Tidland C Series User manual

1

Tidland

Series 'C' Knifeholder

INSTALLATION MANUAL

Rigid Cartridge

Class I, II, III

Shear Slitting

Please read and understand all the

instructions before you install

the Tidland Series 'C' Knifeholder.

For information, contact:

Tidland Corporation

P.O. Box 1008

Camas, WA 98607

1-360-834-2345

1-800-426-1000 (USA)

PART NUMBER 52074

0

B

1 of 3 sections of Part Number 517333B

2

3

Table of Contents

Knifeholder Safety…………………………………………………………………………………. 4

Receiving and Unpacking………………………………………………………………………… 4

Knifeholder Components……………………………………………….………………………….5

A. Determine Web Path………………………………………………………………...6

1. Direction of Web…………………………………………………………………6

2. Type of Slitting………………………………………………………………….. 6

3. Select Contact Side……………………………………………………………..7

4. Select Cant Angle Key………………………………………………………….7

B. Prepare to Mount Guidebar…………………………………………………………8

1. Determine Space Requirements……………………………………………… 8

2. Determine Setback Distance (Tangent Shear Slitting only)……………….. 9

3. Determine Mounting Dimensions……………………………………………...10

a. Vertical Mounting Dimension……………………………………………...10

b. Horizontal Mounting Dimension…………………………………………..10

C. Mount Guidebar………………………………………………………………………11

D. Mount Knifeholder to Guidebar…………………………………….………………12

E. Install Pneumatic System………………………………………….……………….13

4

Knifeholder Safety

IMPORTANT!

§Read and understand all instructions before operating the knifeholder. Failure

to follow instructions may cause the knifeholder to function incorrectly and

cause serious injury.

§The Tidland Series 'C' Knifeholder is intended to be used to produce a slit

when operated with a driven anvil system, and there is no other intended

purpose.

§While operating the knifeholder, follow all existing plant safety instructions

and/or requirements.

§Always wear stainless steel protective gloves when changing or removing the

knife blade.

§Keep fingers clear of the blade edge at all times.

Receiving and Unpacking

§Handle and unpack the equipment carefully. Upon arrival, check the shipment

against the packing list.

§Any damage should be reported to the carrier at once.

§Equipment that will not be installed immediately should be stored in a clean,

dry location.

§Be careful to prevent moisture, dust, and dirt from accumulating in storage

and installation areas.

Sharp knives may cause

severe bodily injury.

Keep clear. Do not put hands in

machines. Keep hands away from

knife blades at all times.

Compliance with Federal, State, and

Local safety regulations is your

responsibility. Be familiar with them

and always work safely.

5

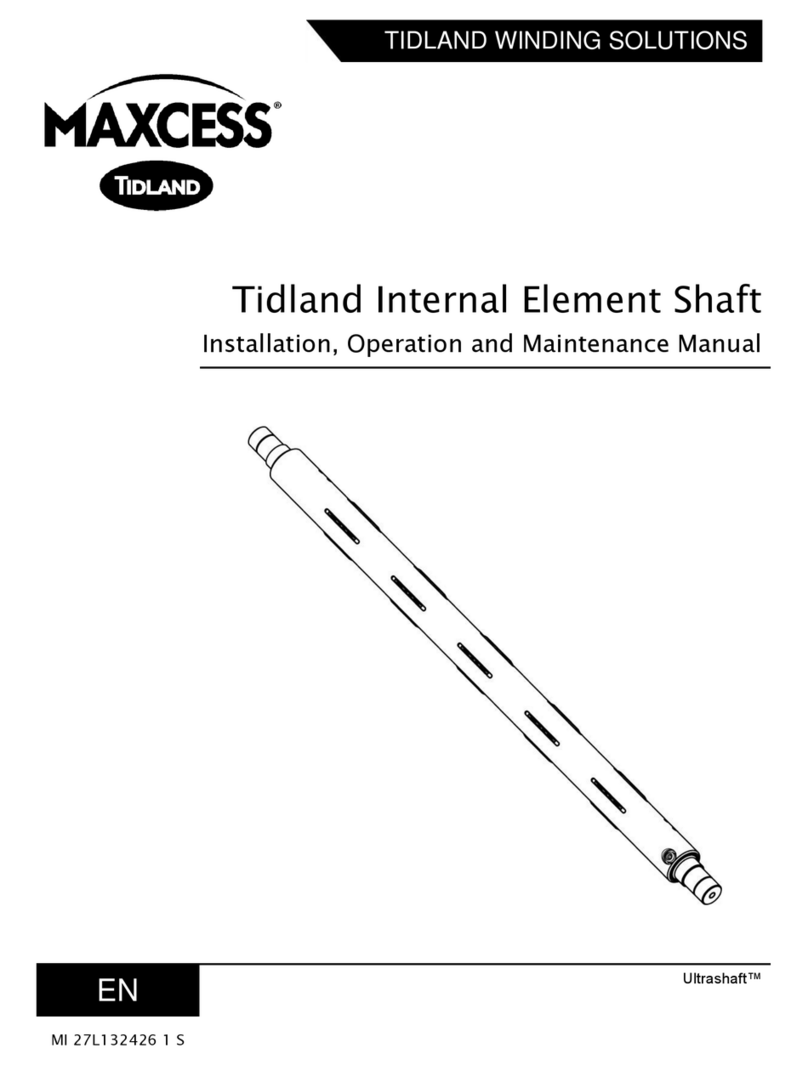

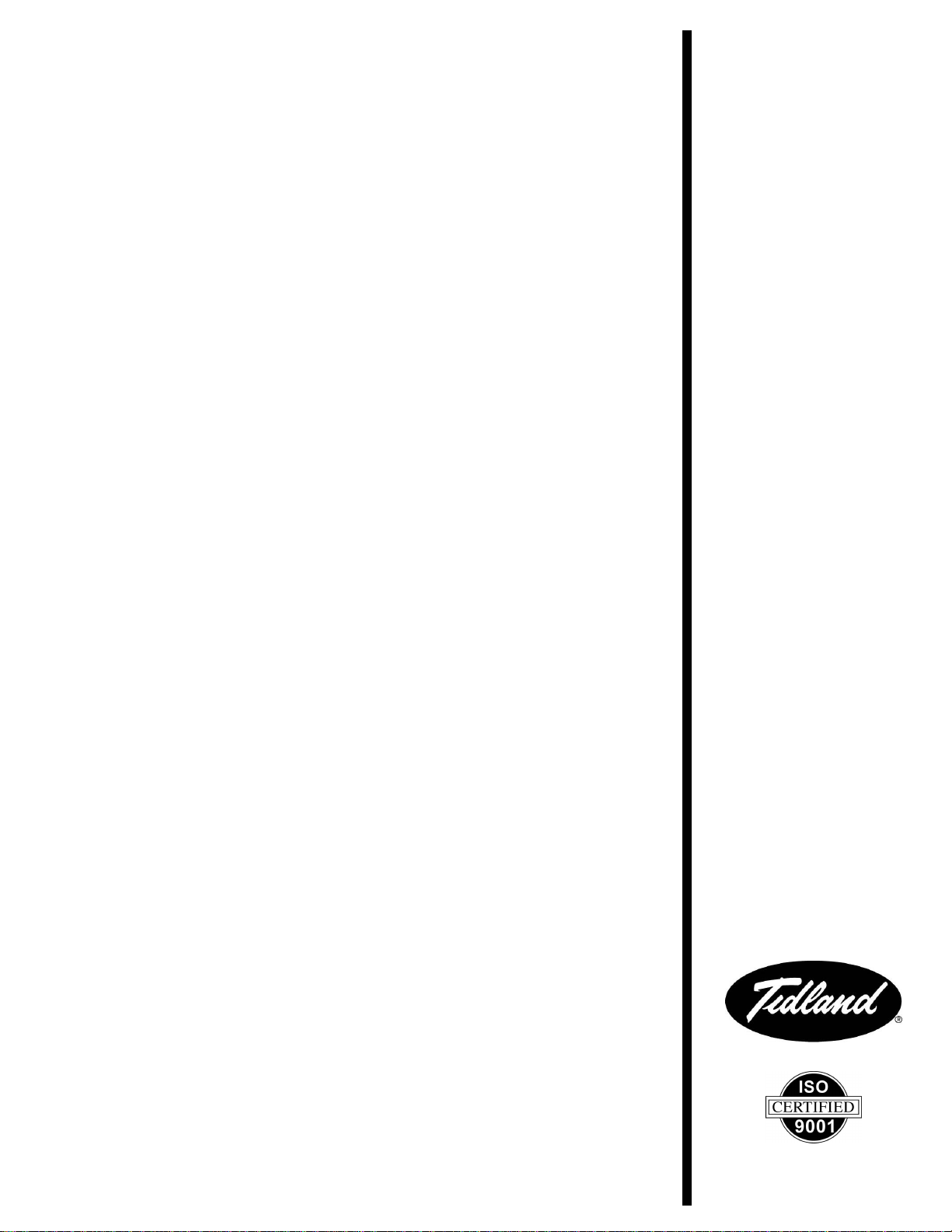

Knifeholder Components

Specifications

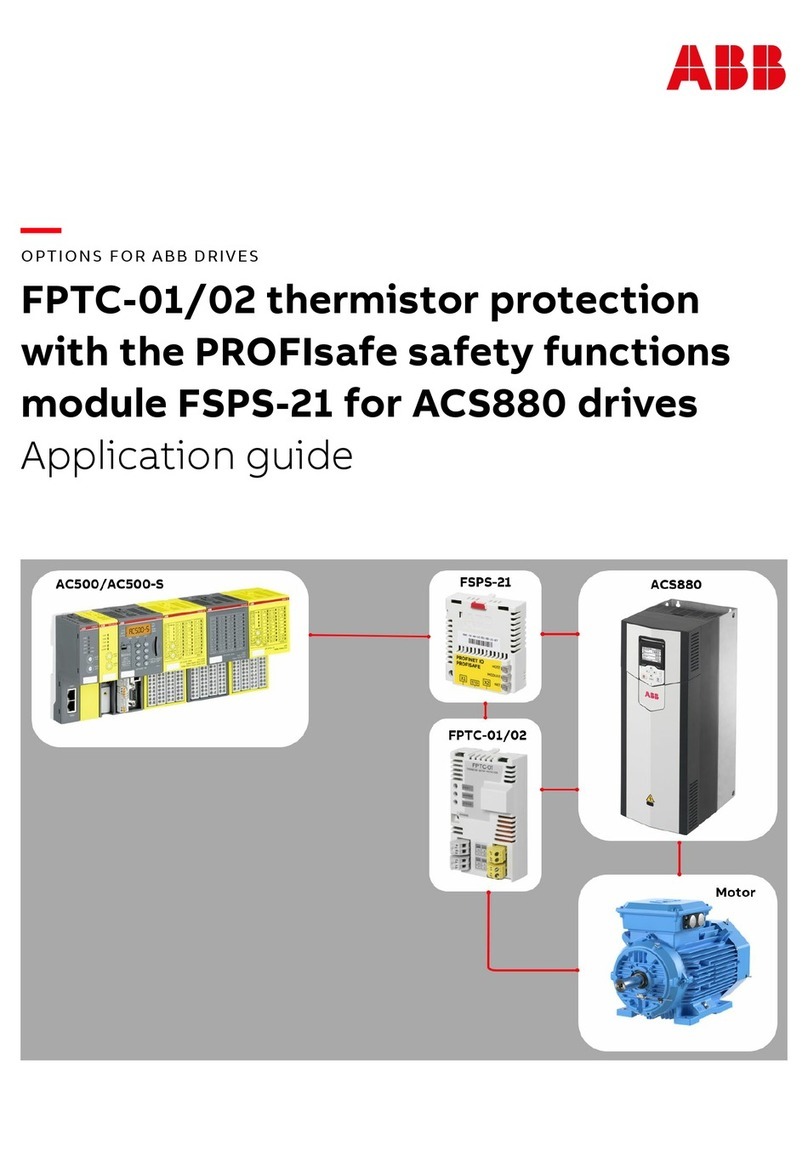

Tidland Series 'C' Knifeholder

Class I-25 Class I-33 Class II Class III

Knife Blade

Diameter

3.5" (90mm) 3.5" (90mm) 5.91" (150mm) 7.87" (200mm)

Minimum Slit 1" (25mm) 1.3" (33mm) 2" (50.80mm) 3" (76.20mm)

Typical Maximum

Speed*

3,500 fpm

(1,000 mpm)

3, 500 fpm

(1,000 mpm)

5,500 fpm

(1,677 mpm)

8,000 fpm

(2,439 mpm)

Recommended

Plant Air

Minimum 90 psi

(6.2 bar)

Minimum 90 psi

(6.2 bar)

Minimum 90 psi

(6.2 bar)

Minimum 90 psi

(6.2 bar)

Recommended

Operating Air

60-75 psi

(4.1-5.2 bar)

60-75 psi

(4.1-5.2 bar)

60-75 psi

(4.1-5.2 bar)

60-75 psi

(4.1-5.2 bar)

*Note: Actual speed is dependent on application and material

22

15

14

5

13

6

7

8

12

11

10

9

18

17

1

2

3

16

4

21

20

19

23

1. Manual Position Lock

2. Locking Gib

3. Auto-Lock Brake Shoe

4. Dovetail Mount

5. Pinion Gear

6. Rod Guide Bushing

7. Cant Angle Key

8. Strut

9. Set Stop Pin

10. Knife Blade

11. Blade Guard

12. Blade Lock

13. Latch Pin

14. Socket Head Capscrew

15. Wedge Lock Screw

16. Traverse Knob

17. Main Body

18. Valve Body

19. Gib Mounting Screws

20. Function Control Knob

21. Hose Barb Fitting

22. Depth Adjustment Knob

23. Depth Adjustment Lock Nut

6

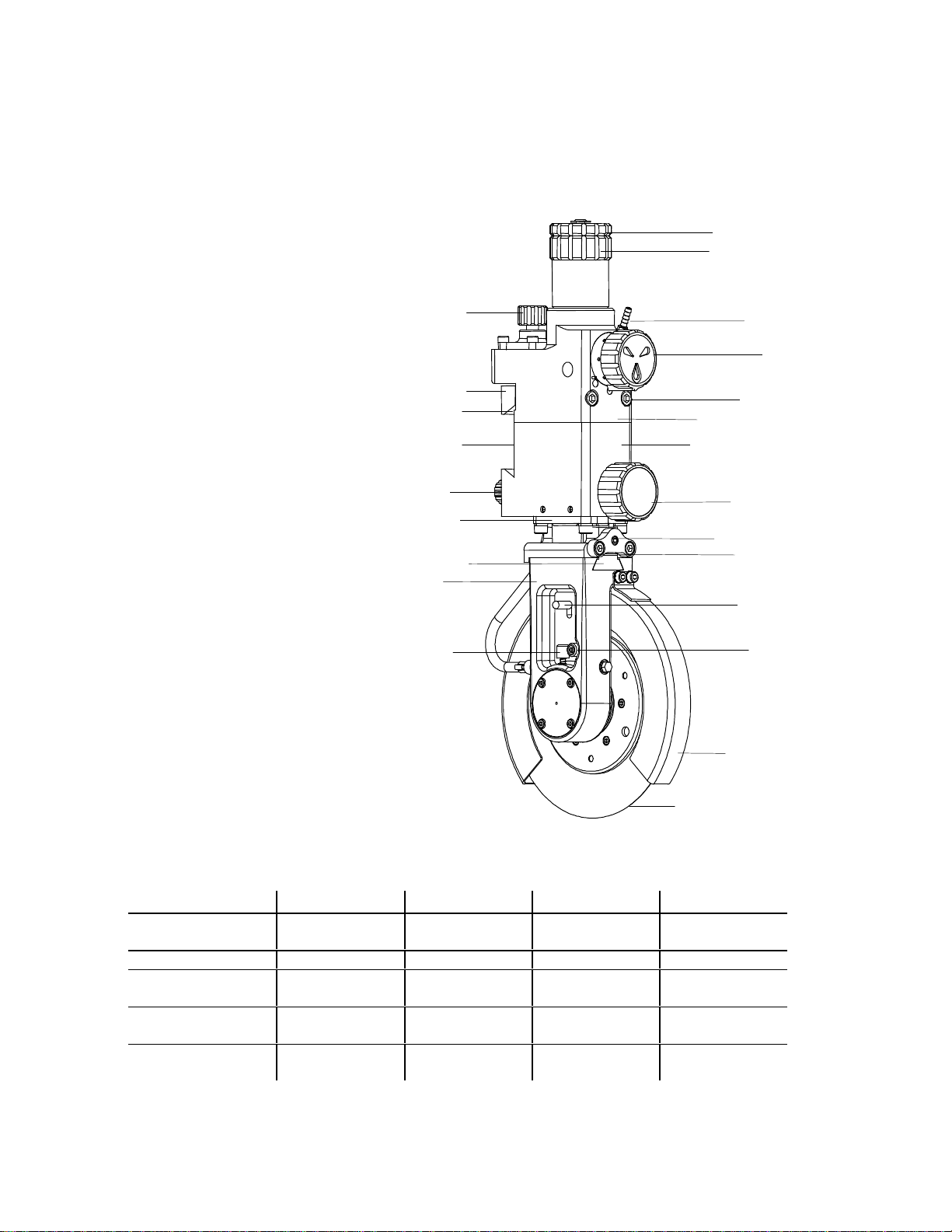

A. Determine Web Path

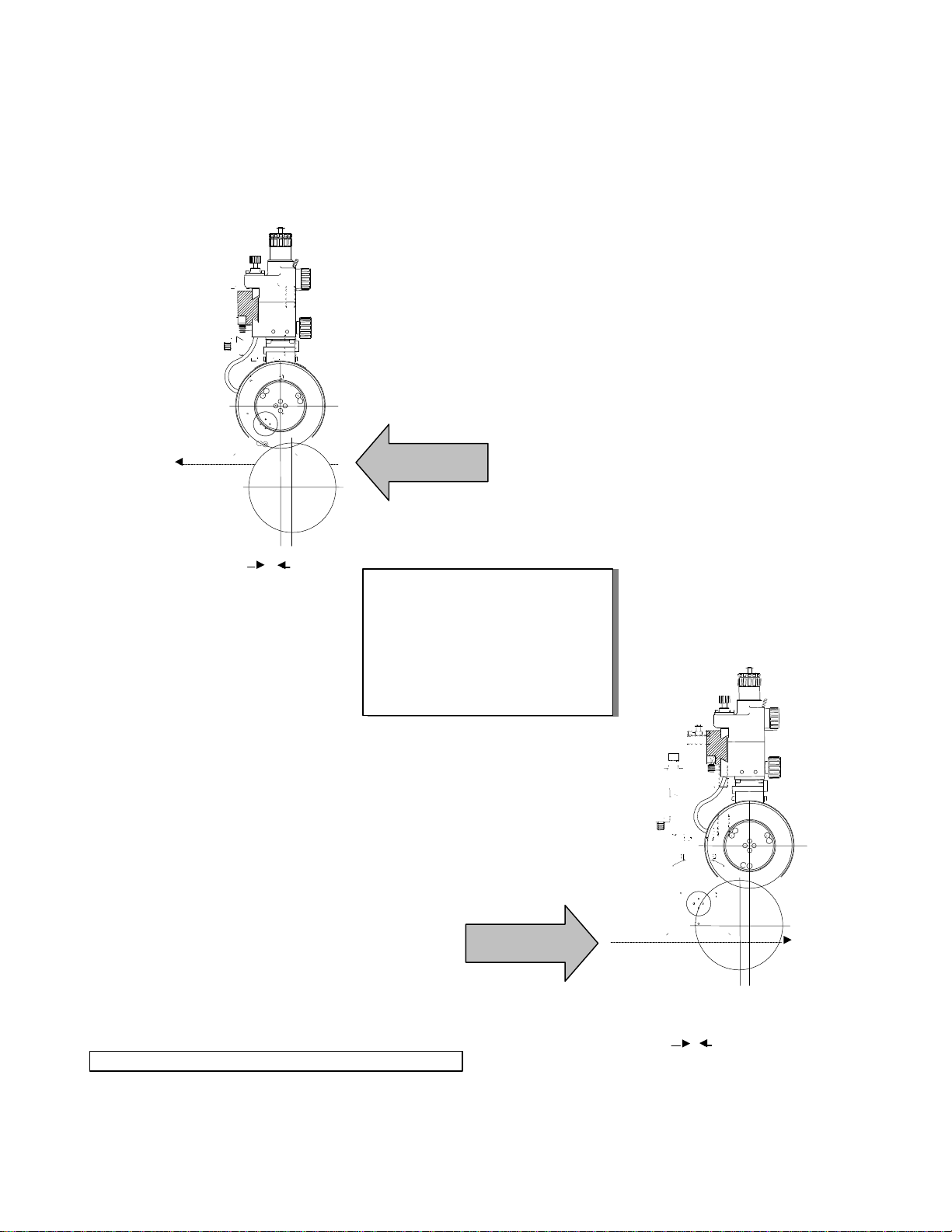

1. Direction of Web:

2. Type of Slitting:

Tangent

Wrap

OR

Knifeholder axis

should be 90° to

web path.

Knifeholder axis

should bisect

the wrap angle.

1/2 of wrap angle

90°

A

B

7

3. Select Contact Side:

4. Select Cant Angle Key:

The cant angle creates a precise shear cut point with the driven anvil

Web

Path

Contact

Side

Key

Required

ALR

ARL

BLL

BRR

See 'Changing the Cant Angle Key' in the Maintenance Manual.

L

Left side

R

Right side

8

B. Prepare to Mount Guidebar

1. Determine Space Requirements

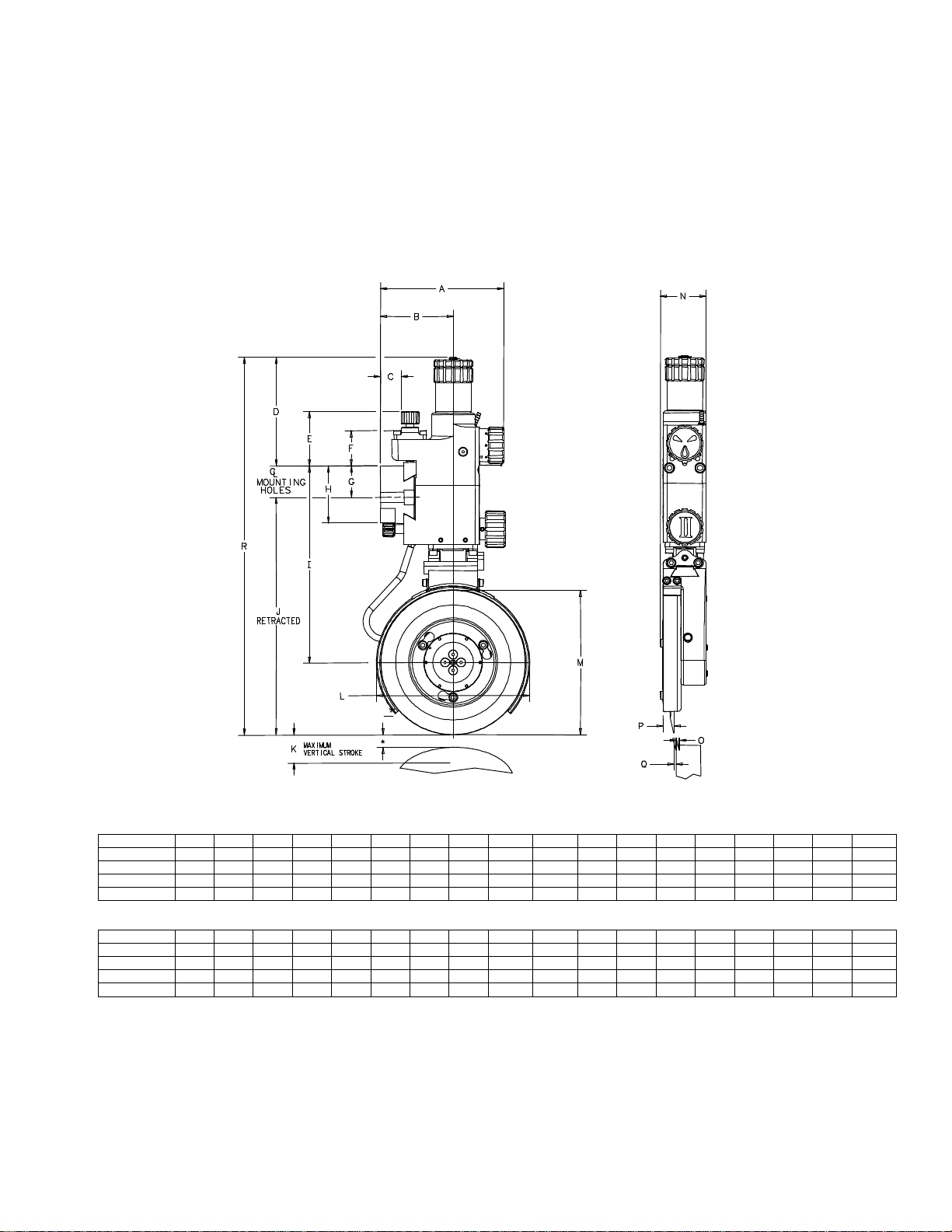

Inches ABCDEFGHIJKLMNOPQR

Class I-25 4.4 2.43 0.6 3.5 2.1 1.3 1.08 1.9 5.90 6.59 0.63 3.9 3.5 1.00 0.07 0.16 0.03 11.21

Class I-33 4.4 2.43 0.6 3.5 2.1 1.3 1.08 1.9 5.90 6.59 0.63 3.9 3.5 1.34 0.16 0.17 0.08 11.21

Class II 5.0 2.97 0.8 4.4 2.3 1.5 1.28 2.3 8.01 9.69 1.00 6.3 5.9 1.88 0.16 0.45 0.08 15.39

Class III 6.0 3.47 0.8 4.4 2.3 1.5 1.28 2.3 9.0211.67 1.00 8.3 7.9 2.75 0.24 0.97 0.12 17.37

Millimeters ABCDEFGHIJKLMNOPQR

Class I-25 112 61.7 15 90 53 33 27.4 48 149.9 167.4 16.0 99 90 25.4 1.8 4.1 0.8 284.6

Class I-33 112 61.7 15 90 53 33 27.4 48 149.9 167.4 16.0 99 90 34.0 4.1 4.3 2.0 284.6

Class II 127 75.4 20 112 58 38 32.5 58 203.5 246.1 25.4 160 150 47.8 4.1 11.4 2.0 390.9

Class III 152 88.1 20 112 58 38 32.5 58 229.1 296.4 25.4 211 200 70.0 6.1 24.6 3.0 441.2

Tidland Series 'C' Knifeholder Geometry

*Note: Reserve 1/2 of the total stroke for blade regrinding

*

Note: Dimensions are nominal and represent the average of assembled units. These are not the specifications of individual parts nor do they

reflect manufacturing tolerances.

9

2. Determine Setback Distance (for Tangent Shear Slitting only)

"A" Web Path

"B" Web Path

Typical Setback for

Paper Based Products*:

Class I-25: 1/8" (3.18mm)

Class I-33: 1/8" (3.18mm)

Class II: 1/4" (6.35mm)

Class III: 3/8" (9.53mm)

Setback

Setback

* Other products may require different setbacks.

10

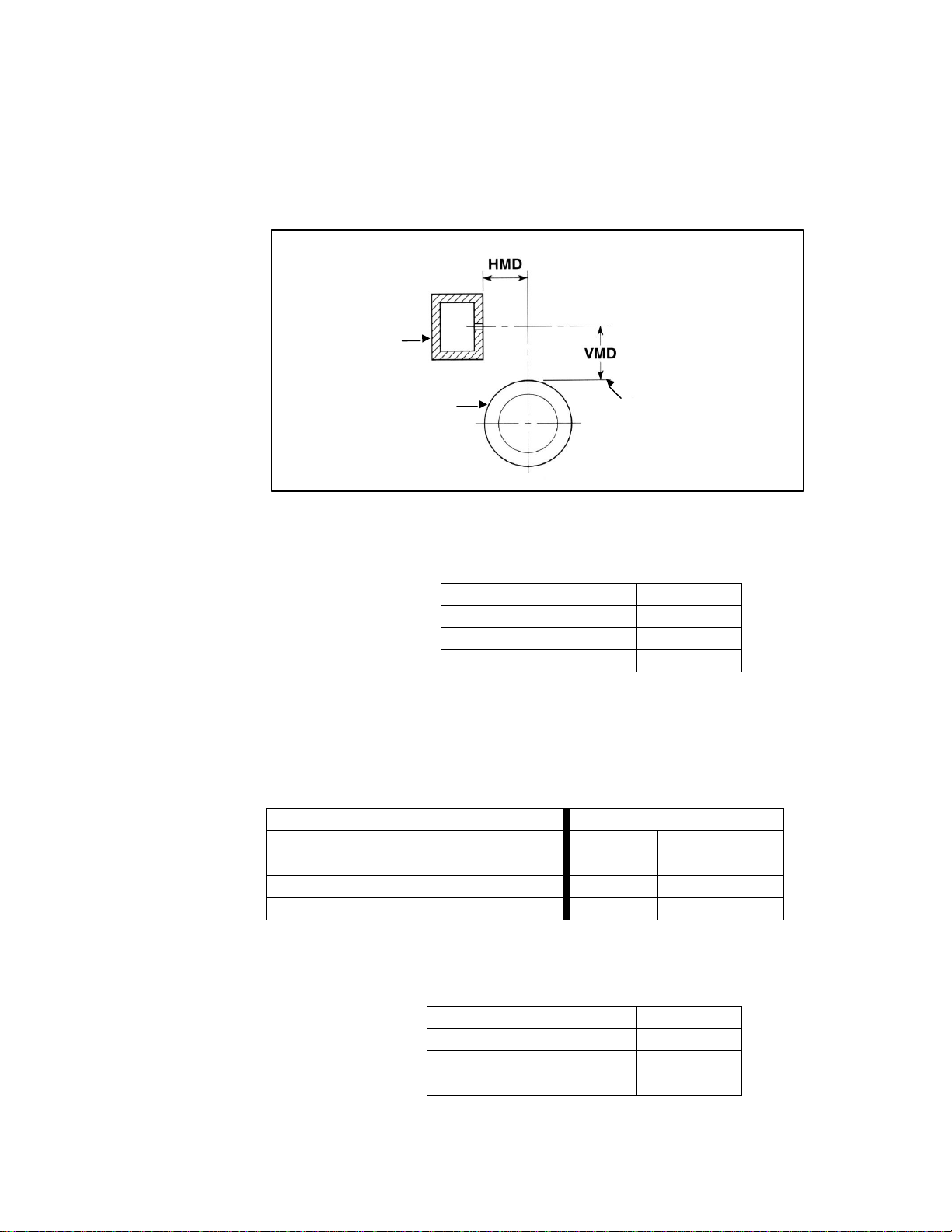

3. Determine Mounting Dimensions

a. Vertical Mounting Dimension (VMD)

Class I-25 6-29/32"

175.39mm

Class I-33 6-29/32"

175.39mm

Class II 10-3/16"

258.76mm

Class III 12-3/16"

309.56mm

b. Horizontal Mounting Dimension (HMD)

"A" Web Path "B" Web Path

Class I-25 2-9/16"65.09mm

2-5/16"58.74mm

Class I-33 2-9/16"65.09mm

2-5/16"58.74mm

Class II 3-7/32" 81.76mm

2-23/32"

69.06mm

Class III 3-27/32"

97.63mm

3-3/32" 78.58mm

Class I-25

2-7/16"61.72mm

Class I-33

2-7/16"61.72mm

Class II 2-31/32" 75.40mm

Class III 3-15/32" 88.10mm

Wrap Shear Slitting

"A" and "B" Web Paths

Tangent Shear Slitting

Tangent and Wrap Slitting

These dimensions reserve approximately 1/2 of knifeholder stroke for blade regrinding.

These dimensions will result in setbacks as listed in 'Determine Setback Distance'.

These dimensions provide

no

setback.

Anvil blade

Support beam

(Horizontal Mounting Dimension)

Parallel to web & tangent

to anvil blade

G

uidebar mounting holes

(Centerline)

(Vertical Mounting Dimension)

11

C. Mount Guidebar

1. Mark the mounting bolt center line on the support beam.

2. The guidebar must be straight within 0.010" (0.25mm) on a rigid and

vibration free support.

3. Measure the center to center distances between the mounting bolt

holes (A) on the guidebar and the overall length of the guidebar (B).

Note: Leave enough free space on each end of the support beam

for knifeholder removal.

Minimum Space Recommended

for Removal (Free Space)

Class I-25 2" (50.80mm)

Class I-33 2" (50.80mm)

Class II 3" (76.20mm)

Class III 4" (101.60mm)

4. Transfer the dimensions(A) on the support beam centerline.See note

in step 2; all mounting holes may not be equally spaced.

5. Center punch the mounting bolt pattern on the marked line.

6. Drill and tap the support beam for the mounting bolts.

7. Clamp the guidebar in place on the support beam.

8. Work from one end to the other installing the bolts until the guidebar is

securely fastened to the support beam.

Note: Make sure that the guidebar is aligned (parallel) with the

driven anvil.

Guidebar

B

Free Space

Note

:

The guidebar mounting bo

lt holes are pre

-

drilled

—

if applicable.

"

A

"

= 12"

(304.80mm). Mounting hole spacing near either end of guidebar may be less

than the standard 12" (304.80mm) spacing.

A

12

D. Mount Knifeholder to Guidebar

1. Turn the manual position lock knob counterclockwise to fully retract.

2. Make sure that the auto-lock brake shoe is fully retracted into the

locking gib.

3. Align the dovetail mount and pinion gear to the guidebar and gear rack.

4. Slide the knifeholder onto the guidebar from one end.

5. Turn the traverse knob to make sure that the knifeholder moves freely

on the guidebar.

6. Adjust the pinion gear clearance using the traverse setscrew. Keep in

mind that the gib brake will "pull" the pinion gear into the gear rack, so

leave enough clearance.

7. Tighten the manual position lock knob to secure the knifeholder in

position.

Note: Where end installation is not possible by sliding the knifeholder

onto the guidebar, the knifeholder can be mounted by removing

the locking gib.

a. Remove locking gib mounting screws located on the front of

the control body.

b. Remove locking gib.

c. Place knifeholder on guidebar.

d. Reinstall the locking gib without altering the setscrew setting.

e. Hold the knifeholder firmly against the locking gib while

alternately tightening the locking gib mounting screws.

Manual Position Lock Knob

Locking Gib

Traverse Knob

Guidebar

Pinion Gear

Auto-Lock Brake Shoe

Dovetail Mount

Locking Gib

Mounting Screws (2)

Gib Adjustment

Setscrews (2)

Traverse Setscrew (1)

Guidebar

Note:

If the knifeholder does not move freely on the guidebar, refer to step 1.

Impact to the knifeholder body should never be used to move the knifeholder.

13

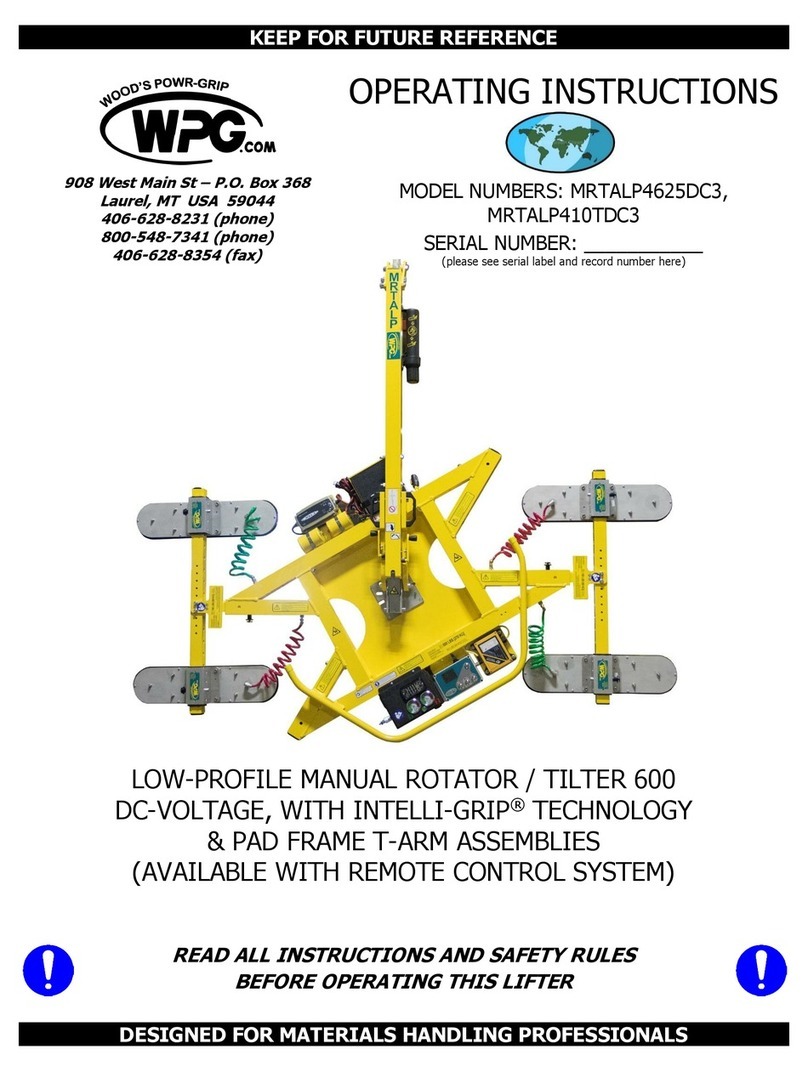

E. Install Pneumatic System

§Tidland Corporation recommends the use of a pneumatic system to prevent

airborne oil or water from contaminating the knifeholders.

The pneumatic system (Part Number: 520984) includes:

§Recommended operating air pressure: 60-75 psi (4.1-5.2 bar).

This is a guideline for knifeholder setup; the actual air pressure is dependent

upon application and material.

§Clean, non-lubricated, dry air is required for optimum performance of the

Series 'C' Knifeholder.

§Before operating the knifeholder, make sure that the air lines from the air

manifold to the blade cartridge are securely connected.

A

B

C

D

A. 3/8" (9.52mm) supply air lines

B. 5 micron air filter/pressure regulator with gauge

(0-100 psi or 0-6.9 bar)

C. Coalescing filter

D. 3-way manual valve with muffler

E.

Quick exhaust valve with muffler

air manifold*

E

quick disconnect fitting*

*

The air manifold and quick disconnect fittings

are also available from Tidland.

14

15

16

In

the United States

In the United Kingdom

In Germany

Tidland products are

Tidland Corporation Tidland-Fife Tidland GmbH also manufactured in:

P.O. Box 1008 70-72, Manchester Road Siemensstrasse 13-15 Keene, NH U.S.A.

Camas, WA 98607 Denton, Manchester D-48683 Ahaus Sao Paulo, Brazil

U.S.A. UK M34 3PR Germany Sydney, Australia

Phone: 1-800-426-1000 Phone: 161-320-2000 Telefon: 02561-6880 Tokyo, Japan

1-360-834-2345 Fax: 161-320-4513 Fax: 02561-6495 Mumbai, India

Fax: 1-360-834-5865 Email: [email protected] Email: info@tidland.de

Web Site: www.tidland.com

© 2000 Tidland Corporation Rights reserved to amend technical details without notice 520740B of 517333B December 2000

Fife Corporation

Magnetic Power Systems, Inc.

Tidland Corporation

Table of contents

Other Tidland Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

3M

3M Flexiguard 8517762 User instruction manual

Sylvac

Sylvac D200S operating instructions

ITW Gema

ITW Gema EasySelect-Cup Operating instructions and spare parts list

turck

turck TN-IOL2 Series Instructions for use

Virutex

Virutex FC116U operating instructions

Somat

Somat SPC-60 Series Service training manual