Call StormTech at 860.529.8188 or 888.892.2694 or visit our website at www.stormtech.com for technical and product information.

2

1.0 Introduction

1.1 INTRODUCTION

StormTech stormwater management systems allow

storm water professionals to create more protable,

environmentally sound developments. Compared with

other subsurface systems, StormTech systems offer

lower overall installed cost, superior design exibility and

enhanced performance. Applications include commercial,

residential, agricultural and highway drainage.

StormTech has invested over $10 million and many years

in the development of StormTech chambers. These

innovative products exceed the rigorous requirements

of the standards governing the design of thermoplastic

structures.

1.2 THE GOLD STANDARD IN STORMWATER

MANAGEMENT

The advanced designs of StormTech chambers were

created by implementing an aggressive research,

development, design and manufacturing protocol.

StormTech chamber products establish the new gold

standard in stormwater management through:

• Collaborations with experts in the eld of buried plastic

structures and polyolen materials

• The development and utilization of new testing methods

and proprietary test methods

• The use of thermoformed prototypes to verify

engineering models, perform in-ground testing and

install observation sites

• The investment in custom-designed, injection molding

equipment

• The utilization of polypropylene and polyethylene as

manufacturing materials

• The design of molded-in features not possible with

traditional thermoformed chambers

Section 3.0 of this design manual, Structural Capabilities,

provides a detailed description of the research,

development and design process.

Many of StormTech’s unique chamber features can

benet a site developer, stormwater system designer,

and installer. Where applicable, StormTech Product

Specications are referenced throughout this design

manual. If StormTech’s unique product benets are

important to a stormwater system design, consider

including the applicable StormTech Product Specications

on the site plans. This can prevent substitutions with

inferior products. Refer to Section 14.0, StormTech

Product Specications.

1.3 PRODUCT QUALITY AND DESIGN TO

INTERNATIONAL STANDARDS

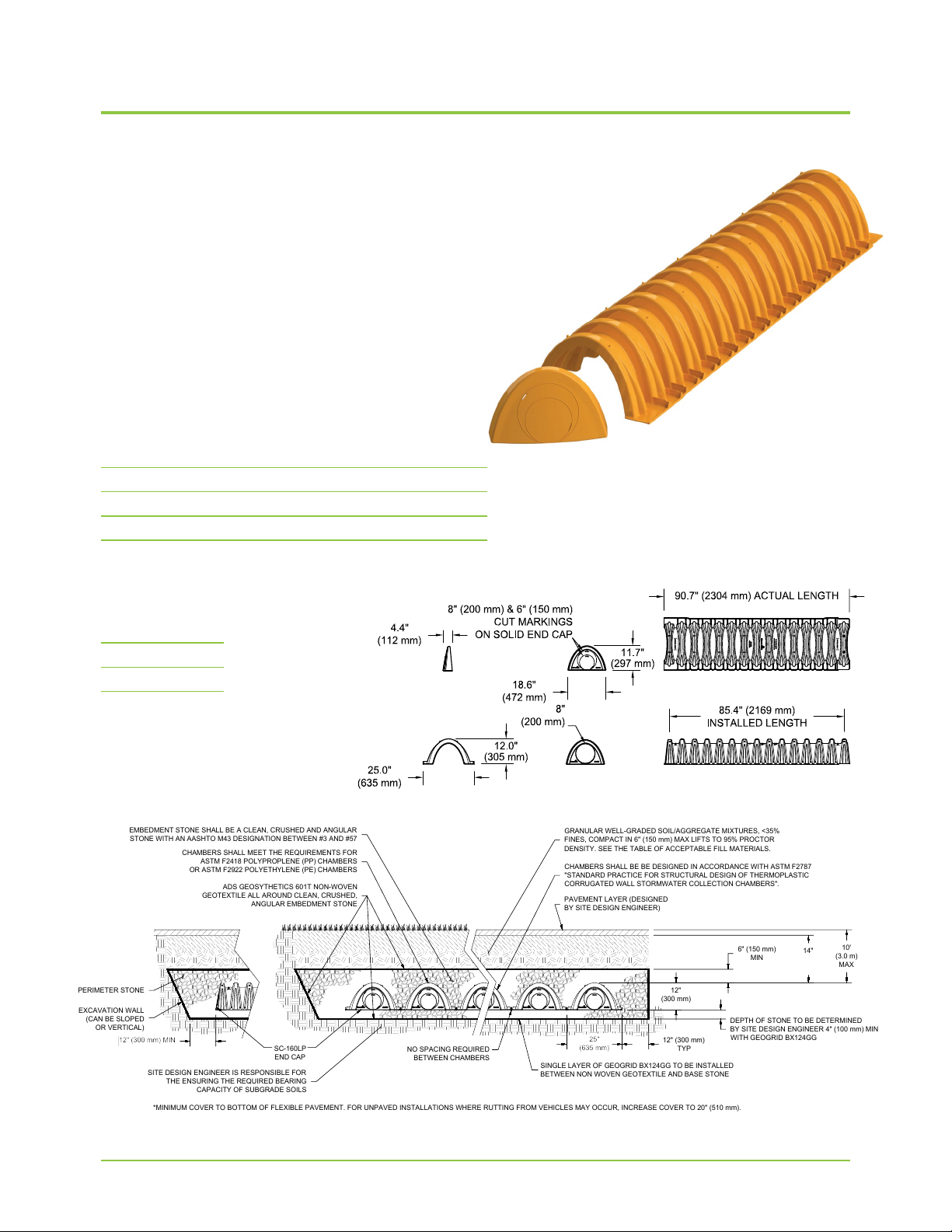

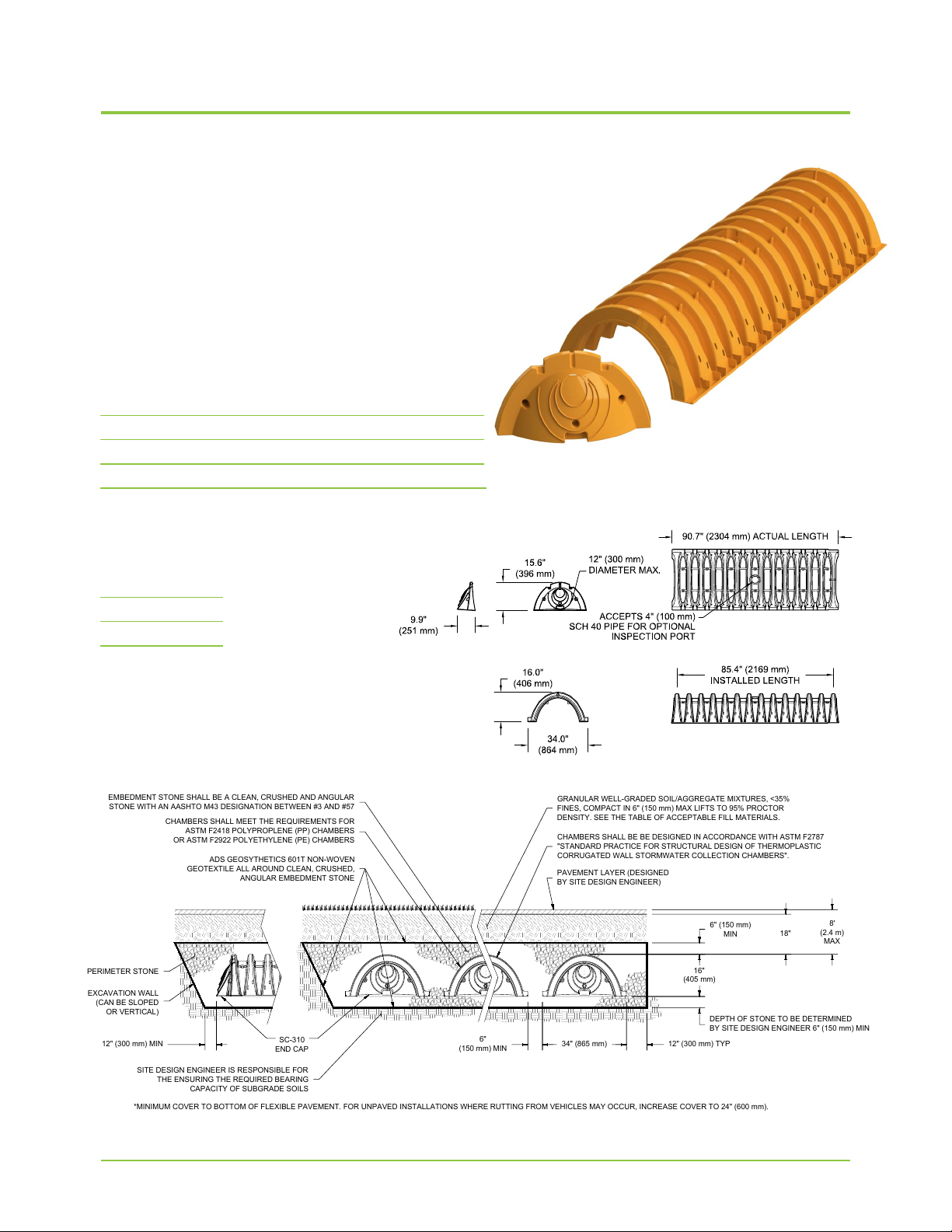

StormTech chambers are designed to meet the full scope

of design requirements of Section 12.12 of the AASHTO

LRFD Bridge Design Specications and produced to the

requirements of the American Society of Testing Materials

(ASTM) International specications F2418 (polypropylene

chambers) and F2922 (polyethylene chambers).

StormTech chambers provide the full AASHTO safety

factors for live loads and permanent earth loads. The two

ASTM standards mentioned previously are linked to the

AASHTO LRFD Bridge Design Specications Section

12.12 design standard. Both ASTM standards require that

the safety factors included in the AASHTO guidance are

achieved as a prerequisite to meeting either ASTM F2418

or ASTM F2922. StormTech chambers are also designed

in accordance with ASTM F2787, “Standard Practice

for Structural Design of Thermoplastic Corrugated

Wall Stormwater Collection Chambers” which provides

specic guidance on how to design thermoplastic

chambers in accordance with AASHTO Section 12.12.

These standards provide both the assurance of product

quality and safe structural design.

For non-proprietary specications for public bids that

ensure high product quality and safe design, consider

including the specication in Section 15.0 Chamber

Specications for Contract Documents.

1.4 TECHNICAL SUPPORT FOR PLAN REVIEWS

StormTech’s in-house technical support staff is available

to review proposed plans that incorporate StormTech

chamber systems. They are also available to assist with

plan conversions from existing products to StormTech.

Not all plan sheets are necessary for StormTech’s review.

Required sheets include plan view sheet(s) with design

contours, cross sections of the stormwater system

including catch basins and drainage details.

When specifying StormTech chambers it is recommended

that the following items are included in project plans:

StormTech chamber system General Notes, applicable

StormTech chamber illustrations and StormTech chamber

system Product Specications. These items are available

in various formats and can be obtained by contacting

StormTech at 1-860-529-8188 or may be downloaded at

www.stormtech.com.

StormTech’s plan review is limited to the sole purpose

of determining whether plans meet StormTech chamber

systems’ minimum requirements. It is the ultimate

responsibility of the design engineer to assure that

the stormwater system’s design is in full compliance

with all applicable laws and regulations. StormTech

products must be designed and installed in accordance

with StormTech’s minimum requirements.

SEND PLANS TO:

E-mail: info@stormtech.com.