Adexa EMP500SDF User manual

1

UNDERCOUNTER TYPE DISHWASHER

CONTENTS

A GENERAL INFORMATION Page 2

A1 PRODUCT DESCRIPTION Page 3

A2 TECHNICAL INFORMATION Page 3

A3 TRANSPORTATION Page 4

A4 UNPACKING Page 4

B INSTALLATION Page 4

C SAFETY INSTRUCTIONS Page 5

D OPERATION Page 6

E CLEANING & MAINTENANCE Page 7

F TROUBLESHOOTING Page 8

G SPARE PART LIST- EXPLODING DRAWING Page 9

H ELECTRIC CIRCUIT SCHEMA Page 12

2

UNDERCOUNTER TYPE DISHWASHER

A GENERAL INFORMATION

Before installing the appliance, read operation and maintenance instructions

carefully.Wrong installation and part changing may damage the product or may cause

injury on people.These are not in our company’s responsibility to damage the

appliance intentionally,negligence,detriments because of disobeying instructions and

regulations,wrong connections.Unauthorized intervention to appliance invalidates the

warranty.

1. This instruction manual should be kept in a safe place for future reference.

2. Installation should be made in accordance with ordinances and security rules of

that country by a qualified service personnel.

3. This appliance has to be used by trained person.

4. Please turn off the appliance immediately in the event of malfunction or failure.The

appliance should be repaired only by authorized service personnel.Please demand

original spare part.

3

UNDERCOUNTER TYPE DISHWASHER

A1 PRODUCT DESCRIPTION and TECHNICAL INFORMATION

4

UNDERCOUNTER TYPE DISHWASHER

A3 TRANSPORTATION

*This appliance can not be moved by hand from area to area.It must be moved on pallet with

forklift truck.

A4 UNPACKING

*Please unpack the package according to the security codes and ordinances of current

country and get rid from the pack.Parts which contacts with food are produced by stainless

steel.All plastic parts are marked by material’s symbol.

*Please check that all the parts of appliance had come completely and if they are damaged or

not during the shippin.

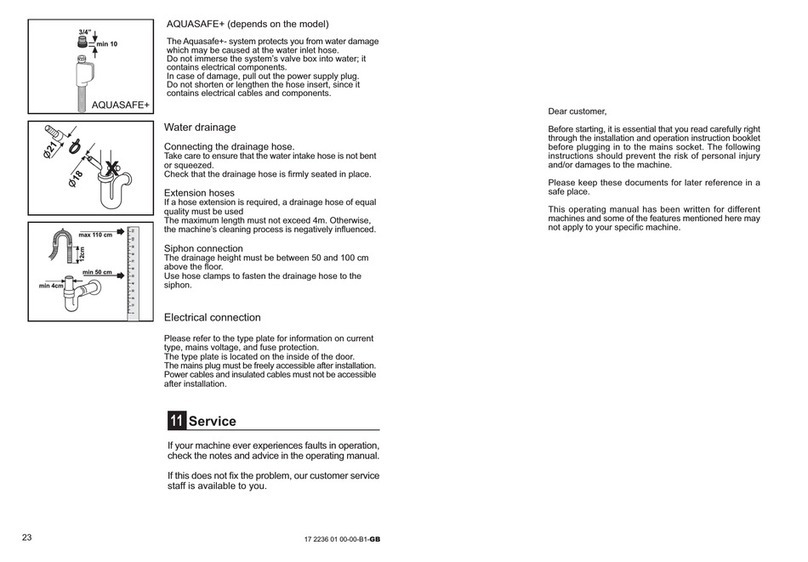

B INSTALLATION

*Please place the product to straight and sturdy ground,please take necessary steps against

possibility of overturn.

*Technician who will serve for installation and service for the appliance must be professional

on this subject and must have installation and service licenses by the company.

*Connection to Electric Power Supply must be done by authorized person.

*Please be sure that the voltage connected to appliance must be equal with the voltage which

is on appliance’s label.

This appliance must be connected to an earthed outlet in accordance with safety rules

and standards.

*Appliance’s earthing must be connected to earthing line on panel which is nearest to

electric installation.

*Connection to the main fuse and leak current fuse must be done in accordance with the

current regulations.

!

5

UNDERCOUNTER TYPE DISHWASHER

C SAFETY INSTRUCTIONS

*Do not use the appliance in insufficient lighted place.

*Do not touch the moving attachments while the appliance operates.

*Do not install the appliance in the presence of flammable or explosive materials.

*Do not operate the appliance when the machine is empty.

*Do not load so less or more than appliance’s capacity.

*Do not attempt to use the appliance without suitable protective equipments.

*Because of any reason if there is a fire or flame flare where the appliance is

used,turn off all gas valves and electric contactor switch quickly and use fire

extinguisher .Never use water to extinguish the fire.

*All the damages because of not having earthing connection will not be on

warranty.

*Do not wash the decorated dishes.Prevent silver wares to contact with the other

metals.

!

!

!

!

!

!

!

6

UNDERCOUNTER TYPE DISHWASHER

7

UNDERCOUNTER TYPE DISHWASHER

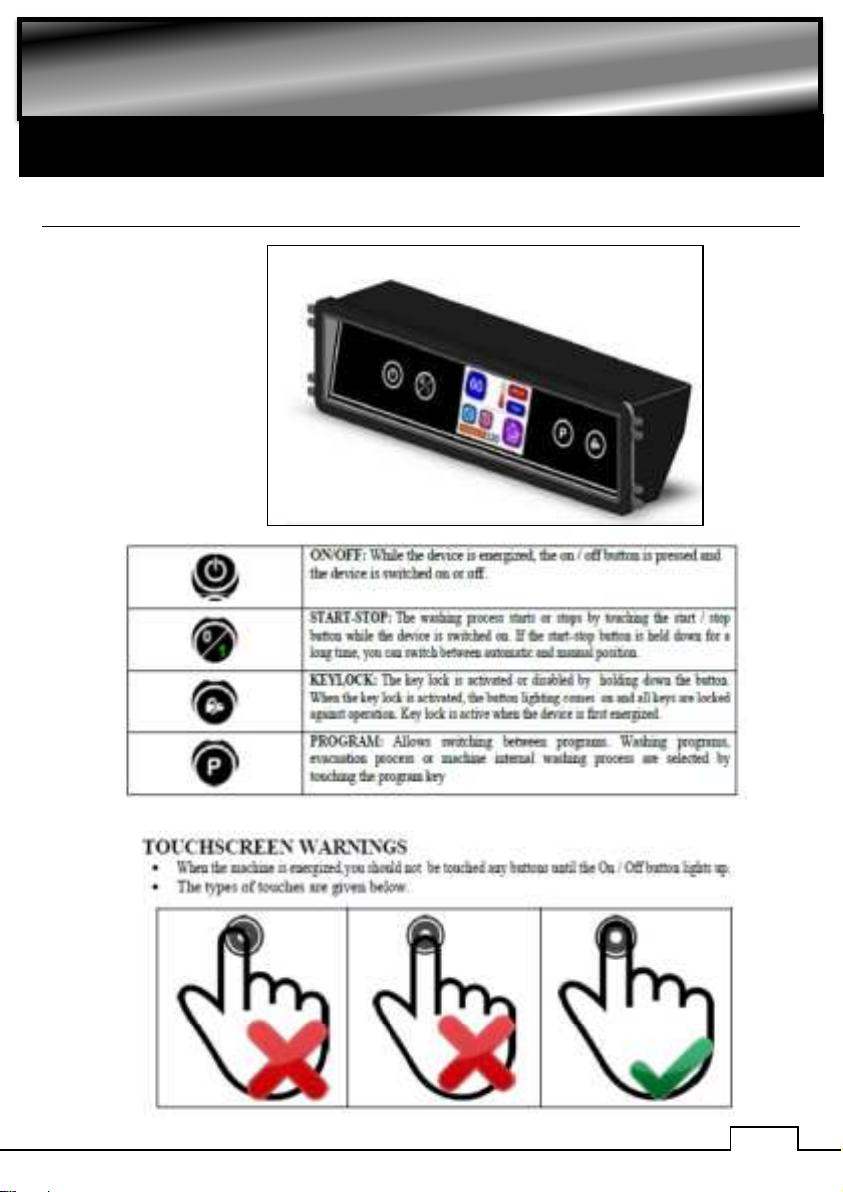

D OPERATION

8

UNDERCOUNTER TYPE DISHWASHER

9

UNDERCOUNTER TYPE DISHWASHER

1 time in 50 washes

10

UNDERCOUNTER TYPE DISHWASHER

E CLEANING & MAINTENANCE

CLEANING AND MAINTENANCE AFTER EVERY USE

Always turn off the appliance and disconnect from the power supply before cleaning.

Evacuate the water by taking off the stopple and switching to evacuation position

after every use.

Clean all surfaces of the appliance with hot soapy water after every use.Rinse and

dry with a wet cloth.

Clean the control panel with soft moisty cloth,if necessary use ineffective detergent.

Do not use abrasive cleaning chemicals as these can leave harmful residues.

Do not clean the appliance by spraying water directly,otherwise electric motor may

get damaged.

PERIODIC CLEANING AND MAINTENANCE

Maintenance should be done by qualified person.

For theefficiency of the product, it is significant to keep the service supported annual

maintenance of the boiler.

According to the scale ratio of your location, it is advised to keep the weekly/monthly

maintenance to clean the washing tank and interior surfaces, water hoses, trunks

and sprinklers.

Please clean the washing nozzles weekly by disassembling.

Please clean the drainage pump and the engine sorption filter weekly.

Utilisation of anti-scale during the cleaning of the apparatus.

- After the entrance of the clean water into the machine, please wait for the

heating time.

- Pour 100 mililiters of of anti-scale in the boiler.

- Run the empty machine for 3-4 times.

- Drain the water.

Do not leave the anti-scale substance within the boiler for a long period of time.

Otherwise, it might damage the internal parts.

11

UNDERCOUNTER TYPE DISHWASHER

F TROUBLESHOOTING

THE APPLIANCE

DOESN’T WASH WELL

1. Clean the absorbing filter if it is dirty.

2. Check the washing nozzles if they are accumulated

with residues or not.

3. Check the amount of detergent.

4. If chosen washing program is too less,repeat the

program.

5. Check if the plates are placed to the baskets correctly.

CUPS AND PLATES ARE

NOT DRIED WELL

1. If there is polisher or not,if not add some.

2. Check the amount of polisher.

MIST OVER ON CUPS

1. After washing process ,take off the cups from baskets.

CORROSİON ON CUPS

1. Only use products that are not foaming for the

professional dishwashers.

MUCH FOAM AT

STORAGE

1. Check the amount of detergent .

2. If foaming detergent is used,pour it and rinse the

storage till the foams are lost.

WASHING OR RINSING

HANDLES ARE TURNING

SLOWLY

1. Take off washing handles and clean them.

2. Clean the washing pump absorbing filter.

VISCIDITY AND SPOTS

ON CUPS

1. Reduce the amount of polisher.

If dishwashing is not done at suitable quality

If any function of security doesn’t work

Do not use the appliance.

*If these problems are still going on,contact with our authorized services.

12

UNDERCOUNTER TYPE DISHWASHER

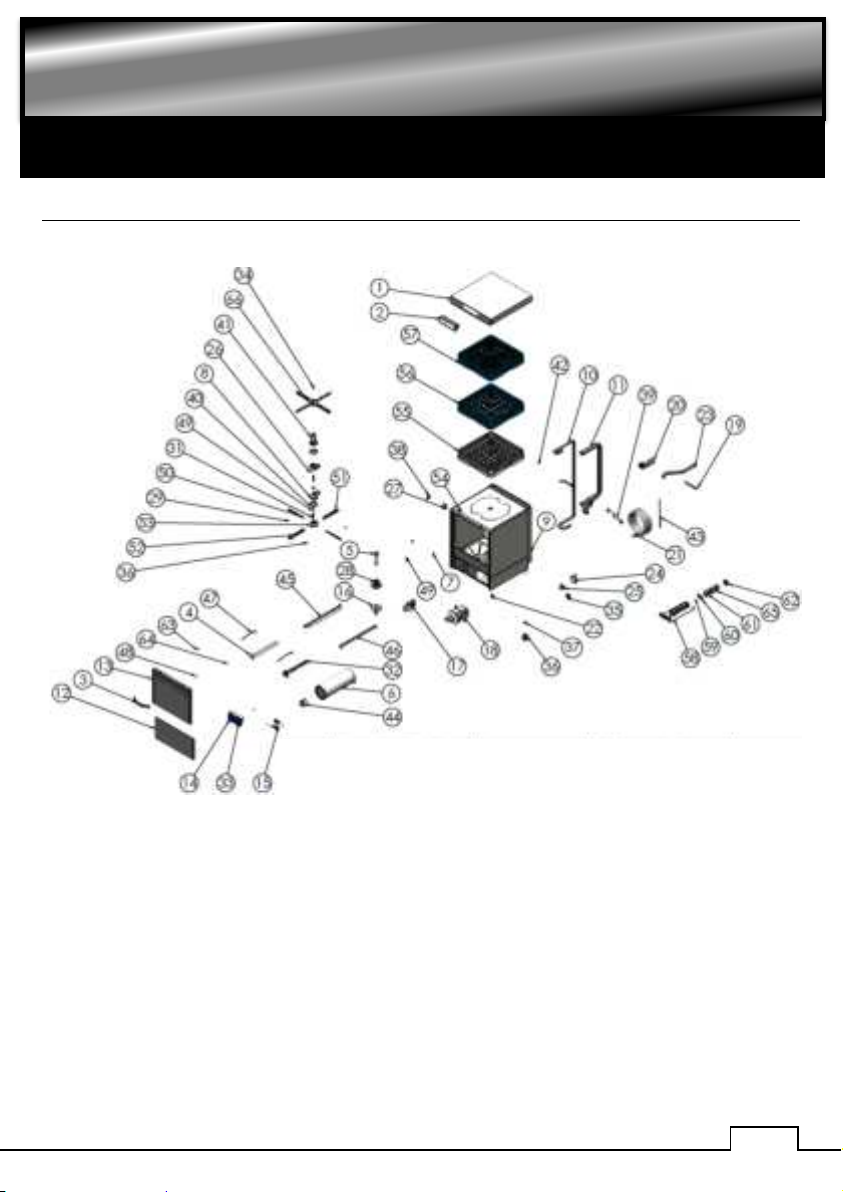

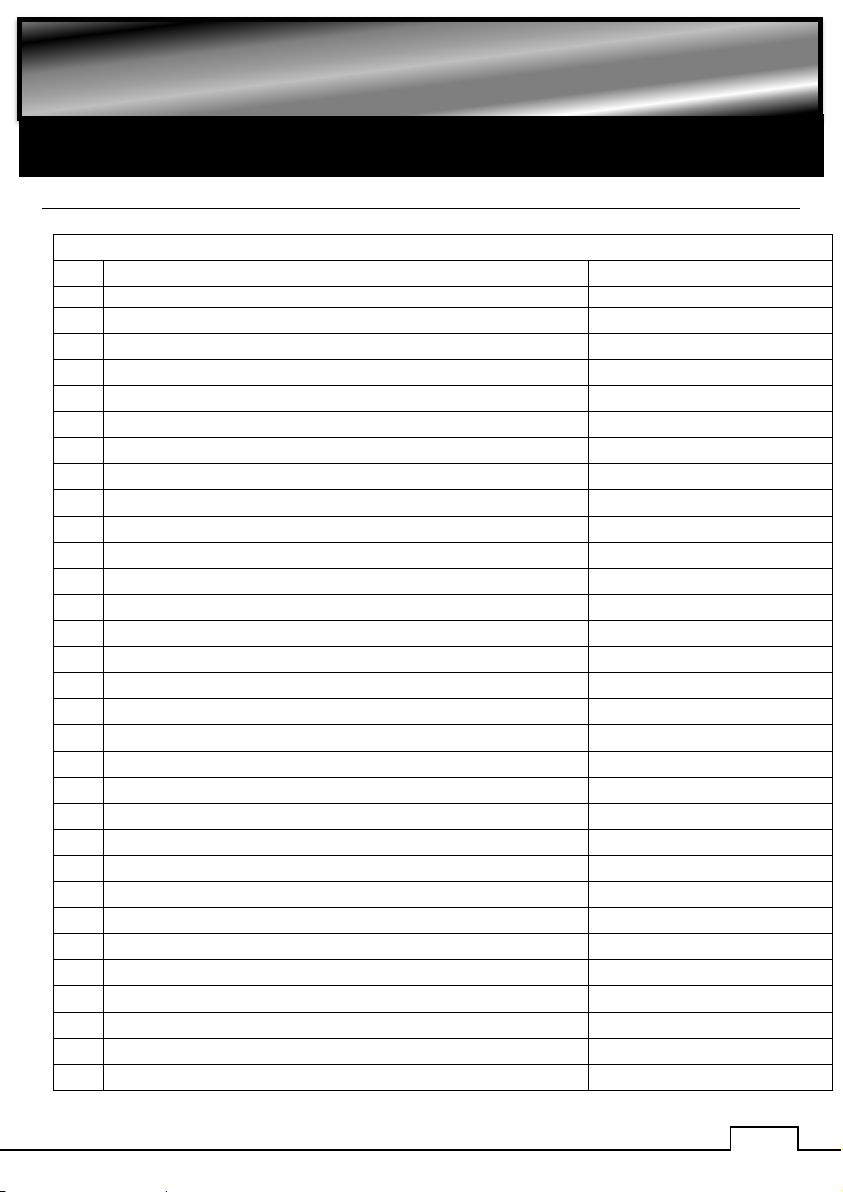

G SPARE PART LIST-EXPLODING DRAWING

13

UNDERCOUNTER TYPE DISHWASHER

G SPARE PART LIST-EXPLODING DRAWING

ÜRÜN KODU :500-SD

NO

ÜRÜN ADI

ÜRÜN KODU

1

TOP COVER

Y.500.SD.001.001

2

DIGITAL DISPLAY

Y.500.SD.001.002

3

COVER HANDLE

Y.500.SD.001.003

4

BOILER RESISTANCE

Y.500.SD.001.004

5

DISCHARGE CHOCK

Y.500.SD.001.005

6

BOILER TANK

Y.500.SD.001.006

7

TOP COVER PASS

Y.500.SD.001.007

8

UPPER HOSE ENTRANCE ELBOW

Y.500.SD.001.008

9

CHASSIS

Y.500.SD.001.009

10

RINSE HOSE

Y.500.SD.001.010

11

WASHING HOSE

Y.500.SD.001.011

12

BOTTOM COVER

Y.500.SD.001.012

13

FRONT COVER

Y.500.SD.001.013

14

DETERGENT PUMP

Y.500.SD.001.014

15

THERMOSTAT

Y.500.SD.001.015

16

CHOCK BED

Y.500.SD.001.016

17

DISCHARGE PUMP

Y.500.SD.001.017

18

ENGINE

Y.500.SD.001.018

19

BOILER VALVE HOSE

Y.500.SD.001.019

20

BOILER PUMP HOSE

Y.500.SD.001.020

21

WASTE WATER HOSE

Y.500.SD.001.021

22

FOOT

Y.500.SD.001.022

23

BOILER DRAIN HOSE

Y.500.SD.001.023

24

AIR TRAP

Y.500.SD.001.024

25

VALVE

Y.500.SD.001.025

26

LOWER HOSE ENTRANCE ELBOW

Y.500.SD.001.026

27

CORNER WEDGE - RIGHT

Y.500.SD.001.027

28

FILTER COVER

Y.500.SD.001.028

29

RINSING EYE

Y.500.SD.001.029

30

WASHING EYE

Y.500.SD.001.030

31

SPRAY SHAFT

Y.500.SD.001.031

14

UNDERCOUNTER TYPE DISHWASHER

32

BOILER RESISTANCE

Y.500.SD.001.032

33

POLISHING PUMP

Y.500.SD.001.033

34

SPRAY NUT

Y.500.SD.001.034

35

PROSESTAT

Y.500.SD.001.035

36

ROUND DRAIN BED

Y.500.SD.001.036

37

STRAINER NUT

Y.500.SD.001.037

38

CORNER WEDGE - LEFT

Y.500.SD.001.038

39

MAINS HOSE

Y.500.SD.001.039

40

LOWER UPPER SPRAY GASKET

Y.500.SD.001.040

41

BOTTOM SPRAY BELLY

Y.500.SD.001.041

42

DETERGENT INLET

Y.500.SD.001.042

43

PROSESTATE HOSE

Y.500.SD.001.043

44

RESISTANCE COVER

Y.500.SD.001.044

45

RIGHT BASKET SLIDE

Y.500.SD.001.045

46

LEFT BASKET SLIDE

Y.500.SD.001.046

47

COVER HANDLE SHEET

Y.500.SD.001.047

48

COVER SCREW

Y.500.SD.001.048

49

SUPPORT CHOCK

Y.500.SD.001.049

50

STOP HANDLE 3 OUTLET

Y.500.SD.001.050

51

STOP HANDLE 4 OUTLET

Y.500.SD.001.051

52

STOP HANDLE 5 OUTLET

Y.500.SD.001.052

53

SPRAY BELL

Y.500.SD.001.053

54

COVER SENSOR

Y.500.SD.001.054

55

PLATE BASKET

Y.500.SD.001.055

56

CUTLERY BASKET

Y.500.SD.001.056

57

CUP BASKET

Y.500.SD.001.057

58

PANEL SLIDE SHEET

Y.500.SD.001.058

59

GLASS INSURANCE

Y.500.SD.001.059

60

FUSED TERMINAL

Y.500.SD.001.060

61

CONTRACTOR DILEM 01

Y.500.SD.001.061

62

RAIL KILIMENS

Y.500.SD.001.062

63

MAGNET BED

Y.500.SD.001.063

64

MAGNET

Y.500.SD.001.064

65

CONTRACTOR DILEM 01

Y.500.SD.001.065

66

SPRAYING SET

Y.500.SD.001.066

15

UNDERCOUNTER TYPE DISHWASHER

H ELECTRIC CIRCUIT SCHEMA

Table of contents

Other Adexa Dishwasher manuals