GEr-861518

DRAWOUT BREAKERS

GENERAL

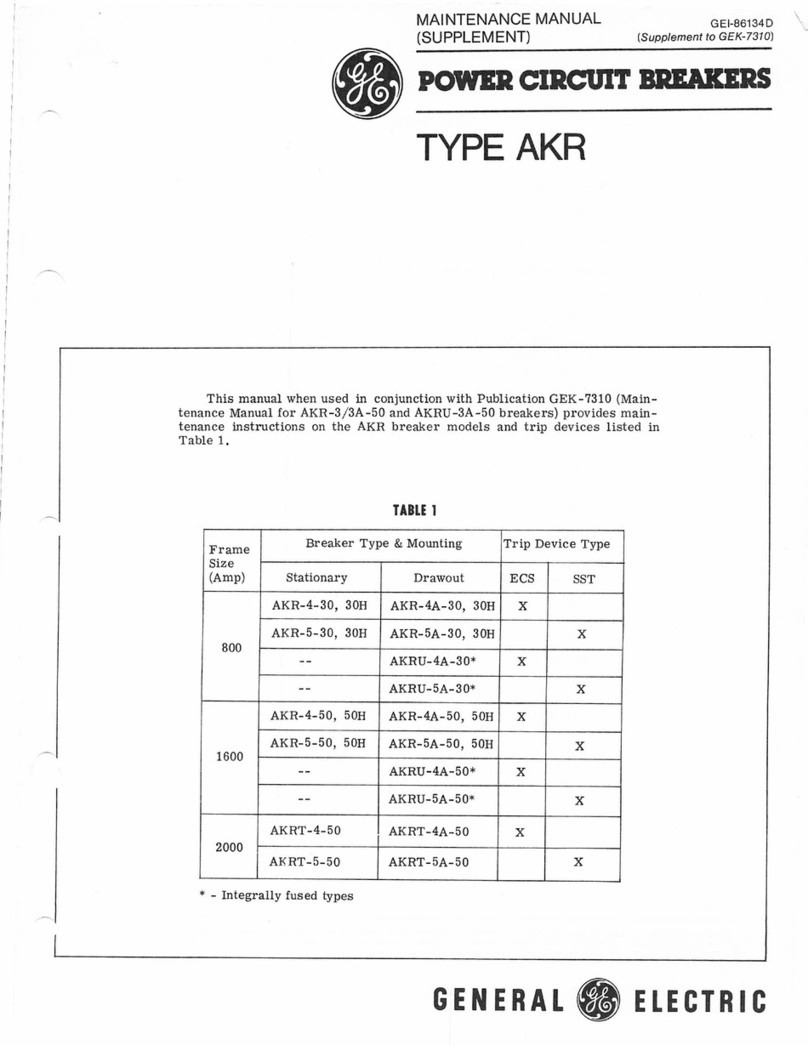

Drawout breakers are manufactured in four different

styles, identified in Table 2 by the mounting code letters

None, A, B & C. The "no-letter" models are used in General

Electric's AKD Switchgear. Code A breakers were later intro-

duced with AKD-5 Switchgear and feature closed-door draw-

out ooeration. Code B breakers provide an alternate closed-

door drawout arrangement with the stationary element

furnished as a preassembled "substructure". Code C

breakers are exclusively for AKD-6 Switchgear; they employ

the Code A drawout mechanism but have finger-type primary

studs instead of tubular. The construction and operation of

each of these drawout styles is covered under respective

headings in the following text.

As a general rule, breakers of the same drawout type,

voltage rating and ampere frame size are physically inter-

changeable. In addition, to be electrically interchangeable

with respect to secondary and control circults, they must

have duplicate wiring. The degree of interchangeability and

the mechanisms for controlling it are discussed separately

on page 1 7.

NOTE: The four drawout types are mutually non-

interchangeable; before attempting to insert a

breaker, verify that the breaker model matches the

compartment.

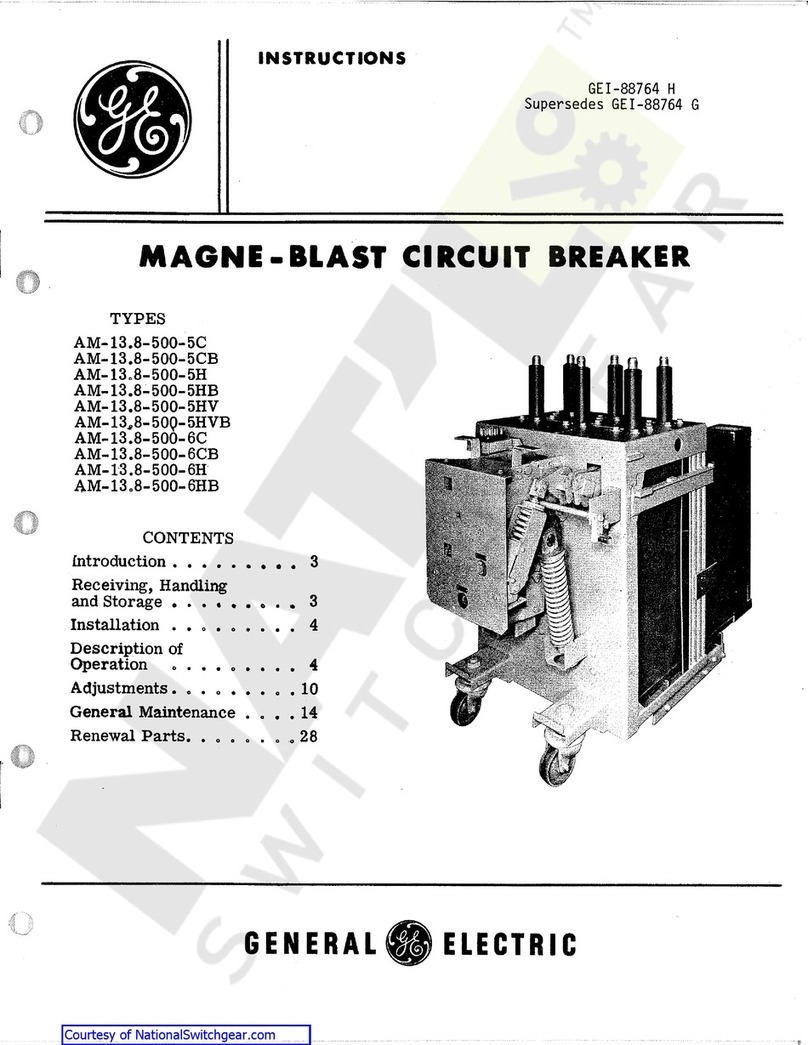

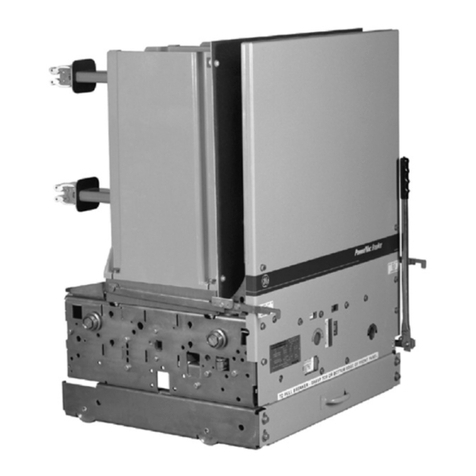

No CODE LETTER (AKD SWITCHGEAR) (Fig. 1)

These "no-lette/' AKR-75/'l 00 models are replacements

for their AK-75 and AK-100 predecessors in AKD switchgear.

The racking mechanism is breaker-mounted and the

breakers are bolted to a roller-mounted tray in an arrange-

ment similar to the B Type (see page 8). In addition to the

characteristics listed in Table 1, the AKD drawout has the

following unique aspects:

1. There are three (3) distinct drawout positions - CON-

NECTED, TEST and WITHDRAWN.

2. Racking travel occurs only between the CONNECTED

position and a point just short of reaching the TEST position.

3. The compartment door must be open during racking.

Breaker Insertion (AKD Type)

1. Prior to lifting a breaker to its intended compartment

location, observe the following precautions:

a. Check the compartment to insure that it is free of

foreign objects.

b. Verify that the breaker is the correct type for that

compartment.

c. Insure that the breaker ls OPEN.

d. Apply athin, fresh coat of D50HD38 lubricantto the

b re ake r's p ri m ary di scon n ects.

e. lnsure that the racking cams on the breaker are

correctly positioned for initial engagement with the

pins in the compartment. To do this, insert the rack-

ing handle and rotate it fully clockwise.

t. lf a compartment contains a keylock, it will not ac'

cept the AKR-751100 replacement breakers as re-

ceived. The AKR drawout mechanism differs from

that of its predecessor AK model, causing the AKR

breaker to mechanically interfere with the keylock

during breaker insertion. To remedy this it will be

necessary to relocate the keylock using new mount-

ing hardware included as a modification kit. So al-

tered, the compartment accepts both AK and AKR

types.

2. Using a suitable lifting mechanism and spreader rig,

position lifting hooks at the cutout notches in the top wrap-

around f rames of the breaker. Exercise care to avoid damage

to the control wiring.

3. Open the compartment.door. Keeping the rollout tray

positioned inside the compartment, raise the breaker above

the elevation of the tray.

4. Depress the test position stop lever and pull the tray all

the way out to its WITHDRAWN position.

5. Lower the breaker over the tray until it is about one-

half inch above the two dowel pins on the tray. Push the

breaker back into the comoartment until the rear bottom

flange of the breaker rests against the guides behind the

dowel oins.

6. Slowly lower and guide the breaker onto the tray so

the holes in the rear flange fit over the two dowel pins. When

correctly positioned on the dowel pins, the breaker's rear and

side bottom flanges will rest firmly on the tray.

7. Secure the breakerto the tray by inserting and tighten-

ing two-s/e inch hex-head screws into the front holes of its side

flanges.

8. lf the breaker is a manually operated type, push it into

the compartment until the TEST position stop engages,

preventing further travel. The breaker is now in the TEST

position.

lf the breaker is electrically operated, push it into the

compartment until the spring discharge stop is encountered.

Release this by depressing the "spring discharge" lever on the

bottom of the breaker (see fig. 1), then continue pushing the

breaker into the compartment until the TEST position stop

engages.

NOTE:A sprlng discharge stopwill not be presentin

some AKD-type compartments originally furnished

for electrically operated AK-75 and AK-100 breakers

of the non-quick-close type.

9. Depress the TEST position stop lever and push the

breakerfarther intothe compartment until the outersurfaces of

the racking cams butt against the racking pins in the housing.

10. Insert the racking handle (673D0500-636-05) on the

jackscrew shaft at the upper right side of the breaker. Rotate

it clockwise until the jackscrew comes to a solid stop. The

breaker is now in the CONNECTED oosition.

5