ADTEK DL1 User manual

- P1 -

DL1 RS-485 Data Collection Recorder < User Manual>

DL1 is design to communicate through RS485 to read variety of

devices (Such as instrumentation, PLC, A / D conversion card ....)

and stored the data collected into a SD card .Data can then be converted

to Excel file format on a computer to perform analysis and production of

related reports needed by users.

This product not only read and record data speed up to 0.1 seconds, and

its flexible software setting allows in many ways for easy planning. For

multiple projects user, DL1 provide two project planning procedures

which stored the data into two separate files. After all setting on

software, parameter can be upload/download to DL1 using a USB

interface cable. Recording can be start by external DI contact or by

meter button.

®

ADPro is the software provided with the hardware for setting parameters

and procedures planning through the USB interface cable to the DL1.

Today there are lots of field (such as industrial, energy, environment

monitoring, commercial information ....),needs record process data,

providing DL1 is rather inexpensive solution compare to present industrial

recorder.

DL1 give a simple, convenient and economical solution for all.

■產品說明

■特點

■Features

■Applications

■Product Description

◎

◎

◎

Communication and display device

l

l

l

l

l

l

l

l

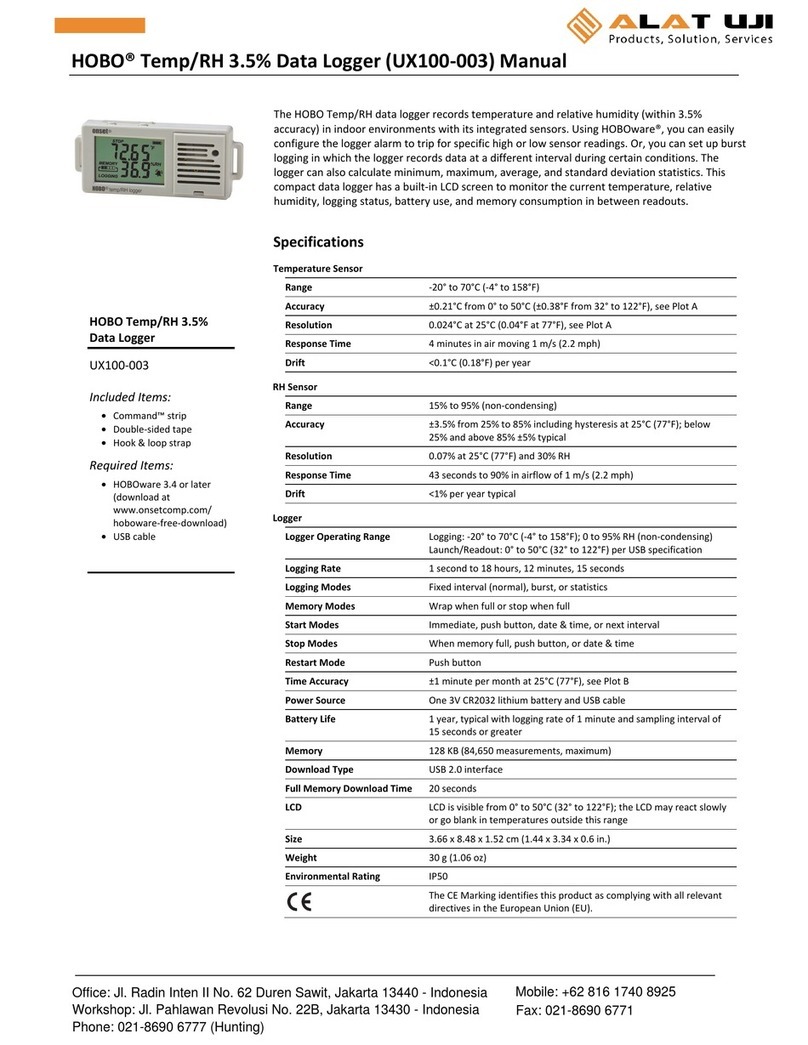

1 Group RS485 Master Communication port (Modbus RTU mode),connectfrom 1 (standard) to 32 devices.The

maximum read speed of 0.1 second

Circular display window showing the document reading position, and information for users to understand the recording

status.

Two external control inputs can be arbitrarily set to start recording or frequency input, and other related functions

Innovative disk installation (96 x 48 mm), installation depth is only 120mm, suitable for installation in a variety of

devices used for long-term record

Storage

1 Group SD card slot, you can use 2 ~ 32GB SDHC card to store the data

1 Group USB interface cable use with the ADPro ® software uploading, downloading configuration parameters and

updating software

Input and output control device

2 set of external control input(E.C.I.)

With the external contact control, instrument can start or stop recording

Upper or lower limits can be set out warning buzzer to alert operators to abnormal conditions in time

l

l

l

Production line test equipment, data recording system ,data online data collection, quality control of portable test

equipment, data recording devices measured.

PLC equipment and abnormal movements of program records, records of power consumption.

Records of solar power generation system and efficiency of power generation.

Thank you for purchasing this instrument, PLEASE READ MANUAL before operating the instrument.

Safety Tips:

Power OFF before any Installation and removal of the instrument

Do not use under direct sunlight (ambient temperature is -10 ~ +60 ℃)

Be sure to ground the instrument (ground resistance <10 ohms). Do not shared same ground with other large electrical load.

Ungrounded or faulty grounding may lead to electric shock, malfunction and other faulty conditions occur

The device uses single-phase AC power supply 85V ~ 264V.

&

&

&

&

- P2 -

■ORDERING INFORMATIOM:

A b C d E F G H i J K L M

abcdefghijklm

n o p q r S t U v W X y Z

nopqrstuvwxyz

1 2 3 4 5 6 7 8 9 / .

123456789/.

ENT/FN

LED status display

AL1:Alarm 1 LED

AL2:Alarm 2 LED

ECI:SD card LED

COM:Communication LED

Enter button

ENT/FN/ENTER

Left button/Left

Next/Increase key

Previous/Reduce key

SDHC card Slot

Max. support to 32G

Main Display

Upper display: 10 digital

Lower display: 5 digital

Mini USB Slot

ADPro for DownLoad

■Seven-segment display (LED) display font table

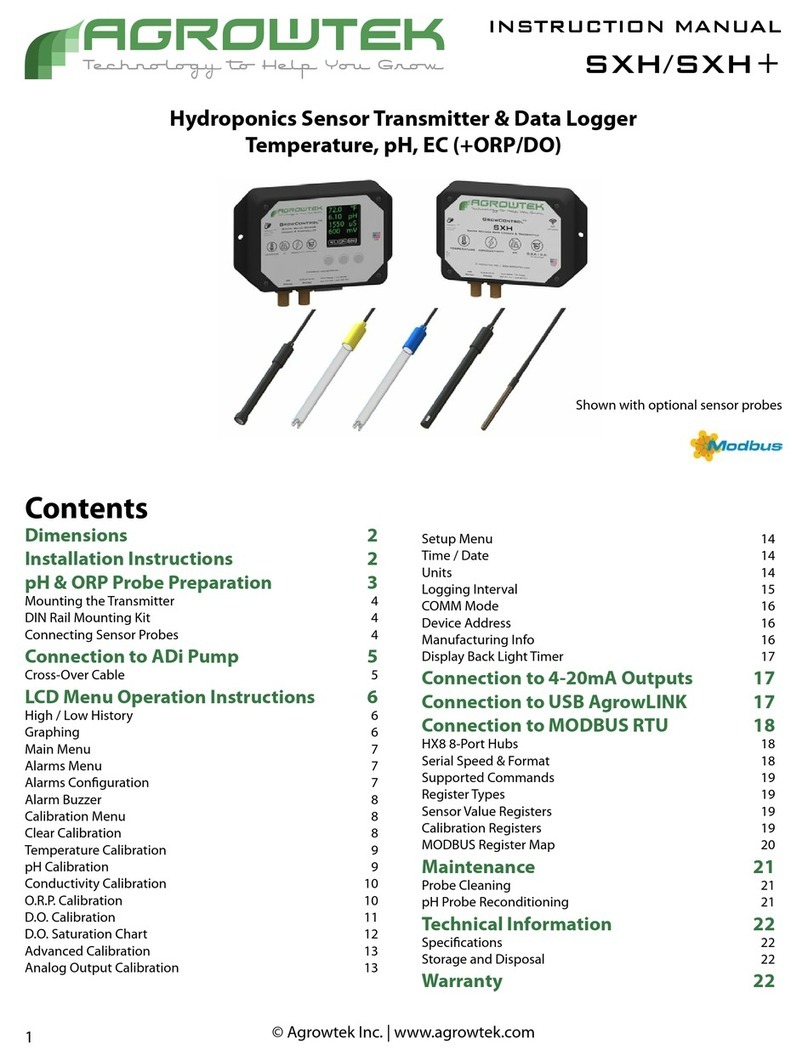

■FRONT PANEL

■DIMENSION

Unit: mm

Dimensions: 96(W) x 48(H) x 120(D)

48.0

FORNT VIEW

PANEL CUT-OUT +0.2

44.0

+0.2

92.0

96.0 100.0

8.0 12.0

+0.2 +0.2

Panel Cutout: 92 (W) x 44 (H)

■CONNECTION DIAGRAM

■INSTALLATION

PANEL CUT-OUT:

+0.2 + 0. 2

92 (W)X44 (H) mm

FIX HOLDER:

104 mm(L) / 12mm(W) M3

When wiring, make sure the power voltage and terminals

connection are correct. Proposed installation of the instrument

before the fuse or no-fuse breaker for safety equipment use.

7.0mm max

7.0mm max

Terminal 1~8: 15A/600Vac, M3.5, 12~22AWG;

Maximum torque: 13Kg-cm

■Power Supply

■Wiring Ter minal

Filter or Transformer

L

N

G

L

N

G

1A Fuse

AC85~264V

8

76

Note: Please state the

header transmission

installation or

replacement of the

battery, otherwise it

will result in reduced

battery life!!

01

06

Rs485 sub-machine

P1

Multi-record

Aux Power

DL1

1 sub-machine

~6

1 sub-machine

12 ~

1 12 sub-machine

18 ~

1 18 sub-machine

32 ~

1 32 sub-machine

3 Group relays

Rs485

sub-machine

AC 85~264V

DC 100~300V

AC 20~56V

DC 20~56V

ADH

ADL

Multi-record

- -

8N NONE

8S RS485 Slave

OUTPUT

-

TN NONE

T1 Ethernet Interface

-

Ethernet Interface

RS485 Slave

Optio n 1 Optio n 2 Optio n 3

P2 can be set 2 Program

CODE CODE CODE CODE CODE

N

無

1

讀 卡 機

USB

CODE

2

下 載 線

USB

-

RN NONE

R3

CODE

Aux Power

-

Optio n 4

Ethernet

Interface

OUTPUT OUTPUT

Single-1 program

Note: The light-colored part of the specifications for the new version of the word book additional features, is currently temporarily unavailable。

FG

D-

D+

AUX.POWER

Clock

Memory

Battery

AC85~2 V64

RS485

com.port

1 2 3 45678

External Control Input

ECI-1

ECI-2

COM

- P3 -

1.Boot test process

Check power

connection

88888

8 8 8 8 8 8 8 8 8 8

Boot test program

Full-light LED

v0)29

dl1-061nn

Indicate that the machine model (model types please refer to

selection table)

DL1-061nn:Connection 1~6 sub machine,Single-1 program

Display the software version of the machine

v00.29:Version 00.29

w a i t

l i n k t e s t

LINK TEST:Test the connection status of all RS485

Slave

(Command sent to determine the connection status,if

test incomplete will jump to abnormal display screen)

1sec

1sec

Connectio n normal

NO

YES

4 8 % c k

D 0 @ l i n k e r

D02 LINK ER:Device 02 link Error

Press “ENT” key into <SKIP/CHECK>

Select SKIP/CHECK press “ENT” to next

error message(Select "SKIP” throughout to

end <LINK TEST>, Select “CHECK” will

repeat <LINK TEST> till OK)

s k i p

c h e c k

s k i p

check

s k i p

c h e c k

SD card normalNO

YES

w a i t

c k s d c a r d

CK SD CARD:Test SD card status

Flashing display "WAIT" word

s d C c k

n o c a r d

no card :no sd card

no space :space less

sdc error :SD Card Exception

unformat :SD card Unformatted

n o s p a c e

s d c e r r o r

D 0 @ l i n k e r

4 8 % c k

D 0 # l i n k e r D 0 # l i n k e r

4 8 % c k

D n N l i n k e r D n N l i n k e r

D03 LINK ER:Device 03 link Error

Press “ENT” key into

<SKIP/CHECK>Select and press “ENT” into

the next error message

Dnn LINK ER:Device nn link Erro

Press “ENT” key into

<SKIP/CHECK>Select and press “ENT” into

the next error message

n o c a r d

AA

A

Test OK to the P4

page display

A

u n f o r m a t

1sec

1sec1sec

Please read the instructions before formal operation:

1.Instrument setting is divided into "user level " and "engineers level ".

2.Do not allow non-engineering personnel to modify within "Engineer level ",to avoid system anomalies caused

by improper setting or damage。

3.Please read the process description below fully, understand the process flow chart, set the appropriate

1sec

Sd card error message is displayed abnormal test

flashing

flashing

Test connection error message :

ENT

ENT

ENT

ENT

ENT

ENT

Press 1 Sec

Repeat test

Press 1 Sec

Repeat test

- P4 -

1sec

0 9 - 3 0

2 0 1 0 - 1 1 - 2 0

Now Date/Hour-Min

s t a n d b y

0 9 - 3 0

Standby Display/Hour-Min

e d k e y

p r o J a a a a a

P1-AAAAA

/Start button

E C I

p r o J b b b b b

P2-BBBBB

/ECI Trigger Start

◎Manual/ECI recording start:

0 9 - 3 0

2 0 1 0 - 1 1 - 2 0

Now Date/Hour-Min

s t a n d b y

0 9 - 3 0

Standby Display/Hour-Min

E C I

p r o j b b b b b

P2-BBBBB

/ECI Trigger Start

◎Timer recording start:

1 0 - 0 5

p r o J a a a a a

PJ-AAAAA/

10:05 start

0 0 - 3 5

p r o J a a a a a

PJ-AAAAA

/Time left

1sec 1sec 1sec

1sec 1sec 1sec 1sec

1sec

0 9 - 3 0

2 0 1 0 - 1 1 - 2 0

Now Date/Hour-Min

d o n e

p r o J a a a a a

P1-AAAAA

/Start button

d o n e

p r o J b b b b b

P2-BBBBB

/ECITrigger Start

◎Recording ended:

1sec 1sec

Standby Display

Press ENT into

0 9 - 3 0

2 0 1 0 - 1 1 - 2 0

Now Date/Hour-Min

0 0 0 0

p a s s w o r d

Password

Enter engineer level parameters setting

go to P7 page

Press ENT + into

S r u n

a a a a a

Started recording and enter record excution

display screen go to P6 page

Choose to start PROJ

s d C m b

4 0 0 0 m b

Prass 1sec into

SD card Memory

Select recording start method go to

P5 page

Code correct

Flow chart display of each parameters setting in details

S t a n d b y s c r e e n d e t a i l s

2.1 Standby display User Level

Flashing

Flashing

Flashing

Flashing Flashing

Flashing

ENT

Flashing

- P5 -

1 Sec Left 1 Sec Enter

s m l P r

0 0 - 0 0 - 1 ) 0

R t i m e

0 # 3 1 - 0 * 3 0

ENT

EXIT

s d C m b

4 0 0 0 m b

SD card Memory

p J s e l

a a a a a

PROJ-1 Startup

settings

p J s e l

b b b b b

PROJ-2 Startup

v 0 ) 3 0

dl1-062nn

Model / Version Display

s T m d

p r e s e t c l k

Start Time

smlPr

0 0 - 0 0 - 0 ! 0

Sample rate/ 1.0 sec【*2】Sample rate/ 1.0 sec

R p r i d

9 9 ( 2 # 5 ( 5 (

Total recording time

【*3】999 days 23:59:59

Start Date/Hour【*4】

At 8:30 on March 31

R p r i d

9 9 ( 2 # 5 ( 5 (

Total recording time

999 days 23:59:59

Display screen of varies start methods

0 9 - 3 0

2 0 1 0 - 1 1 - 2 0

Now Date/Hour-Min

s t a n d b y

0 9 - 3 0

Standby Display/Hour-Min

edkey

p r o J a a a a a

P1-AAAAA Start button

1sec

00-35

p r o j b b b b b

P2-bbbbb/The

remaining 35 min

1 0 - 0 5

p r o J b b b b b

P2-bbbbb/10:05 Start

1sec 1sec 1sec 1sec

2.2 Recording start method setting and display User Level

Standby display

Flashing

Flashing

Flashing

s T m d

f r o n t k e y

Start button【*1】

s T m d

e c i o n

ECI Control start

s m l P r

0 0 - 0 0 - 0 ! 0

Sample rate/ 1.0 sec

c R p i n

e c i - 1

Control Pin/ECI-1【*5】

l e v l

l o w

ECI Action Level/

LOW

To change the start mode,press ENT+▽ into the Edit screen,choose only one type.

PROJ-2 Setting same

as PROJ-1

sTmd:Start recording(Start Mode):

If setting is done in ADPro software, screen display start mode type, same

setting can be change here.

【*2】smlPr:Interval between each recording(Sampling rate)

00-00-0!0:0.1 Sec~23(H)-59(M)-59.9(S)

【*3】Rprid:Set start run time (For timer start method only)

99(2#5(5(: ,All set to "0" for continuous recording, if

set 1 day 11:11:11. Unit end recording after run time ended.

【*4】Rtime:Start recording date( )

0#31-0*30:March 31,8:30 unit follow real time start.

【*5 eci start method:By DL1 external control input contact to start

Contact ON: DL1 execution , contact OFF: DL1 recording stops.

【*1】

】999 days 23:59:59

For timer start method only

】

recording

s T m d

o f f

Close startup mode

Note:

ENT

EXIT

- P6 -

6 4

p r o J a a a a a

1sec

t a G 0 1

1 0 0 ) 0

1sec

t a G 0 2

1 0 0 ) 0

1sec

t a G 6 4

1 0 0 ) 0

1sec

0 9 - 3 0

2 0 1 0 - 1 1 - 2 0

1sec

3 2

p r o J b b b b b

1sec

f l W 0 1

1 0 0 ) 0

1sec

t m P 0 2

1 0 0 ) 0

1sec

p p P n n

1 0 0 ) 0

1sec

Rx flashing->

PROJ AAAAA

The number of TAG ->

Only once

PROJ bbbbb

The number of TAG ->

Only once

Start recording after

setting conditions

2.3 Recording and execution of recording display User Level

0 9 - 3 0

2 0 1 0 - 1 1 - 2 0 s t a n d b y

0 9 - 3 0 e d k e y

p r o j a a a a a

e d k e y

p r o j b b b b b

1sec

Under the screen at any one

Press ENT+ into(Start the project selection screen)

S r u n

! a a a a a

Now Date/Hour-Min

1sec 1sec

Standby Display/Hour-Min P1-AAAAA Start button P2-BBBBB Start button

Start PROJ-1

S r u n

@ b b b b b

Start PROJ-2

ENT

S r u n

b o t h

Start two PROJ

ENT ENT

Press ENT+ into(stop)

S s t o p

! a a a a a

Stop PROJ Choose

S p a u s

! a a a a a

Pause PROJ Choose

@ b b b b b

b o t h

! a a a a a

@ b b b b b

b o t h

! a a a a a

Press ENT+ into(Pause)

Under the any picture

Choose a project which started

PJ1=1.AAAAA

PJ2=2.BBBBB

or on time=BOTH

Standby display

1sec

Recording excution display screen

Flashing

Flashing

ENT/FN

S.RUN

S.STOPS.STOP

S.PAUS

S.RUN:

S.STOP: Select Stop

S.PAUS: Pause

Select Run

Select

a l - h i

1 9 9 ( 9

Alarm screen when

alert occur

t a G 0 1

p r o J a a a a a

1sec

a l - l o

1 ! 5

t m P 0 2

p r o J b b b b b

1sec

1sec

1sec

a l - h i

9 9 9 ( 9

p p P n n

p r o J b b b b b

1sec1sec

1sec

a c k

ENT

1 9 9 ( 9

a c k

ENT

1 9 9 ( 9

a c k

ENT

1 9 9 ( 9

Alarm screen will not show up

if all alert are (ACK)

TAG1 name ->

And numerical

TAG1 name ->

And numerical

TAG2 name ->

And numerical

TAG2 name ->

And numerical

Alarm screen shows:

proJ aaaa :ProjectAAAAA

taG01 : Tag Name(TAG01)

1999.9: Current value

al-hl : alarm set point occurs

Press ENT key to enter ACK confirmation,buzzer off

after ACK.If alert remain, alarm will continue to light

the LED till alert no longer exist.

◎Start and stop buttons◎

- P7 -

2.4.1 System parameters setting display Engineer level

Standby display

ENT

password

correct

NO

YES

0 0 0 0

p a s s w o r d

e d i t

s y S p a r a m

e d i t

s d c a r d o p

e d i t

p r o J 1 p a r a

e d i t

p r o J 2 p a r a

d a t e

2 0 1 0 - 1 1 - 2 6

t i m e

0 ( 5 $ 5 0

d L p w d

1 0 0 0

e c I s t

e d i t

s d s p a c e

e d i t

l d c o n f i G

ENT

EXIT

ENT

EXIT

SYS System parameter Date Set Time Set Code Set ECI State Test

SD Card Parameter SD card remaining capacity load the parameters

PROJ-1 Set the

parameters

PROJ-2 Set the

parameters

0 9 - 3 0

2 0 1 0 - 1 1 - 2 0

Now Date/Hour-Min

s t a n d b y

0 9 - 3 0

Standby Display/Hour-Min

e d k e y

p r o j a a a a a

P1-AAAAA Start button

Password

1sec

0 0 - 3 5

p r o j b b b b b

P2-bbbbb/Remaining 35

points

1 0 - 0 5

p r o j b b b b b

P2-bbbbb/10:05 Start

1sec 1sec 1sec 1sec

System parameters setting flow chart display

PS:Key in password set in

ADPro.

Flashing

Flashing

Project content display

go to P8 page

ENT

ENT

Project content display

go to P8 page

e d i t

m 6 2 n n - t e s t

Select Settings

SD card description message is displayed when loaded the

profile:

no card:No SD CARD

complete:Finished loading

mismatch:Models and settings do not match

f r e e

3 5 7 9 m b

SD card free space

ENT

EXIT ENT

- P8 -

e d i t n a m e

p r o J 1 p a r a

PROJ-1 Set the

parameters PROJ-1 Name

ENT

EXIT

p r o J a a a a a

t o t a l

Project 1 Total number of

instructions

n n

01:first instruction

d01:Header No.

0000:Parameter

address

0000H

0 ! d 0 ! 0 0 0 0

t a G 0 1

Upper limit alarm

2 5 ) 0 0

a L h - 1

Lower limit alarm

Select View instruction point

Flashing

ENT EXIT

Press the arrow keys and then

select View command point name is

entered after ENT command line

view of the selected parameters

Shows the total number of ad

hoc 1 command connection

0 1 0 2 n n

Command line: Name / Station

Number: Address

250.00:If the alarm is

not set alarm value is

displayed none

01: first instruction

AL.H:Alarm limit

100.00:If the alarm is

not set alarm value is

displayed none

01: first instruction

AL.H:Alarm limit

ENT

Project content display(Not able to change parameters here)

2.4.2 System parameters setting display Engineer level

d i s p

c H 0 1 t a G 0 1

1 0 ) 0 0

a L l - 1

0 @ d 0 @ 0 0 0 0

t a G 0 2

Upper limit alarm

n o n e

0 @ a L h

Lower limit alarm

Command line: Name / Station

Number: Address

n o n e

0 @ a L l

n N d n N 0 0 0 0

t a G n N

Upper limit alarm

2 5 ) 0 0

n N a L h

Lower limit alarm

Command line: Name / Station

Number: Address

1 0 ) 0 0

n N a L l

e d i t n a m e

p r o J 2 p a r a

PROJ-2 Set the PROJ-2 Name

ENT

EXIT

p r o J b b b b b

01:first instruction

d01:Header No.

0000:Parameter

address

TAG01:tagname

0 ! d 0 ! 0 0 0 0

t m P 0 1

Upper limit alarm

2 5 ) 0 0

0!aLh

Lower limit alarm

0 1 0 2 n n

Command line: Name / Station

Number: Address

250.00:If the alarm is

not set alarm value is

displayed none

01: first instruction

AL.H:Alarm limit

100.00:If the alarm is

not set alarm value is

displayed none

01: first instruction

AL.H:Alarm limit

1 0 ) 0 0

0!aLl

0 @ d 0 @ 0 0 0 0

f l W 0 2

Upper limit alarm

2 5 ) 0 0

0 @ a L h

Lower limit alarm

Command line: Name / Station

Number: Address

1 0 ) 0 0

0 @ a L l

n N d n N 0 0 0 0

t a G n N

Upper limit alarm

2 5 ) 0 0

n N a L h

Lower limit alarm

Command line: Name / Station

Number: Address

1 0 ) 0 0

nNaLl

c H 0 1 t a G 0 1

c H 0 1 t a G n n

~

t o t a l

Project 2 Total number of

instructions

n n

Select View instruction point

Flashing

ENT EXIT

Press the arrow keys and then select

View command point name is entered

after ENT command line view of the

selected parameters

Shows the total number of ad

hoc 2 command connection nn

ENT

d i s p

c H 0 1 t m P 0 1

c H 0 1 t m P 0 1

c H 0 1 t a G n n

~