ADS TRS User manual

QUICK INSTALLATION GUIDE

TOPSIDE RETRIEVAL SYSTEM

The Topside Retrieval System (TRS) is an alternative installation

method that enables maintenance teams to remove and reinstall the

ADS®ParaFlow™and ParaDePth™sensors from the street level. The

ParaFlow and ParaDePth sensors are compatible with the ADS TRITON+®

ow monitor. After the initial installation that requires manhole entry,

the Topside Retrieval System is used to complete routine maintenance

without descending into the manhole. The Topside Retrieval Tool

extends from 6 to 20 ft (1.8 to 6 m).

Part 1: “How to Install the

Topside Retrieval System”

ADS Instructional Videos

**READ the ENTIRE Document and REVIEW ALL Links BEFORE Installing the Topside Retrieval System**

Sensor

(ParaFlow or

ParaDePth)

Sensor Bracket

Wall Mount Bracket

Topside Retrieval Tool

Part 2: “How to Remove and

Reinstall an ADS ParaDePth or

ParaFlow Sensor Using the

Topside Retrieval System”

Access all ADS instructional videos at

https://www.adsenv.com/video-library

Scan the QR code to watch:

Tools Checklist: The following parts and tools are needed to complete this installation.

Components Checklist: The ADS Topside Retrieval System consists of the following

components that can be acquired via the ADS Storefront. https://store.adsenv.com/

FBattery-powered hammer drill

F⁄ in. Masonry bit

F4 lb. Hammer

F⁄ in. Nut driver or deep well socket & wrench

F12 in. Carpenter’s level

FSmall Phillips-head screwdriver

FDiagonal wire cutters

FFolding carpenter’s rule with brass slide

FMounting Bracket Kit. P/N: 8000-0655-A

Includes Wall Mount Bracket, Sensor Bracket, and a Hardware Kit

FTopside Retrieval Tool. P/N: 8000-0654

Use for removing and reinstalling the sensor on the Wall Mount Bracket from street-level

FSelect an ADS non-contact sensor

ParaFlow sensor. P/N: 8K-CS8-V2-10-30-IS

ParaDePth sensor. P/N: 8K-CS8-D1-00-30-IS

* Tools are listed in standard (SAE) sizes. Select equivalent metric (SI) tools as needed.

* All wedge anchors, nuts, and washers must be stainless steel.

1. Installing the Wall Mount Bracket

1.1 Determine on which wall, upstream

or downstream, to install the Wall Mount

Bracket.

1.2 Make a mark 1 inch (25.4 mm) above

the crown of the pipe and centered over

the manhole invert (the closer to the crown

of the pipe the better in manholes prone

to surcharging). The lower tab of the Wall

Mount Bracket will be placed here.

1.3-1.4 Drill a hole using a hammer drill

and a ⁄inch masonry bit. Hammer the

wedge anchor into place.

1.5 Place the lower tab of the Wall Mount

Bracket on the wedge anchor and nger-

tighten a washer and nut to loosely hold it

in place.

1.6 Use the level to conrm that the bracket

is level side to side.

1.7 Drill a hole through the upper tab using

a hammer drill and hammer the wedge

anchor into place. Place a washer and nut

on the wedge anchor and nger-tighten.

Follow the steps below to complete the Topside Retrieval System installation.

1.8 Re-conrm that the Wall Mount

Bracket is level both front to back and side

to side. Once conrmed, tighten nuts. The

installation of the Wall Mount Bracket is

now complete.

1.9 Installed ParaDePth/ParaFlow Wall

Mount Bracket.

NOTE: If the manhole wall surface is

inconsistent/uneven, run nuts, followed by

washers, onto the top and bottom wedge

anchors before placing the bracket on the

bolts. Adjust the nuts behind the bracket to

more easily level the bracket front to back.

2.1 Attach the ParaDePth/ParaFlow sensor

to the Sensor Bracket. Verify that the

sensor and bracket are properly oriented

for the position of the Wall Mount Bracket.

2.2-a Installation Option A (Recommended):

If the Wall Mount Bracket is installed on the

outgoing manhole with the sensor oriented

to face the incoming ow, slide the sensor

cable into the notch on the non-loop side of

the Sensor Bracket. Then, thread a cable tie

through the hole below the notch to secure

the cable to the bracket.

2.2-b Installation Option B: If the Wall

Mount Bracket is installed on the incoming

manhole wall with the sensor measuring

the incoming ow, slide the sensor cable

into the notch on the loop end of the Sensor

Bracket. Then, thread cable ties through all 5

holes along the edge of the Sensor Bracket

to secure the sensor cable to the bracket.

2. Attaching the ParaDePth/ParaFlow Sensor to the Sensor Bracket

2.2-b Cable Tie Option B2.2-a Cable Tie Option A

or

4. Sensor Cable

4.2 Coil any extra ParaDePth or ParaFlow cable and use a cable tie

to secure it to the manhole rung or monitor handle.

4.1 To prevent debris from collecting on the cable during a

surcharge event, ensure the cable is relatively taut and that there is

only a small amount of slack in the cable.

3.1 Once the sensor is positioned on the Wall Mount Bracket, measure the Physical Oset of the ParaDePth/ParaFlow sensor; the distance

between the face (bottom) of the sensor and the crown of the pipe. Measure this distance directly or indirectly. An indirect measurement

may be the easiest. To measure indirectly, measure the distance from the face of the sensor to the manhole invert below the front portion of

the sensor and subtract the pipe height from this measured distance. The resulting value is the Physical Oset and will be input as a negative

number when conguring the sensor in Qstart™XML.

Refer to the “TRITON+ Installation, Operation, and Maintenance Manual” Chapter 4 - Conguration and Activation for more information.

https://www.adsenv.com/ads-product-manuals.

3. Measuring the Physical Oset of the Sensor Prior to Exiting the Manhole

2.3 Lock the Sensor Bracket in place by turning the Sensor Bracket Loop clockwise.

2.3 Sensor Bracket Loop Closed 2.3 Sensor Locked and Installed2.3 Sensor Bracket Loop Open

Directly Measure the Physical Oset Indirectly Measure the Physical Oset

Sensor Face to Invert – Pipe Height = Physical Oset

Sensor Face to Crown of Pipe = Physical Oset

Sensor Face to

Crown of Pipe

Sensor Face

to Invert

Pipe

Height

Install the cable so it is secure but can move freely should the sensor need to be retrieved. It is best practice to remove as much slack as

possible with the sensor cable to prevent interference.

WARNING! When using the Retrieval Tool to either remove or

reinstall the sensor, be careful to avoid any overhead obstructions.

Be especially aware of any overhead power lines.

The pole extends from 6 ft (1.8 m) to 20 ft (6 m).

IMPORTANT! Manhole and sewer system work involves conned space entry and is inherently

dangerous. Installers and technicians should comply with all federal, state, and municipal

regulations concerning conned space entry.

Download these documents from https://www.adsenv.com/ads-product-manuals to help with installation.

For Further Assistance Call 1-877-237-9585

or Email adssupportcenter@idexcorp.com

www.adsenv.com/triton

© 2022 ADS LLC. All Rights Reserved. QR775039 AO, TRS-QIG_07-14-2022

!

“Topside Retrieval Quick Installation Guide” to share this document with co-workers.

“TRITON+ Installation, Operation, and Maintenance Manual” for detailed information regarding

installation, IS certications, and maintenance restrictions.

DOWNLOAD

5. Testing Removal and Reinstallation of Sensor Using Topside Retrieval Tool

5.1 Using the Topside Retrieval Tool,

unhook the cable from the hook mounted

on the manhole wall.

5.4 As a safeguard, when the sensor

is being raised out of the manhole,

simultaneously retrieve the sensor cable to

minimize the distance the sensor could fall

if it comes o the pole hook.

5.2 Run the Topside Retrieval Tool down the

manhole to the Sensor Bracket, extending

the pole as necessary.

5.5 To reinstall, make sure the Sensor

Bracket is securely looped on the pole

hook, lower the Sensor Bracket down the

manhole, and seat it on the Wall Mount

Bracket. Twist the Sensor Bracket loop

clockwise to lock the bracket back in place.

5.3 Position the hook through the loop

on the Sensor Bracket and turn counter-

clockwise, then slowly raise the sensor to

the top of the manhole.

5.6 Again, use caution when raising the

Topside Retrieval Tool after the sensor

reinstallation.

6 ft (1.8 m) extends to 20 ft (6 m)

Popular Tools manuals by other brands

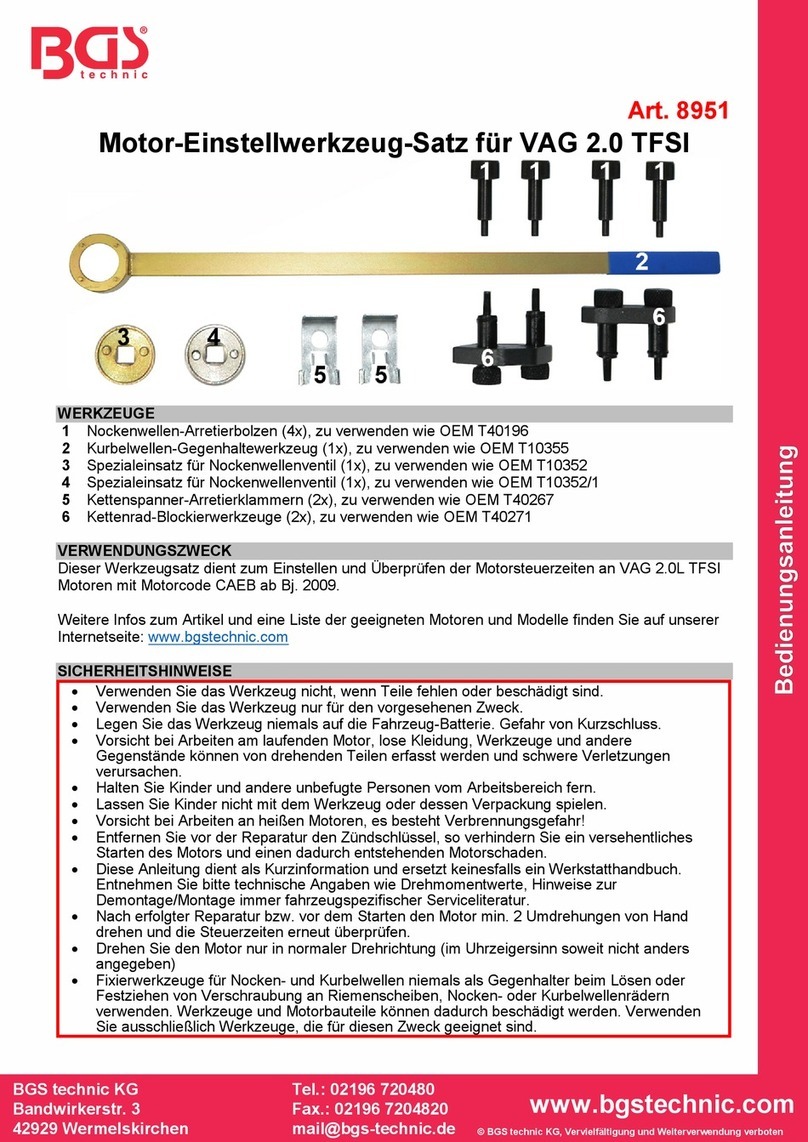

BGS technic

BGS technic 8951 instruction manual

KEENCUT

KEENCUT EXCALIBUR 3S manual

ToolMaster

ToolMaster ATP-50 instruction manual

BGS technic

BGS technic 8766 instruction manual

PCB Piezotronics

PCB Piezotronics 027125-07012 Operation manual

PCB Piezotronics

PCB Piezotronics ICP 086E80 Installation and operating manual