satisfaction and be a notable

help on your job and application.

1 Product Description

The MRF102 2-channel electronic circuit breaker with Din Rail and Wall

mounting is designed for current distribution and protection of 12V or

24V load circuits.

2 Safety and warning notes

WARNING –Explosion Hazard Do not disconnect

Equipment unless power has been switched off or the area

is known to be non-hazardous.

WARNING –Explosion Hazard. Substitution of components

may impair suitability for class I, Division 2.

WARNING –Switch off the system before connecting the module. Never

work on the machine when it is live. The device must be installed in

according to EN61010 or EN62368-1. The device must have a suitable

isolating facility outside the power supply unit, via which can be switched

to idle. Danger of fatal Injury!

WARNING –The device is equipped whit an internal fuse. If the internal

fuse blows Up (fails opens), it is most probable that there is a fault in the

device. If this failure occurs, the device must be returned to the factory.

3 How to Install

Mounting

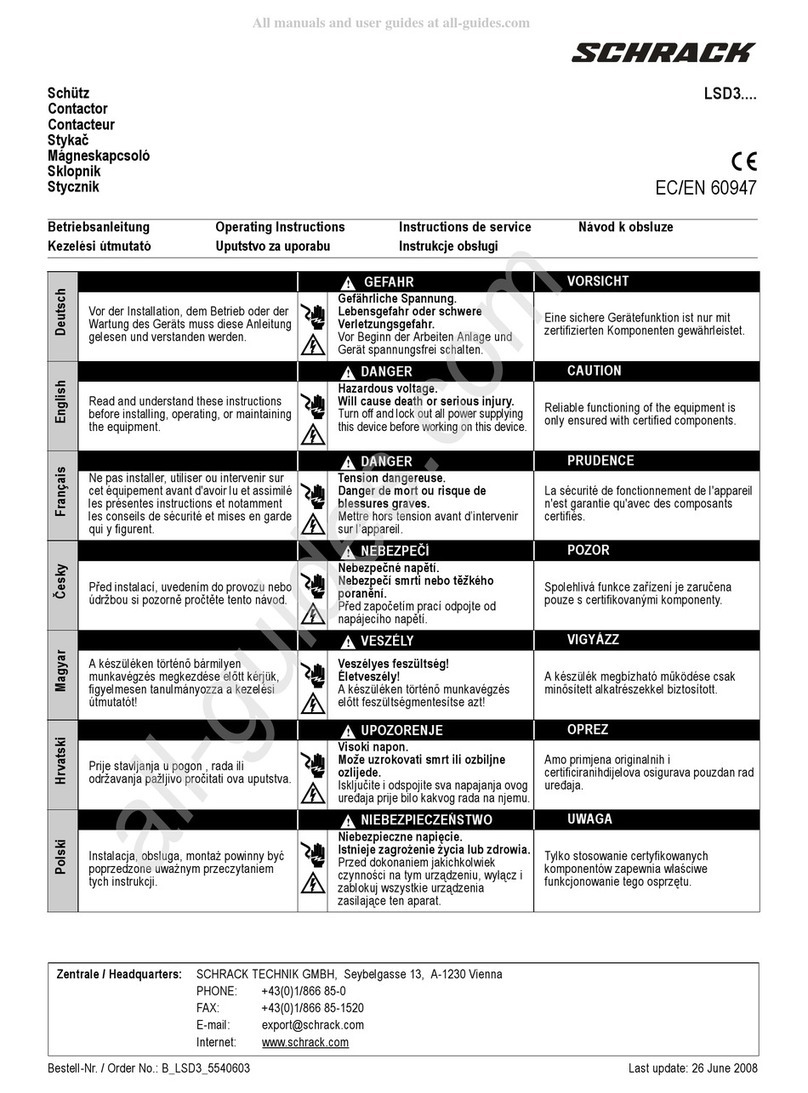

Fig. 1 –Drawing of the MRF102

Din Rail or Panel Mounting

Fig. 1 shows a dimensional drawing of the MRF102. It is possible to

mount the device on Din rail or in panel and fix it by 4 screws 2.9x8-16.

There is no limit for the Panel thickness.

How to Supply MRF102

The MRF102 is supplied directly from the power source which provide

power to the load. The device it is protected by internal physic fuse, also

in worst case situations. The input rating is 8 –35Vdc.

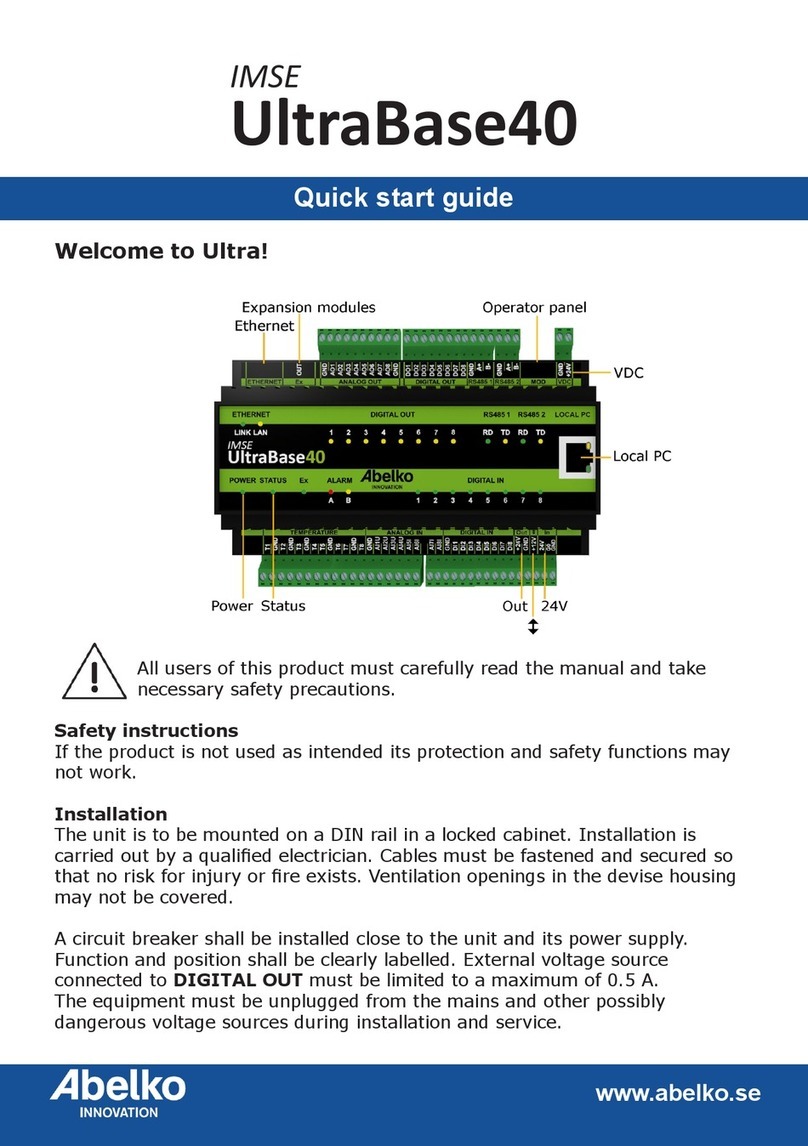

Device Connection (Fig.2)

The following cable cross-sections may be used:

Solid

(mm2)

Stranded

(mm2)

AWG

Torque

(Nm)

Stripping Length

In:

0.2–2.5

0.2–2.5

24 –14

0.5–0.6

7 mm

Out:

0.2–2.5

0.2–2.5

24–14

0.5–0.6

7 mm

Signal:

AMP Modu II

Connection by the screw, type 2.5 mm2. Wiring terminal shall be

marked to indicate the proper connection for the power supply. Use

copper cables only, for supply connections, use wires suitable for at

least 75°C.

Fig. 2 –Connections to MRF102

Connection terminal and wiring

Reference

Description

1

+ Input Power

2

- Input Signal

3

Push Botton: ON / OFF Channel 1 and 2 / Config.Mode

4

LED Green, Orange, Red: Channel controls / Config.Mode

5

LED Green, Orange, Red: Channel controls / Config.Mode

6

Output 1

7

Output 2

8

Output Fail CN1 and CN2 or ADELBus connection

4 Drive a Channel

Turn On Channel

On the first power up, all channel are OFF.

To enabling channel 1(LED Blink Red for short time) push the set button

for short time: one time; < 1 sec.

To enabling channel 2(LED Blink Red for short time) push the set button

for short time: two time; < 1 sec.

Each channel could be enabled after a Switch off for Overload or Short

circuit, (LED Red ON). When the LED Red flash for 3 time, the devise it’s

ready to turn ON the channel. If the channel is ON, the device maintains

in memory the state also without the power; this function it is not enabled

if the device is in configuration mode.

Turn Off Channel

When the channel 1 is ON (LED Blink Green or Orange for short time)

push button for short time: one time and the channel turn OFF; < 1 sec.

When the channel 2 is ON (LED Blink Green or Orange for short time)

push button for short time: Two time and the channel turn OFF; < 1 sec.

If the channel is OFF, the device maintains in memory the state also

without the power.

5 LED indication

•Led RED ON: the channel is in protection due to Overtemperature,

Overcurrent, Over/Under voltage (<8.5V or >32.5V).

The device could be in this situation for some sec.

In this condition it is not possible turn ON the device.

•Led RED flashes three times for short time: the channel is OFF after

switch protection, but is ready to be turned ON.

Push the set button to turn ON the device.

•Led RED flashes one for short time, the channel is OFF but ready

for turn ON. Push the set button to turn ON the device.

•Led GREEN blinks for short time: the channel is ON and the current

through the channel is <80% of the tipping point switch.

•Led ORANGE blinks for short time: the channel is ON and the

current through the channel is >80% of the tipping point switch.

•Config. Mode: One Led OFF and the second Led ORANGE blinks,

in this condition it is enabled the procedure:

•Verify the trip current set for each channel

•Configure the trip current for each channel

7Out 1

6Out 2

1Input +

2Input -

4LED CN1

5LED CN2

3

ON / OFF out 1: Tich -

ON / OFF out 2: Tich –Tich -

PROG: Press 2 sec. -

8 Fail _ ADELBus

Via Luigi Barchi 9/B –Reggio Emilia 42124 –Italy

Tel. +39 0522 345518 –Fax +39 0522 345551 –www.adelsystem.com

Instruction Manual MRF102_7.docx

Page 2

6 Control and Programming

How to verify the trip current sett

Press the set button for more than 2 sec. until LED channel 1 start to blink

Orange.

•The number of Orange blink provide the number of Ampere set for

the trip current: 1 Blink = 1A … 10 Blink 10A

•Press the push button for more than 2 sec. until LED channel 2 start

to blink Orange.

•The number of Orange blink provide the number of Ampere set for

the trip current: 1 Blink = 1A … 10 Blink 10A

•End the procedure by holding down the button for 2 seconds until

the LEDs resume their regular flashing.

If the button is not pressed for 20 seconds, the procedure ends

automatically and the LEDs resume their regular flashing.

How to set the trip Current

Press the push button for more than 2 sec. until LED channel 1 start to

blink Orange.

•Option: it is possible count the number of orange blinks according to

the number of Ampere set for the trip current: 1 Blink = 1A … 10

Blinks = 10A

•Press the push button for a number of time equivalent to the desired

number of tripping Ampere.

•Verify option: successively press the desired Ampere, the device will

return the set number after 2 sec

•Correction option: correction of the current setting by pressing one

more time the set button: e.g., 6A + 1A more = 7A. When 10A is

reached, the counter restart from 1A.

•To confirm the New Trip Current setting, press the push button for 2

sec. until LED channel 2 start flashing orange.

Set the current limit for channel 2 in the same way as for channel 1.

•Confirm the new Trip Current of the channel 2 and finish the

Configuration procedure by holding the button for 2 seconds until the

LEDs start flashing regularly again.

•Mandatory: to ensure the new value is set, the procedure must be

completed. If the button is not pressed for 20 seconds, the procedure

automatically ends and the LEDs resume flashing regularly. The

device retains the old value.

Note: On the first power up the device is programmed at 3A for each

channel.

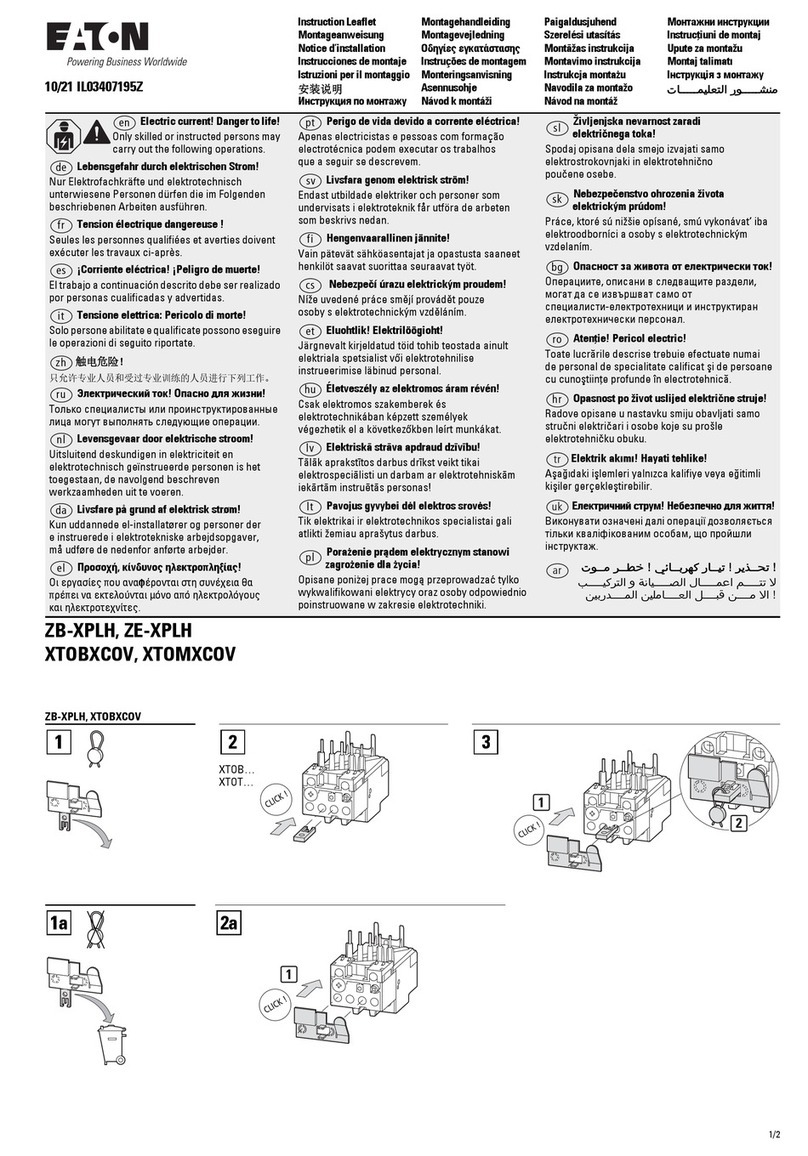

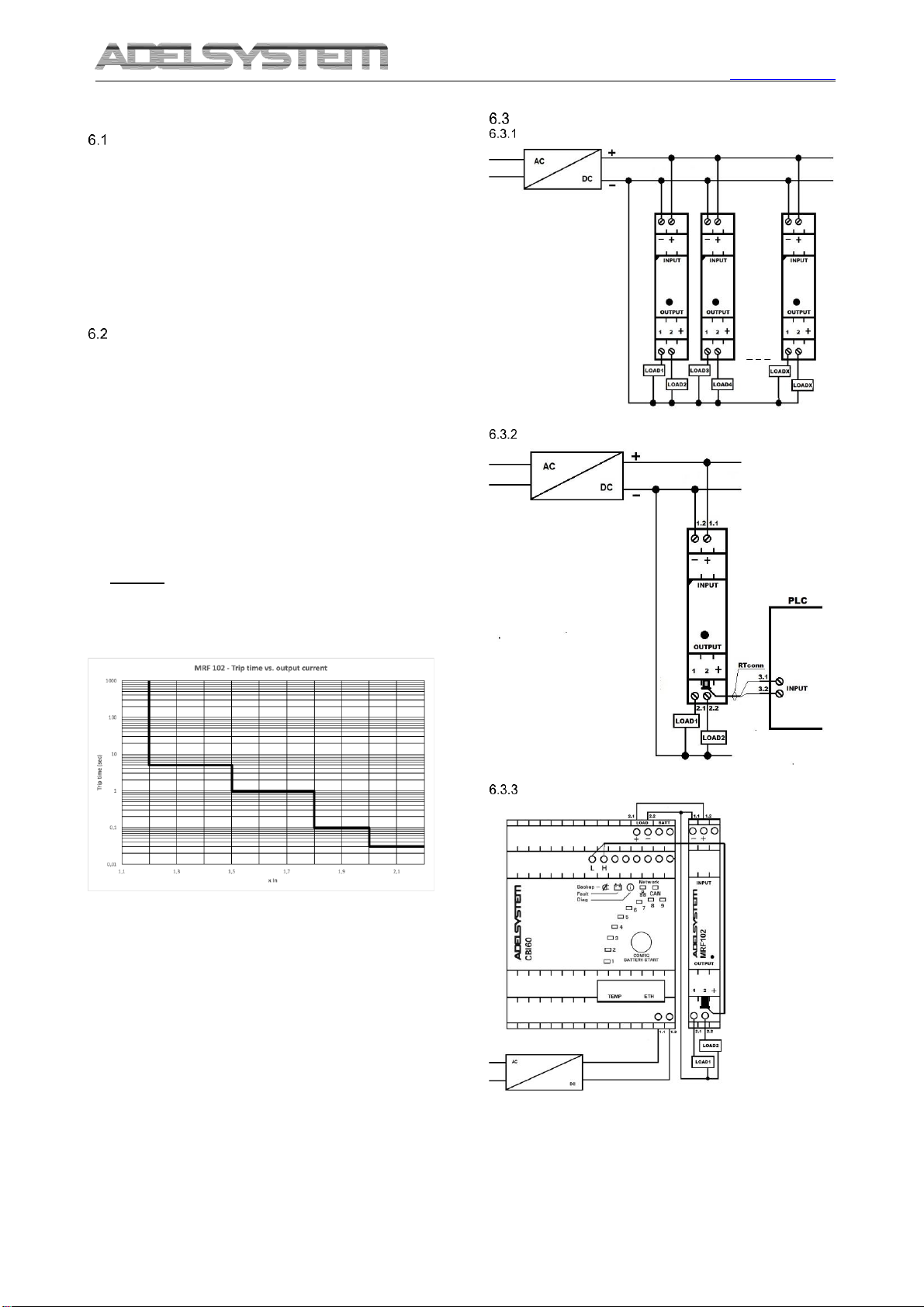

Connection Diagram

Multiple Devices

PLC Fail Connection

CBI60 –MRF102 Driver

Via Luigi Barchi 9/B –Reggio Emilia 42124 –Italy

Tel. +39 0522 345518 –Fax +39 0522 345551 –www.adelsystem.com

Instruction Manual MRF102_7.docx

Page 3

7 Technical data

Input Data

Supply voltage / at DC / Rated

value

12 –24 V

DC Input Voltage range (Vdc)

8 –35 V

Overvoltage overload capability

35 V

Input current / at rated input

voltage 12 - 24 V / Rated Value

20 A max (30A peak max 10

sec)

Maximum current consumption

10mA (12 VDC) - 10mA (24

VDC)

Required Back Up Fuse

Not required. Integrated

failsafe element (internal fuse)

Input Voltage Reset Output

7 …32 Vdc

Output Data

Voltage curve / at output

Controlled DC voltage

Drop Out

0.2 V

Number of outputs

2

Output current / up to 60 °C / per

output / rated value

10 A

Adjustable switch Off out current

1 …10A

Type of response value setting

via Blink code Led

Parallel switching of outputs

Yes

Bridging of equipment’s

No

Start Up

< 0.5 sec.

Surge voltage shutdown load

circuit

>32 Vdc

Max Capacitive Load

50.000 uF

Rated Surge Voltage

0.5 KV

Efficiency

Efficiency

97%

Power loss [W] (max)

1.5W (Nominal Operation)

Power dissipation

0.9 W (No Load operation)

Switching - off per output

Iout = 1.0 ...1.5 x set value

switch-off after approx. 5 s

Iout = 1.5 ...1.8 x set value

switch-off after approx. 1 s

Iout = 1.2 ...2 x set value

switch-off after approx. 0,1 s

Iout > 2 x set value

switch-off after approx. 0,03 s

Iout > set value and Vin < 15%

(24V); (12V)

switch-off after approx. 0,03 s

Turn On Output after Switch Off

-Manual Reset

-By Press Button

Waiting time after switch off Out

-5 sec max. (Hover load / Short

Circuit)

Protection and Monitoring

Internal Fuse protection type

16A per output (not replaceable)

Dielectric strength

Max 32 Vdc (on Load Circuit)

Display version

Three-color LED per output:

-green LED for "Output switched

through"

-Red LED for "Output switched off

manually"

-Red LED Blink for "Output

switched off due to overcurrent"

-Orange LED: Verify and Config

Connection for monitoring

device:

AUX1: connection 2 pin AMP

Configuration Aux1

1: as ADELBus for Driving,

Monitoring, Configuring

2: Out Alarm for For SwitchOff

Output

Diagnosis

-Common Signaling for

disconnection Last Output

-Single Channel: Current, set current

threshold, Status On/Off

- Reason of Output disconnection

Connection

Input 12 or 24V

1 Screw Type

0.2 - 2.5 mm2

(24 –12 AWG);

0.6 - 0.8 Nm

Input 0V

1 Screw Type

Outputs

1 Screw Type

Signal Output:

AUX1: connection 2 pin AMP

Ambient Conditions

Nominal Temperature

operation

-25 up to+60°C (>60°derating

2.5%°C)

Ambient Temperature

operation

-25 up to +70 °C

Ambient Temperature Storage

-40 up to +85 °C

Humidity at 25 °C, no

condensation

95 % to 25 °C (acc. to IEC 60721)

Vibration (operation) IEC

60068-2-6

<15 Hz, amplitude 2.5mm

<15Hz-150Hz, 2.3G 90 min.

Altitude: 0 to 2 000m - 6560

to 20 000ft

No restrictions

General Data

Protection Class (EN/IEC

60529)

IP20

Reliability: MTBF IEC 61709

> 700.000 h (Automatically Switch

Off Beck Light after 30 sec)

Protection class

III

Housing material

Polycarbonate

Foot latch material

Plastic POM

Screw type connection

0.2 - 2.5 mm2(24 –12 AWG

0.6 - 0.8 Nm

Dimension (w-h-d) mm

18 x 90 x 61

Weight

0.1 kg approx.

8 Norms

Immunity and Emission

The CE mark in conformity to EMC 2014/30/EU: Electromagnetic

Compatibility Directive; 2014/35/EU: Low Voltage Directive; ROHS

2011/65/EU: Restriction of the use of certain Hazardous Substances in

Electrical and Electronic Equipment (RoHS), as amended by

2015/863/EU

•EMC Immunity: EN61000-6-2

•EMC Emission: EN61000-6-3, EN 55022 ClassB

Electrical Safety for mounting

According to:

•Electrical Equipment for Machinery EN 60204

•Electrical safety (of information technology equipment)

IEC/EN EN62368-1.

•Safety requirements for electrical equipment for

measurement, control and Laboratory use IEC/EN 61010

9 Accessory

•RTConn: connector cable for the connection to AUX1. It is

possible drive the device through the ADELBus network.