Advanced HBC-3130 User manual

HBC-3130/3140/3160

Multi- Stage Battery Chargers

User Manual

Keep this manual in a safe place for quick reference at all times.

This manual contains important safety and operation instructions for correct use of the battery charger. Read through the manual and

pay special attention to the markings and labels of the charger, battery and equipment connected to the battery system.

Pay special attention to these two types of notices used in this manual.

WARNING :

Failure to heed this warning may cause injury to persons and damage to Equipment.

CAUTION :

Failure to observe this warning may result in damage to equipment and improper functioning of the Charger.

WARNING :

●The charger is designed for in-door use. Protect the charger from ingress of water.

●This charger is made to charge only properly sized lead acid batteries.

●Don't recharging non-rechargeable batteries.

●Charging other types of battery or under-sized lead acid batteries may cause fire or explosion.

●Install the charger in accordance with all local codes

●Do not use the charger if it has been dropped or damaged.

●Do not remove casing of the charger, there is no user –serviceable parts inside.

●Do not charge the battery on boats. Remove the battery and charge on shore.

●Never attempt to charge a frozen battery

●Never attempt to charge a damaged battery.

●Wear protective goggles and turn your face away when connecting or disconnecting the battery.

●Never place the charger on top of a battery .

●Never smoke, use an open flame, or create sparks near battery or charger during normal charging operation as batteries may give

out explosive gas.

●Do not charge batteries in an enclosure (box- in) due to possible explosion of entrapped explosive gas.

●Use of accessory not recommended may cause risk of fire, electric shock.

●Disconnect the mains supply before connecting or disconnecting the links to the battery.

●If the charger does not work properly or if it has been damaged ,unplug its AC and DC connection.

CAUTIONS :

●Refer to battery manufacturer’s specific recommended values for battery type settings and float voltage setting.

●Fix the charger to a horizontal solid support via four grooves at the flange of chassis, with four screws or nuts.

●Ensure all ventilation ports are not obstructed for efficient fan cooling, keep loose soft material or paper off at the bottom of the

charger.

●During charging, the battery must be placed in a well ventilated area.

●If longer output charging cord is required, make sure the diameter is adequate for the current in given cable length.

Introduction

Congratulations on purchasing our new Multi-Stage (IU0U) Switching Mode Battery Charger.

This series of advanced chargers use Micro-Processor to control the charging profiles and protective functions.

Innovative charging profiles blend in with the ever changing “ state of charge “ of the batteries to give just the right amount of

current and voltage so your batteries will not be under or over charged . There are 8 sets of selectable charging profiles

specifically designed for a wide range of Wet , Gel , AGM, LiFePO4 and Calcium-Calcium lead acid batteries . There are two

user programmable charging profiles for the professional users through USB port by personal computer. In addition, the

programmed maintenance charge provides a timely Equalization charge for the Wet lead acid battery and refreshing charge to the

sealed batteries.

Almost all the protections are controlled by the Micro-Processor. On start up, the chargers run a series of self tests on the

protective functions, displays and critical components like the cooling fan.

The optional detachable Remote Control Panel provides exceptional monitoring of the batteries, charger output, protection

status, hours of operation and etc.

Intended Use:

All Automotive, Marine, Mobile Home, Electric Scooters, Golf Carts, Solar, Deep Cycle, UPS Standby, Industrial &

Commercial Applications.

A. Control and Indicators

1. Power Switch

To turn ON and OFF AC power to charger

2. Charger status LED display

Charger ON LED (Green) : Lights up when power ON

Bulk LED (Red) : Bulk charging with constant max. current

Absorption LED (Orange) : Absorption charging with preset constant max. voltage

Float LED (Green) : Float charging with preset constant voltage

Over Temp LED (Red) : Lights up when over temperature protection,

Flashing when current de-rating

Fault LED (Red) : Charger malfunction

(overload, output short circuit, reverse polarity, output over voltage protection)

3. Programming Port

Factory use only

4. Battery selection switch

For AGM, GEL, LiFePO4, Calcium-Calcium, 2x user define & WET (Flooded) batteries (default at GEL P-1)

5. Charging current selection switch

Current can be selected from 10% to 100%. Details please see the table on front panel. (Default at 100%)

6. USB port

Connect charger to computer for charger user define setting

7. Remote display Port

Connect to accessory HBR-3100 remote display

To remote display the charging voltage & charging status and remote control the charger output ON/OFF & Equalization.

8. Equalization mode selection switch

Can be selected by Manual or Auto

9. Charging Banks

Terminal blocks to connect to charging cable

10. Ventilation Fan

11. Inlet AC socket with fuse holder

12. Temperature Sensor Socket

Connection to optional accessory temperature sensor

Sensor to increase / decrease charging voltage at low/ high battery temperature

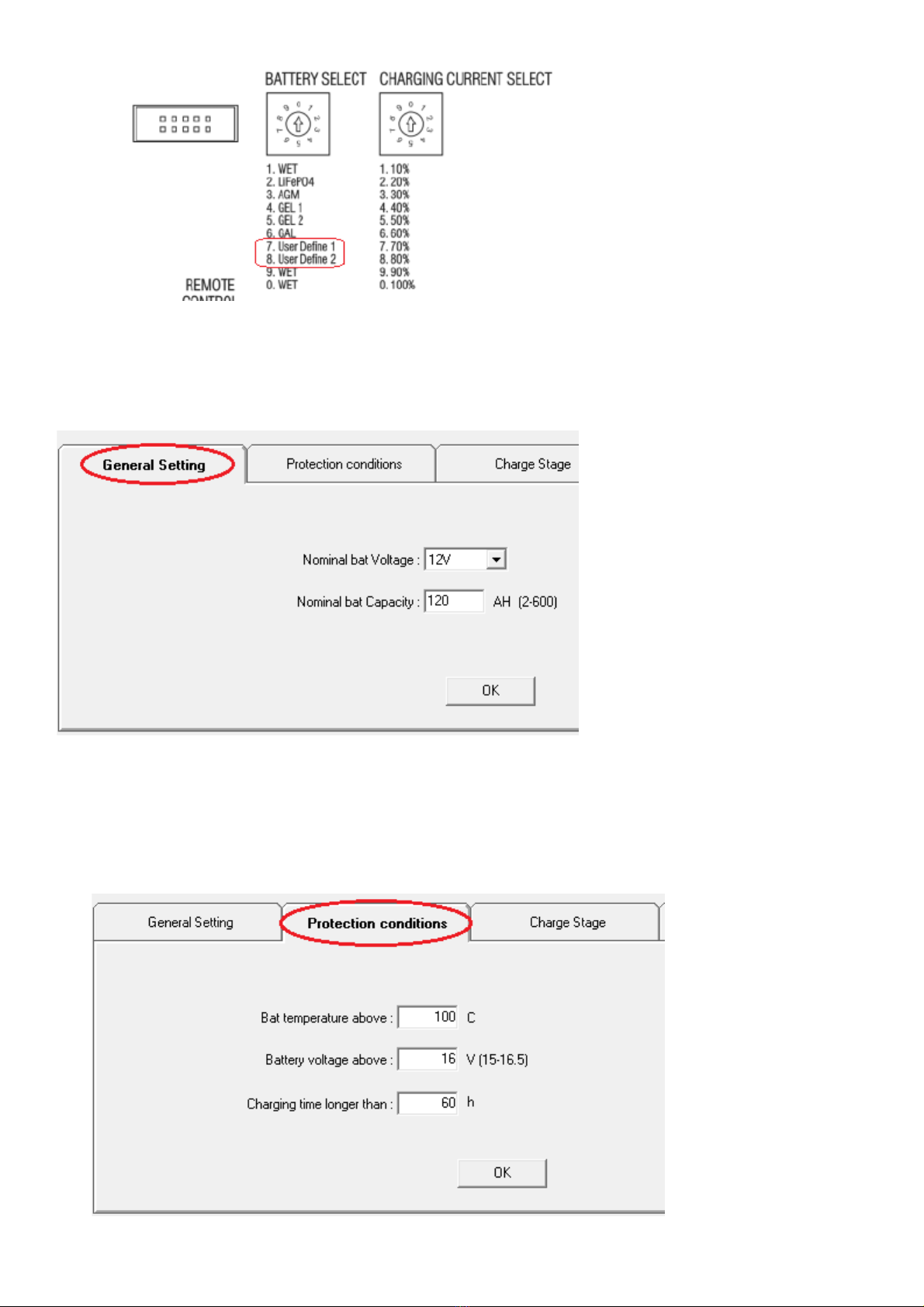

B. Battery Type Selection

Make sure the charger is power OFF, use a small slot type screw driver to select the battery through Battery Selection Switch (4).

AGM/GEL : Sealed type (VRLA) , AGM-GEL , Maintenance Free , Automotive or Deep Cycle lead acid batteries

WET : Flooded Type lead acid batteries (to which water can be added) Automotive or Deep Cycle

Calcium-Calcium : Sealed type (VRLA) Lead Acid batteries with Calcium content Automotive or Deep Cycle

LiFePO4 : Sealed type Lithium Iron Phosphate batteries

User define : User can set their own charging voltage and setting through USB port (6) by personal computer

B1. Recommended Battery Capacity

The following minimum AH capacities are a generalized suggestion, some batteries can take higher charge current, check with

battery manufacturers for charging batteries with smaller capacity.

Charger Model HBC-3130 , 30A HBC-3140 , 40A HBC-3160 , 60A

Battery Capacity 12 AH - 300 AH 15 AH - 400 AH 20 AH - 600 AH

C. Battery Charger Installation and Connection

Observe the warnings & safety precautions before rushing to install and operate the charger.

Check battery condition, fill up cells for wet battery, clean battery poles.

Secure the battery charger in a well ventilated place, make sure the mounting surface is flat and without soft covering material or

loose paper sheet. The air intake is at the bottom and air outlet at the back. Make sure both intake and outlet are not blocked.

Never place charger on top of battery.

Plug in the AC mains and turn on Power Switch. All the indicators on the front panel will lit up, cooling fan spins at full speed

for 10 seconds by means of Self-Testing.

Charger ON LED and the Float LED should be on green indicating Charger is in good order for charging lead acid battery.

Before connecting or disconnecting the charging cable, turn off the Power Switch and unplug AC cord from the mains.

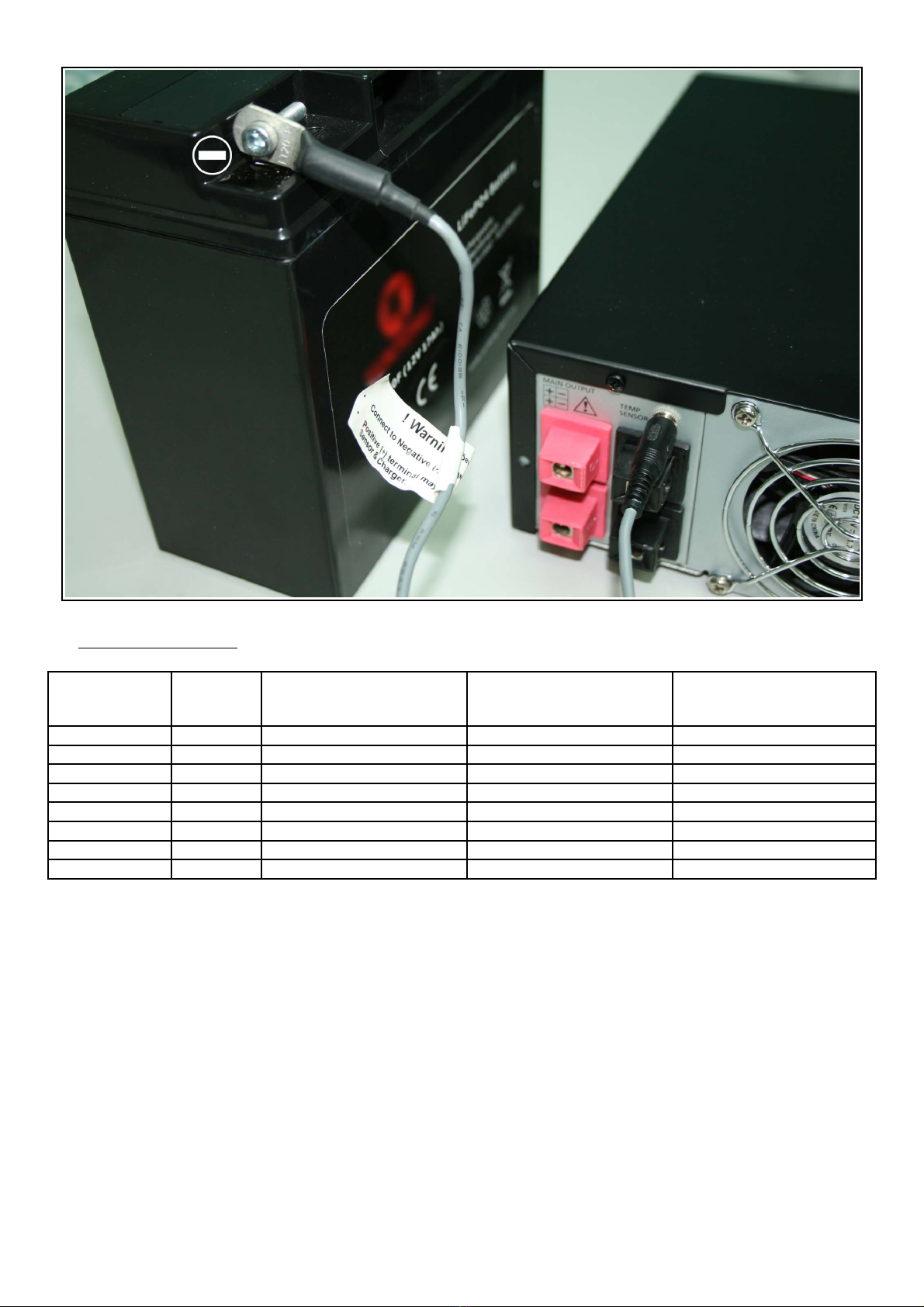

First connect the Red cable to Positive + terminal of charger and the battery Positive + Pole. Then connect the Black cable to the

Negative – terminal and the Negative – Pole of the battery.

Make sure all the connections are secured and well tighten up, double check on the correct polarity.

Double check again for correct selection of Battery Selection Switch (4) for battery type (default at GEL P-1) and Charging

Current Selection Switch (5) for output current setting (default at 100%)

When install in caravans and similar vehicles, the connection to the supply mains is to be in accordance with national wiring

rules.

When charging automotive batteries:

- The battery terminal not connected to the chassis has to be connected first. The other connection is to be made to the chassis,

remote from the battery and fuel line. The battery charger is then to be connected to the supply mains;

- After charging, disconnect the battery charger from the supply mains. Then remove the chassis connection and then the

battery connection.

Please notice the tightness of the power cables from the power supply to the load. If the cables are not fastened well

enough, the total resistance of the connecting cables will increase, resulting in a huge voltage drop between the terminals

to the load.

D. Normal 4-Stage (IUoU) Charging Operation

The 4-stage IUOU charge algorithm ensures fast, complete and at the same time gentle charging of the lead acid battery.

Charging Profile

Stage 1. THE I-PHASE. The constant current charging, Bulk LED is ON.

Normally the battery is charged at constant maximum current until it rises to the selected Absorption voltage level.

The charging voltage changes with the battery voltage.

If the initial battery voltage is less than 10.5V due to deep discharge, the bulk charge current is reduced to half of the maximum

until battery voltage rises over 10.5V.

Stage 2. THE UO-PHASE . The constant voltage charging, Absorption LED is ON.

Battery Type Selection : Gel P-1: 14.1V / Gel P-2: 14.3V/ AGM: 14.3V / LiFePO4: 14.6V/ Wet : 14.4V / Calcium : 15.1V

When the battery voltage rises to the selected Absorption voltage level, the charging switches to Constant voltage charging and

battery is over 85% full. The battery is kept at this high voltage while the current reduces gradually to set value at which the

charger automatically switches to Float Stage.

Stage 3. THE UO-PHASE. The constant voltage charging, Float LED is ON.

In this stage , the battery is full and only takes in the amount of current necessary for maintaining the capacity. The float voltage

is preset by factory according to the type of battery.

In case of the charger keeps at this mode with charging current less than 5A for over 72 hours. The charger will go into the

Standby mode.

Stage 4. THE UO-PHASE. The constant voltage charging, Float LED is ON.

In this stage, The charging voltage at this mode will be 4% less than the Float voltage only for maintaining the capacity.

Remark: If the battery does not reaches the charging voltage in 12 hours, the charger will automatically goes to Float mode. This

is call safety timer.

E. User Define battery setting

There are two user define can be preset by end user, Battery Selection Switch (4) set to position 7 or 8.

Connect the charger to personal computer through USB port (6) then you can set your own charging configuration.

Remark: Optional remote display cannot configure the user define battery.

F. Equalization Charging for wet type battery only

Wet lead acid battery requires periodic high voltage charging (about 10% overcharge absorption voltage) to balance the voltage

of each cell, reverse the high concentration of electrolyte at the bottom and clear up large sulfate crystals on the plates. You can

use the Equalization Selection Switch (8) to perform the manual equalization through optional remote display or Auto

equalization by charger itself.

Once Auto it is selected, the charger will start Equalization automatically if charger keeps at Float mode for over 21 days.

After entered into this mode, the Absorption indicator will flash. This will put the charger keep Equalization for 240 minutes.

The charger will go to Float once completed.

Remark : 1. This mode only can be operated at Flooded battery selected (Battery Selection Switch (4) set to positions 1, 9 or 0)

2. During this mode, operator can press the FUNC button (optional remote display) for 5 seconds to force the

charger to Float mode anytime.

3. Take special precautions as battery will emit explosive gas during equalization charge.

G. Dual bank charging

This feature is for caravans, and vehicles with two separate batteries.

The two batteries must be of same chemical make up and type to avoid over and under charging because only one setting of

charging profile for both.

Two batteries are charged simultaneously and the battery with the lowest level gets most share of the current in the Bulk charge

stage until it is up to the same voltage level of the second battery (battery with higher initial level).

Both batteries will go to the Absorption and the Float Charge at the same time.

H. Power Level adjustment

End user can set the maximum output current so to make the charger can suitable for different capacity battery

Make sure the charger is power OFF before adjust the power level.

Use a small slot type screw driver to select the maximum output current through the Charging Current Selection Switch (5).

1. Position 0: 100% of the rated current

2. Position 9: 90% of the rated current

3. Position 8: 80% of the rated current

4. Position 7: 70% of the rated current

5. Position 6: 60% of the rated current

6. Position 5: 50% of the rated current

7. Position 4: 40% of the rated current

8. Position 3: 30% of the rated current

9. Position 2: 20% of the rated current

0. Position 1: 10% of the rated current

I. Temperature Sensor

Warning :

The temperature sensor must be installed at the Negative Terminal of the battery terminal, wrong connection to the Positive

Terminal will damage the charger and the sensor .

The temperature sensor (accessory) is used to optimal charging over wide ambient temperature range.

Fix the temperature sensor in a position on the battery which is not affected by other cooling or heating source.

Plug in the temperature sensor before switch on the charger to activate the temperature control function, never plug in the charger

during charging.

Compensation voltage for this temperature sensor is 20mV/C, the higher the battery temperature, the lower the charging voltage.

When battery temperature reaches 60°C, the charger will shutdown, Fault and OTP indicator will light up.

J. Cable Size Selection

Wire Size (AWG) Area (mm2) Maximum one-way distance

(feet) for 2% Voltage loss

(30A)

Maximum one-way distance

(feet) for 2% Voltage loss

(40A)

Maximum one-way distance

(feet) for 2% Voltage loss

(60A)

10 5.26 3.8 2.8 1.6

8 8.37 6 4.5 2.5

6 13.3 9.5 7.2 3.6

4 21.2 15 11.2 6.8

2 33.6 24 18 11

1/0 53.5 38 27.5 17.7

2/0 67.4 48 36 22

4/0 107 76 58 34

Table: Selection of cable size and length versus current

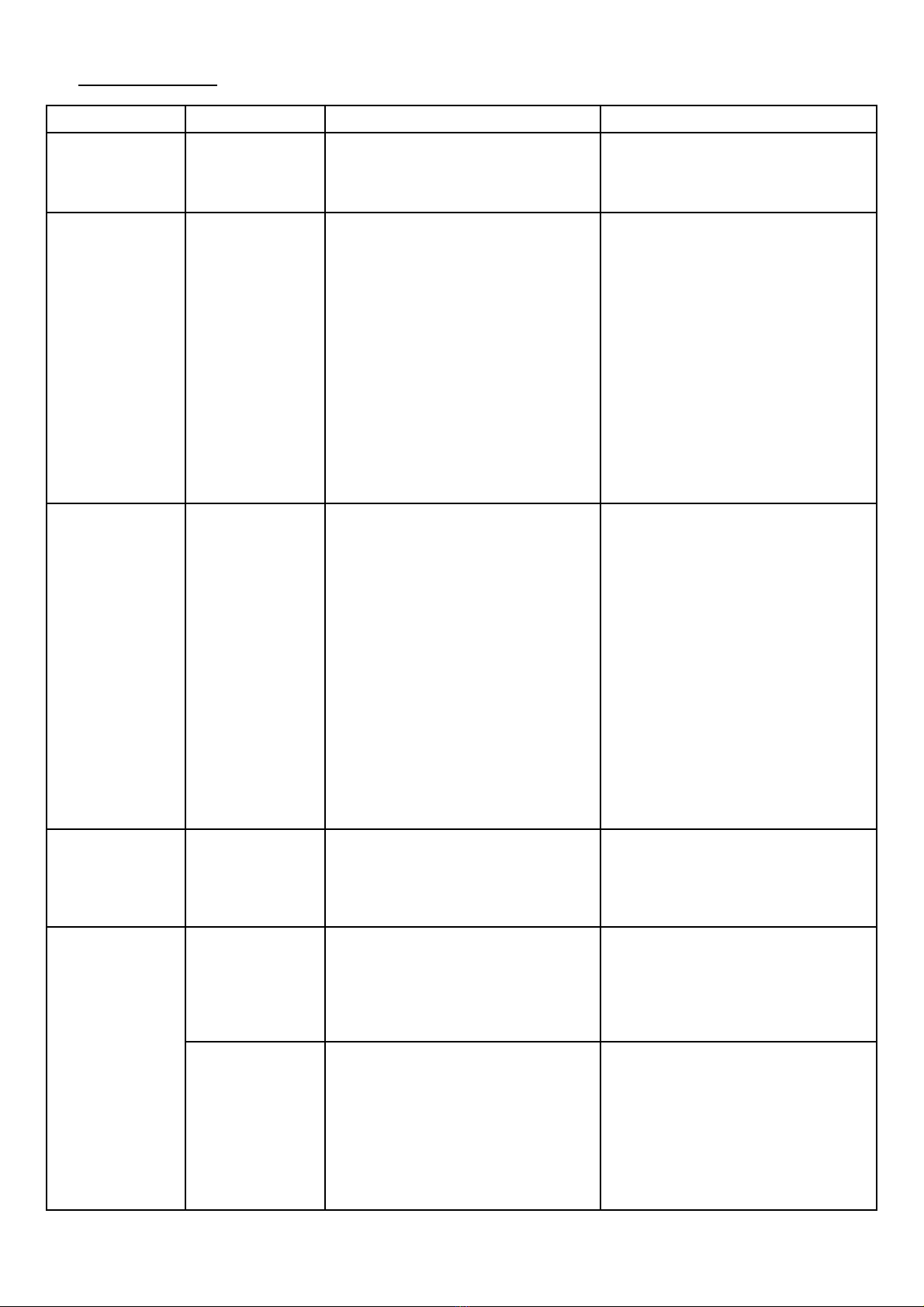

K. Trouble Shooting

PROBLEM INDICATIONS POSSIBLE CAUSES SUGGESTED SOLUTION

Charger does not

work

Indicator lights not

turn on

No AC power

AC input socket fuse blown

Check AC connections are correct

Replace with correct AC fuse by qualified

electrician

No DC output Charger - On LED is

not on, Float and

Fault LEDs are on

Output short circuit

Over temperature protection triggered

Severe over loading charger

Reverse polarity connection

DC fan locked by foreign object or

malfunction

Check DC connections between charger

and battery. Charger can auto reset if

remove the fault within 20 seconds.

Check air intake vent at bottom of charger

is blocked or not. Check charger ambient

ventilation .

Check battery AH capacity within

recommended range

Check for correct polarity, replace car

blade fuse (6)

Check DC fan

Battery does not get

full charge

All indicator LED

work normally and

sequentially

OTP LED flashing

Bad battery connection

Battery type select switch in wrong setting

Battery capacity too large

Ambient temperature too low

Battery has damaged cell or battery is too

old

Wrong set the lower power level

Check for loose contact, right cable size,

cable integrity

Recheck battery type and change to

correct battery selection

Make sure charger rating matches battery

capacity see table (B2)

Move battery to a room temperature

location, or get an optional temperature

sensor

Replace battery

Recheck the current selection switch (5) to

correct right setting

Long charging

time , float light

does not come on

even after 12 hours

charging time.

Absorption light

remains on all the

time

Charger internal fault Return the charger to distributor to repair

Bulk LED is on all

the time

Bulk light remains

on all the time

Wrong battery type selection

Battery is excessively depleted and the

soft charging is triggered

Battery temperature too high

Check charged battery label and change

battery type selection to correct setting

Recharge the battery after a day, if bulk

light remains after several hours, the

battery is most likely damaged and cannot

accept charge. Replace battery.

Use accessory temperature sensor

L. Specifications

Model HBC-3130 HBC-3140 HBC-3160

Output

Output (Charge) Voltage Selections Absorption Float

WET 14.4V 13.5V

LiFePO4 14.6V 13.6V

AGM 14.3V 13.2V

GEL 1 14.1V 13.7V

GEL 2 14.3V 13.8V

CALCIUM 15.1V 13.8V

User Define 1 12V - 16V

User Define 2 12V - 16V

Equalization 15.5V

Maximum Output Charging Current (Continuous) 30A 40A 60A

Recommended Battery Capacity Range 12 – 300AH 15 – 400AH 20 - 600AH

Soft Start Bulk Charge

Battery Voltage to Trigger (cut-in) Soft Start

Bulk Charge Mode

<10.5V

Soft Start Bulk Charge Current (Current Limit) 1/2 of the charging

current

1/2 of the charging

current

1/2 of the charging

current

Ripple and Noise (Peak to Peak) <200mV <200mV <200mV

Efficiency at Maximum Power (230V) >83% >83% >83%

Dual Bank Charging (Battery must be of same type) Yes Yes Yes

Input

AC Voltage Range 200 – 240V 50Hz~

AC Current at Full Load (230V) 2.5A 3.5A 5.0A

Protection

Overload 90-110% Rated Output Current or 50% Rated Output Current (Soft Charge)

Protection Type : Constant Current Limiting, recovers Automatically after

Fault Condition is Removed.

Short Circuit Recovers Automatically if Fault Condition is Removed within 20 seconds

Otherwise the charger will shutdown until re-start the charger again

Reverse Polarity Car Blade Fuse

Over Temperature Protection Type: Shut Down

OVP Output Over Voltage Yes

Cooling Cooling Method Thermostatic, Variable Speed Fan

Indicators

4-Stage Battery Charger Yes

Charge Phase Bulk / Absorption / Float Yes

Fault Mode

Over Temp

Yes

Yes

Charger ON Yes

Fuses

AC Fuses at IEC AC Power Socket T3.15A T4A F8A

DC Car Blade Fuse at Front Panel 25Ax2 30Ax2 30Ax3

Accessories

Remote Temperature Sensor, Cable & Spare Fuses Yes

Remote Control Panel Optional

Approvals

Safety : EN 60335 Yes

EMC: EN 55014; EMF: EN50366 Yes

Others Dimensions and Weight 200x80x260mm ; 3.2kg 200x80x260mm ; 3.2kg 200x80x320mm ; 4.2kg

Remarks All values are based on the standard ambient temperature 25°C and pressure 0.1Mpa.

M. Optional Remote Display HBR-3100

I. Introduction

When the optional remote HBR-3100 is installed, it will display the current status of the charger along with the voltage & amperage

and can remote control the charger to Equalization mode.

It can be mounted on HBC charger by replacing the dummy cover on the front panel or individual mount with 10m extension cable

and coupler (HBR-3100 accessories).

II. Connection

1. 10 Meters Phone Cable

2. In Line Coupler 6P6C

3. HBR-3100 Remote Display Module

III. Control and Indicator

1. Output ON/OFF : To switch the charger output ON and OFF. Green LED is illuminated when output is ON.

2. Alarm : Can be silenced or audible by toggling this button, default is audible.

Red LED will illuminate when fault occurred

3. Func. : To toggle charger setting Menu and select scrolling to make display continue to scroll all setting

(See optional remote programming section)

4. Set : To confirm the chosen feature you selected.

IV. Programming using the optional remote

A. Pressing Func. Button to display “Scrolling” or until any setting you want to display

B. Pressing Set button to confirm

Remote Panel “Scrolling” Menu Options

1. Charger Name Display charger model

2. Charger Status Display Bulk / Absorption / Float

3. Battery Type Display the battery type selected

4. Fault Display the “No Fault Found” or allow scrolling through fault

5. Bat. Bank 1 Display the charging voltage and current of Bank 1

6. Bat. Bank 2 Display the charging voltage and current of Bank 2

7. Bat. Bank 3 Display N.A as no Bank 3 for this series of charger

8. Total Run Time Display units total run time

9. Output Power Level Display current output level

10. Software Version Displays the current control software version

Remote Short cut

1. Press and hold the SET button for 5 seconds and release the button to enter Equalization mode.

(Equalization selection slide switch on main unit should be selected at manual position)

2. Press and hold the Func button for 5 seconds and release the button to force the charger to Float mode.

V. Fault Indication

1. Charger High Temp : Charger over temperature

2. Bat Over Temp : Battery temperature over 60°C as detected by remote sensor

3. Output V High : Output over voltage

4. Overload : Overload (OCP)

5. Output Shorted : Output short circuit

6. Wrong Polarity : Output reverse polarity

7. Fan Fault : Fan stuck or not working

REV.0 2011/02

7673-3130-0000

HBC SOFTWARE INSTALLATION

Introduction

There are two software in the CD , one is the USB Driver for the USB socket , the other one is the

Charge Program for the self–defined charging profile of the charger.

First install the USB Driver into the PC so that your PC can communicate with the charger.

After installation of the USB driver then install the Charge Program software to your PC.

Compatible Operating Systems:

This software is compatible with 32 bit computer and operating systems of Win Vista ,XP and Win

7.

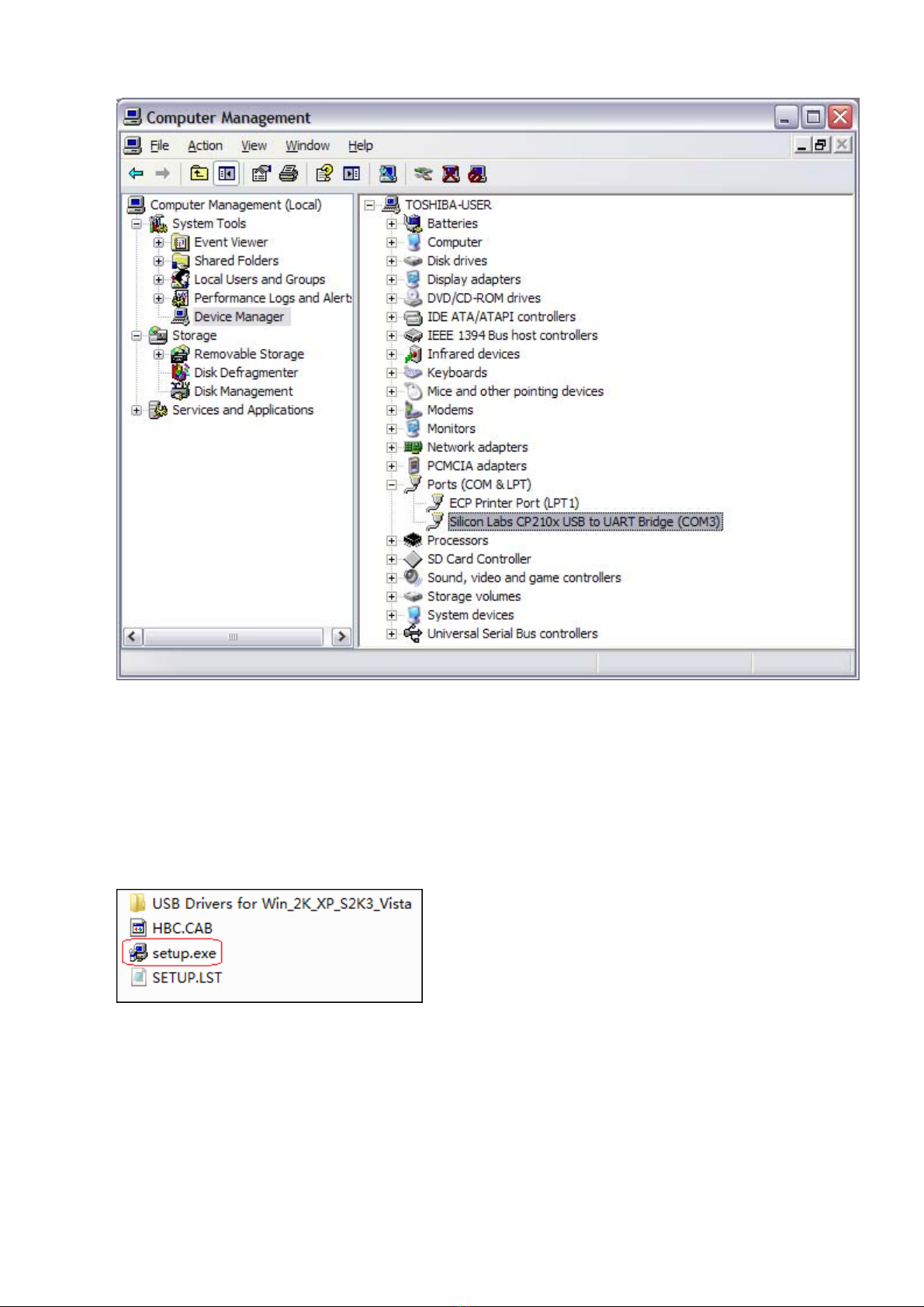

Installing the USB Driver

1.1、(CD)\USB Drivers for Win_2K_XP_S2K3_Vista\CP210xVCPInstaller.exe

1.2、Click [Install] to get to

1.3、After installation of USB Driver , connect the HBC Charger to PC via USB

cable.

1.4、Go to the Computer Management window and click on the Device Manager

At the Ports(COM & LPT1) , you should find” Silicon Labs CP210 x USB to UART Bridge

(COM ) “.

An available Com port number will appear on the Computer Management Window.

In this example it is COM3 is available and has been selected。

This confirms the USB Driver has been successfully installed.

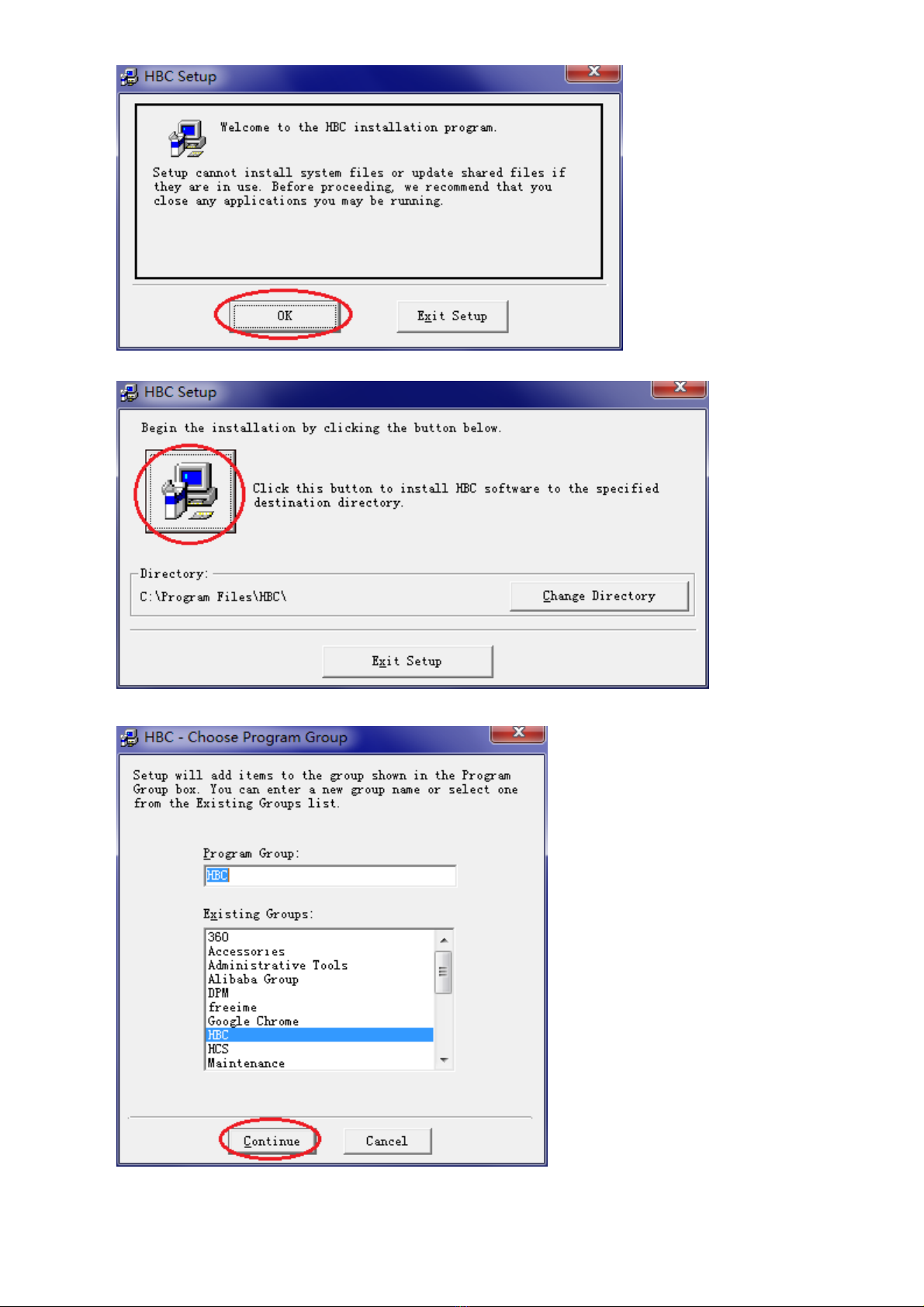

2、Installing the HBC Charge Program

2.1 Double click on (CD)\setup.exe

2.2 Follow the steps as shown in the following windows , it may take a few minutes to install this software .

2.3 You will find the HBC Charge Program/ Icon in your computer .

3、Using the Charging Program

3.1、Connect a USB cable to the PC and charger which is not connected to battery .

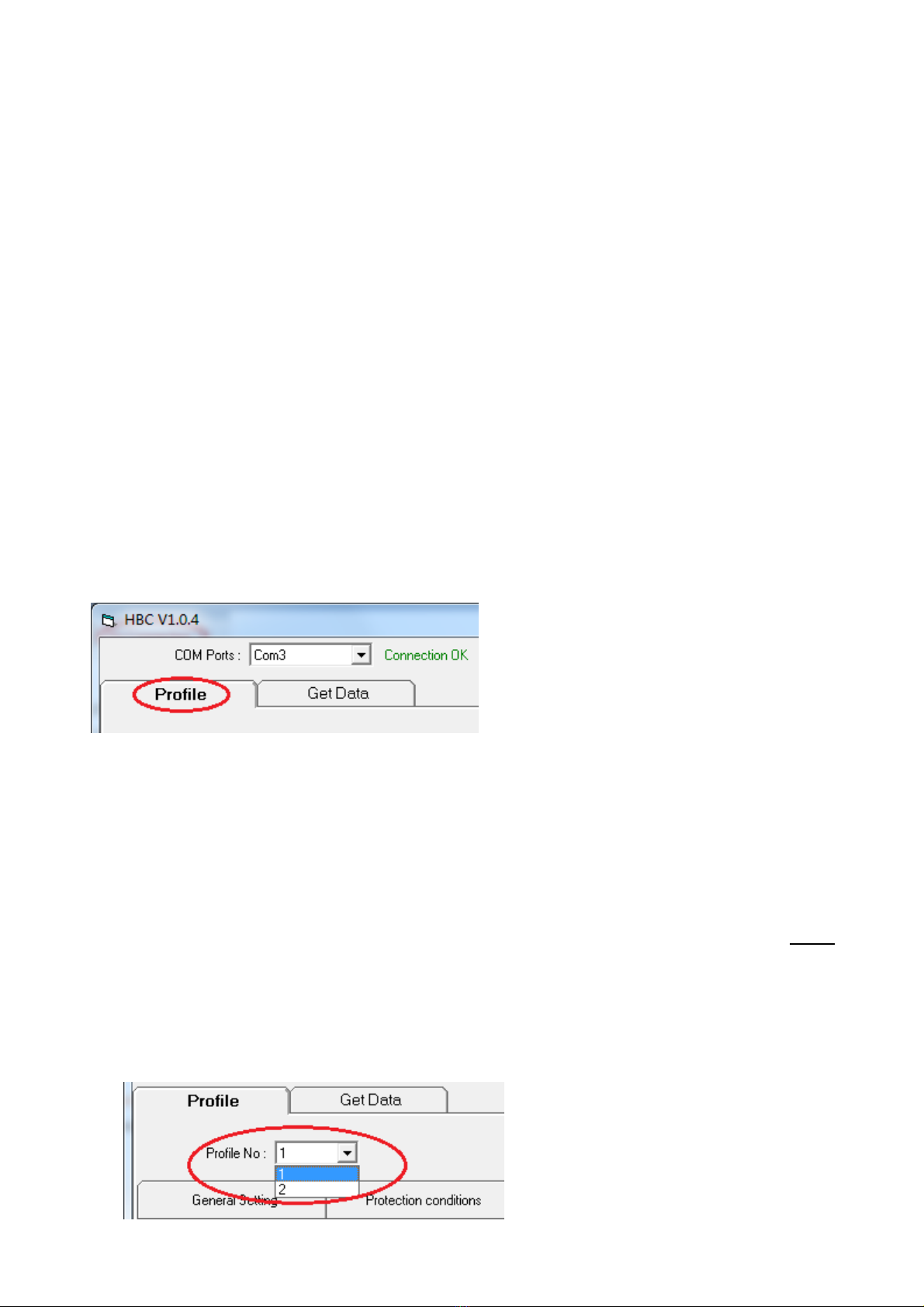

Switch on the charger and run the HBC Charge Program .

3.2 Select a COM Port number that matches the USB com port number .

3.3 You can find your USB Com number from your device manager as shown in

window at section1.4

In this example is Com 3 for the USB Com Port and also Com 3 for the Charger Program .

3.4 Now your PC can communicate with the Charger via the USB using the HBC Charge Program

software.

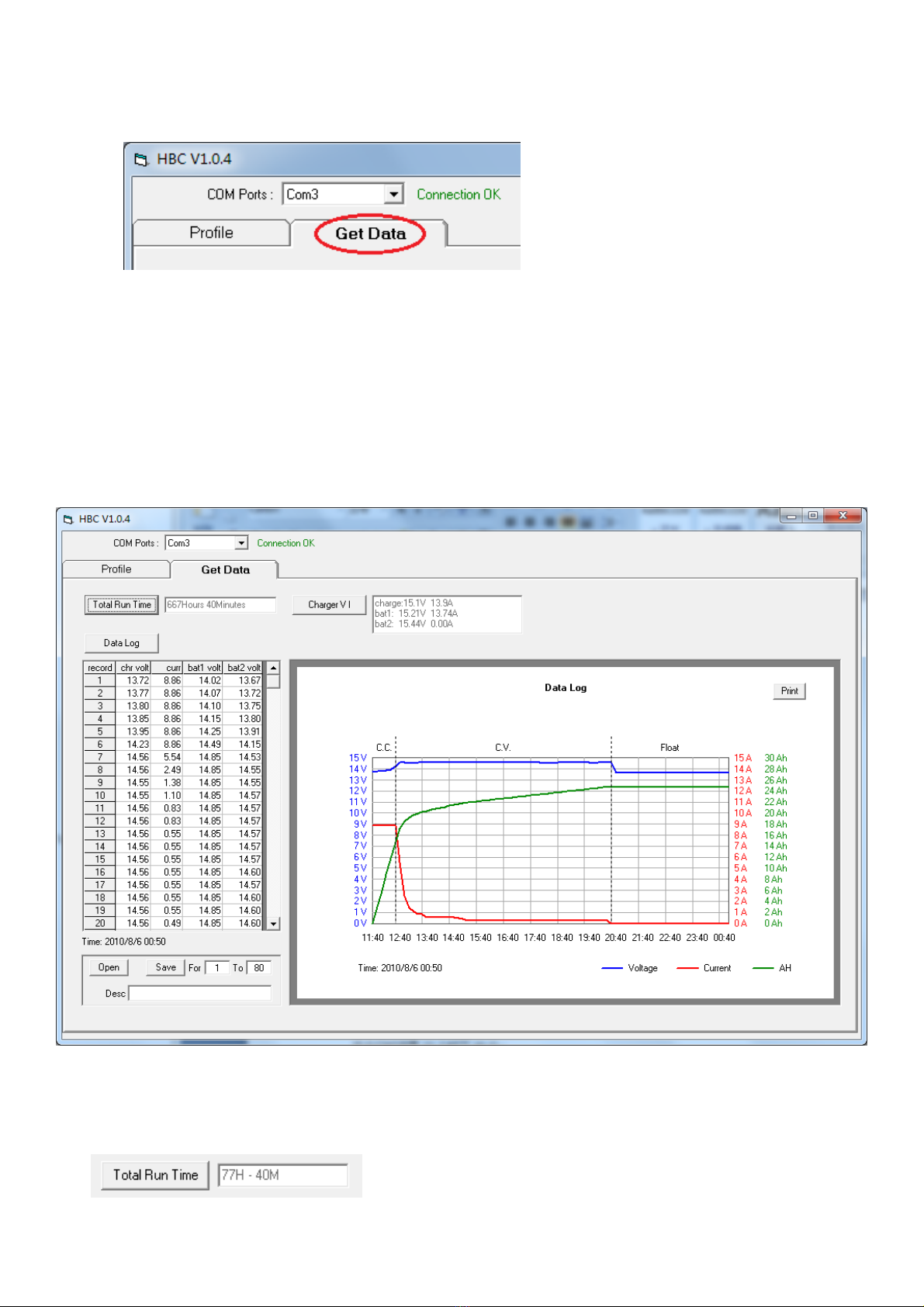

3.5 The following windows show the sequence of a successful communication connection.

a) If the configuration is successful “connection OK “ will appear .

b) If configuration fails , “No Connection “ will appear.

3.6 Trouble shooting for No Connection

A. Check USB cable connections are secured at both ends.

B. Check Charger has been switched on .

C. Make both Com port numbers (one from USB port and one at the Charging Program are the same.

3.6 Overview of the HBC Charge Program

There are two main functions of this program , the “ Profile” allows user to adjust the charging profile such

as charging stages , protection threshold values , conditions to move from one stage to next stage or to jump

from one stage to any stage designated. There are as many as 7 charging stages available , and threthold

values of voltage , current , temperature and time that can be set for moving among set stages.

The “Get Data” allows user to download : accumulative run time of the charger since the first operation , the

Output (charging ) voltage and current values at 10 minute intervals , the voltage at each of the two battery

terminals are also recorded. Each set of the above 10 minute interval data can be retrived to your computer .

User can use our program to plot the charging graph or otherwise .

3.7.1 Profile : setting of user defined charging profiles

There are two self defined charging profiles : Profile 1 is set by position 7 and Profile 2 set by

position 8 at your charger panel . See user manual CONTROL & INDICATORS ,switch4.

User defined Profile 1 corresponds to Position 7 at your charger BATTERY SELECT SWITCH

USER defined Profile 2 corresponds to Position 8 at your charger BATTERY SELECT

SWITCH

PRECAUTION

Before proceed to set the profiles , make sure the Switch 4 is not in

position 7 or 8.

3.7.2 Profile – General setting

Nominal bat Voltage : select 12V or 24 V battery 。

Nominal bat Capacity: Key in the battery bank AH .

Click OK to confirm & save settings.

3.7.3 Profile - Protection conditions setting

Bat temperature above : Charger will shut down output when temperature detected by remote sensor is

about the set value.

Battery voltage above : Charger will shut down output if battery voltage is over this set voltage.

Charging time longer than : Charger shuts down output if the total charging time in bulk and absorption

stages is longer than this set limit in hour。

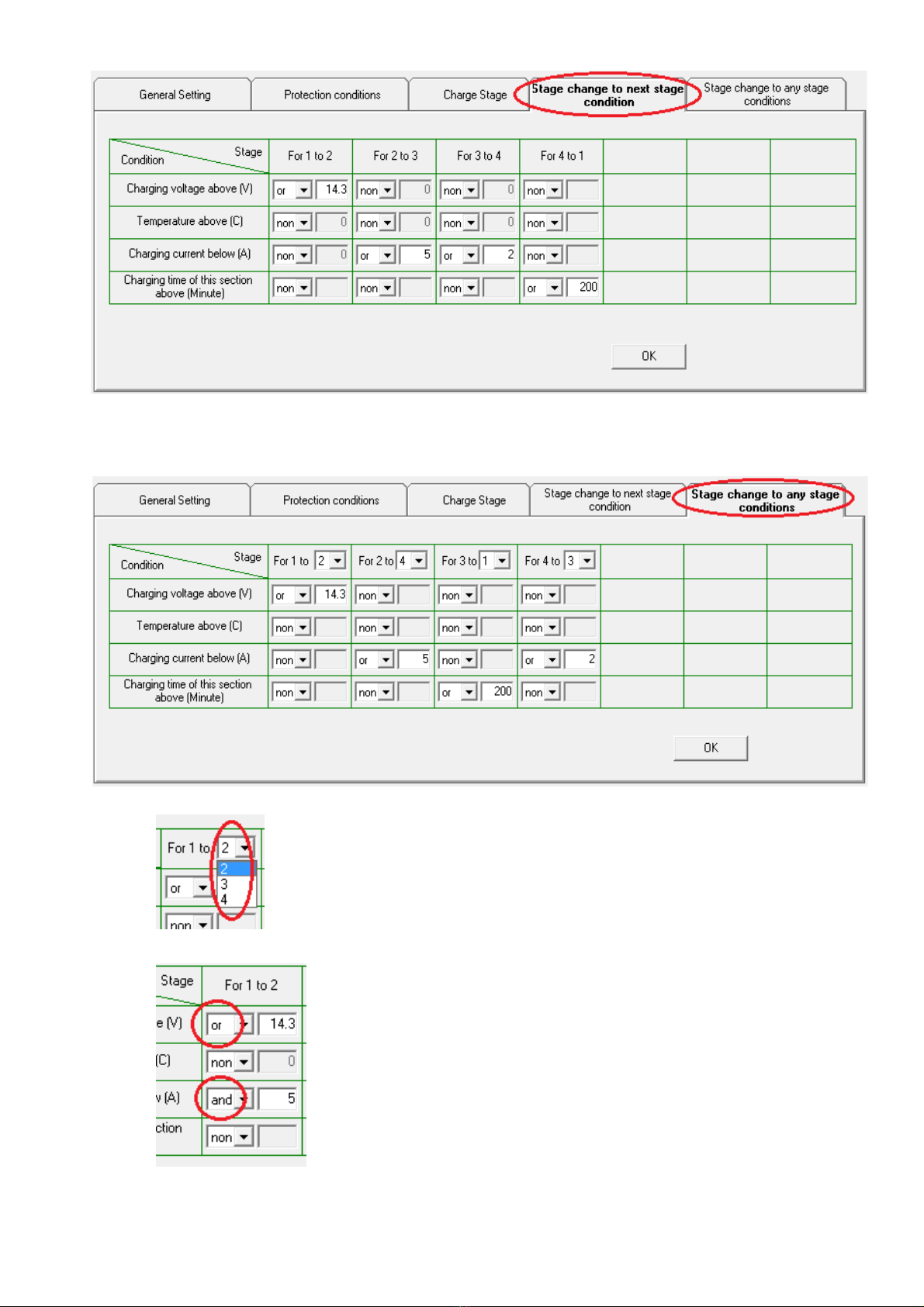

3.7.4 Profile- Charge Stage setting

There are 1 to 7 charging stage that can be used , each has its own charging

voltage and current limit.

3.7.5 Profile- Charge Stage change to next stage condition :

These are the available threshold parameters that cause shift of charging stage to the next one, it is not

necessary to use all the parameters. The inter-action among the parameters is controlled by the following

logic :

None means skip this condition

And means must get to this condition to move to the next stage

Or means any one the selected conditions will move to the next stage

Note: It is not permissible to have “And “ with “Or” in the stage

Always press “OK” key to store set conditions.

3.7.6 Profile - Conditions for Jumping from one Stage to any other Stage

Non-sequential change of stage selection and condition windows

3.8 Get Data

This “ Get Data” program is a separate program that retrieves data stored in the IC of

charger .

Once the charger is switched on , data of charging voltage , charging current , voltage at each

of the battery terminals are recorded down at 10 minute interval . When the data bank is full

new data will push the oldest out .Each set of data is marked with a number , new set of data

has the highest number..

3.8.1 Get Data- Total Run Time

This drop window gives the accumulative run time of charger , as soon as the charger is switched on, the

clock starts counting and even no battery is connected .

The total Run Time here is 77hours and 40 minutes from the first time charger has been switched

on.

This manual suits for next models

2

Table of contents