SkoFlo Industries SF10000HTVB User manual

Pioneering an Industry

SF10000HTVB

Operations and

Maintenance Manual

Industries

DOC-04114 Rev A

Surface CIMV, Low Flow, HTV

10,000 psi

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 1

TABLE OF CONTENTS

About SkoFlo ........................................................................................ 2

General Information........................................................................... 2

Hydraulic Ratings ................................................................................ 3

Storage .................................................................................................... 3

Installation ............................................................................................. 3

1. Mounting ...................................................................... 3

2. Hydraulic Installation................................................ 3

3. Start Up Procedures.................................................. 4

4. Adjustment and Calibration .................................. 4

Maintenance ......................................................................................... 4

5. General........................................................................... 5

6. Disassembling the SF10000HTVB........................ 6

7. Replacing the Stem Assembly Seals................... 7

8. Replacing the Piston Cup Seal.............................. 7

9. Replacing the Gate Pad and Gate Pad

Assembly Seals........................................................................ 8

10. Replacing Stem Seals ............................................... 8

11. Valve Reassembly ...................................................... 9

12. Handle Installation ..................................................10

13. Disconnecting Valve From the SF3 Actuator 11

14. Reconnecting the SF10000HTVB to the SF3

Actuator ...................................................................................11

Frequently Asked Questions.........................................................12

Troubleshooting ................................................................................13

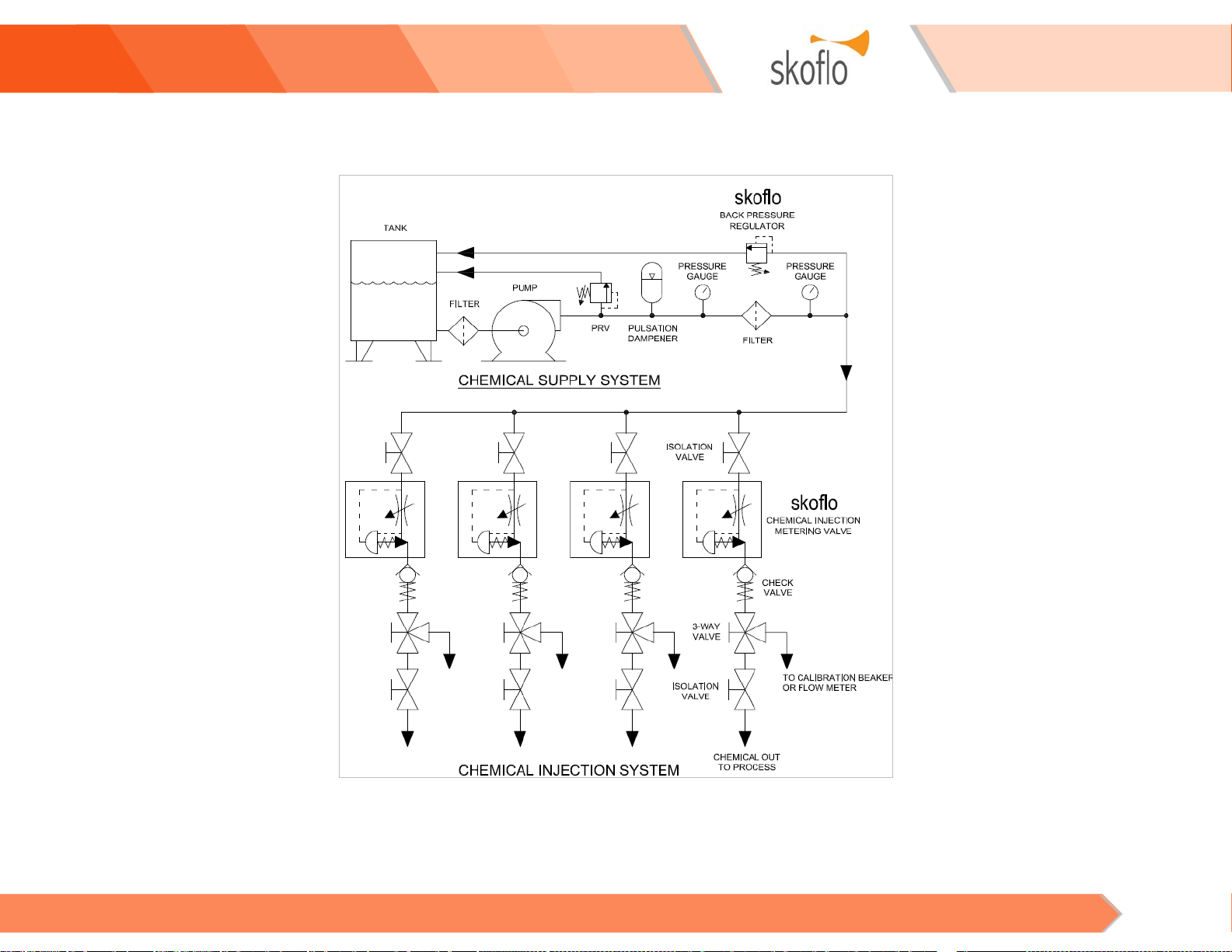

Appendix A – A Typical Chemical Injection System ............14

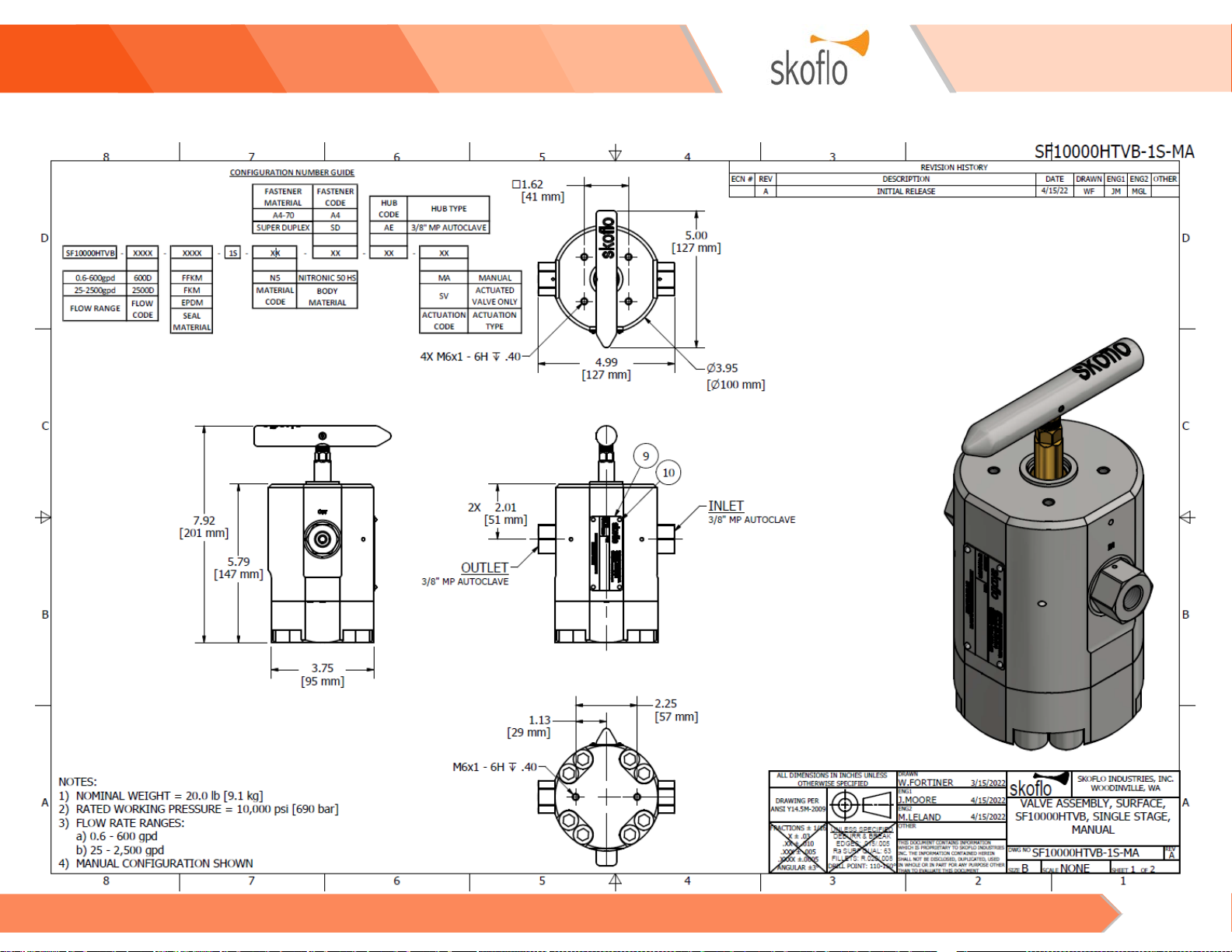

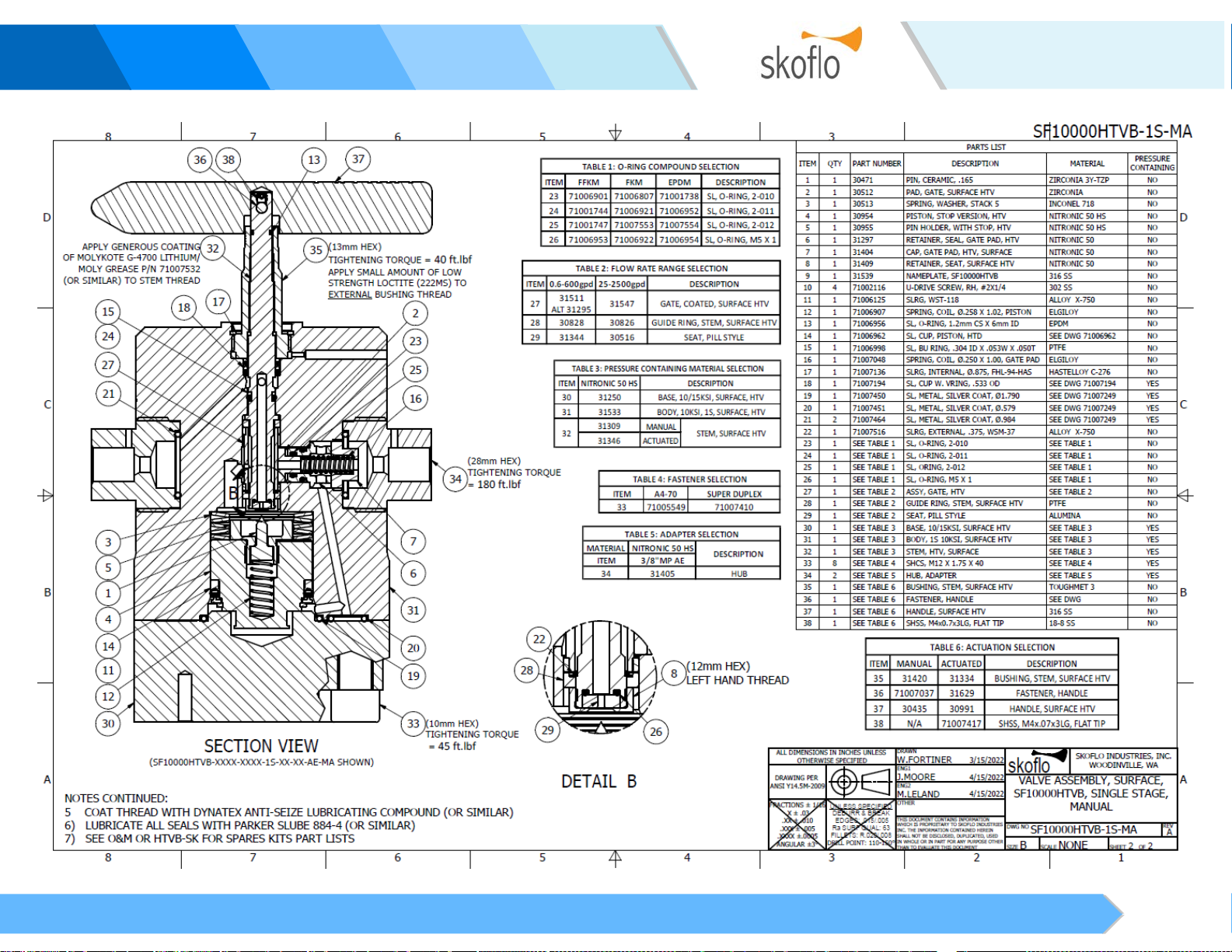

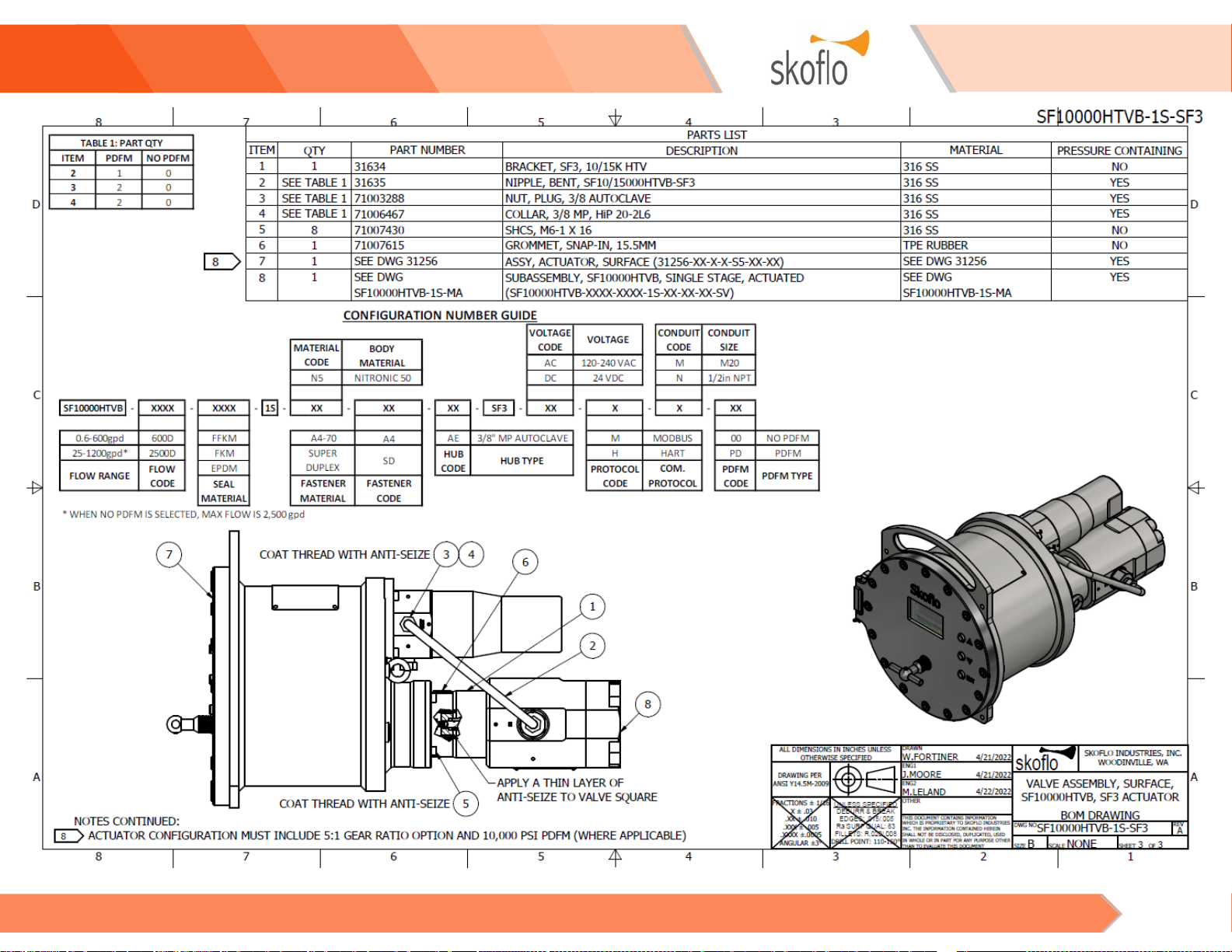

Appendix B – SF10000HTVB GA and BOM Drawings ......15

TABLE OF FIGURES

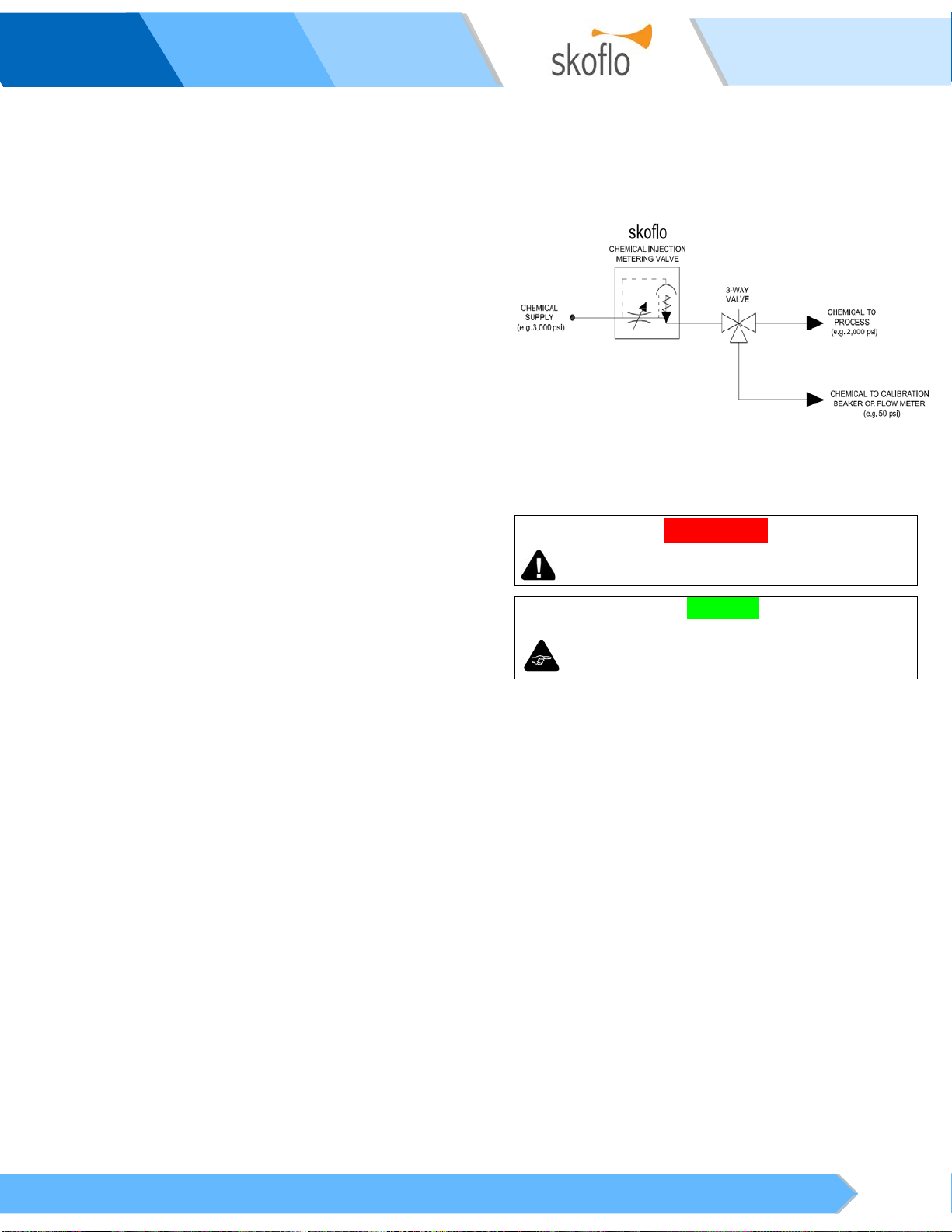

Figure 1 – Valve Calibration Schematic...................................... 4

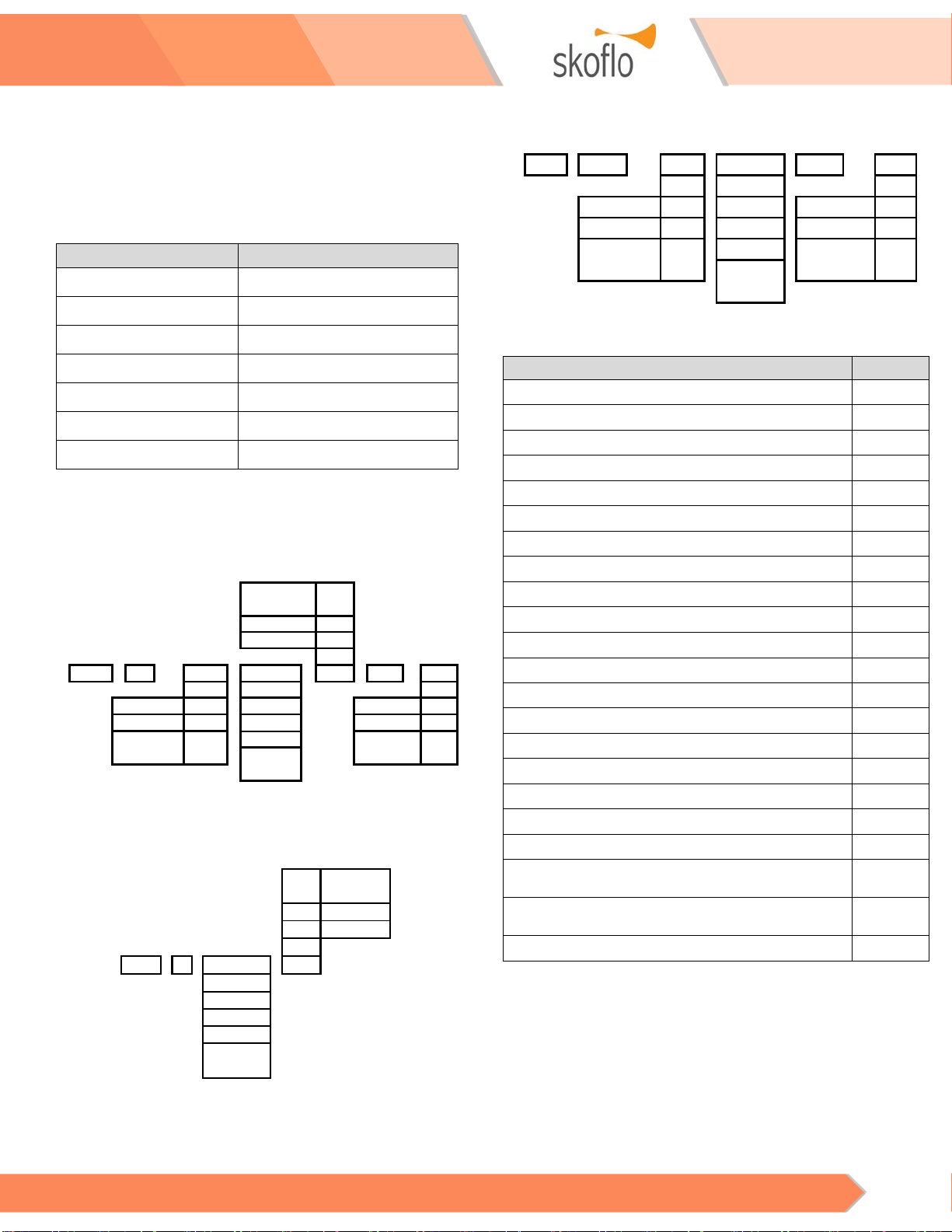

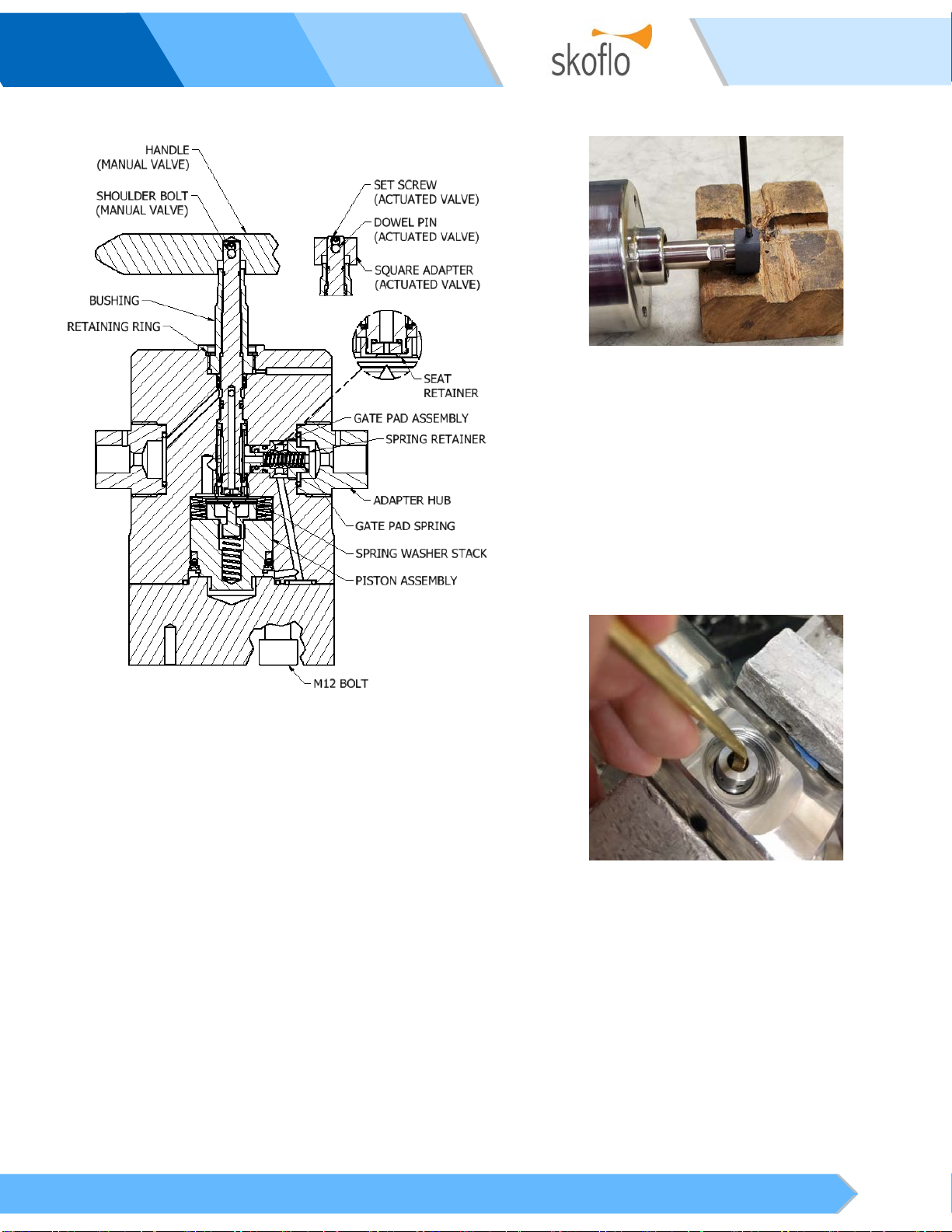

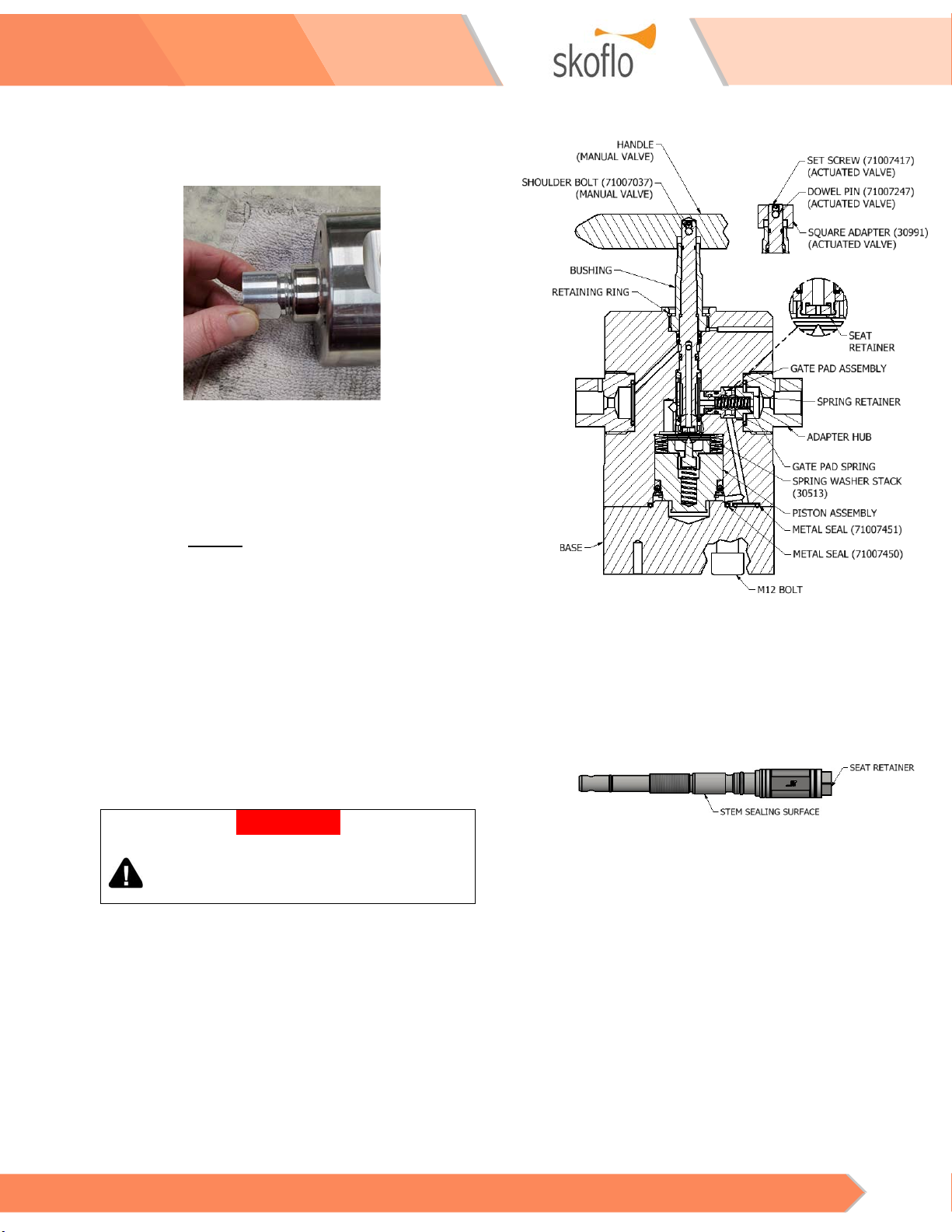

Figure 2 – SF10000HTVB Cross-Section..................................... 6

Figure 3 – Square Adapter Removal............................................ 6

Figure 4 – Gate Pad Assembly Removal .................................... 6

Figure 5 – Piston Assembly Removal .......................................... 7

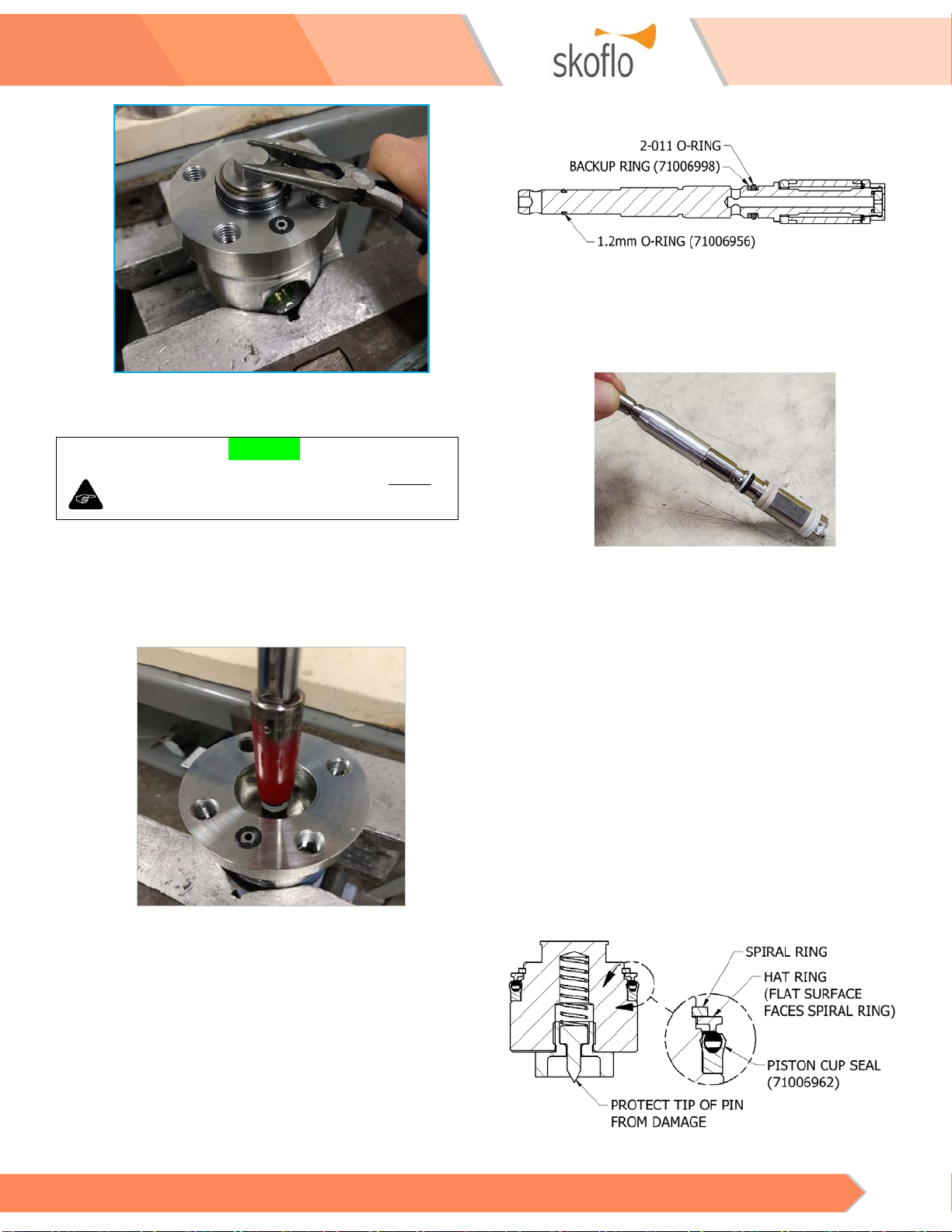

Figure 6 – Stem Assembly Removal............................................. 7

Figure 7 – Stem Assembly Seals.................................................... 7

Figure 8 – Stem O-Ring Tool with Seals..................................... 7

Figure 9 – Piston Assembly.............................................................. 7

Figure 10 – Installing Piston Seal .................................................. 8

Figure 11 – Gate Pad Assembly Cross Section ........................ 8

Figure 12 – Stem Seal Cross Section............................................ 8

Figure 13 – Stem Seals ...................................................................... 8

Figure 14 – O-ring Press Tool......................................................... 9

Figure 15 – SF10000HTVB Cross-Section................................... 9

Figure 16 – Stem Sealing Surface ................................................. 9

Figure 17 – Spring Stack Arrangement.....................................10

Figure 18 – Gate View Through Gate Pad Hole.....................10

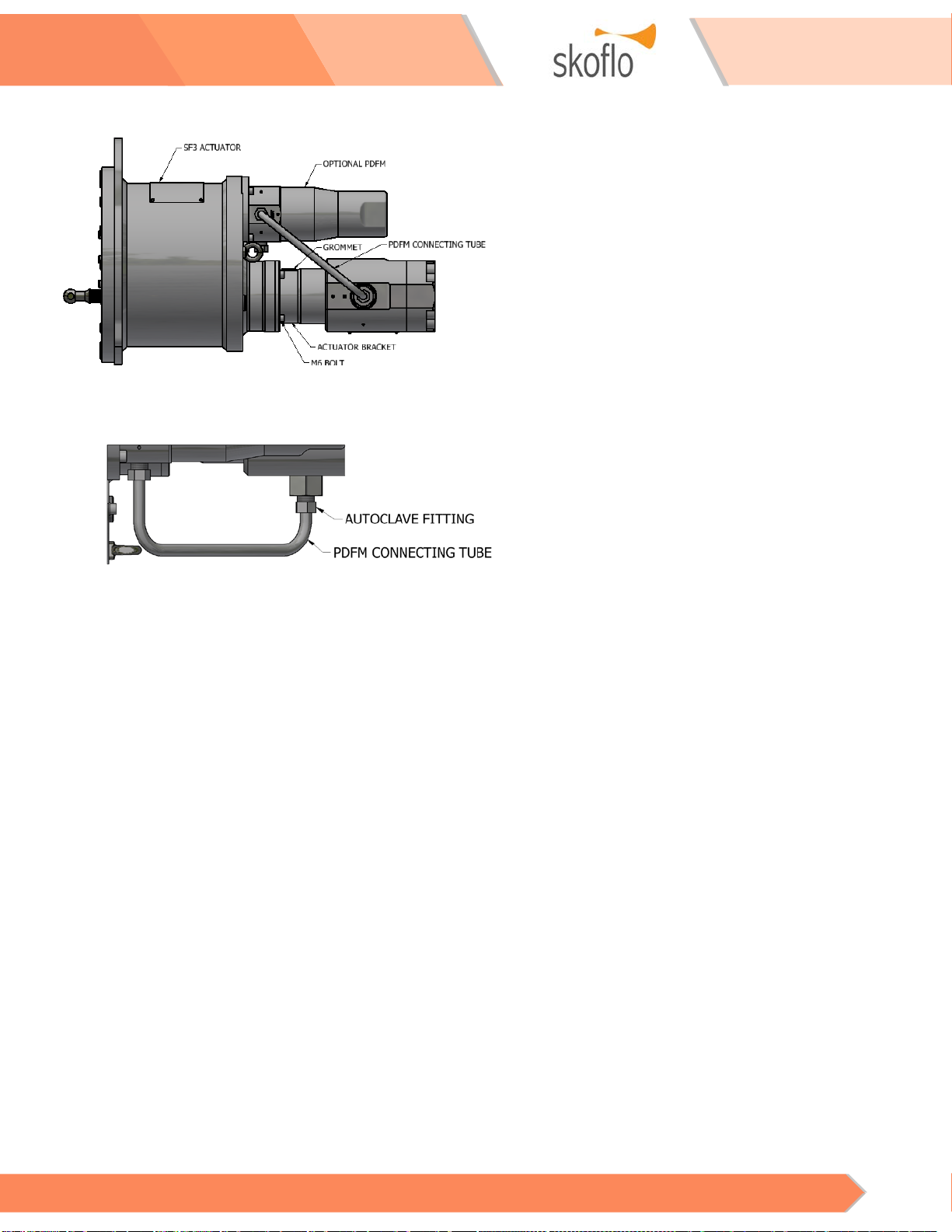

Figure 19 – SF10000HTVB with SF3 Actuator.........................11

Figure 20 – PDFM Connecting Tube..........................................11

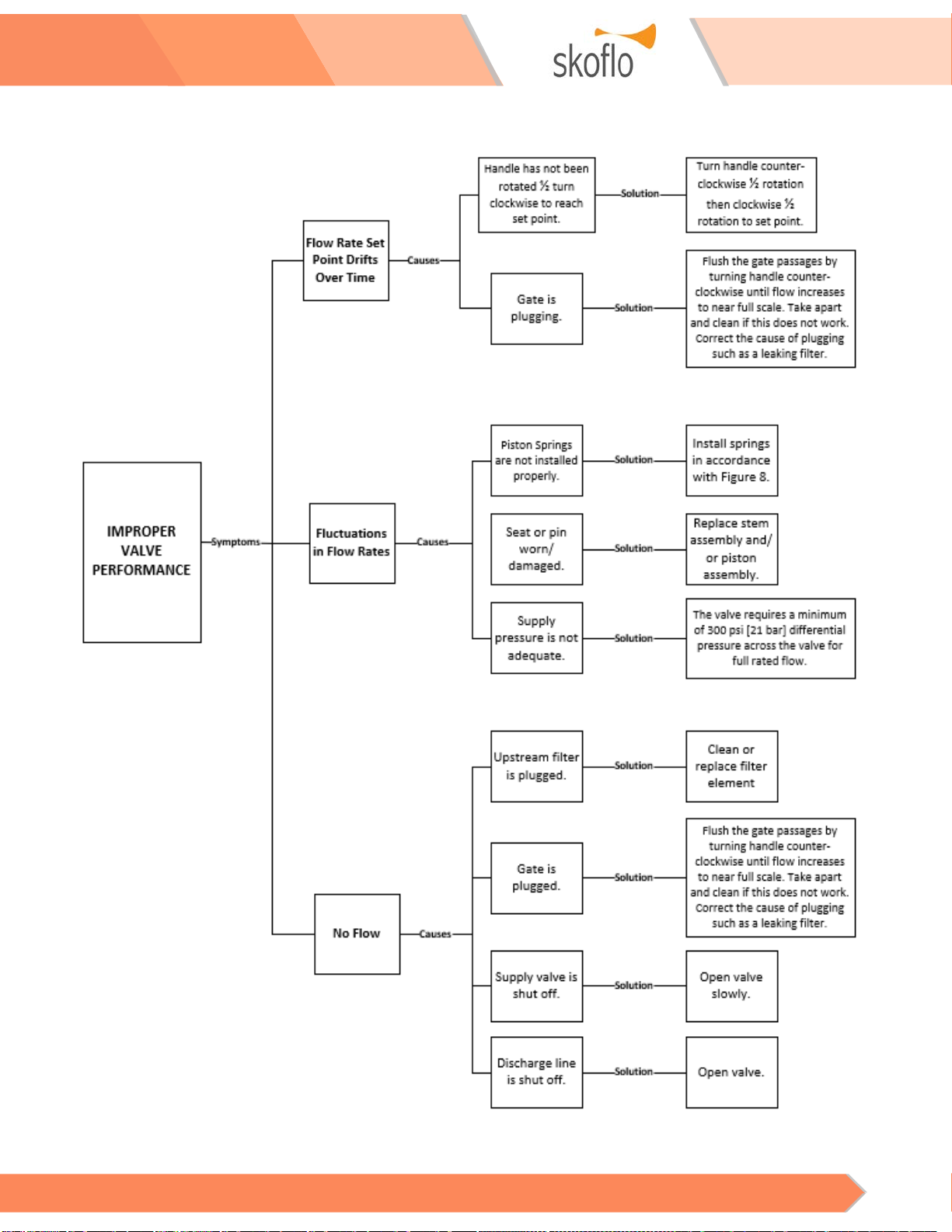

Figure 21 – Troubleshooting.........................................................13

TABLE OF TABLES

Table 1 – Filter Specification ........................................................... 3

Table 2 – SF10000HTVB Spares Kit Part Numbers ................. 5

Table 3 – SF10000HTVB Rebuild Kit Number Guide ............. 5

Table 4 – SF10000HTVB Seal Kit Number Guide .................... 5

Table 5 – SF10000HTVB Stem Kit Number Guide .................. 5

Table 6 - Maintenance Tool Requirements............................... 5

Table 7 – Frequently Asked Questions .....................................12

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 2

ABOUT SKOFLO

Our experience and track record speak for itself. SkoFlo

has delivered over 20,000 valves since 1988. We are the

only company that proves our products by testing in

surface applications before deploying them subsea. The

result is that SkoFlo products have amassed over 25

million continuous operating hours. This level of

experience is unparalleled and provides the basis for being

the solution provider to our served market.

GENERAL INFORMATION

Product Overview

The SF10000HTVB is a pressure independent chemical

injection and metering valve (CIMV), used in the

petroleum industry to accurately control chemical injection

rates. The SF10000HTVB regulates flow to counter

pressure changes on the inlet and outlet of the unit. This is

referred to as “pressure independence”.

Pressure Independence

SkoFlo defines pressure independence as the percent (%)

of reading change for each 1,000 psi (69 bar) change in

supply or outlet pressure.

Pressure independence in the SF10000HTVB is a

completely mechanical process, requiring zero power.

The principle of pressure independence is that the valve

maintains a constant differential pressure (dP) across an

internal orifice (the ‘gate’), thus resulting in a constant flow

rate through that orifice.

The pressure that is generated by flow through the gate is

applied to either side of a spring balanced piston that

carries a regulating pin. The piston will travel to a position

where the spring force equals the pressure force.

Minimum Differential Pressure

For the SF10000HTVB to provide pressure independent

performance, a minimum differential pressure (min dP) is

required across the valve to allow the spring-balanced

piston to move to a truly balanced location.

In general, higher flows and/or viscosities require a higher

min dP across the valve. Refer to the product datasheet for

specific information.

Guidelines for Using this Manual

The following instructions are provided to ensure a safe

and proper installation and operation.

−Read all instructions prior to installation

and operation of this product.

−Follow all warning and caution notes.

−Install this product as specified in the

instructions provided by SkoFlo.

−Prior to use, educate personnel in the

proper installation, operation, and

maintenance of this product.

−Only use replacement parts specified by

SkoFlo.

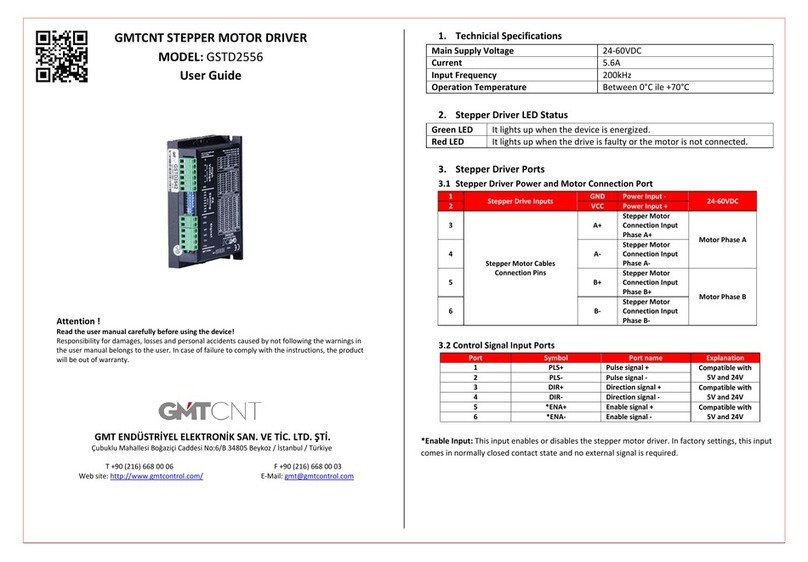

Warning, Caution, Notice

Throughout this manual there are steps and procedures

which, if not followed, may result in a hazard. The

following flags are used to identify the level of potential

hazard.

! WARNING

WARNING IS USED TO INDICATE THE PRESENCE OF A

HAZARD WHICH CAN CAUSE SEVERE INJURY, DEATH, OR

SUBSTANTIAL PROPERTY DAMAGE IF THE WARNING IS

IGNORED.

! CAUTION

CAUTION IS USED TO INDICATE THE PRESENCE OF A

HAZARD WHICH CAN CAUSE INJURY OR PROPERTY

DAMAGE IF THE WARNING IS IGNORED.

! NOTICE

NOTICE IS USED TO NOTIFY PEOPLE OF INSTALLATION,

OPERATION, OR MAINTENANCE INFORMATION,

WHICH IS IMPORTANT BUT NOT HAZARD RELATED.

Abbreviations and Acronyms

CIMV Chemical Injection and Metering Valve

dP Differential Pressure

GA General Arrangement

GPD Gallons Per Day

HTV High Turn-Down Valve

LPH Liters Per Hour

SHCS Socket Head Cap Screw

psi Pounds per Square Inch

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 3

HYDRAULIC RATINGS

! WARNING

REFER TO THE GENERAL SECTION OF THE PRODUCT

DATASHEET FOR DESIGN PRESSURE DETAILS.

Max Working Pressure: 10,000 psi (689 bar)

Hydro-Pressure: 15,000 psi (1,034 bar)

Flow Ranges:

−0.6 to 600 GPD (0.09 to 95 LPH)

−25 to 2500 GPD (3.9 to 394 LPH)

Min Differential Pressure (DP) for Max Rated Flow: 300 psi*

* Lower flow rates require a lower DP

STORAGE

The SF10000HTVB should be stored in a shelter and be

protected from moisture and particulates. Storage

temperatures shall be between –50°F and 158°F (–45°C

and 70°C).

Any open hydraulic connections will be furnished with

plastic blanking plugs.

It is important not to store the SF10000HTVB with

production chemicals in the unit. These chemicals can

settle, possibly resulting in damage to the unit. SkoFlo

recommends that the valve be stored with a mixture of

glycol in water as the preservation fluid.

INSTALLATION

! WARNING

CHEMICAL COMPATIBILITY SHALL BE DONE AND CHECKED

BEFORE USE, EXCEPT FOR MEG AND WATER MIXTURES.

! WARNING

THE SF10000HTVB SHALL NOT BE INSTALLED SUBSEA.

1. Mounting

The SF10000HTVB can be panel or base mounted in any

orientation. See Appendix B for more details.

If panel mounting, unscrew the handle fastener with a

2mm Allen wrench and remove the handle. Mount the

valve, then replace the handle and tighten the fastener in

place.

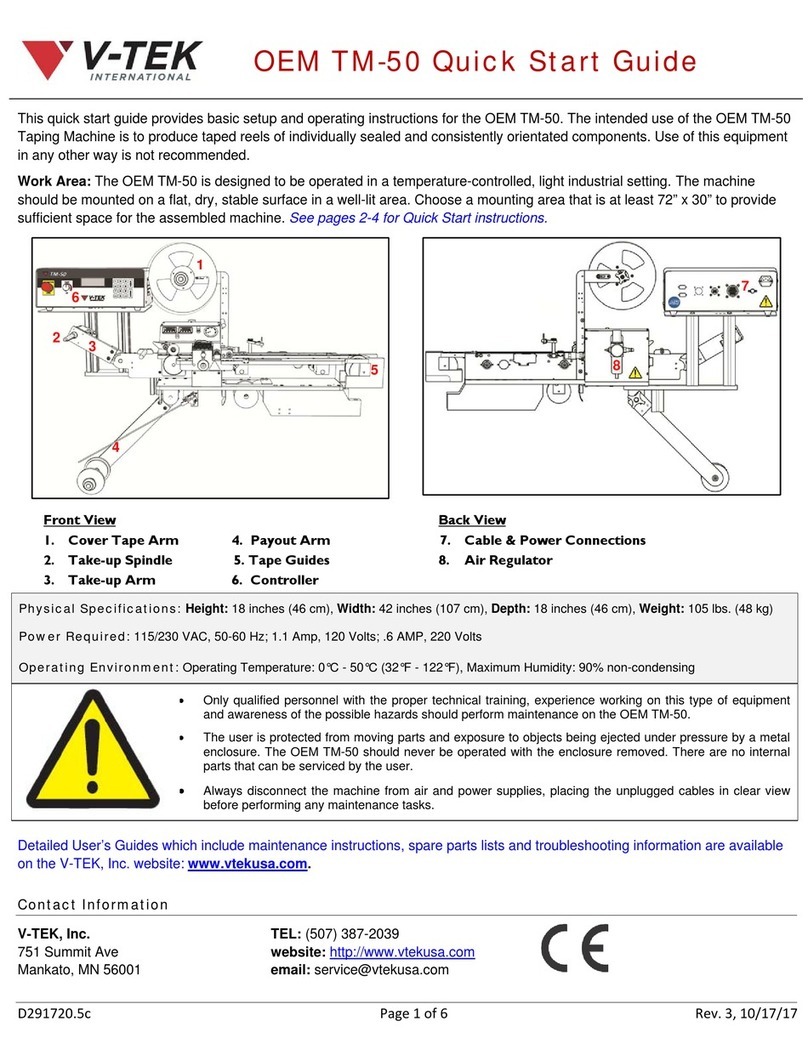

2. Hydraulic Installation

Install the SF10000HTVB so that the flow is in the proper

direction. The IN (inlet) and OUT (outlet) connections are

marked respectively. See Appendix B for details.

Install an inline filter upstream of the SF10000HTVB.

Clean chemicals and proper filtering are very

important. Omitting the filter can cause the valve to

become plugged.

Table 1 lists the filter requirements for the various flow

ranges. Note: if coarser filters are used, the adjustment

handle may need to be periodically opened to flush out

any debris.

Table 1 – Filter Specification

Flow Range Filter Micron Size

0.6 to 10 GPD

40

10 to 700 GPD

80

> 700 GPD

200

A pulsation dampener is recommended to be installed on

the inlet header supplying the SF10000HTVB for improved

longevity and set point consistency. A bladder type

pulsation dampener is preferred over a piston type.

! NOTICE

THE SF10000HTVB REQUIRES A MINIMUM DIFFERENTIAL

PRESSURE ACROSS THE VALVE OF 300 PSI (20.7 BAR) TO

ACHIEVE FULL RATED FLOW.

! NOTICE

IT IS RECOMMENDED TO STORE THE ASSEMBLIES IN THE

SHIPPING CRATE, IF POSSIBLE.

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 4

Reactive dampeners that use baffles will do little to

dampen the pressure over the full flow range of the valve.

The SF10000HTVB is not a positive shut off device,

therefore, a valve on the inlet or outlet will be required to

meet shut off specifications. The preferred location of the

shut off valve is on the outlet of the SkoFlo valve to

minimize the shock to internal parts during start up.

A check valve shall be installed immediately downstream

of the SF10000HTVB (within 6 inches) to prevent damage

to the piston cup seal and to prevent well fluids entering

the valve. The 6-inch maximum is required to eliminate

stored pressure build up during startup. Check valve

cracking pressure is recommended to be under 10 psi to

enhance longevity of check valve seats.

An example of a typical chemical injection system is given

in Appendix A.

3. Start Up Procedures

3.1 Open the supply isolation valve to the SkoFlo

valve slowly (> 1 second). This will allow

pressures within the unit to equalize slowly,

the valve will stabilize quickly.

3.2 Turn the rate adjustment handle clockwise

until you are at the desired flow rate.

3.3 Always start at a flow rate above the desired

flow and decrease to the desired setting (turn

handle clockwise to decrease flow rate).

−For the most consistent set point results,

rotate handle ½ turn clockwise to reach

the set point.

3.4 The flow controller is now set, and further

adjustments are not required.

4. Adjustment and Calibration

The SF10000HTVB is a pressure independent flow control

device. Once the valve is set at a desired flow rate, that

flow rate is maintained even though the pressure

conditions upstream and/or downstream of the valve may

change considerably.

The flow rate can be set using an inline flow meter;

however, it must be capable of withstanding the process

pressure. Another method of calibrating the SF10000HTVB

is with a 3-way valve and a line to a calibration beaker.

Once the flow rate is set, the 3-way valve is switched to

direct the chemical to the process (see Figure 1).

Since the SkoFlo valve regulates the flow independent of

the pressure differential across it, the flow rate to the

process is the same as the flow rate set using the beaker.

Overall monitoring of the flow is done by taking inventory

of the usage from the supply tank.

Figure 1 – Valve Calibration Schematic

MAINTENANCE

! WARNING

ANY SERVICE REPAIR SHALL BE PERFORMED BY TRAINED

PERSONNEL.

! NOTICE

IF ANY ABNORMALITIES ARE FOUND THROUGHOUT THE

MAINTENANCE, PLEASE REPORT TO THE RESPECTIVE

ENGINEERS.

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 5

5. General

Spares kits available for typical maintenance items are

listed in Table 2. See Tables 3, 4, and 5 for part number

guides.

Table 2 – SF10000HTVB Spares Kit Part Numbers

ITEM PART NUMBER

Complete Rebuild Kit

31655-10-XXXX-XXXX-1S-XX-XX

Seal Kit

31664-10-XXXX-1S

Stem Assembly Kit

31625-10-XXXX-XXXX-XX-XX

Piston Assembly Kit

31623

Gate Pad

30512

Washer Spring Stack 30513

O-ring Installation Tool Kit

31624

Table 3 – SF10000HTVB Rebuild Kit Number Guide

2X

1S

31655 -10 -XXXX - - XX -N5 -XX

600D MA

2500D ACT

MANUAL

ACTUATED

ACTUATION

TYPE

CODE

0.6-600gpd

25-2500gpd

FLOW

RANGE

EPDM

CODE

SEAL

MATERIAL

XXXX

FFKM

FKM

DUAL

SINGLE

CODE

STA GE

SELECTION

Table 4 – SF10000HTVB Seal Kit Number Guide

2X DUAL

1S SINGLE

31664 -10 -XXXX -XX

FFKM

FKM

EPDM

SEAL

MATERIAL

CODE

STAGE

SELECTION

Table 5 – SF10000HTVB Stem Kit Number Guide

31625 -10 -XXXX --N5 -XX

600D MA

2500D ACT

EPDM

ACTUATION

TYPE

CODE

SEAL

MATERIAL

FLOW

RANGE

CODE

0.6-600gpd

FFKM

MANUAL

25-2500gpd

FKM

ACTUATED

XXXX

Table 6 - Maintenance Tool Requirements

Tools and Parts

Quantity

Vise

1

250 ft.lb [340 Nm] Torque wrench

1

50 ft.lb [68 Nm] Torque wrench 1

Socket extension

1

28mm socket

1

13mm socket

1

12mm socket

1

10mm Allen socket

1

Pliers

1

2mm Allen wrench

1

5mm Allen wrench (required for SF3 Actuator) 1

Brass Rod (3.5mm Diameter)

1

Hammer (required for SF3 Actuator)

1

9/16” wrench (required for SF3 Actuator with PDFM)

2

Circlip Pliers (.035” Tip Diameter) 1

HTVB O-Ring Installation Kit (P/N: 31624)

1

Brass Pick

1

Pick or small flat head electrical screwdriver

1

Parker Super Lube (or equivalent)

1

Dynatex Anti-Seize & Lubricating Compound (or

equivalent)

1

Molykote G-4700 Lithium/Moly Grease (or

equivalent)

1

Loctite 222 Low Strength Threadlocker (or equivalent)

1

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 6

6. Disassembling the SF10000HTVB

Figure 2– SF10000HTVB Cross-Section

6.1 Remove the valve from the system. If

applicable, see Section 13 for information on

unpairing the valve from an SF3 Actuator.

6.2 Rotate the handle clockwise until you reach

the bottom stop.

6.3 Remove the handle or square adapter

6.3.1 For Manual valves:

6.3.1.1 remove handle fastener –

2mm

Allen wrench

6.3.1.2 Remove handle.

6.3.2 For Actuated valves:

6.3.2.1 Remove set screw –

2mm Allen

wrench

.

6.3.2.2 Remove dowel pin. If necessary,

hold the square drive in a vise and

tap the dowel pin out –

3.5mm

dia rod, hammer

.

6.3.2.3 Remove the square adapter.

Figure 3 – Square Adapter Removal

6.4 Secure the valve in a vise with the inlet hub

facing up.

6.5 Unscrew the adapter hub (31405) –

28mm

socket

.

6.6 Unscrew the spring retainer (31404) –

12mm

socket

.

6.7 Remove the spring and gate pad assembly –

A brass rod can be used to aid pad assembly

removal.

Figure 4 – Gate Pad Assembly Removal

6.8 Resecure the valve in vise with the base

facing up.

6.9 Unscrew the 8x M12 bolts and remove the

base –

10mm Allen socket.

6.10 Remove the piston assembly and washer

springs. Set the piston down pin side up to

protect the tip of the pin –

pliers.

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 7

Figure 5 – Piston Assembly Removal

6.11 Place a 12mm socket over the seat retainer

(31409) and rotate counter-clockwise until

you can withdraw the old stem assembly from

the body –

12mm socket, socket extension

.

Figure 6 – Stem Assembly Removal

6.12 Remove valve from vise.

6.13 Remove the retaining ring (71007136) that

retains the stem bushing and discard –

Circlip

pliers (.035” Tip Diameter)

.

6.14 Resecure the valve in a vise with the stem

bushing facing out.

6.15 Unscrew the bushing from the body –

13mm

socket

.

7. Replacing the Stem Assembly Seals

Figure 7 – Stem Assembly Seals

7.1 Screw the O-ring installation tool onto the

stem as shown in Figure 8 –

PN 31479

(Actuated) or 31480 (Manual)

Figure 8 – Stem O-Ring Tool with Seals

7.2 Apply O-ring lube to the 2-011 O-ring.

7.3 Carefully slide the 2-011 O-ring over the stem

into the O-ring groove. Minimize stretching.

7.4 Carefully slide the backup ring (71006998)

over the stem into the O-ring groove.

Reform the backup ring into the groove as

needed.

7.5 Remove O-ring installation tool.

7.6 Apply O-ring lube to the 1.2mm O-ring

(71006956).

7.7 Slide the 1.2mm O-ring over the stem into

the O-ring groove.

8. Replacing the Piston Cup Seal

Figure 9 – Piston Assembly

! NOTICE

IT IS CRITICAL THAT THE GATE PAD IS REMOVED BEFORE

THE STEM. FAILURE TO DO SO WILL RESULT IN DAMAGE TO

THE STEM GUIDE RINGS.

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 8

8.1 Remove the spiral ring from the piston

assembly –

pick or small screwdriver

.

8.2 Remove the cup seal from the piston and

discard.

8.3 Apply O-ring lube to the new piston cup seal

(71006962)

8.4 Press the cup seal all the way on to the

piston. Protect the tip of the pin from

damage during cup seal installation by

placing a rag between the pin and the bench.

Note: the hat ring can be flipped over to aid

installation. See Figure 10.

Figure 10 – Installing Piston Seal

8.5 Orient the hat ring over so the flat side faces

the spiral ring. See Figure 9 for more details.

8.6 Install the spiral ring on the piston.

9. Replacing the Gate Pad and Gate Pad

Assembly Seals

Figure 11 – Gate Pad Assembly Cross Section

9.1 Remove the two O-rings from the gate pad

seal retainer and discard –

pick with bent tip

.

9.2 Install 2-010 O-ring into gate pad seal

retainer. This will be easier if you do not

lubricate it first.

9.3 Apply O-ring lube to the new 2-012 O-ring

and install on the gate pad seal retainer.

9.4 Apply O-ring lube to the gate pad shaft.

9.5 Insert the gate pad into the seal retainer.

9.6 Look inside seal retainer to verify O-ring was

not cut.

9.7 Remove the metal seal from the gate pad

plug and discard. Take care not to scratch the

sealing surface –

brass pick.

9.8 Apply O-ring lube to the new metal seal and

install in adapter hub.

10. Replacing Stem Seals

Figure 12 – Stem Seal Cross Section

10.1 Apply O-ring lube to stem seal tool. See

Figure 12

10.2 Insert stem seal tool fully into body.

10.3 Apply O-ring lube to a new chevron seal.

10.4 While holding stem seal tool in place, install a

new chevron seal (71007194) over the stem

seal tool. See Figures 12 and 13 for

orientation of the chevron seal.

Figure 13 – Stem Seals

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 9

10.5 Use the O-ring press tool to push seals fully

into gland. Screw in hand tight. See Figure 14

–

O-ring Press Tool (30643)

Figure 14 – O-ring Press Tool

10.6 Remove the O-ring press tool and check that

the chevron seal is correctly installed and not

cut.

10.7 Apply a small amount of low strength Loctite

to the external threads of the stem bushing.

10.8 Screw the stem bushing into the body.

Tighten hand tight. Note: the body must be

held in a horizontal position during this step

to allow the stem seal tool to move out of the

way as the bushing is screwed in.

10.9 Remove the stem seal tool.

10.10 Torque bushing to 40 ft.lbf [54 Nm] –

Torque

wrench, 13mm socket

.

10.11 Install the retaining ring (71007136) –

Circlip

Pliers

11. Valve Reassembly

Figure 15 – SF10000HTVB Cross-Section

11.1 Apply a generous coating of lithium grease to

the stem threads.

11.2 Apply O-ring lube to stem sealing surface.

See Figure 16.

Figure 16 – Stem Sealing Surface

11.3 Align gate profile with gate pad bore. Pushing

on the seat retainer, insert stem fully into

body.

11.4 Screw stem clockwise via seat retainer until

you reach the top stop. Once the handle hole

emerges from the bushing you can use a rod

through the handle hole to finish screwing in

the stem –

12mm socket, ø3.5mm rod

.

11.5 As the gate becomes visible in the gate pad

bore, align the gate profile with the gate pad

bore; use your thumb to keep it aligned as

you screw in the stem.

! WARNING

THE RETAINING RING MUST BE REINSTALLED TO

PREVENT THE STEM BUSHING FROM BACKING OUT,

WHICH COULD LEAD TO A HIGH-PRESSURE LEAK.

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 10

11.6 Verify that the gate profile is visible in the

gate pad bore and the gate guide ring is not

visible. Note: ceramic gate does not have a

top guide ring.

11.7 Place the valve in a bench vise stem facing

down.

11.8 Stack the spring washers, alternating dish up

and dish down. See Figure 17.

Figure 17 – Spring Stack Arrangement

11.9 Insert this stack into the valve body. The

outside edge must be facing down into the

body. See Figure 13.

11.10 Apply O-ring lube to the piston cup seal.

11.11 Insert the piston subassembly into the body,

pin side down. Press down on the piston with

the heel of your hand until the piston

contacts the springs.

11.12 Remove the metal seals from the bottom of

body and discard. Take care not to scratch

the sealing surface –

brass pick

.

11.13 Apply O-ring lube to the new metal seals and

install in the metal seal glands in the bottom

of the body.

11.14 Place the base onto the valve.

11.15 Apply anti-seize to the 8X M12 socket head

cap screws (SHCS) and install in the base.

11.16 Gradually torque the 8 fasteners in a star

pattern (in opposite pairs). It may take a

couple of passes to compress the metal seal

spring. –

10mm T handle hex key

11.17 Tighten SHCS in opposite pairs. Torque to 40

ft.lbf [54 Nm]. –

10mm hex key, torque

wrench

11.18 Double check all the fasteners are torqued

correctly by working clockwise through all 8. –

10mm hex key, torque wrench

11.19 Verify that the gate profile is visible in the

gate pad bore and the gate guide ring is not

visible (if applicable).

Figure 18 – Gate View Through

Gate Pad Hole

11.20 Secure the body in a bench vise with gate pad

bore facing up.

11.21 Insert gate pad subassembly into gate pad

bore, gate pad first.

11.22 Insert gate pad coil spring.

11.23 Screw in spring retainer –

12mm socket

.

11.24 Coat adapter hub threads with anti-seize.

11.25 Install adapter hub and torque to 180 ft.lbf

[244 Nm]. –

28mm hex, Torque Wrench

12. Handle Installation

12.1 Manual Valve

12.1.1 Place handle on stem and align the holes.

12.1.2 Insert shoulder bolt and tighten, be

careful not to shear the hex –

2mm hex

key.

12.2 Actuated Valve

12.2.1 Place square drive adapter on stem,

aligning holes.

12.2.2 Insert dowel pin into hole– ø

3.5mm rod,

hammer

.

12.2.3 Center dowel pin in square drive –

ø

3.5mm rod, hammer

.

12.2.4 Insert SHSS into end of stem and tighten

–

2mm hex key.

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 11

13. Disconnecting Valve From the SF3 Actuator

Figure 19 – SF10000HTVB with SF3 Actuator

13.1 If unit does not have a PDFM skip to step 13.5

Figure 20 – PDFM Connecting Tube

13.2 Unscrew the nut from each fitting –

5/8”

wrench.

13.3 Pull the tube out straight out from the

fittings.

13.4 Note the orientation of the actuator bracket

grommet to the SF3 Actuator and valve for

reference when reassembling.

13.5 Unscrew the 4X M6 bolts attaching the

actuator bracket to the SF3 Actuator.

13.6 Pull Disconnect the valve from the actuator.

13.7 Unscrew the 4X M6 bolts attaching the

actuator bracket to the SF10000HTVB.

13.8 Remove the bracket from the valve.

14. Reconnecting the SF10000HTVB to the SF3

Actuator

14.1 Apply a thin layer of anti-seize to the valve

square.

14.2 Remove the grommet from the actuator

bracket.

14.3 Apply anti-seize to 8X M6 bolts.

14.4 Orient the valve and actuator bracket as they

were prior to disassembly.

14.5 Insert 4X M6 SHCS in the bracket holes.

14.6 Tighten fasteners in opposite pairs –

5mm

hex key.

14.7 With the SF10000HTVB and actuator bracket

oriented as they were prior to disassembly,

align the square drive with the actuator drive

shaft. Rotate valve as necessary. Note: the

square drive can be viewed through the

grommet hole.

14.8 Slide the square drive into the drive shaft.

14.9 Realign the fastener holes.

14.10 Insert 4X M6 SHCS into the bracket.

14.11 Tighten fasteners in opposite pairs –

5mm

hex key.

14.12 Install the grommet in actuator bracket.

14.13 Reinsert the PDFM connecting tube to the

fittings in the valve and PDFM. Note: the

shorter end of the tube goes to the valve.

14.14 Tighten the autoclave nuts –

5/8” wrench.

14.15 After reconnecting the valve to the SF3

actuator, the actuator must be recalibrated.

See the appropriate SF3 Actuator and PDFM

user guide for more details.

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 12

FREQUENTLY ASKED QUESTIONS

Table 7 – Frequently Asked Questions

ALL CIMVs

Question

Answer

CIMV Shutoff

Ability

SkoFlo CIMVs are not shut off devices.

Separate isolation valves should be used for

shutting off the flow.

Protection

Against Reverse

Flow

A check valve shall be installed immediately

downstream of the valve (within 6 inches) to

prevent seal damage.

Minimum

Differential

Pressure to

Operate

See CIMV specification sheet that was supplied

with the CIMV to determine minimum required

pressure drop.

Excessive

Pressure Drop

For flows above 100 US gallons per day (15.8

LPH), pressure drops across the CIMV should

not exceed 3,000 psi (207bar) for extended

periods to avoid cavitation, which could lead

to erosion of the throttling components. As a

general rule, the outlet pressure must be

greater than or equal to the pressure drop to

avoid cavitation.

Fluid Cavitation

Fluid cavitation occurs primarily when CIMV

pressures (and secondarily fluid viscosity and

velocity) cause a drop below the fluid vapor

pressure. When the SkoFlo CIMV enters its

cavitation region, energy release from vapor

compression at the pin/seat interface may

cause premature wear.

Chemical

Filming

Historically, chemical filming has not been

experienced in SkoFlo HTD/HTV models.

Chemical filming is dependent on chemical

composition selection by the user. Injected

chemicals would need to have an affinity to

ceramic to film. Currently, there are no known

chemicals that have this affinity.

Blowout Proof

Stem

The stem design is blowout proof.

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 13

TROUBLESHOOTING

Figure 21 – Troubleshooting

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 14

APPENDIX A–ATYPICAL CHEMICAL INJECTION SYSTEM

NOTES

Any number of injection points can be served by a single pump and header

system. The only limitation is the flow capability of the pump.

Check valve shall be installed within 6 inches of the SkoFlo CIMV.

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 15

APPENDIX B–SF10000HTVB GA AND BOM DRAWINGS

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 16

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 17

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 18

Surface CIMV, Low Flow, HTV SF10000HTVB

Operations and Maintenance Instructions 19

Table of contents

Other SkoFlo Industries Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

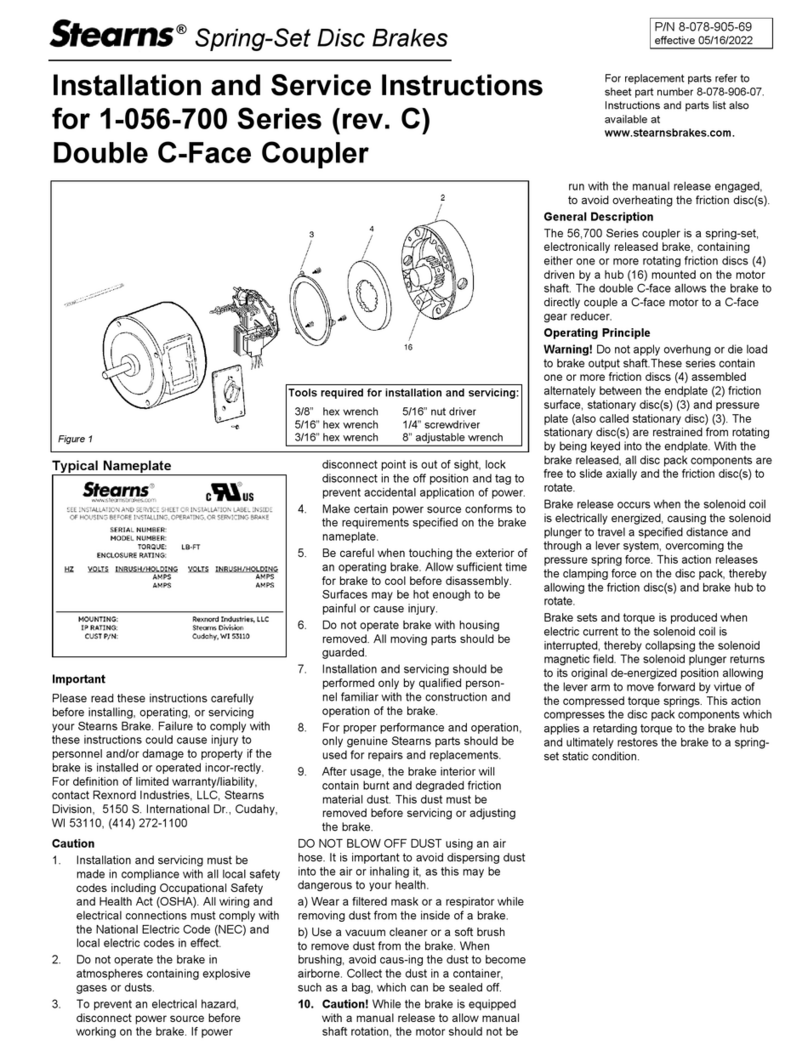

Stearns

Stearns 1-056-700 Series Installation and service instructions

Schaeffler

Schaeffler HEATER Series user manual

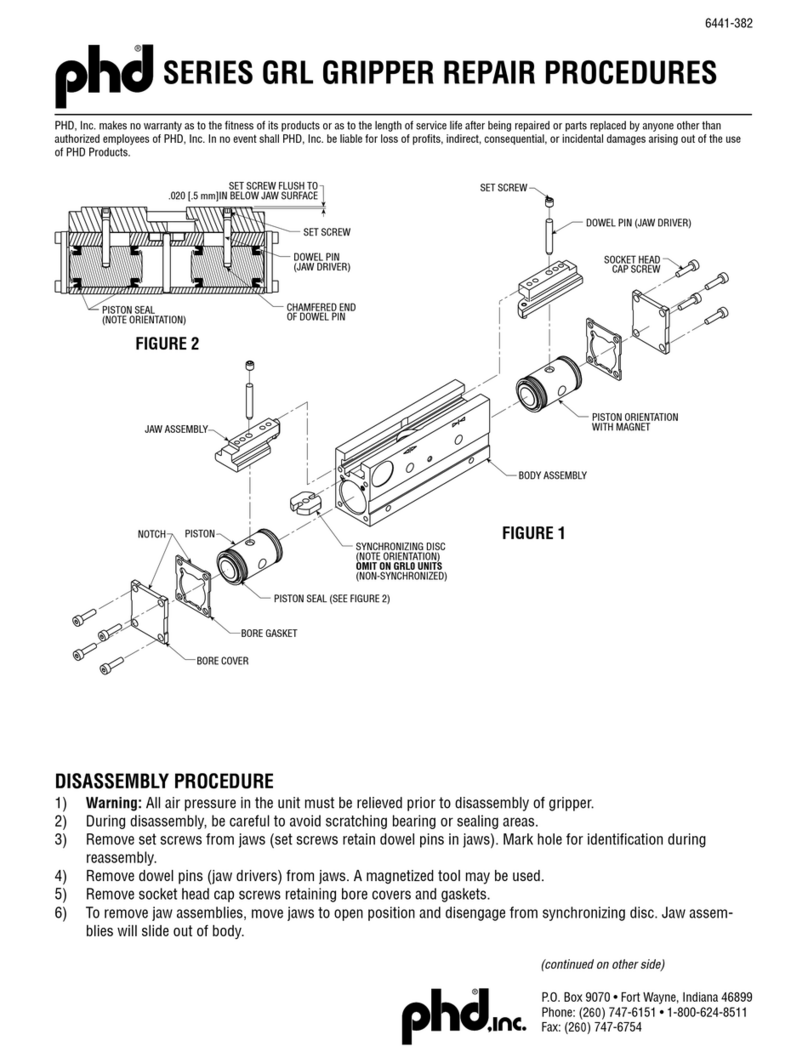

PHD

PHD GRL Series REPAIR PROCEDURES

Siemens

Siemens 3VA91 0JC1 Series operating instructions

Mapal

Mapal WTE Installation and operating instructions

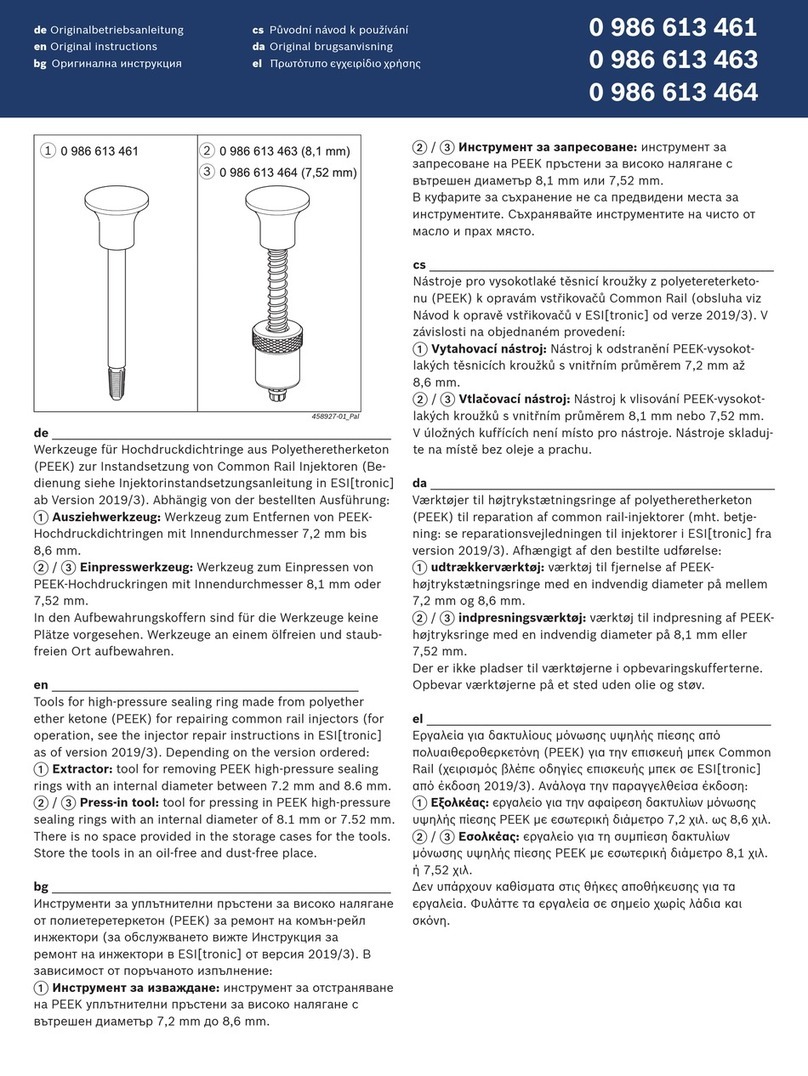

Bosch

Bosch 0 986 613 461 Original instructions