AEROCOMPACT S5 User manual

Install. AE S 2.1 US V0.0 2017-01

INSTALLATION MANUAL

AEROCOMPACT S

5°/10°/15°

2

3

INTRODUCTION

Thank you for choosing the Aerocompact mounting system.

Please read these instructions carefully before starting the installation and make sure that you

can meet the required guidelines in this installation manual.

An important part of this installation manual is the additional

designed project report with the structural analysis based on

the project location. Please make sure that the position of the

modules on the roof and the ballast distribution is installed as

required in project report. In case the module layout changes

do to circumstances like obstructions, the ballast calculation

needs to be modified with the Aerotool software. It is required

to design the static calculation of the system with the Aero Tool

Software program (Solar.Pro.Tool).

The technical documentation is part of the product. The com-

pany AEROCOMPACT is not liable for damages occurring from

non-compliance with the installation instructions, particularly the

safety instructions, as well as from misuse of the products. In

addition to this installation manual the current general condi-

tions as well as warranty conditions apply. The current versions

are available at www.aerocompact.com

Faults and damage as well as limited or lacking operability of the

system as a result of assembly that is faulty and/or deviating

from the installation instructions and/or the project report

(Solar.Pro.Tool) preclude a material defect is not the responsibil-

ity of Aerocompact. With unprofessional installation, all rights of

the purchaser shall expire. The required compressive strength of

the roof insulation and the maximum static roof load needs to be

checked before starting the installation.

Photovoltaic flat roof systems are not maintenance free. Main-

tenance, particular the right position of the ballast blocks and

the building protection pads should be conducted annually. For

exceptional high-wind events, we recommend to do a Mainte-

nance and system check right after the storm event.

Faults and damage as well as limited or lacking operability of the

system as a result of assembly that is faulty and/or deviating

from the installation instructions and/or the project report (So-

lar.Pro.Tool) preclude a material defect is not the responsibility

of Aerocompact. With unprofessional installation, all rights of the

purchaser shall expire.

The system warranty shall be effective only if all system compo-

nents were purchased from Aerocompact.

In case of doubt, please contact the Team of Aerocompact

or call 0800 578 0474

This racking system may be used to ground and/or mount a PV

module complying with UL 1703 only when specific module has

been evaluated for grounding and/or mounting in compliance

with the included instructions. In order to meet this requirement,

installers are supposed ro first seek approval, e.g. through gen-

eral installation instructions or specific application documents,

from module manufacturers, in particular for attaching the mod-

ule clamps along the shorter side of the module frame, and for

grounding/bonding the module frame by clamp-integrated pins.

Aerocompact offers assistance to achieve such approval.

A list of PV modules with proven compliance in terms of UL 1703

is being built up by and can be obtained from Aerocompact upon

request.

The material of the building protection mat that is included in the

scope of delivery avoids accelerated ageing (e.g. through leaking

of plasticizers) of roof membranes, and it usually provides suffi-

cient friction between racking and roofing. Due to the variety of

different sealing types previously and currently customary on the

market, materials compatibility as well the friction coefficient for

ballast calculations must be checked / verified by the assembly

company / buyer for any individual installation. If the measured

friction coefficient (lowest value out of several tests under dry

and wet conditions) is below the value assumed for ballast calcu-

lations (default is 0.7), the system design must be recalculated

and modified accordingly in order to ensure system stability.

If the Roof-Gravel is located right on the water-bearing roof the

Aerocompact System can not be installed on the gravel layer.

The gravel must be removed in this case in the area of the Alumi-

num Brackets.

4

smart mounting solutions

YOUR BIG ADVANTAGE

>25 years product warranty

>Wind tunnel tested

>new protection pads for long service life and enhanced friction

>TUV certified, conforms to UL 2703

>Patent pending

>ballast-only as a standard, roof penetrations optional

>Optimum module ventilation

>Complimentary ballast calculation incl. roof layout

>Made in Europe

>Minimum Order only 2 KWp

>Module Clamps with grounding pins

>TUV certified, conforms to IEC 61215

>Class A fire rated acc. to ANSI/UL 1703 when equipped with

side deflectors (tested with the S5 racking type, to be con-

firmed for S10, S15, and + systems).

>Best price value available

>The fastest installation in the industry 1 kWp 5 min., 2 men

>Statically optimized system

>Less material = Less shipping costs

>Optimized wind suction, therefore less ballasting

than other systems

>Optimum water drainage

>Suitable for roof edge zones

5

New System Update 2.1

NEW module-clamp

incl. grounding-pins, TUV certified to UL2703

NEW cable management solution

NEW fleece building protection mat

certified and long-term tested

6

Technical Details

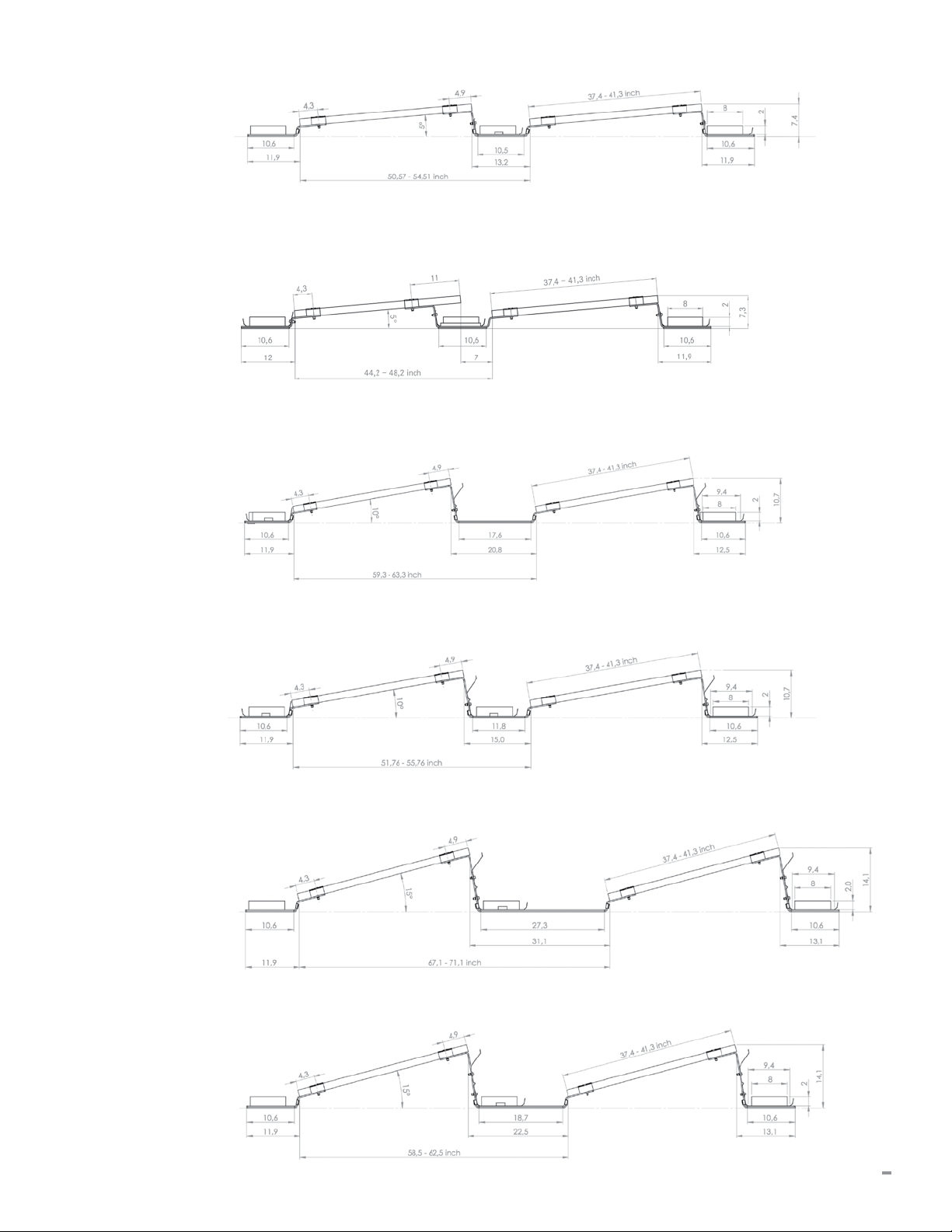

Mounting Tilt: AEROCOMPACT S: 5°, 10°, 15°

Inter-Row Spacing: AEROCOMPACT S 5 (25°): 13.2 inch (335 mm)

AEROCOMPACT S 5 (30°): 7 inch (178 mm)

AEROCOMPACT S 10 (25°): 15 inch (380 mm)

AEROCOMPACT S 15 (25°): 22.5 inch (571 mm)

Min. Array Size: AEROCOMPACT S: 2 rows with 3 modules / 3 rows with 2 modules

Roof Edge Zone: Roof areas F and G can be used

Module Dimensions: 37.4–41.3 inch x 61.1–81.9 inch (width – length)

(standard; other dimensions upon request)

Max. Roof Slope: 5 Degree (standard; steeper roofs upon request)

Roof Height: up to 60 ft (standard; higher buildings upon request)

Windload: up to 50 psf (2,400 Pa) uplift (design load)

Snowload: AEROCOMPACT (standard) up to 50 psf (2,400 Pa) downforce (design load)

AEROCOMPACT “Alpine” up to 92 psf (4,400 Pa) downforce (design load)

Module approval: Please request approved module list from the module

manufacturer or Aerocompact

Materials: Supporting materials made of aluminum EN AW 6060 T64,

module-clamps aluminum EN AW 6063 T66,

stainless steel screws, wind-deflector galvanized steel

Shipping: approx. 40 kW per pallet, 700 kW per truckload

System Requirement: Proof of static load capacity of the roof and the

insulation needs to be provided by customer.

General terms / warranty conditions and usage agreement apply.

7

S5 18° Sun-angle

S5 30° Sun-angle

S10 18° Sun-angle

S15 18° Sun-angle

S10 25° Sun-angle

S15 25° Sun-angle

8

INTRODUCTION

We recommend you read the following information

carefully because it is very important in dealing with the

product.

The installation system AEROCOMPACT S is a robust racking

system for mounting PV modules on flat roofs. It consists of

prefabricated aluminum retaining brackets with glued on building

protection pads, deflector plates and all required small parts

that assure a safe installation. This installation system allows

installation on flat roofs with large surfaces and without roof

penetration. This innovative system uses the frame structure and

aerodynamic effects to ensure stability.

AEROCOMPACT S is designed for systems facing south with an

inclination of 5°, 10° and 15°. It can be used for most framed

PV modules of leading manufacturers with following dimension:

AEROCOMPACT S module width x module length

37.4 – 41.3'' x 61.1 – 81.9''

The AEROCOMPACT S5, S10, S15 standard version is designed

for maximum design loads of 50 psf, downforce and uplift. The

AEROCOMPACT Alpine Version is designed for maximum design

loads of 92 psf downforce (uplift unchanged). All Values are

Design-loads as a load combination of dead weight, wind and

snow. Therefore, check the snow load zone of your location

beforehand. The System is wind-tunnel tested, CE certified and

conforms to UL 2703.

Can be used for the following flat-roof coverings:

Foil roof, bitumen roof, Gravel roof, Green roof.

Note: We recommend to remove the gravel and green in the area

where the bracket touches the roof surface.

AEROCOMPACT offers the AeroTool software to design the

mounting system including ballast weights. The programme

creates a project report with the statistically calculation, ballast

weights and system material list.

If you have any other questions, make use of AEROCOMPACT’s

professional and comprehensive consulting service. Our engi-

neers will be happy to help.

PLEASE MAINTAIN THE FOLLOWING TORQUES WHEN

INSTALLING SCREWS:

133 lbf in

M8 Screw (fixation of module clamps,

wind sheets, ballast trays, and accessories)

REQUIRED TOOLS

Cordless screwdriver spacer bracket (S5 30° only)

Torque wrench

9

SAFETY INFORMATION

It is important that you install person-independent

fall arrest systems or reception system according

to Norm in your Country prior to the start of work!

Occupational Safety Regulation for Construction

Workers and country specific regulations must be

followed!

If person-independent fall arrest systems or re-

ception systems are not available for work-related

reasons then safety harnesses must be used!

Use only safety harnesses (harnesses and catch-

ing belts, connecting ropes/belts, fall absorber,

rope cutter) marked and tested by authorized

testing laboratories.

If person-independent fall arrest systems or recep-

tion systems are not available and safety harness-

es are not used, it can result in falls from great

heights and therefore to severe or deadly injuries!

Leaning ladders can cause dangerous falls, if the

ladder caves in, slips, or falls over!

Work in close proximity of live, electrical overhead

power lines, with which you can come in contact,

only if

- power is turned off and that condition is guaran-

teed for the time of the work

- the parts under power are protected through

covers or barriers.

- the safety distances are not too short.

Radius of voltage:

1 m in 1,000 Volt of voltage

3 m in 1,000 to 11,000 Volts of voltage

4 m in 11,000 to 22,000 Volts of voltage

5 m in 22,000 to 38,000 Volts of voltage

> 5 m if the voltage is unknown

The manufacturer hereby agrees to take back for

recycling all products that are marked with the

eco-label as well as all materials used herein.

Only the approved heat transfer medium may be

used!

If at all possible, the safety harness must be

fastened above the user. Fasten safety harnesses

only on building elements or fastening points that

can carry the load!

Do not use defective ladders, e.g. cracked steps

and rails of wooden ladders, bent and kinked

metal ladders. Do not fix partially broken steps,

rails and braces!

Safely place a leaning ladder. Make sure the

installation angle is correct (68° - 75°). Secure

leaning ladders against sliding, falling, slipping and

sinking e.g. by using enlarged bases, feet braces

of ladders that are adapted to the ground, fasten-

ing devices.

Lean ladders only against secure support points.

Secure ladders in traffic areas with barriers.

Touching live electrical overhead lines can result

in death.

Wear safety goggles when drilling!

Wear safety shoes for the installation!

Wear cut-proof work gloves when installing the

collectors!

Wear a helmet during installation!

10

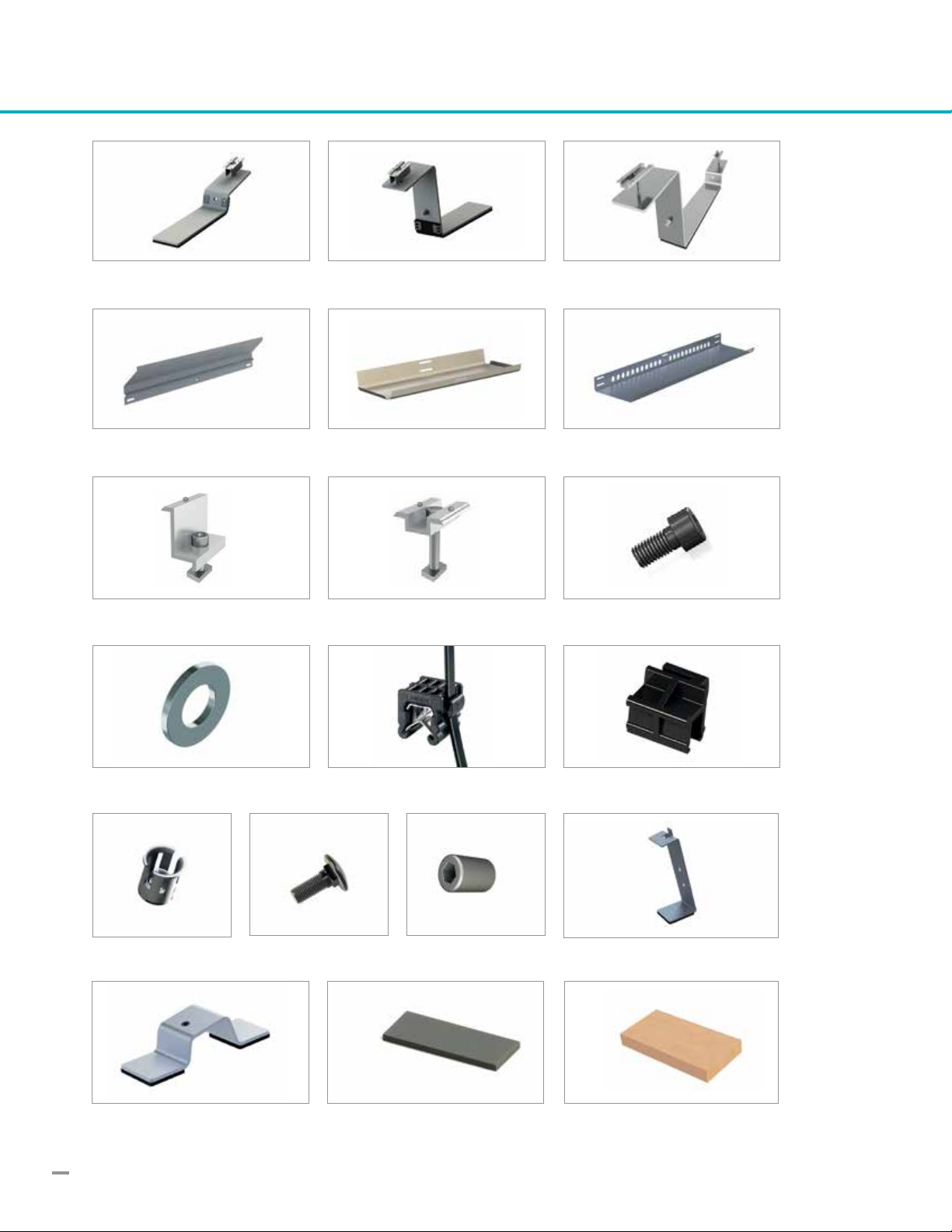

SCOPE OF DELIVERY

Windsheet

Front Bracket

Washer

Ballast Tray

End Bracket

Cable-Tie incl. Clips function

Ballast Tray Long

Connector

Clips for Windsheet

End Clamp

Revet Nut M8 Alpine back Bracket

Middle Clamp Socket Screw M8x30

Flathead Screw

Alpine front Bracket Ballast Block (not included in delivery)

Allenhead Nut

Protection Pad

11

SYSTEM OVERVIEW

Aerocompact

ENDBRACKET

Aerocompact

FRONTBRACKET

Snowload > 2,4 kN

FRONT SUPPORT BRACKET

Snowload > 2,4 kN

BACK SUPPORT BRACKET

Ballast Tray

Aerocompact

CONNECTOR

Ballast Tray

END OR MID CLAMP

PV Module

WINDSHEET

PROTECTION PAD

Rivet NUT M8

Rivet Nut M8

M8 Screw

Ballast Block

16 x 8 x 2 inch

Aerocompact

FRONT SUPPORT BRACKET

END CLAMP

Aerocompact

BACK SUPPORT BRACKET

Screw M8 for Windsheet

suitable for Ballast Tray

and grounding

optional (high snow load) optional (high snow load)

12

INSTALLATION MANUAL

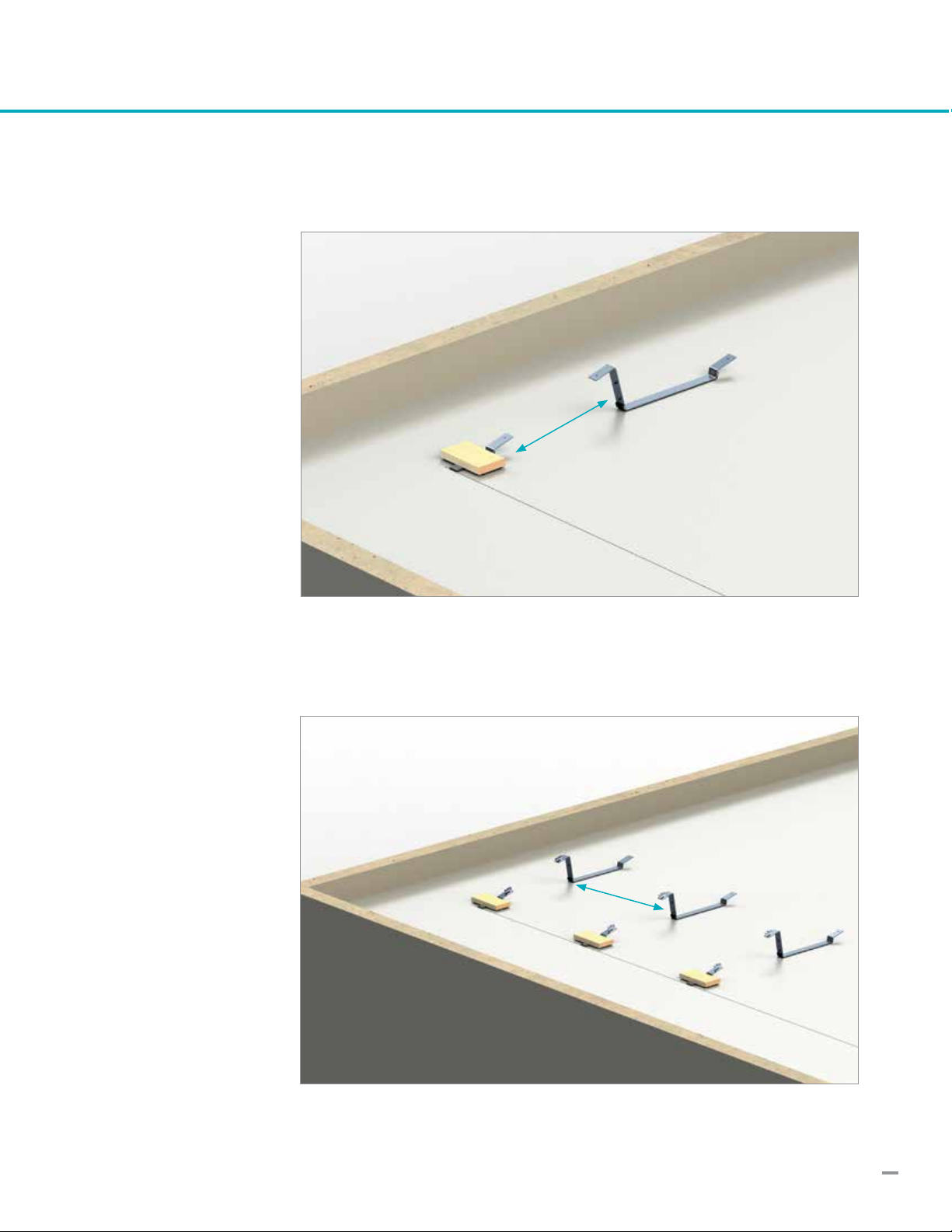

1. Attach the end and middle clamps to the Aerocompact Brackets.

2. Measure the starting point

3. Use chalk line marking

4. Place Front Bracket

5. Attach protection pads to ballast block (Aerocompact

recommends glueing, see p. 22)

6. Secure front bracket with ballast block

13

7. Place the Connector vertically with spacing (module width). The

exact distance is adjusted during module assembly.

Module width

Module length

8. Place the Connector with spacing (module length) in horizontal

position. The exact distance is adjusted during module assembly.

14

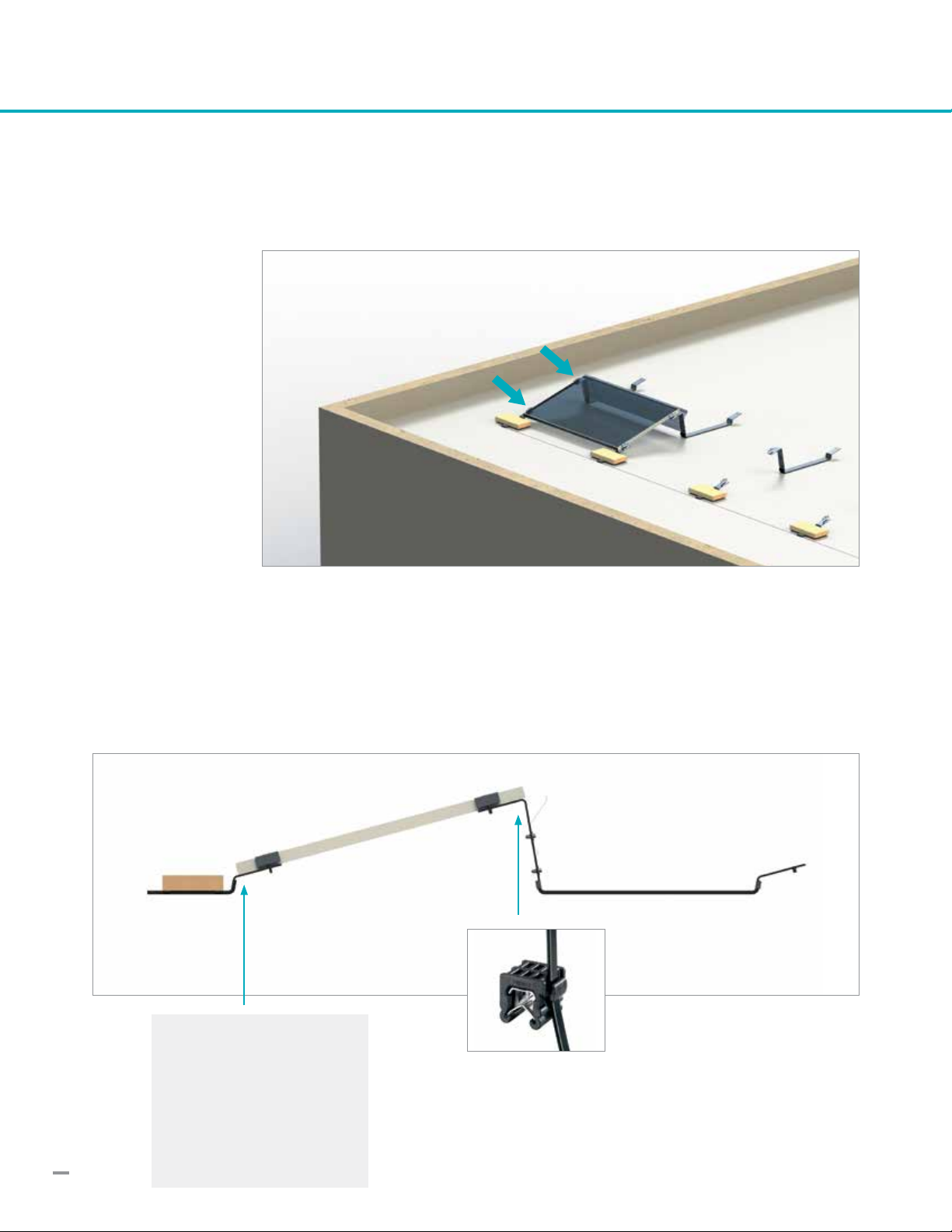

9. Mount the module in landscape orientation on the mounting brack-

ets and align flush above the back of the AEROCOMPACT connec-

tor or end bracket. (NOTE: does not apply to S5/30° system,

see p. 22 for use of the spacer bracket)

Tighten the Clamps

10. Subsequently, the end or middle clamps of the previous module can

be tightened and another module placed. At the end of the array end

clamps are attached and tightened after alignment of the last mod-

ule. The clamps must be tightened with 133 lbf in torque value.

11. Clips the cable tie on the module frame for easier

cable management

NOTE

For easy alignment place

the modules on the lower

end on the marking notch.

1515

INSTALLATION of Alpine Version

1. Place the front support bracket (after pre-assembling an end clamp on top) on the lower module end

centered in the middle and tighten.

2. Place back support bracket under

the upper module edge.

Later, after installation of the wind sheet

and ballast tray (if present), insert 2 cage

nuts through ballast tray (if present)

and wind sheet into the bracket.

3. Fix ballast tray (if present) and wind sheet to the support bracket with allen-head screws and washers (torque 133 lbf in).

For snow load of more than 50 psf (design load) additional support brackets must be

installed on the lower and upper end centered of the module.

16

12 . Installation of the Windsheet

The Windsheet is mounted overlapping on the connectors and end brackets, using

allen-head M8x30 screws with washers. These screws are tightened after the

module installation of each row with 133 lbf in.

The windsheet of the S5 systems has a symmetrical cross section, and thus no “wing tip”.

Install it in a way that the slotted holes are close to the upper edge and the rounded holes are

close to the lower edge.

Standard module lengths are covered by two different lengths of wind sheets and ballast trays.

Type Module length

wind sheet / ballast tray 1775 61.1 – 66.7''

wind sheet / ballast tray 2130 72.0 – 81.9''

ATTENTION

In order to keep the installation time low, the windsheet is always simultane-

ously mounted with the ballast trays.

>See installation guideline for ballast tray on the following page.

> Please note in the S5 system (elevation angle 5°) the ballast tray, where

necessary for high ballasting, replaces the wind sheet (see opposite page).

“Wing tip” of the windsheet

pointing upwards (S10, S15)

Fixation of windsheet to

bracket

17

13. Installation of the Ballast Trays

The ballast trays are used as soon as a certain amount of ballast blocks per module is exceed-

ed. Standard (short) or high-load (long) ballast trays may be required, depending on the ballast

amount per module. In static report, these positions are color-coded.

The ballast tray is also used when the point load for the roof membrane is too low. Thus, the

weight is distributed evenly over the module length.

Attach protection pads to each ballast

tray (Aerocompact recommends glueing,

see p.22). The standard (short) tray

requires 2 pads (left and right end),

the long tray requires 4 pads (evenly

distributed over the tray length).

The ballast tray at the front bracket

is mounted with the Flathead Screw

through the square hole. Plug the screw

from behind through the square and

tighten the allen-head nut and the wash-

er. Because of shadowing reasons max.

5 ballast blocks can be installed in the

front ballast tray. Protection Pads

The ballast trays on the connector and

end bracket are installed together with

the windsheet. The standard or short

tray is bolted between the brackets and

the windsheet. The maximum amount

of ballast blocks depends on tray size,

system type (module elevation angle),

and row spacing (shading angle).

18

Install the windsheet clip at the overlap-

ping point of the sheets.

14. Installation of the last row

During assembly of the last row the end

bracket is used instead of the connector.

The installation of the modules, and the

Windsheet / Ballast Tray takes place

the same as before.

End Bracket, last row

NOTE

In case of the S5 systems, wind sheets are

left out where long ballast trays, running

over the whole length of the module, are

present (see p.22).

Long Ballast Tray

Where ballast is high and/or has to be distributed to avoid high point loads, the long ballast tray needs to be installed.

The tray is installed in front of the windsheet (windsheet between bracket and ballast tray) and tightened with the same

screw. The tray is bolted additionally in the center of the windsheet using a cage nut, allen-head screw and washer.

19

NOTE

It is important to ensure that the installed PV system does not impair the effect

of the existing lightning protection system. It is also necessary to ensure that the

PV system is designed that it can be included within the scope of the building

lightning protection system. According to VDE 0185-305-3 supplement 5 to the

separation distance between the PV system and the lightning protection system

must be observed. AEROCOMPACT is not liable for damages that may result from

lightning strikes or grounding issues.

15. Ballasting

Laydown all required ballast blocks according to the static calcula-

tion of the project report on the front, connector and end bracket.

Make sure that all ballast trays, as well as all ballast blocks in direct

contact with the roof surface, are equipped with the adequate num-

ber of protection pads.

The optimal block size for the AEROCOMPACT system is

16 x 8 x 2 inch and a weight of 15 pounds. Choose ballast blocks

that comply with the local weather conditions and have a compres-

sive strength of min. 20.7 MPa or 3,000 psi.

16. Grounding of the Array

ABC

WARNING

Don’t leave the construction site before the modules and wind-sheets

are tightened and all the required ballast blocks are placed according the

project report. Without installation of the windsheets and ballast blocks

the stability of the module array is not guaranteed. The correct position

of the ballast blocks and building protection pads must be checked at

the annual maintenance inspection. It is the responsibility of the installer

to check the required ballast block specification and weight.

NOTE

Option A: Ballast block(s) without tray,

ballast is placed directly on the bracket.

Option B: Ballast tray up to max. 7 blocks.

Option C: Long ballast tray up to max. 16

blocks

After completing the installation, the entire system must be ground-

ed and connected to the in-house lightning protection system.

One grounding connection per module array, comprising up to 120

modules, is recommended. The AEROCOMPACT system needs to be

grounded according to the valid regulations of the country in which

the plant will be built.

Possible connection point (M8 bolt on bracket) for grounding equip-

ment (example).

Please note: if bare copper wire is used for array grounding, make

sure that copper is permanently kept separated from aluminum and

galvanized steel parts to prevent contact corrosion.

Install the grounding lug with the

same screw used for the windsheet

Due to the UL certified grounding

clamps and the UL certification

for the array it is not necessary to

install grounding wires between the

modules.

Grounding

pins

20

Bonding and Grounding

For grounding and /or bonding of PV modules and PV mounting systems, national/regional/

local codes apply (Aerocompact takes no responsibility for grounding/bonding and any other

electrical details). On US territory, ANSI/NFPA 70 sets minimum requirements, to be met by

the following:

Continuous bonding between modules and the mounting system, and thus between all module frames

and racking elements within an array, is achieved by Aerocompact‘s module clamps with intergrated pins.

The performance of these clamps has been tested and recognized for UL listing.

[PV modules lacking UL 1703 certification may require diverging, specific bonding measures, including

individual bonding/grounding of the racking elements.]

Permanent grounding of each PV array, consisting of and interconnected by the com-

ponents mentioned above, must then be accomplished by at least one (sufficient for a

standard array size of 12x10 modules) point of connection to suitable grounding equipment

of the building.

Keep unprotected copper wire separated from aluminum and especially galvanized steel!

Make sure to sustain continuous grounding/bonding during maintenance work!

The module clamp with its grounding pins is re-usable

and need not be replaced after removal during mainte-

nance.

Stainless steel pins integrated in the module clamps provide

bonding of module frames to racking elements; the pins pierce

through the non-conductive surface of the anodized module

frame; tighten module clamps with a torque of 133 lbf in.

Grounding lug for grounding a module array, to be fixed using

M8 bolting hardware, e.g. in suitable holes found in any support

bracket of the mounting system; the lug accepts a range of

copper and aluminum wires.

Stainless steel M8 hardware used to fix windsheets and/or

ballast trays to the racking elements provides bonding of named

components, adding further to the complete bonding between

all tarts within an array; tighten M8 hardware with a torque of

133 lbf in.

possible connection point for

grounding lug

This manual suits for next models

2

Table of contents

Other AEROCOMPACT Inverter manuals

Popular Inverter manuals by other brands

GYS

GYS PSW 600 W Translation of the original instructions

Yamaha

Yamaha EDL20000TE owner's manual

YASKAWA

YASKAWA VARISPEED-616G5 instruction manual

Aurora

Aurora PVI-3.0-OUTD-ZZ Installation and configuration manual

Champion Global Power Equipment

Champion Global Power Equipment 201081 quick start guide

Telefunken

Telefunken TF-PI05 instruction manual