Adleepower AP2G3-137 User manual

ADLEEPOWER

INSTRUCTION MANUAL

GENERAL-PURPOSE INVERTER

THANK YOU VERY MUCH FOR YOUR PURCHASE

OF ADLEE INVERTER APxG3 SERIES.

PLEASE READ THIS INSTRUCTION MANUAL

BEFORE INSTALLATION OF THE INVERTER.

R

AP2G3-137~AP2G3-1185

AP2G3-337~AP2G3-3220

AP4G3-337~AP4G3-3220

CONTENTS

1. RECEIVING

2. SPECIFICATIONS

3. DIMENSION DRAWINGS

4. INSTALLATION

5. DESCRIPTION OF TERMINALS

6. DIGITAL OPERATION PANEL

7. FUNCTIONS DESCRIPTION

8. PROTECTIVE FUNCTIION

9. PRECAUTIONS

10. TROUBLESHOOTING

11.APPLICATION

12. INVERTER SELECTION

13. APPENDIX

A. Optional braking resistor

B. Terminal wiring diagram

C. Remote operator

1

2

4

6

8

18

19

73

77

78

79

85

89

89

90

91

1. RECEIVING

Befor installation and wiring, check to see :

(1) No damage is found on each product after shipping.

(2) The product is as ordered (check the nameplate, voltage and fre-

quency).

(3) A set of inverter unit and instruction manual is contained in the

package.

For any irregularity, contact the sales shop where you purchased

immediately.

(4) Description of name plate

VER A 01

SOFTWARE

HARDWARE

VERSION

MODEL : AP 4 G3 - 3 37

Max Applicable motor(4 pole)

37 : 3.7KW 55 : 5.5KW 75 : 7.5KW

110 : 11KW 150 : 15KW 185 : 18.5KW

220 : 22KW

1: 1

3: 3

AP series

Voltage class :

2 : 200/220V

4 : 380/440V

IPM AC drive

1

∮

∮

2. SPECIFICATIONS

2

PROG

Model AP2G3

Voltage 1φ 220VAC ± 10% 3φ 220VAC ± 10%

Model No 137 155 175 1110 1150 1185 337 355 375 3110 3150 3185 3220

Input Frequency 50HZ/60HZ ±5%

Output Voltage 3φ 220VAC

Output Frequency 0.5 ~ 400HZ

Output

Rated current (A) 16 23 30 43 56 70 17 24 33 46 61 76 90

Capacity (KVA) 6.1 8.8 11.4 16.4 21.3 26.7 6.5 9.2 12.6 17.6 23.3 29 34

Largest motor

KW ( 2.4.6 poles ) 3.7 5.5 7.5 11 15 18.5 3.7 5.5 7.5 11 15 18.5 22

Control Sine wave pulse width modulation

Braking Regenerative discharge braking

Over current

Capacity 150% of rated current ( 1 minute)

Acceleration time 0.1 ~ 6000 SEC

Deceleration time 0.1 ~ 6000 SEC

Frequency

setting Digital Use keyboard for setting and confirm by

Analog Analog signal input DC 0~5V, 0~10V, 4~20mA

Output signal Open collector output 50v 50mA Max

Cooling Method Air-cooled

Dimension drawing Fig 1 Fig 2 Fig 1 Fig 2

Weight ( KG ) 5.5 6.2 6.6 17 18 18.5 5.5 6.2 6.6 17 18 18.5 19

PROG

3

Model AP4G3

Voltage 3φ 380/440VAC ±10%

Model No 337 355 375 3110 3150 3185 3220

Input Frequency 50HZ/60HZ ±5%

Output Voltage 3φ 380/440VAC

Output Frequency 0.5 ~ 400HZ

Output

Rated current (A) 8.5 12 16.5 23 31 38 45

Capacity (KVA) 6.5 9.2 12.6 17.6 23.6 29 34

Largest motor

KW ( 2.4.6 poles ) 3.7 5.5 7.5 11 15 18.5 22

Control Sine wave pulse width modulation

Braking Regenerative discharge braking

Over current

Capacity 150% of rated current ( 1 minute)

Acceleration time 0.1 ~ 6000 SEC

Deceleration time 0.1 ~ 6000 SEC

Frequency

setting Digital Use keyboard for setting and confirm by

Analog Analog signal input DC 0~5V, 0~10V, 4~20mA

Output signal Open collector output 50v 50mA Max

Cooling Method Air-cooled

Dimension drawing Fig 1 Fig 2

Weight ( KG ) 5.5 6.2 6.6 6.8 18 18.5 19.5

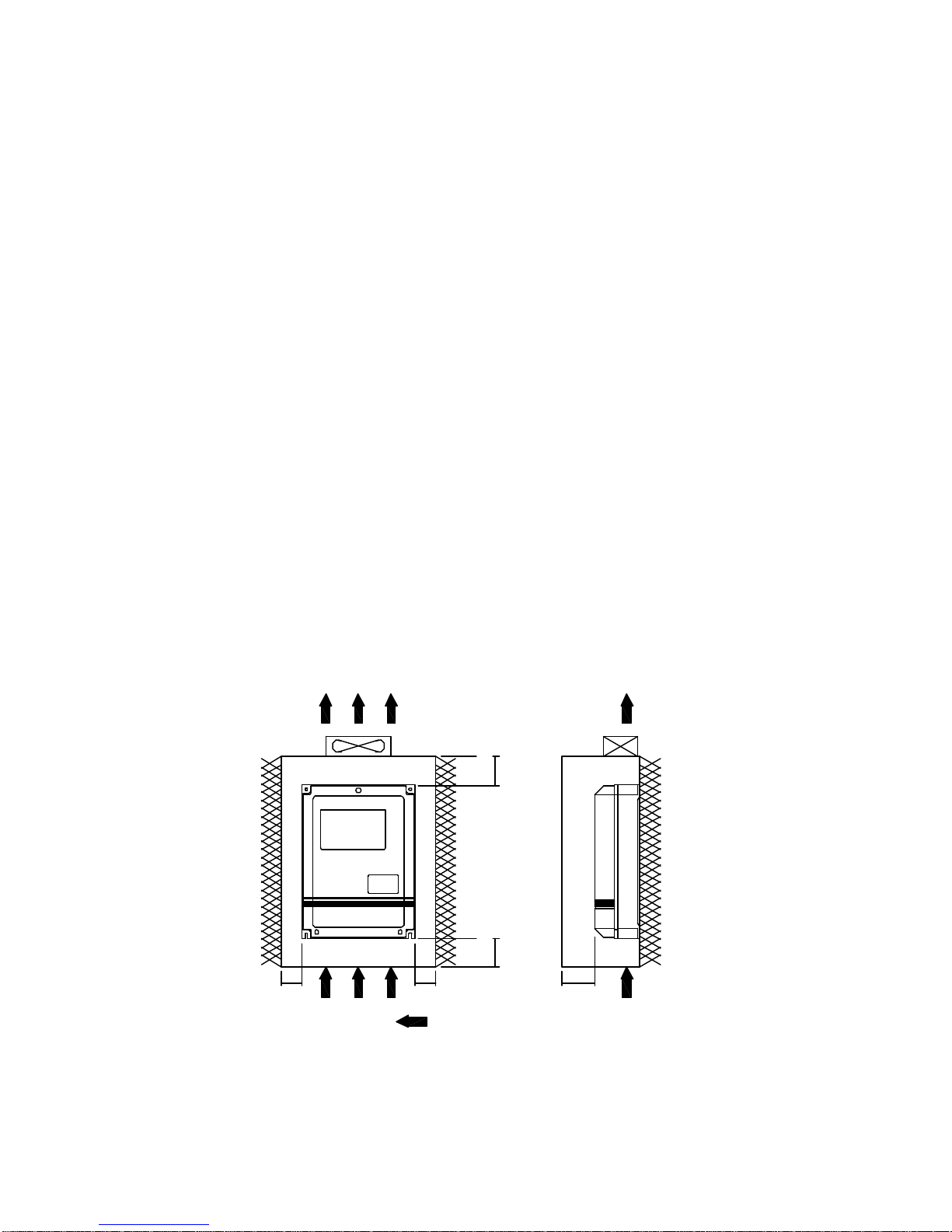

3. DIMENSION DRAWINGS

( AP2G3-137 AP2G3-155 AP2G3-175 )

( AP2G3-337 AP2G3-355 AP2G3-375 )

( AP4G3-337 AP4G3-355 AP4G3-375 AP4G3-3110 )

Fig 1

Unit : mm

4

Fig 2

Unit : mm

5

( AP2G3-1110 AP2G3-1150 AP2G3-1185 )

( AP2G3-3110 AP2G3-3150 AP2G3-3185 AP2G3-3220 )

( AP4G3-3150 AP4G3-3185 AP4G3-3220 )

4. INSTALLATION

Inadequate environment around installation site and installation

surface can result in damage to the inverter.

Before operating the APxG3 series inverter, please check the following

points :

(1) Avoid high temperature, high humidity, easy-to-dew ambient envi-

ronment. Don’t expose to dust or dirt, corrosive gas, and coolant

mist, and direct sunlight. Place the unit in a well-ventilated room.

(2) Avoid a place subjected to substantial vibration.

(3) When installing the unit within the cabinet. Please pay attention to

ventilation and limit the ambient temperature in between -10℃~

45℃. (14℉~ 113℉).

(4) Use a nonflammable material, such a steel sheet on the wall for

installation. (The rear side will generate heat)

(5) Install the unit always vertically with a marginal spacing around.

6

AIR FLOW

15 cm

15 cm

5 cm

10 cm

10 cm

7

AIR FLOW

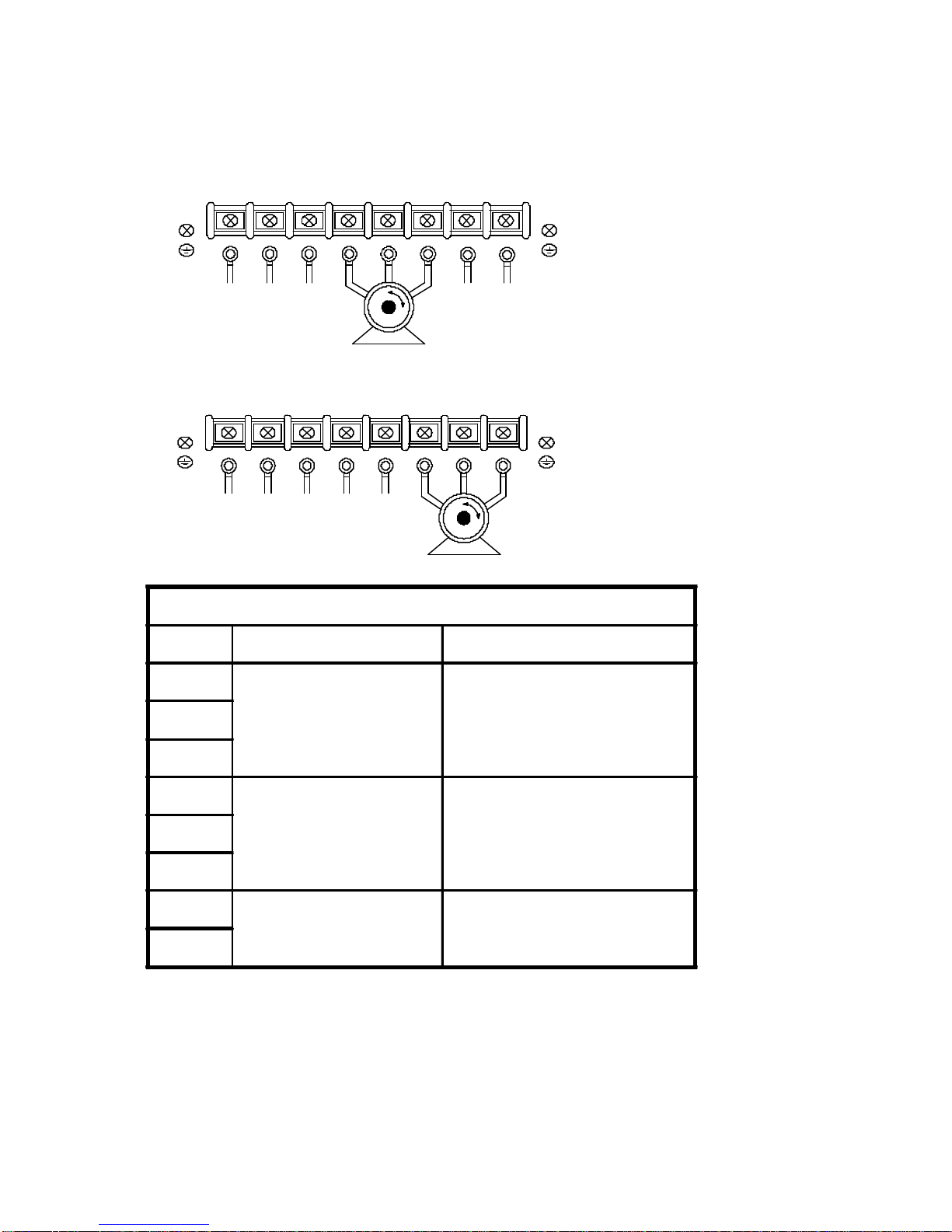

5. DESCRIPTION OF TERMINALS

(1) Main circuit connection diagram

8

RSTP2 P1 U V W

IM

Ground Power source Braking resistor

(★Note)

Ground

AP2G3-137~175

AP2G3-337~375

AP4G3-337~3110

AP2G3-1110~1185

AP2G3-3110~3220

AP4G3-3150~3220

Note : Release the internal braking resistor when connect external brak-

ing resistor.

Main circuit terminal

Symbol Terminal name Description

R / L1

Inverter power source

Terminal connecting with

power source

Single phase input : L1/R,

L2/S

S / L2

T / L3

U

Inverter output terminal Terminal connecting with

motor

V

W

P / P1 DC voltage terminal Regenerative braking resistor

connecting terminal

PR / P2

RSTU V WPPR

IM

Ground Powersource Braking resistor

(★Note)

Ground

(2) Description of hardware setting

AP2G3-137~AP2G3-175, AP2G3-337~AP2G3-375,

AP4G3-337~AP4G3-3110

AP2G3-1110~AP2G3-1185, AP2G3-3110~AP2G3-3220,

AP4G3-3150~AP4G3-3220

GND FA1 FA2 HCOMFWD REV CF1 CF2 FT1 FT2 RST ARR/RUN MET -

JP3

MB+MA AMC BC

RS485

SW1

1 32 4

10VFG1

JP1

J3

JP2

10V GND FA1 FA2 FG1 HCOMFWD REV CF1 CF2 FT1 FT2 RST ARR/RUN

SW1

1 2 3 4

JP1

MBMET MA AMC BCJ4

RS485 5 6

JP2

9

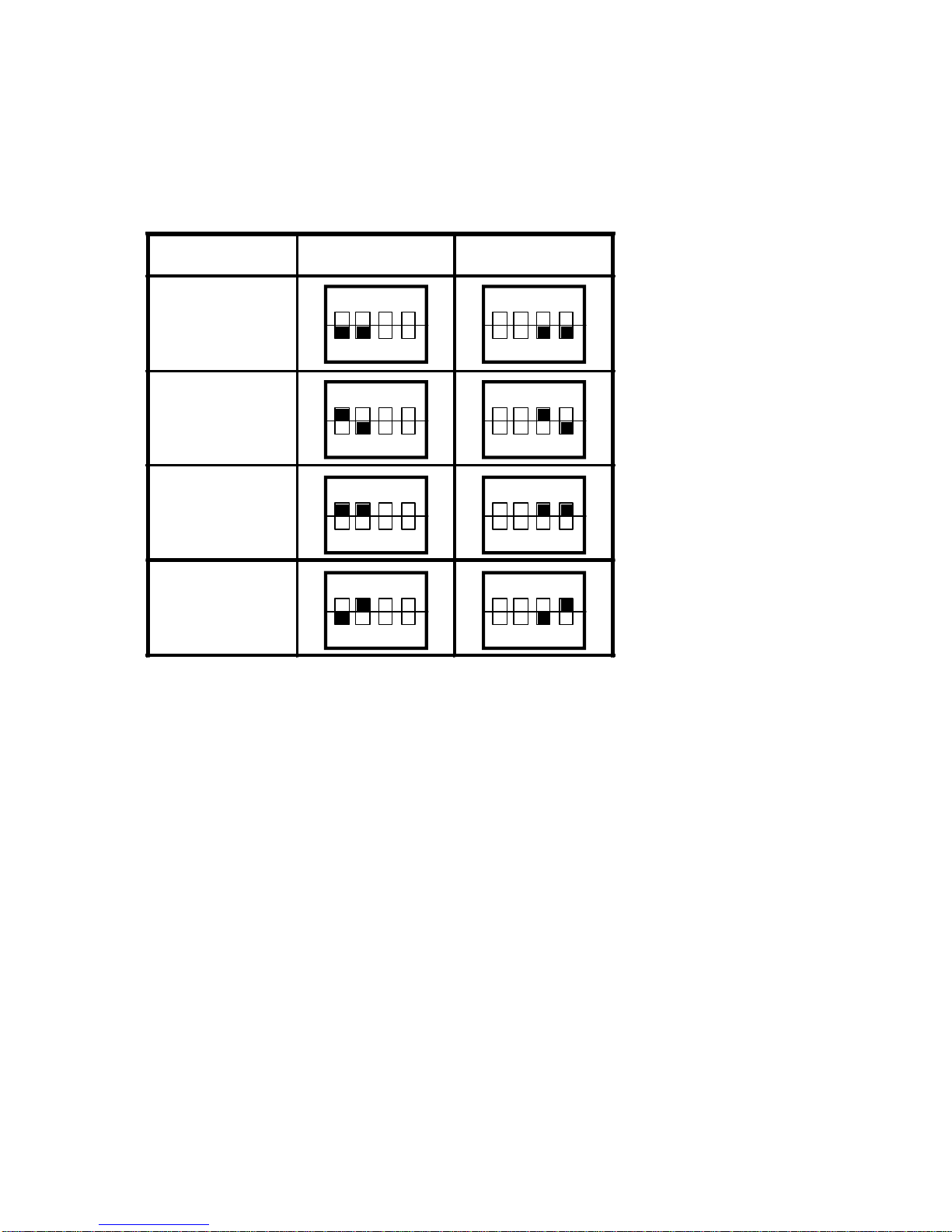

(3) Analog signal switch setting

AP2G3-137~175, AP2G3-337~375, AP4G3-337~3110

ON

1 2 3 4

ON

1 2 3 4

SIGNAL FA1 FA2

0 - 10V

0 - 5V

4 - 20mA

(Note1)★

Error setting

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

10

11

AP2G3-1110~1185, AP2G3-3110~3220, AP4G3-3150~3220

SIGNAL Keypad VR/F306

Keypad VR

F306

Error setting

Error setting

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

Note 1 : Input 4-20mA at FA1 or FA2, refer to function CD10/CD12/

CD44/CD45/CD54.

SIGNAL FA1 FA2

0 - 10V

0 - 5V

4 - 20mA

(Note1)★

Error setting

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

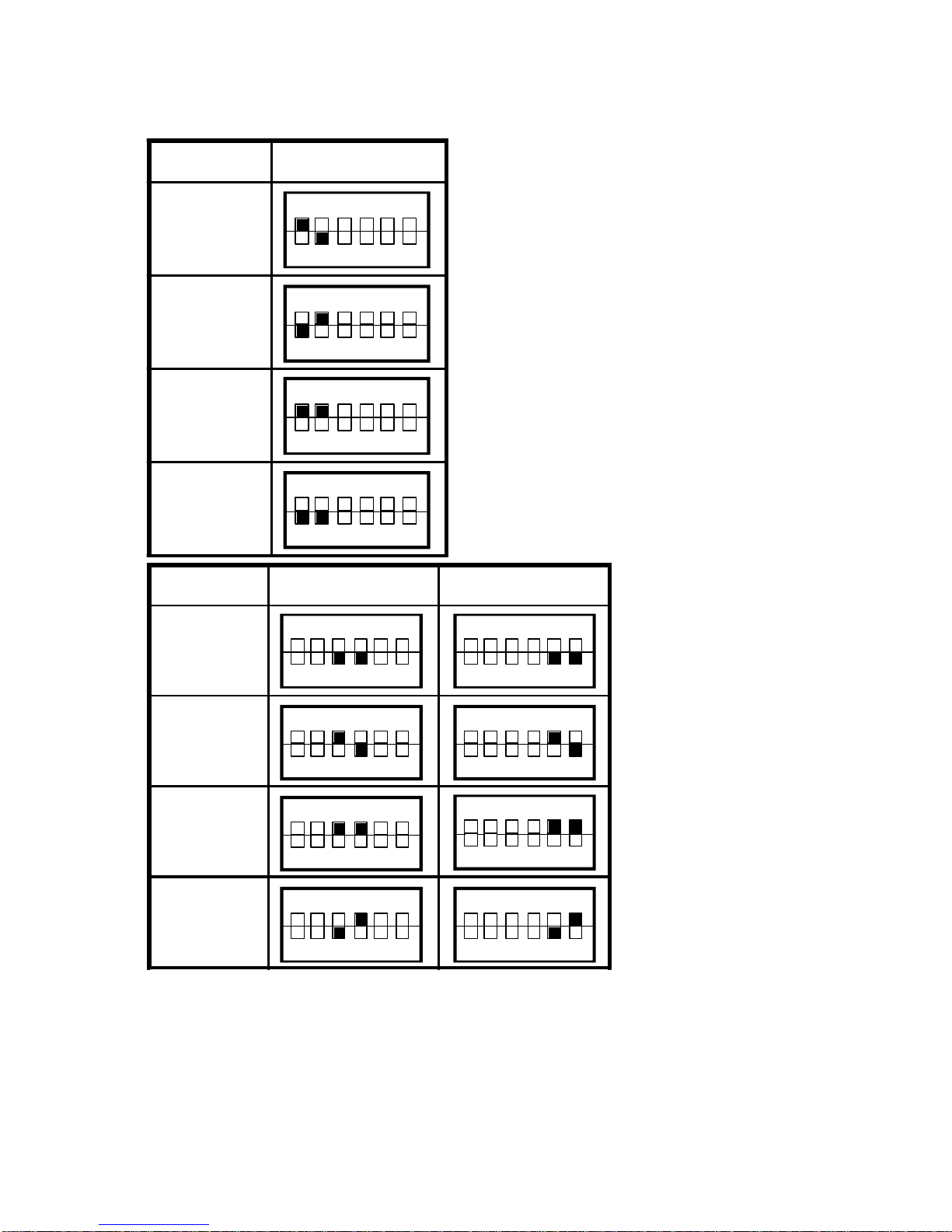

(4) Jumper setting

1. JP1 : FT2 over temperature selection

2. JP2 : MET output selection

3. JP3 : Pannel VR and F306 VR selection

AP2G3-137~AP2G3-175, AP2G3-337~AP2G3-375,

AP4G3-337~AP4G3-3110

4. J3 : RUN/ARR Relay selection

AP2G3-137~AP2G3-175, AP2G3-337~AP2G3-375,

AP4G3-337~AP4G3-3110

5. J4 : RUN/ARR Relay selection

AP2G3-1110~AP2G3-1185, AP2G3-3110~AP2G3-3220,

AP4G3-3150~AP4G3-3220

Note : When J3 or J4 select ARR, ARR/RUN terminal is RUN open

collector output and MA/MB/MC Relay is ARR.

When J3 or J4 select RUN, ARR/RUN terminal is ARR open

collector output and MA/MB/MC Relay is RUN.

12

1 and 2 short circuit : PTC temperature switch.

2 and 3 short circuit : NTC temperature switch.

1

2

3

1 and 2 short circuit : Pannel VR.

2 and 3 short circuit : F306 VR.

1

2

3

Left : ARR Relay.

Right : RUN Relay.

Up : RUN Relay.

Down : ARR Relay.

1 and 2 short circuit : Connect to meter.

2 and 3 short circuit : Analog output.

(0~10VDC refer to 0~CD14)

1

2

3

13

(5) Control circuit terminal

AP2G3-137~175、AP2G3-337~375、AP4G3-337~3110

AP2G3-1110~1185、AP2G3-3110~3220、AP4G3-3150~3220

10V GND FA1 FA2 FG1 HCOM REV CF1 CF2 FT1 FT2 RST ARR/RUN MET MA MB MC A

16321 10654 987 131211 1514 191817 20

B

21

C

22

FWD

HZ

Contact rating :

ARR/RUN 1A 240VAC

Relay Fault Relay

VR5KB Ground

1A 30VDC

FG1 10V GND FA1 FA2 HCOMFWDREV CF1 CF2 FT1 FT2 RSTARR/RUN MET -+MA MB

VR5KB

Fault Relay

Contact rating :

1A 30VDC

HZ

BAMC C

ARR/RUN

RelayFANGround

1A 240VAC

CF1 CF2 SPEED

OFF OFF SPEED - 1

ON OFF SPEED - 2

OFF ON SPEED - 3

ON ON SPEED - 4

14

Symbol Control circuit terminal

Terminal Description

FG1 Ground terminal 1 Grounding

10V Analog source Power source +10V of analog terminals

GND Analog common terminal Common terminal of free analog terminals

FA1 Free analog terminal 1 See functions description (CD44)

FA2 Free analog terminal 2 See functions description (CD45)

HRef. voltage Basic source (+10V) terminal for frequency

COM Common terminal Common terminal of control board

FWD Forward operation Forward operation / stop terminal

REV Reverse operation Reverse operation / stop terminal

CF1

Multistage speed terminal

CF2

FT1 Multi function terminal 1 See functions description (CD42)

FT2 Multi function terminal 2 See functions description (CD43)

RST Reset Reset

RUN

ARR Operation output terminal

Frequency arrival signal Open collector output 50Vdc 50mA Max.

MET Frequency meter terminal 0~100% duty open collector output or

0~10VDC output (0~CD14)

AAlarm output A Fault alarm contact (normal open)

CAlarm output C Fault alarm contact (common)

BAlarm output B Fault alarm contact (normal close)

MA

Relay output RUN/ARR

Relay output contact (normal open)

MB Relay output contact (normal close)

MC Relay output contact (common)

L1/R

L2/S

U

V

W

APxG3-Series

IM

THRY

E

POWER SOURCE

L3/T

(6) WIRING

6-1 Wiring of main circuit

1.AP2G3 1 power source

terminal connect L1/R and L2/S.

2.AP2G3 3 and AP4G3 3

power source terminal connect

L1/R, L2/S and L3/T.

6-2 Wiring equipments

Select the wiring equipment and wiring size, refer to the table

below.

1. On the input power side, a molded case circuit breaker (MCCB)

to protect inverter primary wiring should be installed.

2. A leakage current breaker threshold of 200mA and above, or of

inverter use is recommended.

3. Use of input side magnetic contactor. An input MC can be used to

prevent an automatic restart after recovery from an external power

loss during remote control operation. However, do not use the MC

frequently for start/stop operation, or will lead to a reduced reliabil-

ity.

4. In general, magnetic contactors on the output of the inverter,

Should not be used for motor control. Starting a motor with the

inverter running will cause large surge currents and the inverter

overcurrent protector to trigger.

15

Model AP2G3 AP4G3

Model No 137 155 175 1110 1150 1185 337 355 375 3110 3150 3185 3220 337 355 375 3110 3150 3185 3220

Capacity (KVA) 6.1 8.8 11.4 16.4 21.3 26.7 6.5 9.2 12.6 17.6 23.3 29 34 6.5 9.2 12.6 17.6 23.6 29 34

Current (A) 16 23 30 43 56 70 17 24 33 46 61 76 90 9 12 17 23 31 38 45

Circuit Breaker

(MCCB) (A) 20 30 50 75 100 125 20 30 50 75 100 125 150 15 20 30 50 50 75 75

Electro-Magnetic

Contactor (A) 18 35 50 65 80 93 18 35 50 65 80 93 93 12 18 18 35 48 50 50

Thermal relay

RC value (A) 15 20 28 40 55 67 15 20 28 40 55 67 80 6.8 915 20 28 40 40

∮

∮

∮

6-3 Surge absorber

In order to prevent malfunction, provide the surge absorber on the

coils of the electromagnetic contactors, relays and other devices

which are to be used adjacent of the inverter.

6-4 Cable size and length

If the inverter is connected to a distant motor (especially when low

frequency is output), motor torque decreases because of voltage

drop in the cable. Use sufficiently heavy wire.

Changing the carrier frequency reduce RF1 noise and leakage

current. (Refere to the table below)

16

Distance

INVERTER →MOTOR under

25M under

50M under

100M above

100M

APxG3 SERIES under

16KHZ under

10KHZ under

5KHZ under

2.5KHZ

(a) (b) (c)

17

6-5 Wiring and cautionary points

A. Main circuit

1. Don’t connect the cables of the power supply side (L1/R,L2/S,L3/

T) to the U, V and W output terminals for the motor.

2. Don’t connect any electromagnetic contactor between the

inverter and motor. If it is inevitable, turn on the contactor when

both the inverter and motor are both at stand still.

3. Don’t put the advance phase capacitor between the inverter and

motor.

4. Put MCCB in the input power supply.

B. Control signal circuit

1. Separate the power cables of main circuit etc. from the control

cables of the sequence and analog signals by passing the cables

through the different ducts.

2. Use twisted pair shielded wire for control signal and connect the

shield to earth terminal at on end, COMMON terminal of

control board. Leave the other end of shielding open.

3. Avoid common Ground leads between high and low level

voltage equipment.

C. Grounding

1. Be sure ground both the inverter and motor.

2. Keep grounded leads as short as possible.

3. Shield cables used to protect low-level signal leads should

grounded at one end point.

4. Provide class 3 grounding (100Ωor less) for a terminal.

5. When grounding several inverters, make connections as shown

below, no loop is produced as shown in FIG “a “, FIG “b“.

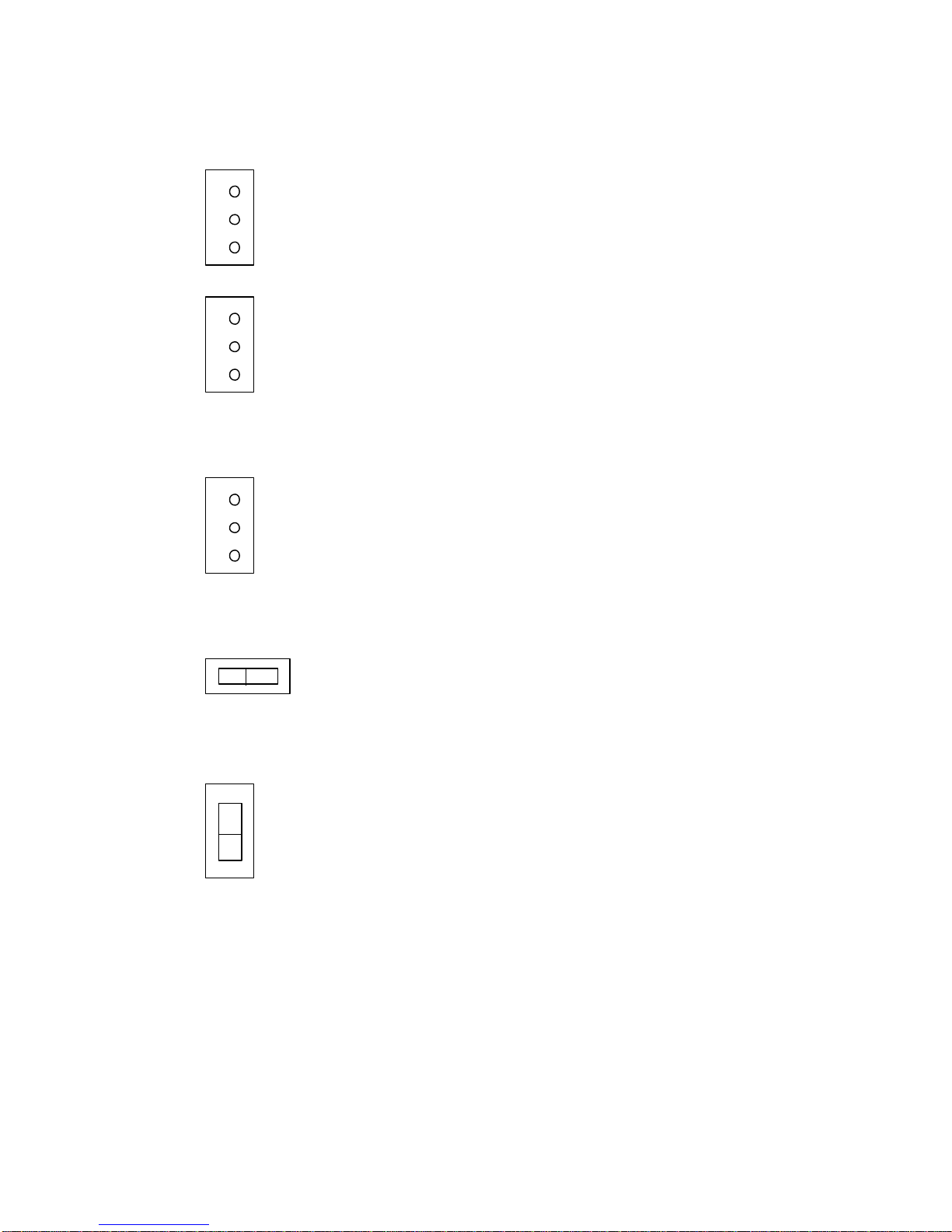

6. DIGITAL OPERATION PANEL

Operation key Key function Description

FWD RUN Forward run Commands forward run

REV RUN Reverse run Commands reverse run

SHIFT Cursor

movement Select the digit

DOWN Down Decrease the parameter value

UP Up Increase the parameter value

PROG Memory

storage Saves the setting vaule

FUNC Function Press once to select function CDxx and

press again to change its content

STOP Stop Stop operation / Escape to standby mode

18

PROG

FUNC

STOP

FWD FREQ. SET

REV

AP G3DSP

Model

Indication

VR

Key

LED Operating

Indication

AP-G3 DSP

SMART INVERTER

PROG STOP

FUNC

FWDREV

Indication

Model

Key

Digital

Indication

Indication

LED Operating

Other manuals for AP2G3-137

1

This manual suits for next models

5

Table of contents

Other Adleepower Inverter manuals